Professional Documents

Culture Documents

004 Hirac Confined Space

Uploaded by

eunice.pacerstradingsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

004 Hirac Confined Space

Uploaded by

eunice.pacerstradingsCopyright:

Available Formats

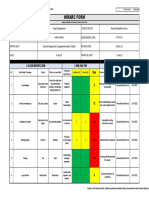

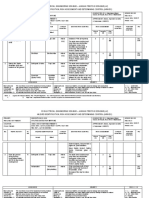

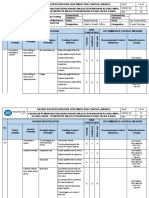

STEP JOB STEP POTENTIAL HAZARD REQUIRED HAZARD OR IMPACT CONTROL RESPONSIBLE

(For each identified hazard list control measures required to eliminate minimize the risk of injury or

NO. harm to the environment. Follow the hierarchy of control)

PERSON

List the major steps required to perform the (Against each step list the potential hazards that could cause (Identify the person

task in the sequence they are carried out. injury / damage / harm when the task step is perform) responsible for the control)

CONFINED DANGERS FROM PEPOI AND CONTRACTOR PROJECT CONTRACTOR /

SPACE: CONFINED SPACE: COORDINATOR MUST SECURE A CONFINED ALL WORKERS

WORKING INSIDE ASPHYXATION FROM SPACE PERMIT.

THE OF GATE #5 ATHMOSPHERIC OXYGEN A “COMPETENT PERSON” SHOULD BE

SUMP BEING MADE OR TOXIC / DEPLETION APPOINTED TO CARRY OUT A RISK

OF INTAKE AIR (A LACK ASSESSMENT OF THE CONDITIONS AND

OF OXYGEN FOR THE WORK AND ACTIVITIES TO BE

BREATHING) CONDUCTED IN THE CONFINED SPACE

POISONUOUS GASES, AND IDENTIFY THE NECESSARY SAFETY

FUMES OR VAPOURS: PRECAUTIONS TO BE TAKEN

EXPERIENCING ACCORDING TO THE FINDINGS TO

HEADACHE, FAINTING, AVOID POSING HAZARDS TO THE

DIZZINESS, etc. WORKERS.

PRESENCE OF DUST ISOLATION: DISCONNECT AND

IN HIGH PROPERLY LOCK OFF THE POWER

CONCENTRATIONS SUPPLY OF ALL THE MACHINERY AND

EQUIPMENT THAT COULD CAUSE

HAZARDS IN THE CONFINED SPACE;

BLANK OFF PIPELINES AND SERVICE

PIPES WITH CONTENTS THAT COULD

CAUSE HAZARDS; TAKE EFFECTIVE

STEPS TO PREVENT AN INGRESS OR IN-

RUSH TO THE CONFINED SPACE OF

HAZARDOUS GAS, VAPOUR, DUST, FUME

OR FREE FLOWING SOLID AND LIQUID.

ENSURE THAT THE CONFINED

SPACE IS ADEQUATELY PURGED,

VENTED AND DRAINED WITH SUFFICIENT

LIGHTINGS BEFORE THE ENTRY OF

WORKERS TO ENSURE THAT NO

DEPOSITS WILL GIVE OFF HAZARDOUS

GAS, VAPOUR, DUST OR FUME DURING

THE COURSE OF WORK.

PROVISION OF PERSONAL

PROTECTIVE EQUIPMENT: THE USE

SUPPLIED AIR BREATHING APPARATUS

(C/O PEPOI) IS RECOMMENDED IN

ENTERING CONFINED SPACE FOR INITIAL

INSPECTION AND CLEANING;

THEREAFTER, THE USE OF FULL-FACE

MASK ON THE ENTIRE CONFINED SPACE

ACTIVITY.

VENTS AND DRAINS OF THE VESSEL ARE

OPEN

AIR QUALITY SHOULD BE FROM 19.5 TO

23.5% OXYGEN AND MUST BE

INSPECTED AND TESTED BY QUALIFIED

GAS TESTER.

LOWER FLAMMABLE LIMIT (LEL): 10%

MAXIMUM

CARBON MONOXIDE (CO): 1H TWA OF 35

PPM 8H TWA OF 9 PPM

UNDER CONDITION OF HIGH TEMPERATURE

HOT CONDITIONS WORKING AREA.

LEADING TO A DON’T WAIT UNTIL YOU ARE THIRSTY

DANGEROUS INCREASE DRINK MORE WATER.

IN BODY

PROVIDE VENTILATION / BLOWER: IF

TEMPERATURE.

THE AREA HAS RETRICTED OR NO

THE RISK OF HEAT NATURAL AIR SUPPLY, USE BREATHING

STROKE IS INCREASED, APPARATRUS TO PROVIDE AN AIR

EASPECIALLY IN SUPPLY TO THE USER.

EXTREMELY HOT

NECESSARY RESCUE AND SAFETY

HUMID CONDITION.

EQUIPMENT SHALL BE IN THE

HEAT EXHAUSTION – WORKPLACE

EXPERIENCING

HEADACHE, FAINTING, A HOLE WATCHMAN SHALL BE

DIZZINESS, PROVIDED AT THE ENTRANCE TO

DEHYDRATION MONITOR THE INGRESS AND EGRESS OF

THE WORKERS.

MAKE SURE THAT ALL FABRIC

GARMENTS USE BY THE WELDERS ARE

RESISTANT TO SPARK, HEAT AND

FLAME.

You might also like

- 2.4 JHA Slope Triming & Laying Alpha MatDocument10 pages2.4 JHA Slope Triming & Laying Alpha MatSamsiah Tola100% (1)

- Hse Risk Assessment For Civil Works, Isolators and Duct InstallationDocument6 pagesHse Risk Assessment For Civil Works, Isolators and Duct Installationvenkatesh snkNo ratings yet

- Hirarc FormDocument2 pagesHirarc FormAusNo ratings yet

- Daily SSS Work Report 2 July 2019 - Copy 1Document7 pagesDaily SSS Work Report 2 July 2019 - Copy 1Ahmad FaridNo ratings yet

- Hazard Risk Assessment Light Bulb ChangeDocument1 pageHazard Risk Assessment Light Bulb ChangePHH9834No ratings yet

- Xbep4103 Final Question Sep 2013Document5 pagesXbep4103 Final Question Sep 2013Roy Seven SymptomsNo ratings yet

- Risk Assessment Form - JEOL 7100FLV SEM - Vysakh - MRes Mol MicroDocument2 pagesRisk Assessment Form - JEOL 7100FLV SEM - Vysakh - MRes Mol MicroVysakh PRNo ratings yet

- HIRAC Work at HeightDocument7 pagesHIRAC Work at HeightMitchRappNo ratings yet

- Boiler Station - DoneDocument7 pagesBoiler Station - DoneJega YuvanNo ratings yet

- Daily Checklist Bulldozerpdf PDF FreeDocument1 pageDaily Checklist Bulldozerpdf PDF FreeRama Asmara TariganNo ratings yet

- RA For Air Compressor-RA 15Document8 pagesRA For Air Compressor-RA 15alla malikNo ratings yet

- Confind Space RCDocument11 pagesConfind Space RCIrfan ashrafNo ratings yet

- Hirarc Kerja Membuat JalanDocument3 pagesHirarc Kerja Membuat JalanNoralbaniah Ahmadul100% (2)

- A. 3 HirarcDocument29 pagesA. 3 HirarcJeny MulyaNo ratings yet

- Hirarc FoundationDocument3 pagesHirarc FoundationknabpshoNo ratings yet

- NIOSH Train The Trainer Module One EnvironmentDocument48 pagesNIOSH Train The Trainer Module One EnvironmentNadyathul Ashykin Wan SofianNo ratings yet

- Lecturer Name: Section: 1 Date of Submission: 5: November 2020Document3 pagesLecturer Name: Section: 1 Date of Submission: 5: November 2020little projectNo ratings yet

- HSE Department Graduate Associate Program and IJM Scholar Program Project MonitoringDocument16 pagesHSE Department Graduate Associate Program and IJM Scholar Program Project MonitoringRoza AzaleaNo ratings yet

- Centre For Diploma Studies: Occupational Safety & HealthDocument7 pagesCentre For Diploma Studies: Occupational Safety & HealthCik Mizza MijotNo ratings yet

- Safety-Overhead CraneDocument2 pagesSafety-Overhead CraneaisyahNo ratings yet

- Awning Install JhaDocument2 pagesAwning Install JhafatimahNo ratings yet

- Cleaning Chlorination Water Tank Risk AnalysisDocument2 pagesCleaning Chlorination Water Tank Risk AnalysisRamyNo ratings yet

- 130 Metal-Inert Gas (MIG) WeldingDocument2 pages130 Metal-Inert Gas (MIG) Weldinglara cross100% (1)

- 27 Risk Assessment-Construction of Ecm Holding Tank and Silt TrapDocument5 pages27 Risk Assessment-Construction of Ecm Holding Tank and Silt TrapprabuNo ratings yet

- Hiradc Merentang KabelDocument3 pagesHiradc Merentang KabeladelenaNo ratings yet

- Manual Gabungan StrategikDocument97 pagesManual Gabungan StrategikSachi AnandNo ratings yet

- C&C-EHS-F-002 HIRARC Working at Height (Tower and Monopole)Document5 pagesC&C-EHS-F-002 HIRARC Working at Height (Tower and Monopole)Najman HamdiNo ratings yet

- 023 Ladder UseDocument3 pages023 Ladder Useraathi_cdiNo ratings yet

- Bird Netting & Pipe Gantry JSADocument1 pageBird Netting & Pipe Gantry JSAShakinah As SaadNo ratings yet

- HIRARC Part2Document54 pagesHIRARC Part2Danial Akram Bakri100% (2)

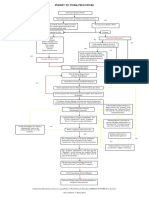

- Permit to Work Procedure FlowchartDocument1 pagePermit to Work Procedure FlowchartRenatoNo ratings yet

- HIRARCDocument7 pagesHIRARCWong TonyNo ratings yet

- Hirarc PDFDocument97 pagesHirarc PDFWan ZahirNo ratings yet

- 05 LiftingDocument6 pages05 LiftingabdulhalimbinamrinNo ratings yet

- Hirarc JKKP ClosingDocument40 pagesHirarc JKKP ClosingThegym le Greene100% (1)

- Isolation Work PermitDocument2 pagesIsolation Work PermitVijayakumar KarunanidhiNo ratings yet

- JKJ 103 Report For DoshDocument9 pagesJKJ 103 Report For DoshMohd Fadli100% (1)

- Gross Pollutant Trap CleaningDocument2 pagesGross Pollutant Trap CleaningcityofdarwingisNo ratings yet

- Hazard Identification for Utilities Detection MappingDocument3 pagesHazard Identification for Utilities Detection MappingZhafri SyazwiNo ratings yet

- Sarawak Water Supply Safety ReportDocument19 pagesSarawak Water Supply Safety ReportKelvin LauNo ratings yet

- Hazard identification, risk assessment and control formDocument2 pagesHazard identification, risk assessment and control formmyn maliQue100% (1)

- SAFETY CAMPAIGN-30 Tips For Hand and Power Tool SafetyDocument2 pagesSAFETY CAMPAIGN-30 Tips For Hand and Power Tool SafetyRomaine MillerNo ratings yet

- Hilti Firestop Mortar CFS-M RG CP 636: Safety Data SheetDocument8 pagesHilti Firestop Mortar CFS-M RG CP 636: Safety Data SheetIndra RahmadhaniNo ratings yet

- Mech-5-20-JSA - Activity For Erection of ScaffoldingDocument10 pagesMech-5-20-JSA - Activity For Erection of ScaffoldingNasrullah JanNo ratings yet

- HIRARC Mobilisation Machinery, Tools, Equipment and MaterialDocument12 pagesHIRARC Mobilisation Machinery, Tools, Equipment and MaterialAbdul Rahman Hamir100% (2)

- Chemical Legislation in Malaysia: Purpose of AssessmentDocument8 pagesChemical Legislation in Malaysia: Purpose of AssessmentAwatifNo ratings yet

- Exam Paper Occupational 2 PDFDocument8 pagesExam Paper Occupational 2 PDFHema0% (1)

- Presentation 1 Demolition Work EditedDocument17 pagesPresentation 1 Demolition Work EditedSham AranNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument20 pagesSafety Data Sheet: 1. Product and Company IdentificationPubcrawlNo ratings yet

- Risk Assessment Template BathroomDocument2 pagesRisk Assessment Template BathroomRNo ratings yet

- JSA Pipeworks - UEM - RAPID PETRONAS - Common FacilitiesDocument10 pagesJSA Pipeworks - UEM - RAPID PETRONAS - Common FacilitiesNazreen AzriNo ratings yet

- HSE-RA-060 Using A Personnel Bucket - Rev 0Document11 pagesHSE-RA-060 Using A Personnel Bucket - Rev 0عمروNo ratings yet

- Sealcoating /crack Repair Parking Lots: Job Safety AnalysisDocument3 pagesSealcoating /crack Repair Parking Lots: Job Safety AnalysisRetselisitsoe0% (1)

- Kursus Sijil Kompeten Penyelia Keselamatan Tapak Bina: Site Safety Supervisor Competency Course CertificateDocument163 pagesKursus Sijil Kompeten Penyelia Keselamatan Tapak Bina: Site Safety Supervisor Competency Course CertificateDurga SreetharanNo ratings yet

- Erect ScaffoldingDocument2 pagesErect ScaffoldingAbdul Hakam Mohamed YusofNo ratings yet

- Erction and Dismantle ScaffoldingDocument4 pagesErction and Dismantle Scaffoldingdownload dokumenNo ratings yet

- JSA ScaffoldingDocument2 pagesJSA Scaffoldingmyco samNo ratings yet

- HSF-PR-0063 Work at HeightDocument32 pagesHSF-PR-0063 Work at HeightChris Bonnington0% (1)

- Fma PDFDocument25 pagesFma PDFasyraf_zamanNo ratings yet

- 003 Hirac Ladder SafetyDocument2 pages003 Hirac Ladder Safetyeunice.pacerstradingsNo ratings yet

- Mapeh 4Document3 pagesMapeh 4Carl Canitan CapasgordoNo ratings yet

- Rapid Earthquake Damage Assessment System (REDAS) SoftwareDocument34 pagesRapid Earthquake Damage Assessment System (REDAS) SoftwareDilg Lgrrc CaragaNo ratings yet

- Biorisk Mitigation Strategies - PASMETH - PhBBA - DTRADocument66 pagesBiorisk Mitigation Strategies - PASMETH - PhBBA - DTRARyan Marañon PedregosaNo ratings yet

- Cicet (M) Corporation SDN BHD: Hazard Identification, Risk Assessment and Determining Control (Hiradc)Document15 pagesCicet (M) Corporation SDN BHD: Hazard Identification, Risk Assessment and Determining Control (Hiradc)nara100% (2)

- DRR11 12 Ic D 34Document3 pagesDRR11 12 Ic D 34allanrnmanalotoNo ratings yet

- University: Adama Science and TechnologyDocument23 pagesUniversity: Adama Science and TechnologyTesfuGebreslassieNo ratings yet

- Siemens SW Improving Medical Device Risk Management White PaperDocument19 pagesSiemens SW Improving Medical Device Risk Management White PaperDr.Sivakumar SelvarajNo ratings yet

- BRCGS Global Standard Packaging Materials, Issue 6: P618: Position Statements For Issue 6Document14 pagesBRCGS Global Standard Packaging Materials, Issue 6: P618: Position Statements For Issue 6SMRNo ratings yet

- City of Malolos DRRM Plan 2022 2026Document235 pagesCity of Malolos DRRM Plan 2022 2026arch.stephenbuenaventuraNo ratings yet

- ProjectDocument21 pagesProjectAnudeepNo ratings yet

- Tle Ict Cy9 W3 PDFDocument4 pagesTle Ict Cy9 W3 PDFMichelle DaurogNo ratings yet

- Operating Manual: VD (E2.1) Vacuum Drying OvenDocument95 pagesOperating Manual: VD (E2.1) Vacuum Drying OvenKevin FungNo ratings yet

- Chapter 1 Hazarduos Saftey Chemical EngnieerwDocument60 pagesChapter 1 Hazarduos Saftey Chemical EngnieerwmohammedNo ratings yet

- 2.2.14 - QPR-RHT-REG-001 Health Safety and Environment Regulation RevDocument18 pages2.2.14 - QPR-RHT-REG-001 Health Safety and Environment Regulation RevLyle Korytar100% (1)

- Graphics Development User GuideDocument18 pagesGraphics Development User GuideIdan FreibergNo ratings yet

- Disaster Response and Risk Reduction: Philippine Central Islands CollegeDocument19 pagesDisaster Response and Risk Reduction: Philippine Central Islands CollegeQuijano, Stephanie L.No ratings yet

- M1aa1 PorrasDocument4 pagesM1aa1 PorrasHanna PorrasNo ratings yet

- RISK ASSESSMENT FOR SWRO PLANT FOUNDATION WORKDocument7 pagesRISK ASSESSMENT FOR SWRO PLANT FOUNDATION WORKabhinav djNo ratings yet

- (80000350-102) c8000 Global FS Training Guide PGDocument104 pages(80000350-102) c8000 Global FS Training Guide PGJavier Humberto Barrera BuitragoNo ratings yet

- PrintJet ADVANCED Servicemanual Ver 1.7 ENDocument113 pagesPrintJet ADVANCED Servicemanual Ver 1.7 ENCovei Gabriel100% (1)

- What Is Process Safety EngineeringDocument3 pagesWhat Is Process Safety EngineeringCLPWC100% (11)

- Action Plan Tugawe Cove Cafe FINAL 7Document11 pagesAction Plan Tugawe Cove Cafe FINAL 7Myrel Cedron TucioNo ratings yet

- Hägglunds 2-Speed Valve for CA MotorsDocument24 pagesHägglunds 2-Speed Valve for CA MotorsSunny KumarNo ratings yet

- Desaster Research at The CrossroadsDocument26 pagesDesaster Research at The CrossroadsGiselly SantiagoNo ratings yet

- Data Driven Planning For City Resilience, Climate Adaptation, and RecoveryDocument47 pagesData Driven Planning For City Resilience, Climate Adaptation, and RecoveryImron BhattiNo ratings yet

- Health Emergency Preparedness Response and Recovery PlanDocument11 pagesHealth Emergency Preparedness Response and Recovery PlanReslyn YanocNo ratings yet

- KRONES Colclean DI 6001 - 760611 - GB - EN - V-1.0.1 - SDBDocument10 pagesKRONES Colclean DI 6001 - 760611 - GB - EN - V-1.0.1 - SDBjayNo ratings yet

- Writing Food Safety Plan 2024Document21 pagesWriting Food Safety Plan 2024amit.crypto.bitNo ratings yet

- Environmental DegradationDocument13 pagesEnvironmental DegradationVINEETH 003No ratings yet

- SDS EN - Cambrex S31Document4 pagesSDS EN - Cambrex S31Dhruvi KansaraNo ratings yet