Professional Documents

Culture Documents

HSE-RA-060 Using A Personnel Bucket - Rev 0

Uploaded by

عمروOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSE-RA-060 Using A Personnel Bucket - Rev 0

Uploaded by

عمروCopyright:

Available Formats

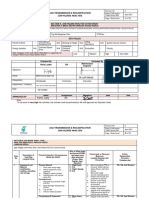

DOC No DS/CA006P02/00022

PAGE No 1 of 11

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 060

Job Description: Using a Personnel Bucket

Index:

Form 1 Task Analysis Initiation

Form 2 Risk Assessment Process As per Risk Assessment Procedure.

Form 3 Written Safe Work Procedure Result

Compiled by the following team:

NAME DESIGNATION SIGNATURE

Project Manager

Construction Manager

Site Engineer

Safety Officer

Risk Assessment Review 1 Review 2 Review 3 Review 4

Review Date: Date : Date : Date:

Name and Signature

of person reviewing :

AUTHORISATION

Prepared by: Approved by

Signature Date Signature Date

HSE Manager Project Manager

TASK ANALYSIS - FORM 1

HSE QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 2 of 11

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 060

Job Description: Using a Personnel Bucket

Impact

SEQUENCE OF TASK STEPS POTENTIAL INJURIES OR HAZARDS RECOMMENDED CONTROLS

H, S, E

1. Pre-use inspection and use of all equipment Failure of equipment will cause injuries to Faulty equipment to be repaired/maintained or replaced.

persons and / or property damage. Guards to be on all Machinery and appropriate PPE to

Faulty hand tools and power tools. be worn.

Fuel/oil leaks could cause environmental Engine ran machinery to have fire extinguishers

concerns. H, S, E

available locally.

Drip trays/heavy gauge plastic to be provided in case of

leaks and spill kit to be within the project for accidental

spills.

2. Wear appropriate Personal Protective Failure to use Personal Protective

Equipment. Equipment will cause injuries to employees.

Gloves.

Safety boots. Enforce the use of Personal Protective Equipment AT

H

Overalls. ALL times

Hard hat.

Hearing protection.

Eye protection

3. Use trained employees only Failure may result in injuries to persons and Enforce the use of competent persons only throughout

H, S

property damage. the project.

4. Competent supervisor should be appointed for every

activity to monitor the workers.

H, S Work task instruction should be provided for every

Competent supervision Failure will cause injuries to employees and activity.

or property damage

5. Failure will result in accidents causing Ensure that bucket is in a good sound condition not

Before using the personnel bucket injuries to persons and / or property damage H, S rusted or any visual cracks. Lifting handle no wear or

damage, test certificate available. Safety chain fitted.

6. Barricade off safe working area and place Unauthorised entry under overhead work Ensure the work area has been barricaded and warning

H,S

overhead work safety signs increases the risks of injuries sign placed.

HSE QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 3 of 11

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 060

Job Description: Using a Personnel Bucket

Watchman should be posted in necessary positions.

7. Never exceed Personnel Bucket SWL(Safe Exceeding SWL will cause failure of Under no circumstances must the SWL(Safe Working

Working Load) equipment resulting in injuries to employees H, S Load) be exceeded

and / or property damage

8. Lifting the buckets using crane. Failure may result in injuries to persons and Crane must be inspected and certified by third party.

property damage. Enforce the use of competent operator and rigger.

Rigger to ensure path of movement is kept free from

possible obstruction and / or persons.

Ensure the use of certified lifting gears.

Do not operate during adverse weather conditions.

H,S,

Cordoned off the lifting area.

Ensure nobody working under the suspended load.

Ensure the visibility at all times.

Ensure the availability and accuracy of wind speed

meter on the equipment and do not operate above 35

KPH.

9. Provision of fall protection. Failure can cause employees to fall from the Ensure the employees are using full body safety

Personnel Bucket and leads to serious harness.

H, S

injuries including fatality. Provide an independent life line from crane hook and

lanyard to be anchor on it.

10. Use guide rope on the Personnel Bucket Failure will allow the bucket to bump into Enforce the use of guide ropes

during slewing equipment or constructions leads to injury to S

the person and property damage.

11. Permit for use must be obtained. Failure will results in injuries fall from height Ensure a permit to work obtained from the concerned

H,S

and property damage. engineer and safety dept:

12. Working on adverse weather conditions Uncontrolled lifting, injury and property Never allow to work with the bucket on adverse weather

damage conditions.

H,S,E

HSE QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 4 of 11

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 060

Job Description: Using a Personnel Bucket

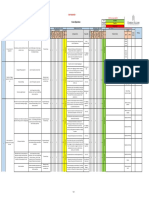

RISK ASSESSMENT – FORM 2

Risk Rating Calculation

Risk Rating = A + B + C + D.

A + B + C + D

Risk Rating Matrix

Injury Severity Potential Damage / Loss Frequency or Likelihood Environmental Impact

Risk Rating

0 No injury 0 No damage 0 Never happened before 0 16

14

No effect

12

10

HSE QUALITY SYSTEM DOCUMENTATION 8

6

4

2

0

5

1

2 4

3

4 3

5 Probability

Potential Impact 6 (C)

7 2

(A / B / D) 8

9 1

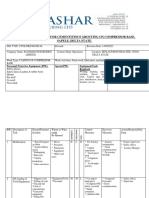

DOC No DS/CA006P02/00022

PAGE No 5 of 11

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 060

Job Description: Using a Personnel Bucket

1 Minor – (FAC) 1 Minor < 500 AED, No delay 1 Happened somewhere 1 Minor Effect - Short term < less 1 month

2 Major – (MTC) 2 Major > 500 AED, No delay 2 Happens occasionally 2 Major Effect - Long term > Greater 1 month

3 LTI 3 Major > 10 000 AED, one day delay 3 Happened before

4 Disabling Injuries 4 Serious > 100, 000 AED, >1 day delay 4 Happens regularly

5 Fatality 5 Severe > 1, 000, 000 AED, Weeks delay. 5 Daily occurrence

Result Classification:

Critical = 17►15 High = 14►11 Medium = 10►7 Low = 6►0

Immediate action. Action in 24 hours. Action in a week. ASAP.

Risk Reduction Hierarchy:

1. Engineering to reduce risk.

2. Replacement with lower risk.

3. Isolation of risk – Barricading or Guarding.

4. Reduction of exposure to risk.

5. PPE and Training

RISK ASSESSMENT – FORM 2 (continued)

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

1 Faulty hand tools Bruises, cuts. H,S,E 13 Gloves, trowels in good Supervisor Before & 6

condition. during

Mechanical guards not Entanglement, Skeletal Damage. the use

in place Guards in place and equipment of

regularly maintained. equipme

nt

HSE QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 6 of 11

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 060

Job Description: Using a Personnel Bucket

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

Unwanted Fuel/Oil Contamination of the soil, atmospheric Care to be taken refuelling and

Spillages pollution, risk of fire. drip trays/heavy gauge plastic to

be in place as required.

2 Injury to project Potential Death, Major/Minor Skeletal Following PPE to be worn Supervisor Before &

employees damage, cuts and bruises to all parts of appropriately to the task – during

the body, asthma. Gloves. work

Safety boots.

H,S 10 5

Overalls.

Hard hat.

Hearing protection.

Eye protection

3 Un trained employees Poor quality of work, chance for Provided trained/competent PE/FM Always

H,S 7 5

accident /incident or property lost/damage worker and supervision

4 Poor Supervision Poor quality of work, chance for Engineer/ Supervisor/ Forman PE/FM Always

accident /incident or property lost/damage will be present when night duties

commences

H,S 10 3

Work task instruction should be

provided to the workers prior to

the commencement of activity

5 Using substandard Collapse of the buckets Ensure that bucket is in a good FM/ Before

buckets Minor/major injuries/potential death sound condition not rusted or any Supervisor and

Property damage. visual cracks. Lifting handle no during

Uncertified buckets wear or damage, Safety chain work

H,S 10 fitted. 3

Never overload the buckets,

comply with the SWL

Enforce the use of third party

certified buckets

6 Fail to barricade the Falling materials Major/minor injuries, H.S Ensure the work area has been FM Before & 4

underneath area of cradle potential death, property damage. barricaded and warning sign /Supervisor during

HSE QUALITY SYSTEM DOCUMENTATION

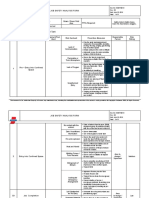

DOC No DS/CA006P02/00022

PAGE No 7 of 11

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 060

Job Description: Using a Personnel Bucket

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

12 placed. work

Watchman should be posted in

necessary positions.

7 Overloading of the bucket Collapse of the platform Never overload the bucket Supervisor Always

Fall of person from height.

H, S 4

Major injuries, Potential Death 10 Comply with the Safe Working

Property damage. Load

8 Failure to adhere to lifting Falling materials. Crane must be inspected and FM/ Always

procedures while using Minor/major injuries/potential death certified by third party. Supervisor

crane Property damage. Enforce the use of competent

operator and rigger.

Rigger to ensure path of

movement is kept free from

possible obstruction and / or

persons.

Ensure the use of certified lifting

gears.

H, S 3

12 Do not operate during adverse

weather conditions.

Cordoned off the lifting area.

Ensure nobody working under

the suspended load.

Ensure the visibility at all times.

Ensure the availability and

accuracy of wind speed meter on

the equipment and do not

operate above 35 KPH..

9 Failure to use fall Fall from height 12 Ensure the employees PE/FM/

H,S

protection Major injuries, are using full body safety Supervisor

HSE QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 8 of 11

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 060

Job Description: Using a Personnel Bucket

Impact HOW IS HAZARD TO BE BY Result

No HAZARD IDENTIFIED RISK ASSOCIATED WITH HAZARD H, S, E RR BY WHOM RR

DEALT WITH WHEN

Potential death harness.

Provide an independent life line

from crane hook and lanyard to

be anchor on it.

10 Failure to use guide ropes Swinging of bucket and bumping against Never allow the lifting of the FM/ During

structures causing minor and major H,S 12 cradle without guide ropes Supervisor operation 4

injuries /death or property damage

11 Incompliance with the Incompliance with the authorities/client Ensure a permit to work obtained PE/FM/ Before

permit to work system requirements. from the concerned engineer and Safety Dept the

Legal actions /Penalties safety dept: operation

H,S 7 5

Ensure 100% compliance with

regulations and requirements on

permit.

12 Adverse weather Uncontrolled lifting, injury and property Never allow to work with the PE/FM/ Always

conditions damage bucket on adverse weather Safety Dept

H,S,E 12 conditions. 2

Atmospheric impact

* RR = Risk Rating

HSE QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 9 of 11

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 060

Job Description: Using a Personnel Bucket

WRITTEN SAFE WORK PROCEDURE

1. OBJECTIVE

1. To prevent injuries to employees and / or property damage incidents.

2. PROCEDURE

1. Do pre-use inspection of all equipment to be used and replace or repair faulty items.

2. Use trained competent employees only.

3. Use appropriate Personal Protective Equipment i.e.:

3.1. Hardhat.

3.2. Safety boots.

3.3. Overalls.

3.4. Eye protection.

Prior to work commencement

1. Must have PPE – safety footwear, gloves, hardhat, goggles, face musk, protective clothing etc.

2. Must have appropriate tools and equipment in good condition.

3. Must have weatherproof covers for materials and equipment, waste containers, warning tape.

4. Consider risks and hazards in work area. Refer any concerns to supervisor. Are relevant permits in place?

5. Check if it is necessary to secure area adjacent to work. Refer to supervisor if appropriate.

6. Arrange for transport of materials and equipment to site via supervisor.

7. Ensure materials and equipment are secure or removed when site unattended, eg overnight or during breaks.

Hazards

HSE QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 10 of 11

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 060

Job Description: Using a Personnel Bucket

1. Manual handling of materials and equipment – LITE to be considered at all times.

2. Slips and trips from untidy work area.

3. Falling of materials.

4. Working on elevated areas (fall from height)

5. Suspended equipments eg: Discharge chute.

6. Collapse of existing structures, eg scaffolding, working platform.

7. Hazards associated with equipment used for lifting activity, eg. Cranes, concrete bucket

8. Contact with sharp edges of materials.

9. Contact with hazardous cement, eg: Irritations dermatitis (see COSSH sheet and materials packaging).

10. Exceeded working hours resulting dizziness and fatigue to workers

11. Adverse weather conditions, if any doubt refer to the supervisor.

12. Environmental damage.

13. Fire hazard.

14. Electrical hazard.

Harm

Potential Death, Minor/major cuts and contusion, loss of limbs, fractures, damage to respiratory system, electric shock.

Persons in danger

1. Carpenters, Steel fixers, Masons, installers, technicians, Ordinary labours

2. .Riggers and operators.

3. Other workers and public

Control measures

No lone working

HSE QUALITY SYSTEM DOCUMENTATION

DOC No DS/CA006P02/00022

PAGE No 11 of 11

AL SHAFAR GENERAL CONTRACTING LLC. REV 0

DATE 05/01/2017

SAFETY, HEALTH AND ENVIRONMENTAL PROCEDURE

Project Name: Festival Living Stream-02 HSE-RA 060

Job Description: Using a Personnel Bucket

1. A pre-use check will be done against an approved checklist, the inspection be Carried out by a Supervisor.

2. Ensure safe hooking of the safety harness to the chains of the TC.

3. Never exceed the S.W.L of the Personnel Bucket.

4. Persons in the Personnel Bucket will be secured with a Safety harness to the TC chains

5. A Safe working area will be barricaded off below.

6. Overhead work signs to be placed.

7. A guide rope to be used on the Personnel Bucket at all times during operations.

8. Only small equipment / material and hand tools will be hoist with the Personnel Bucket (Considering the S.W.L. at all times).

9. Maximum 2 (two) persons will be allowed in the Personnel Bucket at any one time.

10. No person will stand / or sit on the handrails.

11. No person will be allowed to stand / or walk in underneath the Personnel Bucket in use.

12. Nobody will hang over the handrails.

13. Stop all lifting in high wind conditions – maximum 25 km/h.

HSE QUALITY SYSTEM DOCUMENTATION

You might also like

- HSE-RA-041 Water Proofing - Activities - Rev 0Document11 pagesHSE-RA-041 Water Proofing - Activities - Rev 0عمروNo ratings yet

- HSE-RA-028 Straight and Cut Machine - Rev 0Document10 pagesHSE-RA-028 Straight and Cut Machine - Rev 0عمروNo ratings yet

- HSE-RA-024 Civil Store - Rev 0Document15 pagesHSE-RA-024 Civil Store - Rev 0عمروNo ratings yet

- HSE-RA-021 Blockwork - Rev 0Document10 pagesHSE-RA-021 Blockwork - Rev 0عمروNo ratings yet

- HSE-RA-053 Floor Screed - Rev 0Document9 pagesHSE-RA-053 Floor Screed - Rev 0عمروNo ratings yet

- HSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0Document16 pagesHSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0عمروNo ratings yet

- HSE-RA-022 Environmental Management - Rev 0Document22 pagesHSE-RA-022 Environmental Management - Rev 0عمروNo ratings yet

- HSE-RA-011 Manual Handling - Rev 0Document11 pagesHSE-RA-011 Manual Handling - Rev 0عمروNo ratings yet

- Job Safety Analysis for Poly Pipe InstallationDocument2 pagesJob Safety Analysis for Poly Pipe InstallationHow Chin Engineering Sdn BhdNo ratings yet

- Green TAGDocument1 pageGreen TAGKhaty JahNo ratings yet

- Rock BreakingDocument1 pageRock BreakingGyanendra Narayan NayakNo ratings yet

- Dismantling of StagingDocument1 pageDismantling of StagingChandruNo ratings yet

- 42-JSA-Construction of Fence (Excavation, Installation of Fence Posts and Accessories) PDFDocument11 pages42-JSA-Construction of Fence (Excavation, Installation of Fence Posts and Accessories) PDFFarhan MNo ratings yet

- Gas TestingDocument1 pageGas TestingHow Chin Engineering Sdn BhdNo ratings yet

- Plastering & RenderingDocument7 pagesPlastering & Renderingmohd firdausNo ratings yet

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- Hadeed JSA Shearing Machine InstallationDocument11 pagesHadeed JSA Shearing Machine InstallationDhanu NikkuNo ratings yet

- Rapid P20ai Jsa Box CulvertDocument8 pagesRapid P20ai Jsa Box Culvertfadli.lpgNo ratings yet

- Jsa-Rp-002 General Excavation & TrenchingDocument16 pagesJsa-Rp-002 General Excavation & Trenchingibaig1970100% (1)

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Document6 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Nitesh KumarNo ratings yet

- JSA Sheet for Foundation ConcretingDocument2 pagesJSA Sheet for Foundation ConcretingGunjan Sinha AdityaNo ratings yet

- Grounding Rod Installation SafetyDocument5 pagesGrounding Rod Installation SafetyHow Chin Engineering Sdn BhdNo ratings yet

- Tile WorkDocument1 pageTile WorknabeelNo ratings yet

- JHA (Excavation of IPS Rev. B)Document4 pagesJHA (Excavation of IPS Rev. B)Armando AballeNo ratings yet

- JSA NO 3-Pile CapDocument8 pagesJSA NO 3-Pile Capknabpsho50% (2)

- JSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationDocument10 pagesJSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationMohammad Al Masa'dehNo ratings yet

- Power ToolsDocument2 pagesPower ToolspradheepNo ratings yet

- TieDocument5 pagesTieshinto LawrenceNo ratings yet

- Scaffold Tag: Inspection RecordDocument1 pageScaffold Tag: Inspection RecordZainal AzizNo ratings yet

- Brick Work BSM Jha - 1Document3 pagesBrick Work BSM Jha - 1Dwitikrushna RoutNo ratings yet

- JSA GrinderAngleDocument2 pagesJSA GrinderAngleslamet_rNo ratings yet

- Work Permit 2.13Document14 pagesWork Permit 2.13Oliva Del Rosario Sagpao100% (1)

- JSA Ceiling Access by LadderDocument3 pagesJSA Ceiling Access by LadderHow Chin Engineering Sdn BhdNo ratings yet

- JHA For Earth Work - MS 04Document14 pagesJHA For Earth Work - MS 04RaheenNo ratings yet

- Permit To Work Shafts and Elevators: Compliance ChecklistDocument1 pagePermit To Work Shafts and Elevators: Compliance ChecklistNeil Buyco VillamorNo ratings yet

- Form E26-Inspection of Earthing Electrodes-SignDocument16 pagesForm E26-Inspection of Earthing Electrodes-SignFinanceAdmin FKSIENo ratings yet

- Formwork Safety Manual Section 3Document1 pageFormwork Safety Manual Section 3Rickesh Nunkoo100% (1)

- 001 SWMS - Piling WorkDocument20 pages001 SWMS - Piling Worksasi kumar0% (1)

- Jsa-Rp-001 Site Preparation and General EarthworksDocument20 pagesJsa-Rp-001 Site Preparation and General Earthworksibaig1970No ratings yet

- ARK JSA Manual ExcavationDocument8 pagesARK JSA Manual ExcavationMohammed Ali QaziNo ratings yet

- JHA FOR CEMENTITIOUS GROUTING ON COMPRESSOR BASEDocument8 pagesJHA FOR CEMENTITIOUS GROUTING ON COMPRESSOR BASEaloysius akpanNo ratings yet

- Working at Height Rescue Plan: WHS-FM-008Document2 pagesWorking at Height Rescue Plan: WHS-FM-008Purwo PrihartonoNo ratings yet

- JSEA FOR EARTH WORK (Alumina Silo Area)Document13 pagesJSEA FOR EARTH WORK (Alumina Silo Area)MD AbdullahNo ratings yet

- J718 SCX1800a RA 220322 Rev02Document13 pagesJ718 SCX1800a RA 220322 Rev02Ion Domnari100% (1)

- Job Safety Analysis Template V2.2Document11 pagesJob Safety Analysis Template V2.2Muhammad YusufNo ratings yet

- Awning Install JhaDocument2 pagesAwning Install JhafatimahNo ratings yet

- Garbage Chute Tender 2Document60 pagesGarbage Chute Tender 2Faizan100% (1)

- Risk Assessment Template BathroomDocument2 pagesRisk Assessment Template BathroomRNo ratings yet

- JESA - HVAC Control WorksDocument7 pagesJESA - HVAC Control WorksResearcherNo ratings yet

- (SWMS - 04) Carpentry Work Temporary & PermanentDocument6 pages(SWMS - 04) Carpentry Work Temporary & PermanentPRATEEK SINGHNo ratings yet

- SWP Grinder Bench AS520Document1 pageSWP Grinder Bench AS520Tosif AliNo ratings yet

- JSA For IFRDocument3 pagesJSA For IFRDilshad ali100% (1)

- 2.4 JHA Slope Triming & Laying Alpha MatDocument10 pages2.4 JHA Slope Triming & Laying Alpha MatSamsiah Tola100% (1)

- Construction Demolition HazardsDocument2 pagesConstruction Demolition Hazardschirese2000No ratings yet

- JHA CoatingDocument9 pagesJHA Coatingبسام كريم100% (1)

- Environmental, Health and Safety Risks AnalysisDocument1 pageEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- SEOT JSA For Fence Installation 16-08-2021Document4 pagesSEOT JSA For Fence Installation 16-08-2021Archana SoorajNo ratings yet

- JSW Roof Sheet PricesDocument1 pageJSW Roof Sheet PricesDhanraj PatilNo ratings yet

- Risk Assessment - Installation of Safety Zone Wolf AreaDocument10 pagesRisk Assessment - Installation of Safety Zone Wolf AreaJIHUL GEORGENo ratings yet

- HSE-RA-015 Fire Fighting and Prevention - Rev 0Document10 pagesHSE-RA-015 Fire Fighting and Prevention - Rev 0عمروNo ratings yet

- HSE-RA-015 Fire Fighting and Prevention - Rev 0Document10 pagesHSE-RA-015 Fire Fighting and Prevention - Rev 0عمروNo ratings yet

- HSE-RA-008 Scaffold Erection and Dismantling - Rev 0Document20 pagesHSE-RA-008 Scaffold Erection and Dismantling - Rev 0عمرو100% (1)

- HSE-RA-011 Manual Handling - Rev 0Document11 pagesHSE-RA-011 Manual Handling - Rev 0عمروNo ratings yet

- HSE-RA-019 Steel Fixing - Rev 0Document15 pagesHSE-RA-019 Steel Fixing - Rev 0عمروNo ratings yet

- HSE-RA-022 Environmental Management - Rev 0Document22 pagesHSE-RA-022 Environmental Management - Rev 0عمروNo ratings yet

- HSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0Document16 pagesHSE-RA-025 Erecting, Dismantling and Maintanance of Tower Crane - Rev 0عمروNo ratings yet

- HSE-RA-007 Crane Usage - Rev 0Document13 pagesHSE-RA-007 Crane Usage - Rev 0عمروNo ratings yet

- HSE-RA-018 Use of An Angle Grinder - Rev 0Document15 pagesHSE-RA-018 Use of An Angle Grinder - Rev 0عمروNo ratings yet

- RA - EIA HousekeepingDocument1 pageRA - EIA HousekeepingعمروNo ratings yet

- HSE-RA-023 Site Establishment - Rev 0Document17 pagesHSE-RA-023 Site Establishment - Rev 0عمروNo ratings yet

- HSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0Document15 pagesHSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0عمروNo ratings yet

- RA - EIA ErgonomicsDocument2 pagesRA - EIA ErgonomicsعمروNo ratings yet

- RISK-REGISTERDocument2 pagesRISK-REGISTERعمرو100% (1)

- HSE-RA-016 Waste Materials - Rev 0Document12 pagesHSE-RA-016 Waste Materials - Rev 0عمروNo ratings yet

- RA - Crane OperationDocument3 pagesRA - Crane OperationعمروNo ratings yet

- RA - EIA GeneratorDocument4 pagesRA - EIA GeneratorعمروNo ratings yet

- RA - Concrete PouringDocument1 pageRA - Concrete PouringعمروNo ratings yet

- Information Security Governance and Risk ManagementDocument6 pagesInformation Security Governance and Risk Managementjbrackett239No ratings yet

- Falls Prevention: Assessments and InterventionsDocument5 pagesFalls Prevention: Assessments and InterventionswidijambiNo ratings yet

- O&m Hse ManualDocument33 pagesO&m Hse ManualNia MagdalenaNo ratings yet

- ISO 27001 2022 Mind MapDocument1 pageISO 27001 2022 Mind MapAbdo CasaNo ratings yet

- Method Statement For Construction For Sub-Base and Road Base WorksDocument20 pagesMethod Statement For Construction For Sub-Base and Road Base WorksBleep NewsNo ratings yet

- Assets IEEE Paper Reference 1Document4 pagesAssets IEEE Paper Reference 1tesNo ratings yet

- CE013 - CE31S10 - Final Project - Cruz, Robert JR., A.Document30 pagesCE013 - CE31S10 - Final Project - Cruz, Robert JR., A.jrcruzpogi0242424No ratings yet

- Emergency Management Plan TemplateDocument19 pagesEmergency Management Plan TemplateShady medhatNo ratings yet

- INS - Asset Condition Evaluation Tool (ACET) A4Document2 pagesINS - Asset Condition Evaluation Tool (ACET) A4khanz88_rulz1039No ratings yet

- Matrix OhaDocument4 pagesMatrix OhaLeuri MoraesNo ratings yet

- Group 7 Project PlanDocument46 pagesGroup 7 Project PlanJian yiNo ratings yet

- EHS Risk Assessment Template User GuideDocument11 pagesEHS Risk Assessment Template User GuideIsaac Samuel100% (1)

- Design Safety ManagementDocument14 pagesDesign Safety Management임동우100% (2)

- Ra Lightning Protection SystemDocument16 pagesRa Lightning Protection SystemamalNo ratings yet

- FACADE Maintenance Risk AssessmentDocument2 pagesFACADE Maintenance Risk Assessmentطارق رضوانNo ratings yet

- FactoryDocument8 pagesFactoryJonathan D'limaNo ratings yet

- OT Security ChecklistDocument15 pagesOT Security Checklistct pentestNo ratings yet

- Risk Based Inspection: Upfront Corrosion EngineeringDocument4 pagesRisk Based Inspection: Upfront Corrosion Engineeringleliopinto50% (2)

- Enterprise Risk Management Framwork For BanksDocument12 pagesEnterprise Risk Management Framwork For BanksAnuNo ratings yet

- Sample Form-HIRARC 10.11.2010Document21 pagesSample Form-HIRARC 10.11.2010mrsmartguys100% (1)

- Api Et AlDocument21 pagesApi Et AlRavishankar NagarajanNo ratings yet

- Integrated Management System Manual Based On ISO 9001, 14001 & 45001Document49 pagesIntegrated Management System Manual Based On ISO 9001, 14001 & 45001Polco-SwapnilNo ratings yet

- Task 2 Literature Review & Case StudyDocument28 pagesTask 2 Literature Review & Case Studynajihaizz97No ratings yet

- QSP-511-01 Management of ChangeDocument33 pagesQSP-511-01 Management of ChangeMacelNo ratings yet

- Royal Commission Risk Assessment Form: Risk Assessment For Testing & Commissioning of Overhead CranesDocument2 pagesRoyal Commission Risk Assessment Form: Risk Assessment For Testing & Commissioning of Overhead CranesLenaj Ebron100% (3)

- Risk Assessment Fire HazardDocument3 pagesRisk Assessment Fire HazardSathi shNo ratings yet

- Field Density Testing with Nuclear GaugeDocument10 pagesField Density Testing with Nuclear GaugedavethiyaguNo ratings yet

- Ms-Wet Fire Fighting SystemDocument23 pagesMs-Wet Fire Fighting Systemachusanachu100% (3)

- QCAR 091 - Safety ManagementDocument25 pagesQCAR 091 - Safety ManagementibrahimNo ratings yet

- Unit Assessment Pack (UAP) - Cover Sheet: Student and Trainer/Assessor DetailsDocument67 pagesUnit Assessment Pack (UAP) - Cover Sheet: Student and Trainer/Assessor DetailsArícia Leonidas0% (1)