Professional Documents

Culture Documents

17 How To Identify Hazards Requiring Risk Management PDF

17 How To Identify Hazards Requiring Risk Management PDF

Uploaded by

Edgar Palacio0 ratings0% found this document useful (0 votes)

17 views4 pagesOriginal Title

17_How_to_identify_hazards_requiring_risk_management.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views4 pages17 How To Identify Hazards Requiring Risk Management PDF

17 How To Identify Hazards Requiring Risk Management PDF

Uploaded by

Edgar PalacioCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Supplementary Systematic Risk Management

Guidance 17 Conduct Full Risk Management

How to identify hazards requiring risk management

Background

The Designing Safer Buildings and Structures guide to Section 28 suggests that where a Standard

fits the scope of a hazard then the designer may adopt the control measures without going through

a full risk assessment approach. Many hazards encountered may be satisfied with this approach.

Workplaces with complex hazards will require detailed hazard identification to start the design

process. These workplaces will include manufacturing sites and workplaces with complex systems

of work that have OHS issues. These workplaces will require systematic methods to identify

hazards, to assess the risk, to identify control measures and to evaluate cumulative risk. Generally,

consultative techniques and expert advice will be needed to conduct some of this work.

Purpose

To suggest a number of systematic processes for identifying hazards.

Method/Discussion

The following tables are intended to stimulate ‘brainstorming’ but they are not intended to be

exhaustive in content. Hazard identification should be comprehensive and identify all hazards with

screening to remove low risk hazards carried out in the assessment phase. Much of the resulting

information should be passed on to the final workplace users.

Table 1 is a hazard prompt table that is based on the principle of potentially damaging energies. It

assumes that injury or damage occurs as a result of uncontrolled energy interacting with a person.

Damaging Energy Hazard

High forces

Biomechanical

Repetitive movement or sustained posture

Explosion

Fire

Toxicity

Chemical Incompatible materials

Asphyxiant

Dust

Fumes/Lack of ventilation

Electrical energy Electrical wiring and equipment

Fall from height

Slips/trips

Gravitational

Dropped objects

Structural collapse

Moving material/equipment

Mechanical Mobile equipment

Physical trauma

Microbiological Bacteria, viruses or other pathogens

Noise and vibration Noise

High pressure

Pressure

Low pressure

Revised: July 2006

Designing Safer Buildings and Structures guide - Supplementary guidance 17

Page 1

Violence

Psychological

Stress

Radiation Radiation

Thermal Heat/Cold

Table 2 provides hazard examples, regulatory references and some possible risk control

measures.

Hazard Examples Examples of risk controls from

Standards

Fire/Explosion - Refer to the Regulations and Codes of Practice for Hazardous Substances and

Dangerous Goods Storage and Handling and Explosives Regulations

Explosion Fire or explosion from flammable solids, Hazardous area rated electrical

dusts, liquids or gases equipment, controlled ignition sources,

Combustible materials or liquids bunding, explosion venting.

Fire Escalation of fire, lack of fire Fire resistant materials, reduction of

prevention/suppression, inadequate combustibles, bulk/local storage areas

emergency egress or assembly points. and bunding, fire walls, area separation

detection and alarms, fire suppression

systems (e.g. sprinklers), extinguishers.

Chemical - Refer to the Regulations and Codes of Practice for Hazardous Substances and Dangerous

Goods Storage and Handling.

Toxicity Storage, transport or handling toxic Adequate containment and separation

solids, liquids or gases. from persons, bulk/local storage areas

and bunding, ventilation/extraction,

detection and alarms.

Incompatible materials Incompatible dangerous goods (e.g. Separation of incompatible dangerous

acids/caustics) causing high goods, bulk/local storage areas and

temperature or pressure or creating bunding.

toxic by-products.

Asphyxiant Asphyxiants such as carbon monoxide Ventilation/extraction, detection and

or exhaust fumes. alarms.

Gases that displace oxygen (e.g.

nitrogen, carbon dioxide).

Pressure Vessels - Refer to the Regulations and Code of Practice for Plant

High pressure Release of liquids (e.g. large tanks) or Reduce pressure, separation and

gases (tyres, gas cylinders) under barriers, pressure rated equipment

pressure from impact, corrosion or pipes, hoses and fittings, pressure relief

vibration. devices.

Low pressure Tank/silo collapse as level or Reduce pressure differential, pressure

temperature drops, vacuum. rating on vessels, pressure relief

devices.

Plant/Equipment - Refer to the Regulations and Code of Practice for Plant

Moving In-running nips, entanglement, Separation/guarding.

material/equipment shearing, striking, etc.

Mobile equipment Forklifts, cranes, vehicles, deliveries. Separation of people and mobile

equipment, barriers.

Cuts Sharp edges, broken glass. Reduce or protect sharp edges. Use

toughened glass.

Electrical

Electrical wiring and Overhead cables near roadways, Locate roads/access away from

equipment underground cables, switch rooms, overhead cables, fencing, signs and

electrical equipment, switch boxes. restricted access.

Physical Environment - Asbestos, Hazardous Substances, Manual Handling, and Noise Regulations.

Confined Spaces, First Aid in the Workplace, Hazardous Substances, Manual Handling, Plant, and

Workplaces Codes of Practice.

Revised: July 2006

Designing Safer Buildings and Structures guide - Supplementary guidance 17

Page 2

Noise Noisy equipment, lack of attenuation. Reduction of noise at source, isolation,

attenuating materials, separation of

equipment from persons.

Heat/Cold Cool rooms, draughts from ventilation Air conditioning, ventilation, fans.

systems. Insulation, heat guards, separation

Furnaces, heaters, sun. distances from workers, shade

structures.

Radiation Sun/UV light, electromagnetic, ionising, Shade structures, UV protective glass,

infra-red, lasers. separate radiation emitting devices

from persons by separation and

protective structures.

Dust Dust generated by equipment or Separation, ventilation.

storage and handling of material.

Fumes/lack of Location of air conditioning intake, Separation, ventilation.

ventilation engine exhaust, process by-products,

burners.

Inclement weather Slippery surfaces, flooding, wind, Surface materials, drainage, design

lightning. loadings for wind, lightning conduction.

Manual Handling - Refer to the Code of Practice for Manual Handling

High forces Lifting, pushing, pulling, holding, Mechanical aids, ergonomic design.

throwing and carrying.

Repetitive movement Packing, typing, assembling, cleaning Mechanical aids, ergonomic design.

or sustained posture and sorting, using hand tools and

operating equipment.

Environment See Environment hazards above (e.g.

climatic conditions may increase risk of

injury).

Microbiological

Bacteria, viruses or Legionella, blood products, waste. Dry air conditioning. Isolation of areas.

other pathogens

Psychosocial - Refer to the prevention of bullying and violence at work guidance note

Violence Violent customers, illegal activities (e.g. Barriers, separation from potentially

robberies), access at night. violent customers, distress alarms,

lighting, reduction of staff isolation.

Stress

Working at height - Refer to the Code of Practice for prevention of falls

Fall from height Unprotected edges, inadequate height Allow work to be done at ground level,

access, ladders. platforms, stairs, guard railing, height

access equipment.

Slips/trips Change in levels, steps, slippery floor Appropriate ramps/steps, adequate

surface, poor lighting. lighting, surface finish/texture.

Dropped objects Elevated work platforms, work near Toe guards, barriers.

unprotected edges.

Structural collapse Inadequate strength, fatigue. Appropriate design limits.

Other

This table is provided as a guide, it is not intended as a complete listing of all potential hazards. Any

hazards not considered in the table should also be considered if relevant to the building or structure

workplaces being designed.

Outputs

An understanding of the complexity of the OHS issues and to be able to plan what expertise and

resources are available.

Linkage

Acts, Regulations, Codes: http://www.workcover.vic.gov.au/vwa/home.nsf/pages/worksafe_home#legal

Hazard identification:

http://www.workcover.vic.gov.au/vwa/alerts.nsf/docsbyUNID/F9933C3F016D9133CA256FDC008037CF?Open

Revised: July 2006

Designing Safer Buildings and Structures guide - Supplementary guidance 17

Page 3

Hazard and risk identification: http://www.wsrm.com.au/hazard_&_risk_assessments.htm

Categorising risk: http://www.google.com.au/search?hl=en&q=categorising+risk+difficulty&btnG=Search&meta=

Major Hazard Facilities Regulations – Guidance Note GN – 13 – Hazard Identification:

http://www.workcover.vic.gov.au/vwa/home.nsf/pages/so_majhaz_guidance/$File/GN13.pdf

Revised: July 2006

Designing Safer Buildings and Structures guide - Supplementary guidance 17

Page 4

You might also like

- Sociosexual BehaviorDocument10 pagesSociosexual Behaviornegurii hearteuNo ratings yet

- Ayurveda and VirilityDocument4 pagesAyurveda and VirilityManvir Singh Dandona100% (1)

- Behavioural SafetyDocument103 pagesBehavioural SafetyVikram TNo ratings yet

- High Reliability Organization A Complete Guide - 2021 EditionFrom EverandHigh Reliability Organization A Complete Guide - 2021 EditionNo ratings yet

- Welding Safety TrainingDocument23 pagesWelding Safety TrainingTinna Puspita Marita SariNo ratings yet

- EHS-FRM-0006 - Toolbox Talks FormDocument2 pagesEHS-FRM-0006 - Toolbox Talks FormBobby CastleNo ratings yet

- Assignment Safe Work ProceduresDocument5 pagesAssignment Safe Work ProceduresRahim ManaiNo ratings yet

- Business Leaflet TemplateDocument1 pageBusiness Leaflet TemplateSanti YuliandariNo ratings yet

- Construction HazardsDocument44 pagesConstruction HazardsPrashant dhadukNo ratings yet

- Behavior Based Safety & YouDocument15 pagesBehavior Based Safety & YouHaider AliNo ratings yet

- Toolbox Meeting Risk Identification Card1Document2 pagesToolbox Meeting Risk Identification Card1samuel adeogunNo ratings yet

- LGC Shadow Title Master - Pot: Workplace ErgonomicsDocument57 pagesLGC Shadow Title Master - Pot: Workplace ErgonomicsAlexandra BanteguiNo ratings yet

- 6 Machine HazardsDocument12 pages6 Machine Hazardsosama1928No ratings yet

- Worksite Hazard Analysis: Presented By: Thomas Dean Georgia TechDocument113 pagesWorksite Hazard Analysis: Presented By: Thomas Dean Georgia TechsahibjotNo ratings yet

- ICAM Lead Investigator - Course Overview 2017.pubDocument1 pageICAM Lead Investigator - Course Overview 2017.pubHSEQ SURNo ratings yet

- All Appandixes of IS-14489-2018Document20 pagesAll Appandixes of IS-14489-2018Nisith SahooNo ratings yet

- Weld Fume Control MethodologyPPDocument63 pagesWeld Fume Control MethodologyPPamalioismeNo ratings yet

- CHAPTER 4 Example-Workplace Hazard in ConcretingDocument2 pagesCHAPTER 4 Example-Workplace Hazard in ConcretingKerol Kerol KerolNo ratings yet

- Hazard Identification ProcessDocument30 pagesHazard Identification ProcessRahul SiwakotiNo ratings yet

- Accident Prevention in Industry: BY Suresh PatilDocument50 pagesAccident Prevention in Industry: BY Suresh PatilgohelgohelNo ratings yet

- Safe Work Practices and Procedures - Capt. Muhammad IrwansyahDocument11 pagesSafe Work Practices and Procedures - Capt. Muhammad IrwansyahMuhammad IrwansyahNo ratings yet

- 6 Thinking About Where Failure Will Happen: Questions About Your OrganizationDocument8 pages6 Thinking About Where Failure Will Happen: Questions About Your OrganizationRauf HuseynovNo ratings yet

- Annexure 10-Safety Audit-2019Document49 pagesAnnexure 10-Safety Audit-2019Tehman SiddiquiNo ratings yet

- Job Hazards Analysis (CST)Document23 pagesJob Hazards Analysis (CST)RaDaCa CabsNo ratings yet

- The Work at Height Regulations 2005: A Brief GuideDocument12 pagesThe Work at Height Regulations 2005: A Brief Guidesyed jeelani ahmedNo ratings yet

- Comparison of Welding Inspector Qualification or Certification SchemesDocument7 pagesComparison of Welding Inspector Qualification or Certification Schemeswahyu santosoNo ratings yet

- Iso 9000Document31 pagesIso 9000snikideNo ratings yet

- Pos Safeguards Plant and Machinery 1004642-ENU-01Document1 pagePos Safeguards Plant and Machinery 1004642-ENU-01Joelcio Alfonzo AguilarNo ratings yet

- Philosophy of SafetyDocument34 pagesPhilosophy of Safetysuraj100% (1)

- Risk ProfilingDocument1 pageRisk ProfilingSaeed MalikNo ratings yet

- Welding Inspector: Weld Repairs Section 16Document20 pagesWelding Inspector: Weld Repairs Section 16manojballaNo ratings yet

- Hazard Analysis: Using The Hazard Identification ChecklistDocument3 pagesHazard Analysis: Using The Hazard Identification ChecklistRamkrishna PatelNo ratings yet

- ACP Cutting Incident-InvestigationDocument3 pagesACP Cutting Incident-InvestigationolaogunNo ratings yet

- Oper Guideline Ccu&Hdu Ver 3.0Document99 pagesOper Guideline Ccu&Hdu Ver 3.0Bijan DebnathNo ratings yet

- Nebosh Study Guide PDFDocument42 pagesNebosh Study Guide PDFB singhNo ratings yet

- LOTO OshaDocument36 pagesLOTO OshaYoga PradanaNo ratings yet

- Oxy Fuel Cutting PDFDocument28 pagesOxy Fuel Cutting PDFruhul01No ratings yet

- Warning! Behavior-Based Safety Can Be Hazardous To Your Health and Safety Program!Document24 pagesWarning! Behavior-Based Safety Can Be Hazardous To Your Health and Safety Program!HevyNo ratings yet

- TIG Welding (GTAW) - MIG Welding (GMAW) - Stick Welding (SMAW) Questions, and AnswersDocument23 pagesTIG Welding (GTAW) - MIG Welding (GMAW) - Stick Welding (SMAW) Questions, and AnswerssanthakumarNo ratings yet

- Noise HazardsDocument27 pagesNoise HazardsZainorin Ali0% (1)

- Automatic Fire Detection and Suppression SystemDocument2 pagesAutomatic Fire Detection and Suppression SystemProdip SarkarNo ratings yet

- SAFETY Alert-Dont Mix Oxygen and OilDocument1 pageSAFETY Alert-Dont Mix Oxygen and OilHaleemUrRashidBangashNo ratings yet

- Ehs Think Tank: Welcome Back To The ChannelDocument7 pagesEhs Think Tank: Welcome Back To The Channelbk reddyNo ratings yet

- Bhopal IncidentDocument22 pagesBhopal IncidentAnonymous MwhZ2eVnB100% (1)

- Hand Safety and Injury Prevention TBTDocument5 pagesHand Safety and Injury Prevention TBTAlok SinghNo ratings yet

- Robot Welding TipsDocument50 pagesRobot Welding Tipscentaury20130% (1)

- Assessment of Tailors by Rula and Reba ADocument6 pagesAssessment of Tailors by Rula and Reba AMD Al-AminNo ratings yet

- Outlines Nebosh Revision Guide IGC 1 1Document30 pagesOutlines Nebosh Revision Guide IGC 1 1Sohna BachaNo ratings yet

- PPT. Accidents Direct & Indirect CostDocument8 pagesPPT. Accidents Direct & Indirect CostVishwash GoyalNo ratings yet

- Ewh Vi PDFDocument66 pagesEwh Vi PDFEnrike GarciaNo ratings yet

- Form: 1002 Project:: Name: Initial Name: Initial Name: InitialDocument1 pageForm: 1002 Project:: Name: Initial Name: Initial Name: InitialcrnkarlosNo ratings yet

- Global Manufacturing Training: SAF-111 Noise HazardsDocument53 pagesGlobal Manufacturing Training: SAF-111 Noise HazardsZaid Tariq AlabiryNo ratings yet

- Ergonomics PPT v-03!01!17Document50 pagesErgonomics PPT v-03!01!17Swapnil ShilamkarNo ratings yet

- Team + Work Safety: News & NotesDocument5 pagesTeam + Work Safety: News & NotesGomzalez Bin GembozNo ratings yet

- SOS Hazard Identification Checklist FMDocument10 pagesSOS Hazard Identification Checklist FMBrigita MariaNo ratings yet

- Confined Space HazardsDocument29 pagesConfined Space HazardskishorsinghNo ratings yet

- SP02 JSA Form EnglishDocument5 pagesSP02 JSA Form Englishmartina19No ratings yet

- Utility Hazard AssessmentDocument2 pagesUtility Hazard AssessmentsafwanNo ratings yet

- Risk Assessment MatrixDocument4 pagesRisk Assessment MatrixKunju MathewsNo ratings yet

- Hazard EvaluationDocument3 pagesHazard EvaluationMobile SunNo ratings yet

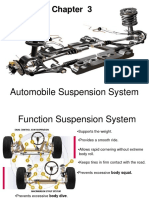

- Suspension SystemDocument36 pagesSuspension SystemRahul VermaNo ratings yet

- Service Manual: DSC-W120/W125Document72 pagesService Manual: DSC-W120/W125pasantitoNo ratings yet

- TechfestDocument5 pagesTechfestNived NarayananNo ratings yet

- Spare Part Catalogue For Old Type FONA1000 SeriesDocument41 pagesSpare Part Catalogue For Old Type FONA1000 SeriesIsrael MedinaNo ratings yet

- Content: 1 Heidelberg Systemservice 4 2 Presses 7Document6 pagesContent: 1 Heidelberg Systemservice 4 2 Presses 7edwin corderoNo ratings yet

- Jet BrochureDocument12 pagesJet Brochureramkumar4441No ratings yet

- TSGDocument52 pagesTSGsirishghrceNo ratings yet

- Shining Service Manual Air ConditionDocument62 pagesShining Service Manual Air Conditionespagnita100% (2)

- Bringing Deep Learning To Embedded Systems: Mark NadeskiDocument7 pagesBringing Deep Learning To Embedded Systems: Mark NadeskiMarlessonSantanaNo ratings yet

- Garware-Wall Ropes LTD.: Geosynthetics DivisionDocument1 pageGarware-Wall Ropes LTD.: Geosynthetics DivisionGautam RaiNo ratings yet

- Catalog April 2014 BAG 1 REVDocument20 pagesCatalog April 2014 BAG 1 REVArif FebriantoNo ratings yet

- A PROJECT ON g+5 BuildingsDocument36 pagesA PROJECT ON g+5 BuildingsVishakha PatelNo ratings yet

- Ry 30160Document6 pagesRy 30160Ionescu TiberiuNo ratings yet

- Housing R&B SOR 21-22Document31 pagesHousing R&B SOR 21-22vikramjeet singhNo ratings yet

- SPE-1167-Wettability of Porous Rock by Amott, 1960)Document7 pagesSPE-1167-Wettability of Porous Rock by Amott, 1960)Murat SyzdykovNo ratings yet

- Operation Manual 950 PagesDocument950 pagesOperation Manual 950 Pageskatibra67% (3)

- Kim Lighting B30 Series Bollard Brochure 1994Document12 pagesKim Lighting B30 Series Bollard Brochure 1994Alan MastersNo ratings yet

- Planning, Analyzing and Designing of Staff Quaters Building by Using STAAD ProDocument12 pagesPlanning, Analyzing and Designing of Staff Quaters Building by Using STAAD ProInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Vantran: H1 H2 H3 XO X1 X2 X3Document2 pagesVantran: H1 H2 H3 XO X1 X2 X3Carlos Luis Oyuela GomezNo ratings yet

- Hydrogen Economy, Hydrogen Storage and Fuelcell StackDocument20 pagesHydrogen Economy, Hydrogen Storage and Fuelcell StackpolysourceNo ratings yet

- Sr. No. Uni. Roll No. Name of StudentDocument8 pagesSr. No. Uni. Roll No. Name of StudentragvshahNo ratings yet

- The Thermal Conductivity DetectorDocument8 pagesThe Thermal Conductivity DetectorchmsarfrazNo ratings yet

- Underground Petroleum Piping Systems PDFDocument21 pagesUnderground Petroleum Piping Systems PDFMichael J. BaneNo ratings yet

- Teras Ariel 50M-5200BHP/65TSBP/AHT/OCEAN TOWING: Please Email Us atDocument2 pagesTeras Ariel 50M-5200BHP/65TSBP/AHT/OCEAN TOWING: Please Email Us atKenRoczen CaesarNo ratings yet

- Everest Tools - Valisons & CompanyDocument24 pagesEverest Tools - Valisons & CompanyMurtuza LucknowwalaNo ratings yet

- Users Manual Phenix Technologies Inc.: PPD September 19, 2007Document31 pagesUsers Manual Phenix Technologies Inc.: PPD September 19, 2007Edinson Cardenas AlikhanNo ratings yet

- PS118 PDFDocument3 pagesPS118 PDFVishwakarma VishwakarmaNo ratings yet

- DD Env 1401-3-2001 PDFDocument12 pagesDD Env 1401-3-2001 PDFCss100% (1)

- Architectural Report On Frank O GehryDocument5 pagesArchitectural Report On Frank O Gehryanuj gothiNo ratings yet

- Iso 2859-1Document2 pagesIso 2859-1Daniel MargineanNo ratings yet