TABLE OF CONTENT

Page

Front Page

Table of Contents 1

1. Title 2

2. Objectives 2

3. Introduction 2

4. Apparatus 4

4.1 Industrial Apparatus

5. Experimental Procedure 7

6. Result and Data Analysis 8

7. Discussion of Results 10

8. Conclusion 10

9. Recommendations 10

10. References 11

1

�1.0 TITLE

Profile Measurement (Horizontal Profile)

2.0 OBJECTIVE

1. To identify the screw thread profile and measure the parameters of the screw threap

using the Horizontal Profile Projector.

2. To compare the screw threap profile between the experimental and ISO standart value

by measure the major diameter, minor diameter, effective diameter and screw pitch.

3.0 INTRODUCTION

An Profile Projectoris define that a device that applies the principle of optics where is

use to the inspection of manufactured parts. The manufactured part is projected to the screen

diplay by the lens. The idea of using profile projector, which is created by James Hartness and

Russell W. Poerter, came from mixing optics and measurement in a device. it is employed for

inspecting and comparing very small and complex parts, which play very significant role in

system structure, as an application of quality.

The specimen that to be measure by Profile Pojector is Screw Thread Plug Gauge

(M12×3 ISO 6H). The first part that has to measure is major diameter for that screw. For the

major diameter are the first numbers found in screw thread designation. In this case is M12

mean major diameter is 12mm. The major diameter thread is determine by the cross-section

view that taken in a plane that contain the axis of the threads. In other case is, the height of the

thread profile.

The second part in screw thread that to be measure is minor diameter. The minor

diameter screw thread is define by the lower extreme diameter of the thread. The minor

diameater screw thread can be measure by measuring the depth of the screw thread with the

lens at an profile projector. Dimension for the minor diameter is from the major diameter minus

with the upper depth and lower depth. To measure the hight thread, major diameter must be

minus with the minor diameter and then must divided by two.

The third part of screw thread that measure is effective diameter. The effective diameter

is the avarage pitch diameter where the minimum pitch diameter plus with the maximum pitch

diameter and then divided by two. For this type of Screw Thread Plug Gauge (M12×3 ISO 6H)

type thje minimum pitch value and the maximum pitch value is 21.803mm and 22.003mm. to

2

�measure the effective diameter for this type of screw thread, first must get the value of the depth

height. Second is, the value of the upper depth height devided by two at the same time, the

lower depth height must do the same thing. the values that get trhen minor with the major

diameter. The the effective diameter screw thread value is obtain.

The last part is pitch diameter. For the pitch diameter, the firt thing that can get

information at manufactured part number. In this case is M12×3 ISO 6H. Number 3 is

determined by the length of the pict of for that screw thread. Pitch diameter screw thread is the

diameter at which the thread tooth and the thread space are equal.

Figure 1: ACME Screw Thread All Dimension.

3

�4.0 APPARATUS

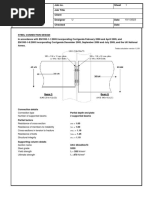

Figure 2:Screw Thread Plug Gauge (M24×3 ISO 6H).

Screen Display

X- Axis Controller

Calibration

Y- Axis Controller

Switch

Figure 3 : Horizontal Profile Projection.

Figure 4 : Magnifying Glass.

4

�4.1 INDUSTRIAL APPARATUS

Experiment: Horizontal Profile

1. Manual Quick Scope QS-L Series

Figure 5 : Manual Quick Scope QS-L Series

0.1 μm resolution and 150mm z-axis range.

The power zoom that can easily to change magnification.

The auto-focus system function.

The quick navigation function (repeated the measurement quickly).

2. M-nanocoord

Figure 6 : M-nanocoord

Laser Holoscales with nanometer resolution and thermal expantion virtually

zero.

High-precision air bearing that can improve the measurement accuracy.

Suitable for the very small dimension specimen.

5

�No Differences

Laboratory Industrrial

1. Can measure only the certain shape. Can measure the complex shape

dimension.

2. Not very accuate. High percision and accurate for the result.

3. Need to adjust for the focus. Auto focus function.

6

�5.0 EXPERIMENTAL PROCEDURE

1. The screw thread plug gauge (M24 X 3.0 ISO 6H) was placed parallel to the lens.

2. The projector was switch on.

3. Then image of the screw profile was appeared at the projector.

4. Then, any peak of the thread was aligned to the origin and set to zero at Y-axis

reading.

5. The position of thread was moved to the peak bottom by rotating the Y-axis

controller.

6. The reading at the Y-axis was recorded.

7. Steps 4 to 6 were repeated for four times to get an average diameter reading.

8. Steps 4 to 7 were repeated with different parameters which were minor diameter,

effective diameter and pitch.

7

�6.0 RESULTS

Reading Number Major Diameter Minor Diameter Effective Diameter Pitch

R1 23.986 19.575 21.921 3.017

R2 23.902 19.589 21.954 2.938

R3 23.984 19.585 21.895 2.986

R4 24.001 19.640 21.860 3.001

Total, ∑ 95.873 78.389 87.630 11.942

Sample Calculation

𝑻𝒐𝒕𝒂𝒍 𝒅𝒊𝒂𝒎𝒆𝒕𝒆𝒓

𝑨𝒗𝒆𝒓𝒂𝒈𝒆 𝒅𝒊𝒂𝒎𝒆𝒕𝒆𝒓 =

𝟒

|𝑻𝒉𝒆𝒐𝒓𝒆𝒕𝒊𝒄𝒂𝒍 − 𝑬𝒙𝒑𝒆𝒓𝒊𝒎𝒆𝒏𝒕|

𝑷𝒆𝒓𝒄𝒆𝒏𝒕𝒂𝒈𝒆 𝑬𝒓𝒓𝒐𝒓 = 𝒙 𝟏𝟎𝟎%

𝑻𝒉𝒆𝒐𝒓𝒆𝒕𝒊𝒄𝒂𝒍

Major diameter

95.873

𝐴𝑣𝑒𝑟𝑎𝑔𝑒 𝑚𝑎𝑗𝑜𝑟 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟 = = 23.968 𝑚𝑚

4

|24 − 23.968|

𝑃𝑒𝑟𝑐𝑒𝑛𝑡𝑎𝑔𝑒 𝐸𝑟𝑟𝑜𝑟 = 𝑥 100% = 0.133%

24

Minor diameter

78.389

𝐴𝑣𝑒𝑟𝑎𝑔𝑒 𝑚𝑖𝑛𝑜𝑟 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟 = = 19.597 𝑚𝑚

4

|19.855 − 19.597|

𝑃𝑒𝑟𝑐𝑒𝑛𝑡𝑎𝑔𝑒 𝐸𝑟𝑟𝑜𝑟 = 𝑥 100% = 1.299%

19.855

Effective diameter

87.630

𝐴𝑣𝑒𝑟𝑎𝑔𝑒 𝑒𝑓𝑓𝑒𝑐𝑡𝑖𝑣𝑒 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟 = = 22.408 𝑚𝑚

4

|21.903 − 22.408|

𝑃𝑒𝑟𝑐𝑒𝑛𝑡𝑎𝑔𝑒 𝐸𝑟𝑟𝑜𝑟 = 𝑥 100% = 2.306%

21.903

8

� Pitch

11.942

𝐴𝑣𝑒𝑟𝑎𝑔𝑒 𝑝𝑖𝑡𝑐ℎ = = 2.986 𝑚𝑚

4

|3 − 2.986|

𝑃𝑒𝑟𝑐𝑒𝑛𝑡𝑎𝑔𝑒 𝐸𝑟𝑟𝑜𝑟 = 𝑥 100% = 0.467%

3

Parameters Average reading, mm ISO dimension, mm Percentage error,%

Major diameter 23.968 24.000 0.133

Minor diameter 19.597 19.855 1.299

Effective diameter 22.408 21.903 2.306

Pitch 2.986 3.000 0.467

9

�7.0 DISCUSSION

From this experiment, each student in a group need to take reading of a workpiece by using

horizontal profile projector. The readings that need to be recorded are major diameter, minor

diameter, effective diameter and pitch of the workpiece. Four readings that had been recorded

are all different by each student. Then, average reading was calculated for all parameters. The

value for average major diameter was 23.968 mm, for minor diameter was 19.597 mm, for

effective diameter was 22.408 mm and for pitch value was 2.986 mm. The reading values were

compared with the workpiece with ISO dimension of M24 X 3.0 ISO 6H. The percentage error

for major diameter, minor diameter, effective diameter and pitch were 0.133%, 1.299%, 2.306%

and 0.467% respectively. There are many reasons for the variations of the reading and

percentage error. One of the reasons is parallax error. In order to avoid this error, the eye must

be perpendicular to the projector screen when set the position of the workpiece at the origin to

get the accurate reading. Besides, the presence of dust and contaminants on the bolt thread may

affect the reading. So, before conducting the experiment, make sure to clean up the bolt thread

to minimise the error.

8.0 CONCLUSION

As a conclusion from this experiment, we have obtain new knowledge on how to use horizontal

profile projector in order to determine the parameters of the bolt thread which are major

diameter, minor diameter, effective diameter and pitch. Then, we compared our average results

with the ISO dimension of the bolt and the determine reasons of the difference. This machine

is very important especially in metrology industry in order to get more precise and accurate

reading of a small product.

9.0 RECOMMENDATIONS

Clean up the surface of bolt thread for dust and contaminant.

The eye must be perpendicular to the projector screen when set the position of the

workpiece at the origin to avoid parallax error.

Use magnifying glass to see clear image of the profile on the projector.

Record the readings multiple times to get more accurate reading.

10

�10.0 REFERENCES

1. Serope Kalpakjian & Steven R. Schmid, Manufacturing Processes for Engineering

Materials, 4th Edition, Illinois Institute of Technology, Prentice Hall, 2003.

2. Advantages and Applications of Profile Projectors in Industries, (2018). Presto group.

http://www.prestogroup.com/blog/advantages-and-applications-of-profile-

projectorsin-industries/

3. Maryland Metrics Thread Data Charts (2009). Metric Thread Extended Thread Size

Range.

http://mdmetric.com/tech/M-thead%20600.htm

4. Climate change and urban resilience (2011). Current Opinion in Environmental

Sustainability.

https://www.sciencedirect.com/science/article/pii/S187538921100455X

5. Screw thread (2018). Wikipedia.

https://en.wikipedia.org/wiki/Screw_thread

6. ISO thread (2018). Thurmer.

http://www.thurmer.com/iso-thread/

7. Gear and Screw measurement (2016). LinkedIn SlideShare.

https://www.slideshare.net/AFAQAHMEDJAMADAR/gear-and-screw-measurement

8. External Metric Thread Dimensions Chart (2013). External Metric Thread Dimensions

Chart.

https://www.amesweb.info/Screws/External-Metric-Thread-Dimensions-Chart.aspx

9. Oberg, E, Jones ,F.D. , Horton H.L. ,Ryffel H.H., (2016) . Machinery's Handbook . 30th

edition. Industrial Press Inc.

10. How to Use Profile Projector Machine (2016), Profile Projector Procedure.

http://www.dahometerinstrument.com/sale-10719302-how-to-use-profile-

projectormachine-profile-projector-procedure.html

11