Professional Documents

Culture Documents

HBE COLD Weather: High Build Liquid Coating For Low Temperature Applications

Uploaded by

olalekanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HBE COLD Weather: High Build Liquid Coating For Low Temperature Applications

Uploaded by

olalekanCopyright:

Available Formats

HBE COLD Weather

High build liquid coating for low

temperature applications

The Canusa HBE COLD Weather is an advanced liquid coat-

ing specifically designed for cold weather application. The high

build formulation is capable of curing fast when applied to

colder substrates at colder ambient temperatures – even down

to subzero conditions of -20°C (-4°F). Applied to bare steel, the

HBE COLD Weather coating is used for protection of pipeline

field joint girth welds, valves and fittings, as a holiday repair

material on FBE coated mainline pipe or for pipeline coating

rehabilitation.

Applications

Cures in the Winter

• The HBE COLD Weather coating will cure in the Winter season

Oil & Gas

without the requirement of external heat. Just apply it and leave

it. No preheating or post heating necessary.

Superior Corrosion Resistance Repair & Rehab

• Canusa’s HBE COLD Weather coating has proven to outperform

competitive equivalents in a variety of different test methods

including cathodic disbondment, hot water soak and impact Low Temperature

resistance.

Saves Time

• The fast cure formulation allows for quick handling and d quick

backfilling for an efficient end-to-end coating process.

High Build in Single Coat

• A single pass application direct-to-metal will achieve a high build

coating thickness of 20-40 mils (500-1000 microns)

Variety of Uses

• Field joint girth welds, valves and fittings, holiday repairr

material on FBE mainline pipe, pipeline rehabilitation or

new construction.

PRODUCT DATA SHEET canusacps.com

The product information

HBE COLD Weather shown here is intended as a

guide for standard products.

Consult your Canusa

High build liquid coating for low temperature representative for specific

projects or unique applications.

applications

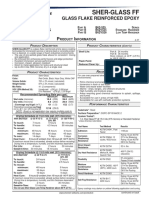

Performance All performance testing followed CSA-Z245.20-10 unless specified.

Service Temp. Up to 65°C (150°F)

Typical Thickness > 25 mils (635 microns)

Mixing Ratio 12.5:1 (by volume)

Percent Solids 100%

Base: 1.45

Specific Gravity

Cure: 1.58

Hardness (ASTM D2240) > 87 Shore D

Adhesion to Steel (ASTM D4541) 3200 psi

Adhesion to FBE (ASTM D4541) 3000 psi

Cathodic Disbondment @ 28 days, 23°C 4.1 mm

Canusa-CPS

Cathodic Disbondment @ 28 days, 50°C 10.0 mm A division of ShawCor Ltd.

Impact Resistance @ 0°C > 3.0 J Head Office

25 Bethridge Rd.

Impact Resistance @ -40°C > 3.0 J Toronto, ON M9W 1M7 Canada

Tel: +1 416 743 7111

Hot Water Immersion @ 28 days, 50°C Rating 1

Fax: +1 416 743 5927

Hot Water Immersion @ 28 days, 65°C Rating 1

Canada

Hot Water Immersion @ 28 days, 95°C Rating 1 Suite 3200, 450 - 1st Street S.W.

Calgary, AB T2P 5H1 Canada

Minimum Curing Temperature (Surface) -20°C

Tel: +1 403 218 8207

6 months when stored in original packaging Fax: +1 403 264 3649

Shelf Life

between 0.5°C – 27°C.

Americas

Pot Life/Gel Time (100 g Sample) 3838 N. Sam Houston Pkwy E.

Suite 300

Pot Life/Gel Time @ 23°C (73°F) 13 minutes

Houston, TX 77032

Pot Life/Gel Time @ 0°C (32°F) 35 minutes Tel: +1 281 886 2350

Fax: +1 281 886 2353

Pot Life/Gel Time @ -10°C (14°F) 55 minutes

Europe, Middle East, Africa & Russia

Pot Life increases as temperature decreases

Unit 3, Sterling Park,

Typical Kit Size Required by Pipe Diameter1 Gatwick Road, Crawley, West Sussex

RH10 9QT United Kingdom

4.5” – 26” 0.8 Liter Kit Tel: +44 1293 541254

Fax: +44 1293 541777

28” to 50” 1.5 Liter Kit

1 Based on 400 mm coating width, 25 mils (635 micron) average thickness and 50% wastage factor. Asia-Pacific

101 Thomson Road,

#11-03 United Square

307591 Singapore

Tel: +65 6749 8918

Safety Fax: +65 6749 8919

Handle with care. Before and during use, observe all safety labels on packaging Canusa-CPS is registered

containers, consult with Canusa-CPS Material Safety Data Sheets and abide by all to ISO 9001:2008

local or national safety regulations. Canusa warrants that the product conforms to

its chemical and physical description and is

appropriate for the use stated on the

product data sheet when used in compliance

with Canusa’s written instructions. Since many

installation factors are beyond our control,

the user shall determine the suitability of the

products for the intended use and assume all

risks and liabilities in connection therewith.

Canusa’s liability is stated in the standard

terms and conditions of sale. Canusa makes

Since 1967, Canusa-CPS has been a leading developer and manufacturer of specialty pipeline coatings no other warranty either expressed or implied.

All information contained in this data sheet is

for the sealing and corrosion protection of pipeline joints and other substrates. Canusa-CPS high to be used as a guide and is subject to change

without notice. This data sheet supersedes all

performance products are manufactured to the highest quality standards and are available in a number previous data sheets on this product. E&OE

of configurations to accommodate many specific project applications.

PDS_HBE-CW_rev016

You might also like

- How To Cast Out Demons and Break CursesDocument84 pagesHow To Cast Out Demons and Break CursesChiChi Ndu100% (4)

- How To Cast Out Demons and Break CursesDocument84 pagesHow To Cast Out Demons and Break CursesChiChi Ndu100% (4)

- Motorcycle Engine MaintainanceDocument6 pagesMotorcycle Engine MaintainanceAlvin100% (2)

- Structural Design of FootingsDocument82 pagesStructural Design of FootingsRafi Sulaiman100% (1)

- ASME Brazing Procedures Qualification (BPQ)Document1 pageASME Brazing Procedures Qualification (BPQ)ChowKC03No ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- DEFCON 23 Lin Huang Qing Yang GPS Spoofing PDFDocument54 pagesDEFCON 23 Lin Huang Qing Yang GPS Spoofing PDFsdgpass2585No ratings yet

- Overlock Mauser 500 ManualDocument98 pagesOverlock Mauser 500 ManualMauricio GonzalezNo ratings yet

- Philippine Arena Structural DesignDocument12 pagesPhilippine Arena Structural DesignTos Hernando100% (1)

- Superpave Mix DesignDocument28 pagesSuperpave Mix DesignGabriel Omar100% (3)

- Tutorial - Import Coordinates From Excel To AutoPIPE PDFDocument23 pagesTutorial - Import Coordinates From Excel To AutoPIPE PDFolalekanNo ratings yet

- Tutorial - Import Coordinates From Excel To AutoPIPE PDFDocument23 pagesTutorial - Import Coordinates From Excel To AutoPIPE PDFolalekanNo ratings yet

- PPL-SU-5023 Materials and Fabrication of Liquid Transportation PipelinesDocument74 pagesPPL-SU-5023 Materials and Fabrication of Liquid Transportation PipelinesolalekanNo ratings yet

- Heat-Shrink Sleeve Installation StandardDocument32 pagesHeat-Shrink Sleeve Installation Standardolalekan100% (1)

- Feed Mill Design (ONIOT)Document12 pagesFeed Mill Design (ONIOT)Rodel MarataNo ratings yet

- Com Su 4042 IDocument38 pagesCom Su 4042 Iolalekan100% (1)

- Fundamentals of S Lay and Engineering Analysis Using OFFPIPE GEP PDFDocument98 pagesFundamentals of S Lay and Engineering Analysis Using OFFPIPE GEP PDFolalekan100% (1)

- Relay Interlocking Siemense Type NotesDocument79 pagesRelay Interlocking Siemense Type NotesVikas Srivastav96% (23)

- Setup guide for Oneal Audio amplifiersDocument11 pagesSetup guide for Oneal Audio amplifiersGuto LiberatoNo ratings yet

- Advances in High Voltage Insulation and Arc Interruption in SF6 and VacuumFrom EverandAdvances in High Voltage Insulation and Arc Interruption in SF6 and VacuumNo ratings yet

- Epofine 556 FR/ FInehard 951Document3 pagesEpofine 556 FR/ FInehard 951Karishma Prabhu100% (1)

- Wind TurbineDocument8 pagesWind TurbineDennyy IttyNo ratings yet

- Sid Su 5106 CDocument13 pagesSid Su 5106 ColalekanNo ratings yet

- Hbe-Cw: High Build Liquid Coating For Low Temperature ApplicationsDocument2 pagesHbe-Cw: High Build Liquid Coating For Low Temperature ApplicationsMohammad Mehdi JafariNo ratings yet

- HBE-HT High Build Epoxy Coating 150°C PipelinesDocument2 pagesHBE-HT High Build Epoxy Coating 150°C PipelinesdakidofdaboomNo ratings yet

- Hbe-Os: High Build Epoxy Coating For Offshore Corrosion ProtectionDocument2 pagesHbe-Os: High Build Epoxy Coating For Offshore Corrosion Protectionsamkarthik47No ratings yet

- High Build Epoxy Coating For Pipelines: Product Data SheetDocument2 pagesHigh Build Epoxy Coating For Pipelines: Product Data SheetChegg ChemNo ratings yet

- High Build Epoxy Coating For Pipelines: Product Data SheetDocument2 pagesHigh Build Epoxy Coating For Pipelines: Product Data Sheetdemi bajakanNo ratings yet

- Wrapidcoat PVC: Superior Mechanical ProtectionDocument2 pagesWrapidcoat PVC: Superior Mechanical ProtectionsenthilkumarNo ratings yet

- Wrapidcoat PVC: Superior Mechanical ProtectionDocument2 pagesWrapidcoat PVC: Superior Mechanical ProtectionHendra AwanNo ratings yet

- Pds Na Gts65Document2 pagesPds Na Gts65Yan FerizalNo ratings yet

- My T Bond 1161 TDS Structural Adhesive For Low Surface Energy PlasticsDocument2 pagesMy T Bond 1161 TDS Structural Adhesive For Low Surface Energy PlasticsShabarish KeshavNo ratings yet

- TDS L2057216Document3 pagesTDS L2057216erolsarNo ratings yet

- Wrapidcoat PVC: Superior Mechanical ProtectionDocument2 pagesWrapidcoat PVC: Superior Mechanical ProtectioncocoaNo ratings yet

- 7-2500 FbeDocument3 pages7-2500 FbejleonosNo ratings yet

- Tds Ral 7037 Haa Hfhr02s8Document1 pageTds Ral 7037 Haa Hfhr02s8Jaskaran SinghNo ratings yet

- Sherglass FFDocument4 pagesSherglass FFJhose BonillaNo ratings yet

- Product Data Sheet: No-Tox HD Food Grade GreaseDocument3 pagesProduct Data Sheet: No-Tox HD Food Grade GreaseDaniel ColinsNo ratings yet

- Loctite Nordbak Wear Resistant Putty: Product Description MixedDocument3 pagesLoctite Nordbak Wear Resistant Putty: Product Description MixedFurqan ShabbirNo ratings yet

- TDS - 7-0008 - Internal Pipe Coating - EngDocument3 pagesTDS - 7-0008 - Internal Pipe Coating - Englong chanNo ratings yet

- Hempaline Defend 630: Product DescriptionDocument3 pagesHempaline Defend 630: Product DescriptionJorge Alberto MontalatNo ratings yet

- 521+technical Data Sheet V-6Document2 pages521+technical Data Sheet V-6TeenTeen GaMingNo ratings yet

- Spectrasyn™ 10: Polyalphaolefin (Pao) FluidDocument2 pagesSpectrasyn™ 10: Polyalphaolefin (Pao) FluidMaram YasserNo ratings yet

- Technical Data Sheet Product 406: Worldwide Version, February 1996Document3 pagesTechnical Data Sheet Product 406: Worldwide Version, February 1996Muhammad irtizaNo ratings yet

- DOWSIL™ 340 Heat Sink Compound: Features & Benefits ApplicationsDocument2 pagesDOWSIL™ 340 Heat Sink Compound: Features & Benefits ApplicationsMauricio Fernandez GuevaraNo ratings yet

- NC-558 TDS enDocument2 pagesNC-558 TDS enniteshacharya100% (1)

- Dow CorningDocument2 pagesDow Corningwardoyoclp75No ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Technical Information Sheet: 7-2508 Pipe CoatingDocument3 pagesTechnical Information Sheet: 7-2508 Pipe Coatingreza329329No ratings yet

- K-Resin BK10: Styrene Butadiene Copolymer (SBC)Document2 pagesK-Resin BK10: Styrene Butadiene Copolymer (SBC)Manikanta Sai KumarNo ratings yet

- Scar Guard EnglishDocument2 pagesScar Guard EnglishVismael SantosNo ratings yet

- Cardolite NX 2016Document2 pagesCardolite NX 2016Lê TiếnNo ratings yet

- Umeguard HS 6174 20100430RDocument2 pagesUmeguard HS 6174 20100430Rrhannie garciaNo ratings yet

- K-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationsDocument1 pageK-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationssumherilNo ratings yet

- 009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Document1 page009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Yousef LotfyNo ratings yet

- Pao 100Document2 pagesPao 100Антон СтепураNo ratings yet

- 400 00030953en Engage 8180 TdsDocument3 pages400 00030953en Engage 8180 TdsSIDDHARTH BHASNEYNo ratings yet

- NorylDocument1 pageNorylAnonymous P8Bt46mk5INo ratings yet

- Protective DTM Acrylic Primer/Finish Product DescriptionDocument4 pagesProtective DTM Acrylic Primer/Finish Product DescriptionVernon Jiménez FonsecaNo ratings yet

- Cardolite NX-2007: Epoxy Curing Agent Technical DatasheetDocument2 pagesCardolite NX-2007: Epoxy Curing Agent Technical Datasheettrường phạmNo ratings yet

- Nap-Gard Gold-Dual Powder Coating Technical Data SheetDocument3 pagesNap-Gard Gold-Dual Powder Coating Technical Data Sheetlong chanNo ratings yet

- Nap-Gard 7-2500 PDFDocument2 pagesNap-Gard 7-2500 PDFPietro ViganNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- 4070-4072 Product InfoDocument2 pages4070-4072 Product InfoCesar Marcello Cordova GuerreroNo ratings yet

- Ficha Técnica Hule BlairDocument1 pageFicha Técnica Hule BlairSergio Olvera GNo ratings yet

- 400 00285217en Hdpe 6200 TdsDocument2 pages400 00285217en Hdpe 6200 TdsOriana Gudiño GaliñoNo ratings yet

- Dfense Blok™: Technical Data SheetDocument1 pageDfense Blok™: Technical Data SheetjohnNo ratings yet

- GTS-80 Provides Superior Corrosion Protection Up To 80°CDocument2 pagesGTS-80 Provides Superior Corrosion Protection Up To 80°CZainudinNo ratings yet

- WWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinDocument2 pagesWWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinVinodKandukuriNo ratings yet

- K-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationsDocument1 pageK-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationsPatricio Bravo CastilloNo ratings yet

- Renolin Therm 300Document1 pageRenolin Therm 300Mohamed SalemNo ratings yet

- TDS - CRYOPIR50f - 202004-1Document1 pageTDS - CRYOPIR50f - 202004-1Nguyen Thi Bich ThuyNo ratings yet

- Specification TOPSOL A150pdfDocument1 pageSpecification TOPSOL A150pdfHenry FloresNo ratings yet

- Kocetal K700 Property DataDocument1 pageKocetal K700 Property DataRanjan GnanaoliNo ratings yet

- 7727 Auto - Dispensable Glossy White Thermal Transfer Printable PolyimideDocument4 pages7727 Auto - Dispensable Glossy White Thermal Transfer Printable Polyimidetoumi amineNo ratings yet

- Hempaline Defend 630: Product DescriptionDocument3 pagesHempaline Defend 630: Product DescriptionSalas VinicioNo ratings yet

- Loctite PC 7222: Technical Data SheetDocument3 pagesLoctite PC 7222: Technical Data Sheetfrancisca ferrerNo ratings yet

- Sabic Hdpe Bm1052: High Density PolyethyleneDocument2 pagesSabic Hdpe Bm1052: High Density PolyethyleneifahNo ratings yet

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Wem Pu 6089 ADocument52 pagesWem Pu 6089 AolalekanNo ratings yet

- Wem Pu 6089 A PDFDocument74 pagesWem Pu 6089 A PDFolalekanNo ratings yet

- DVD PowerSuite 2Document1 pageDVD PowerSuite 2Adelaida Stoian GhercaNo ratings yet

- Edu 768 Sosial Studies MethodsDocument115 pagesEdu 768 Sosial Studies MethodsolalekanNo ratings yet

- PPL Su 1050 O.1Document56 pagesPPL Su 1050 O.1olalekanNo ratings yet

- Agricultural Science Teaching MethodsDocument120 pagesAgricultural Science Teaching MethodsolalekanNo ratings yet

- How To Cast Out Demons and Break CursesDocument11 pagesHow To Cast Out Demons and Break CursesolalekanNo ratings yet

- Teaching History2Document74 pagesTeaching History2yrszie100% (1)

- Edu 726 Measurement and EvaluationDocument21 pagesEdu 726 Measurement and EvaluationolalekanNo ratings yet

- Edu 768 Sosial Studies MethodsDocument115 pagesEdu 768 Sosial Studies MethodsolalekanNo ratings yet

- Tutorial - Import Coordinates From Excel To AutoPIPEDocument1 pageTutorial - Import Coordinates From Excel To AutoPIPEolalekanNo ratings yet

- HSE Trainnig SlideDocument82 pagesHSE Trainnig SlideolalekanNo ratings yet

- Edu 726 Measurement and Evaluation PDFDocument213 pagesEdu 726 Measurement and Evaluation PDFolalekan100% (1)

- Os H203 PDFDocument33 pagesOs H203 PDFolalekanNo ratings yet

- HSE Trainnig Slide PDFDocument117 pagesHSE Trainnig Slide PDFolalekanNo ratings yet

- HBE COLD Weather: High Build Liquid Coating For Low Temperature ApplicationsDocument2 pagesHBE COLD Weather: High Build Liquid Coating For Low Temperature ApplicationsolalekanNo ratings yet

- Course Code EDU 712 Professionalism in TeachingDocument73 pagesCourse Code EDU 712 Professionalism in TeachingolalekanNo ratings yet

- Getting Started With OFFPIPE 3Document13 pagesGetting Started With OFFPIPE 3olalekan100% (1)

- HBE COLD Weather: High Build Liquid Coating For Low Temperature ApplicationsDocument2 pagesHBE COLD Weather: High Build Liquid Coating For Low Temperature ApplicationsolalekanNo ratings yet

- 020 GCMS of PlasticizersDocument4 pages020 GCMS of PlasticizersFrancesca PorcelliNo ratings yet

- Fan Coil Solutions BrochureDocument8 pagesFan Coil Solutions BrochureDemetrios GkikasNo ratings yet

- BoqDocument24 pagesBoqDilshad AhemadNo ratings yet

- Other Other Technologies: A SurveyDocument27 pagesOther Other Technologies: A SurveyArinjayKumarNo ratings yet

- 8 - Analysis of Doubly Reinforced BeamDocument13 pages8 - Analysis of Doubly Reinforced BeamgarhgelhNo ratings yet

- Engine Parts Guide for Komatsu PC130F-7 ExcavatorDocument5 pagesEngine Parts Guide for Komatsu PC130F-7 ExcavatorChimanNo ratings yet

- Ms 1933 Part 12007 Methods of Test For Masonry Units Part 1 Determination of Compressive Strength-872238Document17 pagesMs 1933 Part 12007 Methods of Test For Masonry Units Part 1 Determination of Compressive Strength-872238Fauziah Aziz0% (1)

- Solid Waste ManagementDocument16 pagesSolid Waste ManagementAshish AroraNo ratings yet

- QSX15-G8: TA Luft CompliantDocument3 pagesQSX15-G8: TA Luft CompliantNguyen CuongNo ratings yet

- Instruction Manual RH9820 PDFDocument134 pagesInstruction Manual RH9820 PDFMaskusyaniNo ratings yet

- Cycom-919 CM en PDFDocument7 pagesCycom-919 CM en PDFstaedtlerpNo ratings yet

- Xantia XM Evasion 2001Document310 pagesXantia XM Evasion 2001Ramon PaixaoNo ratings yet

- Gypsum Board, Fibrous Plaster and Calcium Silicate Ceiling SpecDocument8 pagesGypsum Board, Fibrous Plaster and Calcium Silicate Ceiling SpecKiran D AnvekarNo ratings yet

- DVC6000 Digital Valve Controller Instruction ManualDocument160 pagesDVC6000 Digital Valve Controller Instruction ManualJose Gustavo Robles MoralesNo ratings yet

- Wishing Well: Fun To Build!Document5 pagesWishing Well: Fun To Build!Daniel LourençoNo ratings yet

- Types of PrintersDocument9 pagesTypes of Printershasnain572No ratings yet

- DWTT Reduce ThicknessDocument1 pageDWTT Reduce ThicknessAnonymous B7pghhNo ratings yet

- Biogas Enrichment & Bottling Technology For Vehicular UseDocument4 pagesBiogas Enrichment & Bottling Technology For Vehicular Useउमेश पाण्डेयNo ratings yet

- A Case Studies of Intelligent Buildings in MalaysiaDocument12 pagesA Case Studies of Intelligent Buildings in MalaysiaPrakash BalagurunathanNo ratings yet