Professional Documents

Culture Documents

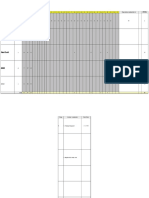

Please Tick Wherever Is Applicable (A) General Information On 5S Yes No

Uploaded by

Khushboo Raj0 ratings0% found this document useful (0 votes)

11 views1 pageThis document contains a survey to assess the implementation of 5S practices in different areas. It is divided into six sections - general 5S information, the five S's (Seiri, Seiton, Seiso, Seiketsu, Shitsuke), and requests supporting documents. Respondents are asked to check boxes to indicate whether various 5S policies, tools, and practices are available in their area related to organization, auditing, training, identification, storage, cleaning, labeling, and continuous improvement.

Original Description:

test

Original Title

5S Checklist

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains a survey to assess the implementation of 5S practices in different areas. It is divided into six sections - general 5S information, the five S's (Seiri, Seiton, Seiso, Seiketsu, Shitsuke), and requests supporting documents. Respondents are asked to check boxes to indicate whether various 5S policies, tools, and practices are available in their area related to organization, auditing, training, identification, storage, cleaning, labeling, and continuous improvement.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views1 pagePlease Tick Wherever Is Applicable (A) General Information On 5S Yes No

Uploaded by

Khushboo RajThis document contains a survey to assess the implementation of 5S practices in different areas. It is divided into six sections - general 5S information, the five S's (Seiri, Seiton, Seiso, Seiketsu, Shitsuke), and requests supporting documents. Respondents are asked to check boxes to indicate whether various 5S policies, tools, and practices are available in their area related to organization, auditing, training, identification, storage, cleaning, labeling, and continuous improvement.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Please tick wherever is applicable

(A) General information on 5S

Yes No

5 5 5S organization structure

5 5 5S Internal Audit Team

5 5 5S Suggestion Scheme

5 5 5S Score Board

5 5 5S Internal Awards Scheme for Best Performance

(B) Seiri - 1S

5 5 Availability of RED TAG area

5 5 Identified storage area for scraps

5 5 Disposal plan is available in all the areas

(C) Seiton -2S

5 5 All the items and areas are identified

5 5 Storage and stacking plan is available

5 5 Item quantity is easily visible

5 5 Retrieval of item/record within 30 seconds (if “NO” mention the approximate time taken)

(D) Seiso - 3S

5 5 Cleaning schedule is available

5 5 Responsibility is assigned for every area

(E) Seiketsu - 4S

5 5 Sign boards and direction indicates area available

5 5 5S – rules and regulations are displayed

5 5 Colour coding used wherever necessary

5 5 5S – manual is prepared and followed

5 5 Work instructions are displayed

(F) Shitsuke - 5S

5 5 Regular training calendar is available

5 5 Training register is maintained

5 5 Audit feedback – corrective action in register is available

5 5 5S – trend chart is updated monthly

5 5 5S – corner is available

5 5 Disciplinary action on slow runners is formulated

Supporting documents to be attached

v Before & after “5S” photographs

v 5S manual, if any

v Organisation structure for 5S

v 5S vision statement and objectives

v Waste disposal procedures

v Implementation steps adopted

v Tangible and intangible benefits out of 5S initiatives

You might also like

- 5S Basic TrainingDocument28 pages5S Basic TrainingJayantRK100% (1)

- Gap Analysis (Vda Vs TS)Document4 pagesGap Analysis (Vda Vs TS)Saipul Iza100% (2)

- Kaizen Structure Rev0Document86 pagesKaizen Structure Rev0hiattolaNo ratings yet

- 5S Training Manual GuideDocument50 pages5S Training Manual GuideLEAR to lear IndustriesNo ratings yet

- 5S Training ManualDocument26 pages5S Training Manualmahendkakde100% (1)

- Lecture-02 (TQM-5S System) PDFDocument17 pagesLecture-02 (TQM-5S System) PDFZahid Hasan OpuNo ratings yet

- Super 5S Is For EveryoneDocument64 pagesSuper 5S Is For EveryoneKatherine Villaran GonzalezNo ratings yet

- Paynter Chart With CCARDocument11 pagesPaynter Chart With CCARKhushboo RajNo ratings yet

- 5S Housekeeping TrainingDocument28 pages5S Housekeeping TrainingKvt VivekanandanNo ratings yet

- Welcomes All The Participants To The: Continuous Training & Development ProgramDocument47 pagesWelcomes All The Participants To The: Continuous Training & Development Programselvarangam govindarajanNo ratings yet

- Chapter 05 The Visual Workplace PDFDocument26 pagesChapter 05 The Visual Workplace PDFultramin12No ratings yet

- 5S Awareness PresentationDocument19 pages5S Awareness PresentationishyutNo ratings yet

- 5S - Becoming A Visual FactoryDocument38 pages5S - Becoming A Visual Factory7twofour67% (3)

- 5S Training for Lean ManufacturingDocument15 pages5S Training for Lean ManufacturingMahdi ZeynNo ratings yet

- Business Excellence 5SDocument20 pagesBusiness Excellence 5SSubhash MukherjeeNo ratings yet

- 5S Audit Report - V3Document1 page5S Audit Report - V3Rachmat Boerhan100% (1)

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

- The Secret To Japanese SuccessDocument51 pagesThe Secret To Japanese Successshahzaiblatafat12No ratings yet

- 5S Implementation Plan at Work PlaceDocument18 pages5S Implementation Plan at Work PlacemanishlmehtaNo ratings yet

- UNI-DIL 5S REVAMP MASTER PLANDocument1 pageUNI-DIL 5S REVAMP MASTER PLANDayal Weerasooriya100% (4)

- 5SDocument8 pages5SAbdul Karim100% (1)

- Lean Management: Swapnil Vashishtha Project Trainee Sanofi India LTDDocument36 pagesLean Management: Swapnil Vashishtha Project Trainee Sanofi India LTDmortalsrsszNo ratings yet

- Gauss Seidel MethodDocument5 pagesGauss Seidel MethodKhushboo RajNo ratings yet

- 5SDocument29 pages5Sshweta.gdp100% (10)

- Lean GamesDocument22 pagesLean Gamesroshaero100% (7)

- Toyota 5S - ALJ GroupDocument110 pagesToyota 5S - ALJ GroupMostafa Sherif100% (1)

- Lean ManufacturingDocument46 pagesLean Manufacturingsmajafri100% (1)

- Five SDocument60 pagesFive SShrikant MojeNo ratings yet

- Learn How to Implement the 5S Methodology for Workplace OrganizationDocument26 pagesLearn How to Implement the 5S Methodology for Workplace Organizationvips1992No ratings yet

- To Create and Maintain World Class Environment by Consistently Practicing 5S' Methodologies Through Total Employee InvolvementDocument16 pagesTo Create and Maintain World Class Environment by Consistently Practicing 5S' Methodologies Through Total Employee InvolvementAbhinav SinghNo ratings yet

- 5.1 - 5.3 5S Pillar BoardDocument22 pages5.1 - 5.3 5S Pillar BoardGilang AperlinNo ratings yet

- 5S Industrial Training: Creating A Clean, Organized and Productive WorkplaceDocument80 pages5S Industrial Training: Creating A Clean, Organized and Productive WorkplaceKhairun NisaNo ratings yet

- 5s Basic TrainingDocument15 pages5s Basic TrainingMaja BookmarksNo ratings yet

- 5S Basic Training: Whatis5Sandwhydowewanttodoit?Document15 pages5S Basic Training: Whatis5Sandwhydowewanttodoit?arvindrathodNo ratings yet

- 5S Basic Training: Whatis5Sandwhydowewanttodoit?Document15 pages5S Basic Training: Whatis5Sandwhydowewanttodoit?jacob thangamNo ratings yet

- 5S Training for Lean ManufacturingDocument15 pages5S Training for Lean ManufacturingR&D DaffyNo ratings yet

- 5S Basic Training: Whatis5Sandwhydowewanttodoit?Document15 pages5S Basic Training: Whatis5Sandwhydowewanttodoit?pankaj singhNo ratings yet

- 03 5S An Intro W Pictures 36 pgs10Document31 pages03 5S An Intro W Pictures 36 pgs10blitzkrigNo ratings yet

- Typical Activities IncludeDocument19 pagesTypical Activities IncludeAnthony Joao Mieles AnchundiaNo ratings yet

- SMA Study Plan S2 2023 14 June 2023Document3 pagesSMA Study Plan S2 2023 14 June 2023Quỳnh ChâuNo ratings yet

- 5S Working Time Table Implementation ScheduleDocument1 page5S Working Time Table Implementation ScheduleVbaluyoNo ratings yet

- 5S BasicsDocument26 pages5S BasicsKoGi NiShaNo ratings yet

- 5S Training for Continuous ImprovementDocument15 pages5S Training for Continuous ImprovementAkingbeyiju KayodeNo ratings yet

- 5s MethodologyDocument5 pages5s MethodologySer Crz JyNo ratings yet

- Welcome !: The Practice of Good WorkplaceDocument43 pagesWelcome !: The Practice of Good WorkplaceIsrael LópezNo ratings yet

- SAP Suggests To Go For ASAP Methodology Which Contain 5 PhasesDocument2 pagesSAP Suggests To Go For ASAP Methodology Which Contain 5 PhasesKhushi MughalNo ratings yet

- What Is 5S?Document1 pageWhat Is 5S?kalpak121No ratings yet

- Team member roles and 5S implementation targetsDocument3 pagesTeam member roles and 5S implementation targetsshadabb chowdharyNo ratings yet

- 5s Training ModuleDocument13 pages5s Training Modulemd jonaidNo ratings yet

- Beena Edward MSW HRMDocument10 pagesBeena Edward MSW HRMjS132No ratings yet

- 5 SsDocument15 pages5 SsgirdharskNo ratings yet

- Lec 4 WastesDocument10 pagesLec 4 WastesWaleed AhmedNo ratings yet

- 5 SDocument15 pages5 SScholar WinterflameNo ratings yet

- 5S Basic TrainingDocument15 pages5S Basic TrainingShams ShabahatNo ratings yet

- 5S Lean Manufacturing ToolsDocument6 pages5S Lean Manufacturing ToolsBrunoZottiNo ratings yet

- From 5S To 7S: Towards Organizational Efficiency and EffectivenessDocument18 pagesFrom 5S To 7S: Towards Organizational Efficiency and EffectivenessjS132No ratings yet

- 5S Basic Training: Whatis5Sandwhydowewanttodoit?Document15 pages5S Basic Training: Whatis5Sandwhydowewanttodoit?LunaNo ratings yet

- Learn About Quality: What Are The Five S'S (5S) of LeanDocument4 pagesLearn About Quality: What Are The Five S'S (5S) of Leannurreshhh mattupalliNo ratings yet

- 5s ShortDocument24 pages5s ShortSMAKNo ratings yet

- TestDocument1 pageTestKhushboo RajNo ratings yet

- Calculate Continuous Compounding Rate of Return from Discrete ReturnsDocument6 pagesCalculate Continuous Compounding Rate of Return from Discrete ReturnsKhushboo RajNo ratings yet

- TIM SemIV OperationsDocument4 pagesTIM SemIV OperationsKhushboo RajNo ratings yet

- AssignmentDocument3 pagesAssignmentKhushboo RajNo ratings yet

- CAS Group Project: The OpportunityDocument12 pagesCAS Group Project: The OpportunityKhushboo RajNo ratings yet

- TIM AssignmentDocument3 pagesTIM AssignmentKhushboo RajNo ratings yet

- IHRM - Rashi ChaudhariDocument2 pagesIHRM - Rashi ChaudhariKhushboo RajNo ratings yet

- Technology & Innovation in Management: Group 7Document10 pagesTechnology & Innovation in Management: Group 7Khushboo RajNo ratings yet

- New Microsoft PowerPoint PresentationDocument2 pagesNew Microsoft PowerPoint PresentationKhushboo RajNo ratings yet

- Technology and Innovation Management Project Submission Deadline: 17 DeliverablesDocument1 pageTechnology and Innovation Management Project Submission Deadline: 17 DeliverablesKhushboo RajNo ratings yet

- IHRM - Rashi ChaudhariDocument5 pagesIHRM - Rashi ChaudhariKhushboo RajNo ratings yet

- Sustainable Development Goals and IndiaDocument1 pageSustainable Development Goals and IndiaKhushboo RajNo ratings yet

- Yahoo in ChinaDocument5 pagesYahoo in ChinaKhushboo RajNo ratings yet

- Opportunities in BusinessDocument1 pageOpportunities in BusinessKhushboo RajNo ratings yet

- Arvel Omics Urnaround: The Causes of Marvel'S DeclineDocument6 pagesArvel Omics Urnaround: The Causes of Marvel'S DeclineKhushboo RajNo ratings yet

- Empowering communities through Project PRABHATDocument2 pagesEmpowering communities through Project PRABHATKhushboo RajNo ratings yet

- Gauss 3 Stage EquationDocument2 pagesGauss 3 Stage EquationKhushboo RajNo ratings yet

- Opportunities in BusinessDocument1 pageOpportunities in BusinessKhushboo RajNo ratings yet

- Difference between Simple and Log ReturnsDocument2 pagesDifference between Simple and Log ReturnsKhushboo RajNo ratings yet

- Taxonomy of Innovation - LearningsFromBioconDocument2 pagesTaxonomy of Innovation - LearningsFromBioconKhushboo RajNo ratings yet

- Project Is Ramping UpDocument1 pageProject Is Ramping UpKhushboo RajNo ratings yet

- DDocument2 pagesDKhushboo RajNo ratings yet

- ProjectDocument12 pagesProjectKhushboo RajNo ratings yet

- Forecasting Assumptions Vitex CorpDocument6 pagesForecasting Assumptions Vitex CorpKhushboo RajNo ratings yet

- S. No. Educ Ation Salar y Dum My - H S Dum My - G Dum My - P GDocument5 pagesS. No. Educ Ation Salar y Dum My - H S Dum My - G Dum My - P GKhushboo RajNo ratings yet

- Indian Tyre Industry: Comprehensive Study of Evolution, Market Dynamics and Future OutlookDocument9 pagesIndian Tyre Industry: Comprehensive Study of Evolution, Market Dynamics and Future OutlookKhushboo RajNo ratings yet

- ConstructionDocument32 pagesConstructionKhushboo RajNo ratings yet