Professional Documents

Culture Documents

Estudio de Litio

Uploaded by

Andres Rodrigo BarrazaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Estudio de Litio

Uploaded by

Andres Rodrigo BarrazaCopyright:

Available Formats

A RRMA Z HELPS SPODUMENE PRODUCER

E XCEED GR ADE & RECOV ERY TARGE T S W HILE

REDUCING COLLEC TOR CONSUMP TION BY 68%

CASE STUDY

THE CHALLENGE

Our client, a spodumene mineral processor, opened a mine with intentions of producing a battery-grade spodumene product.

Their deposit presents unique metallurgical challenges related to mica- and iron-containing silicate minerals. The mineralogy of

the deposit is 10-20% spodumene with a high percentage of quartz and iron silicates, mica, amphibole and more.

In order to produce a battery-grade product, the spodumene concentrate had to be upgraded from 0.8-1.2% Li2O to >6.0%

Li2O. The client’s processing facility was having difficulties achieving concentrate levels above 4.5% Li2O, as well as making the

recovery and production targets projected in the mine prefeasibility study.

As the plant started up, several processing challenges reduced recovery versus targets and hindered processing steps:

• The operation had difficulty meeting production goals

• The mine started up on a commodity-type collector

• Reagent consumption was high

• Grade targets were not consistently being met.

THE SOLUTION

A technical partnership was established between ArrMaz and the mineral processor focused on

two key areas:

1. Collector formulation customized to their unique feed, water and process

2. Process optimization.

ArrMaz manufactures custom surfactants designed to improve the selectivity and strength of

spodumene flotation. Laboratory floats on the processor’s feed samples were conducted in

ArrMaz’s Mulberry, Florida metallurgical lab to pre-screen the chemistry and formulary types LABORATORY FROTH

to meet grade and recovery requirements. A custom-formulated surfactant-enhanced reagent, FLOTATION LOADED WITH

CustoFloat ® 7080, was found to be the most effective. Selectivity and froth structure were custom SPODUMENE

designed to reject iron-containing contaminants in order to satisfy grade requirements.

4800 State Road 60 East, Mulberry, FL 33680

MINING@ARRMAZ.COM | +1-863-578-1206 | ARRMAZ.COM

Arrangements were then made to conduct laboratory tests at the processor’s site to verify the initial findings. CustoFloat 7080

was proven to handle the range of varying feed and operating conditions encountered in the plant. CustoFloat 7080 plant

testing was conducted versus the commodity collectors previously used and the new collector was found to successfully meet

their grade target of 6%.

A team comprising members from each company was formed and a brainstorming session on process troubleshooting was

conducted. Working with the client, ArrMaz laboratory and process consultants examined their process from beginning to end,

and were able to adjust feed processing and mineral conditioning parameters to maximize plant and reagent performance.

THE RESULTS

Over the 3-4 month testing period, CustoFloat 7080 was able to consistently make grade targets, as well as provide acceptable

recovery and production tons. The following key results were achieved:

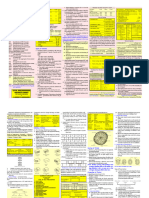

• Flotation selectivity was improved as the ratio of Li to Fe FLOTATION SELECTIVITY SUMMARY

increased significantly. (SINGLE CLEANER)

• A stepwise process was developed to tweak operating 5

parameters. CustoFloat 7080 formulary was fine-tuned to

better match the collector and feed.

4

• Collector consumption was reduced by 68%.

• Collector ease-of-handling and make-down efficiency was

improved. 3

Li/Fe

• During the course of this development effort, the

performance criteria for the site was met, putting the plant 2

back on track with the expectations of the prefeasibility

study.

1

The supplier-client partnership continues today, now focused

on further increasing recovery with new collector development.

Work on new collector formulas show further improvement in 0

lithium flotation selectivity over iron contamination as shown in 7080 7080-1 7080-3 7080B 7080C

the chart opposite. Reagent

THE ARRMAZ ADVANTAGE

Since 1967, ArrMaz has been a trusted partner to mining companies worldwide, delivering innovative chemical solutions for process improvement

with superior responsiveness, expert technical advice and outstanding customer support. Some of the world’s largest industrial mineral producers

trust ArrMaz’s proven solutions to optimize their process performance and efficiency. Send us your mineral and let us do the same for you.

Contact ArrMaz today to discover how our high-quality custom mining solutions can improve your mineral grade and recovery.

Email Mining@ArrMaz.com or call +1-863-578-1206 for further information.

The information contained herein is presented in good faith and believed to be accurate, however, ArrMaz Products, LP assumes no responsibility or liability for the information provided.

ArrMaz Products, LP further makes no representations or warranties, either express or implied, of merchantability, fitness for a particular purpose or of any other nature with respect to the

information or the product(s) to which the information refers.

© 2018 ArrMaz Products, LP. All rights reserved. This material may not be reproduced, displayed, modified or distributed without the express prior written permission of the copyright holder.

4800 State Road 60 East, Mulberry, FL 33680

MINING@ARRMAZ.COM | +1-863-578-1206 | ARRMAZ.COM

You might also like

- Reactivod de FlotacionDocument4 pagesReactivod de FlotacionHector RamosNo ratings yet

- Adiabatic Fixed-Bed Reactors: Practical Guides in Chemical EngineeringFrom EverandAdiabatic Fixed-Bed Reactors: Practical Guides in Chemical EngineeringNo ratings yet

- Iron Ore Dressing Plant Auditing - LectureDocument7 pagesIron Ore Dressing Plant Auditing - LectureravibelavadiNo ratings yet

- Heavy and Extra-heavy Oil Upgrading TechnologiesFrom EverandHeavy and Extra-heavy Oil Upgrading TechnologiesRating: 4 out of 5 stars4/5 (2)

- 4.project ReportDocument38 pages4.project ReportJagadeeshan SivanNo ratings yet

- Expansion of A UnitDocument54 pagesExpansion of A UnitashwaniNo ratings yet

- STP Renovation Fact SheetDocument2 pagesSTP Renovation Fact Sheetjeykumar.BalannairNo ratings yet

- Jasbir Singh Presentation For Indonesian Sugar IndustryDocument36 pagesJasbir Singh Presentation For Indonesian Sugar IndustryraviNo ratings yet

- Winery PresentationDocument66 pagesWinery Presentationdnyanu143100% (3)

- Resin in PulpDocument20 pagesResin in PulpAnastasia YuandyNo ratings yet

- SPE 84212 Completion Optimization in The Wamsutter Field, SW WyomingDocument10 pagesSPE 84212 Completion Optimization in The Wamsutter Field, SW WyomingloralaraNo ratings yet

- Novel Chemistry For Precious and Base Metals Flotation 1Document4 pagesNovel Chemistry For Precious and Base Metals Flotation 1Edinson Klever Ponce RamirezNo ratings yet

- High Shear MixersDocument25 pagesHigh Shear MixersArturo Marquez Maya100% (1)

- SPE 181142 MS Successful Application of Root Cause Analysis On ProgressiveDocument21 pagesSPE 181142 MS Successful Application of Root Cause Analysis On Progressivejainrakeshj4987No ratings yet

- Pump Efficiency Improvement Program (Cost Saving & Energy Saving)Document42 pagesPump Efficiency Improvement Program (Cost Saving & Energy Saving)Ns KimNo ratings yet

- Fluid Cat Cracking ZSM-5Document22 pagesFluid Cat Cracking ZSM-5Muddyz100% (2)

- Throughput MineDocument8 pagesThroughput MineAlexis SaavedraNo ratings yet

- Kent 1997 Milling ModellingDocument7 pagesKent 1997 Milling Modellinggustool7No ratings yet

- Naptha Hydrotreating Catalysts PDFDocument2 pagesNaptha Hydrotreating Catalysts PDFElena Ricci100% (1)

- Pilot Plant Testing Methods - BPRDocument17 pagesPilot Plant Testing Methods - BPRravibelavadiNo ratings yet

- Sustainable Initiatives Towards Co-Processing of Waste in Cement Kiln - Sucesses TrendsDocument16 pagesSustainable Initiatives Towards Co-Processing of Waste in Cement Kiln - Sucesses Trendsamara gopiNo ratings yet

- Milton Roy Mixer Design Considerations Whitepaper-Final 12-7-2020Document7 pagesMilton Roy Mixer Design Considerations Whitepaper-Final 12-7-2020Mohamed AliNo ratings yet

- 2008 Oct MT Keith PresentationDocument19 pages2008 Oct MT Keith PresentationTimBarrowsNo ratings yet

- An Innovative Methodology For Predicting Cement Bond Before The Cement Is Pumped: Case Histories in EcuadorDocument12 pagesAn Innovative Methodology For Predicting Cement Bond Before The Cement Is Pumped: Case Histories in EcuadorPAOLA ANDREA DUARTE PRADANo ratings yet

- Catalagram 121 PDFDocument38 pagesCatalagram 121 PDFMón Quà Vô GiáNo ratings yet

- Scan 0008Document5 pagesScan 0008Abdallah R. AwadNo ratings yet

- SPE 94080 Adapting Drilling Rigs To Operate Under New and Restrictive Environmental LegislationDocument3 pagesSPE 94080 Adapting Drilling Rigs To Operate Under New and Restrictive Environmental Legislationmsmsoft90No ratings yet

- WTP NotesDocument9 pagesWTP Notessanjee2No ratings yet

- Summer Internship Report 3Document29 pagesSummer Internship Report 3Bharat SharmaNo ratings yet

- Company Profile PT Adromeda Rekayasa Fluida - Final-1Document37 pagesCompany Profile PT Adromeda Rekayasa Fluida - Final-1jamsir sabaraNo ratings yet

- Hydroprocessing Reactor and Process Design To Optimize Catalyst Performance PDFDocument18 pagesHydroprocessing Reactor and Process Design To Optimize Catalyst Performance PDFJupichi TMNo ratings yet

- New Challanges in OM - Two Case StudiesDocument2 pagesNew Challanges in OM - Two Case StudiesAnonymous qucSJYNo ratings yet

- Case Study Right First Time Improvement Through Process OptimizationDocument2 pagesCase Study Right First Time Improvement Through Process OptimizationmuhammadNo ratings yet

- SPE - 200408 - MS Bhagyam ASP PilotDocument16 pagesSPE - 200408 - MS Bhagyam ASP PilotEvelyn QuinteroNo ratings yet

- Report File InternshipDocument30 pagesReport File InternshipYashdeep Singh sankhalaNo ratings yet

- HF Alkylation SolutionDocument16 pagesHF Alkylation SolutionEman El DsoukyNo ratings yet

- Report InternshipDocument30 pagesReport InternshipNurul Shazana100% (1)

- Uchen Du 2006Document9 pagesUchen Du 2006sina giahkarNo ratings yet

- SPE 144112 Application of Silicate/Polymer Water Shut-Off Treatment in Faulted Reservoirs With Extreme High PermeabilityDocument16 pagesSPE 144112 Application of Silicate/Polymer Water Shut-Off Treatment in Faulted Reservoirs With Extreme High PermeabilityQaiser HafeezNo ratings yet

- A Novel Low PH Antiscalant Delivers Signficant Savings To The Mining IndustryDocument2 pagesA Novel Low PH Antiscalant Delivers Signficant Savings To The Mining IndustryApple servicesNo ratings yet

- Articles - LiftDocument12 pagesArticles - LiftfabianhualpaNo ratings yet

- 100 KLD STP New-1Document13 pages100 KLD STP New-1Anjita KumariNo ratings yet

- Performance Evaluation of Fixed Film Fixed Bed Anaerobic Bio-Reactor For Treating Dairy Industry WastewaterDocument6 pagesPerformance Evaluation of Fixed Film Fixed Bed Anaerobic Bio-Reactor For Treating Dairy Industry WastewaterIJRASETPublicationsNo ratings yet

- Summer Training Presentation: ON Distillation Unit OF Mathura RefineryDocument14 pagesSummer Training Presentation: ON Distillation Unit OF Mathura RefineryGovindPatelNo ratings yet

- Naveed UpdatedDocument2 pagesNaveed UpdatedNaveed Ul Qamar MughalNo ratings yet

- Lithium Battery Development Manager in Allentown PA Resume Larry SchappellDocument2 pagesLithium Battery Development Manager in Allentown PA Resume Larry SchappellLarrySchappellNo ratings yet

- Wet ConcentratorDocument8 pagesWet ConcentratorpodakopeNo ratings yet

- AuditReportAarti TarapurDocument12 pagesAuditReportAarti TarapurVijay KotwalNo ratings yet

- 201106midyear Ruggiero 2Document15 pages201106midyear Ruggiero 2vishesh0211No ratings yet

- CYTEC Solutions Newsletter 3-12 V2 PROOFDocument40 pagesCYTEC Solutions Newsletter 3-12 V2 PROOFLela SepulvedaNo ratings yet

- SPE 154452 Challenges in Sour Gas Handling For Kuwait Jurassic Sour GasDocument4 pagesSPE 154452 Challenges in Sour Gas Handling For Kuwait Jurassic Sour GasRizal HidayatullahNo ratings yet

- 2015 09Document189 pages2015 09nikhil_barshettiwatNo ratings yet

- Machinery Turnaround PracticesDocument11 pagesMachinery Turnaround PracticesAmar NatourNo ratings yet

- Mahendran 2 PDFDocument5 pagesMahendran 2 PDFMahendran ChokkanathanNo ratings yet

- The Importance of Coagulant (By GE)Document2 pagesThe Importance of Coagulant (By GE)Hammam AlkezmazyNo ratings yet

- Advances in CatalystsDocument104 pagesAdvances in CatalystsKrishnamoorthy VijayalakshmiNo ratings yet

- Weidenbach p105Document5 pagesWeidenbach p105seansara1No ratings yet

- Paradip Etp O&m Sop-FinalDocument39 pagesParadip Etp O&m Sop-FinalDhal Engineering Company SalesNo ratings yet

- Presentacion SteynDocument14 pagesPresentacion SteynJonatan Y. GrijalvaNo ratings yet

- Dunham and Vann 2007Document8 pagesDunham and Vann 2007OROSCOROCANo ratings yet

- Best Practice 6.grease Construction and FunctionDocument7 pagesBest Practice 6.grease Construction and FunctionJorge ZegarraNo ratings yet

- SAG Conference 2019 Agenda FinalDocument1 pageSAG Conference 2019 Agenda FinalrodrigoNo ratings yet

- Buiding ROOFDocument32 pagesBuiding ROOFZeleke Taimu67% (3)

- Ch-17 Compatibility ModeDocument10 pagesCh-17 Compatibility Modedreamgurl9011No ratings yet

- Assignment 1Document15 pagesAssignment 1AmyNo ratings yet

- 16 10 en Carbon Sliding Strip Span To Graphs Trolley Pole SystemsDocument16 pages16 10 en Carbon Sliding Strip Span To Graphs Trolley Pole SystemsIsmet HizyoluNo ratings yet

- Nuevo Catalogo 2015 Endchile/magnafluxDocument79 pagesNuevo Catalogo 2015 Endchile/magnafluxEric Figueroa UribeNo ratings yet

- Copper AlloysDocument61 pagesCopper Alloysbvalinhas100% (2)

- Kjeldahl Tabs Guide en 0Document4 pagesKjeldahl Tabs Guide en 0Ku BonNo ratings yet

- Cathodic Protection of Aboveground Petroleum Storage Tanks: Api Recommended Practice 651 Second Edition, December 1997Document23 pagesCathodic Protection of Aboveground Petroleum Storage Tanks: Api Recommended Practice 651 Second Edition, December 1997Hendra Yudistira100% (2)

- Civil Engineering Chart Subjectwise in A3 SizeDocument16 pagesCivil Engineering Chart Subjectwise in A3 SizeEr Aman RaahiNo ratings yet

- AbicorBinzel 700.1186.10Document2 pagesAbicorBinzel 700.1186.10Humberto GalvezNo ratings yet

- Machine Design Elements11 - : God BlessDocument101 pagesMachine Design Elements11 - : God BlessReynald de VeraNo ratings yet

- CYANEX For Selective Extraction of Ni and CoDocument16 pagesCYANEX For Selective Extraction of Ni and CoArifo Gunawan CahyanegoroNo ratings yet

- Kingpin Mounting InstructionsDocument1 pageKingpin Mounting InstructionsPablo César Suárez NogalesNo ratings yet

- Pyrometallurgy Towards Clean Metallurgical Processing 2012Document438 pagesPyrometallurgy Towards Clean Metallurgical Processing 2012Abie BadhurahmanNo ratings yet

- 5183 Aluminum Welding WireDocument1 page5183 Aluminum Welding Wiresank79No ratings yet

- Asme Section II A Sa-216 Sa-216mDocument4 pagesAsme Section II A Sa-216 Sa-216mAnonymous GhPzn1xNo ratings yet

- U Bolt Guide PDFDocument1 pageU Bolt Guide PDFAhmad Dzulfiqar RahmanNo ratings yet

- Elements in Our Body and in TechnologyDocument46 pagesElements in Our Body and in TechnologySherilyn Closa BunagNo ratings yet

- Lab Report Exp 1 Organic ChemistryDocument7 pagesLab Report Exp 1 Organic ChemistrydzikranNo ratings yet

- Ton Lanh Mau-Theo JIS 3322Document5 pagesTon Lanh Mau-Theo JIS 3322mrphongvnctNo ratings yet

- Granular BoraxDocument4 pagesGranular BoraxHanurizal HashariNo ratings yet

- Aluminium Alloy - L165 L167 T6 Sheet: Specifications Supplied FormsDocument2 pagesAluminium Alloy - L165 L167 T6 Sheet: Specifications Supplied Formsgrg_greNo ratings yet

- Allmineral Productinfo GBDocument16 pagesAllmineral Productinfo GBTitanicNo ratings yet

- 2.4 Limit TestsDocument2 pages2.4 Limit TestsDanielRivPNo ratings yet

- A Project Report ON "Working Capital Management"Document66 pagesA Project Report ON "Working Capital Management"Radhika BhatiaNo ratings yet

- High-Leaded Tin Bronze, UNS C93700, Copper Casting Alloy (SAE 64)Document4 pagesHigh-Leaded Tin Bronze, UNS C93700, Copper Casting Alloy (SAE 64)Masood AlamNo ratings yet

- Municipal Castings Farm Equipment Construction, Mining & Oil Field Machinery RailroadDocument81 pagesMunicipal Castings Farm Equipment Construction, Mining & Oil Field Machinery RailroadNata 1986No ratings yet

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsFrom EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsRating: 3.5 out of 5 stars3.5/5 (13)

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldFrom EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldRating: 4 out of 5 stars4/5 (598)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessFrom EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNo ratings yet

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseFrom EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseRating: 3.5 out of 5 stars3.5/5 (69)

- The Soul of an Octopus: A Surprising Exploration into the Wonder of ConsciousnessFrom EverandThe Soul of an Octopus: A Surprising Exploration into the Wonder of ConsciousnessRating: 4.5 out of 5 stars4.5/5 (254)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsFrom EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsRating: 4 out of 5 stars4/5 (223)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionFrom EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionRating: 4 out of 5 stars4/5 (812)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorFrom EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorRating: 4.5 out of 5 stars4.5/5 (139)

- Fire Season: Field Notes from a Wilderness LookoutFrom EverandFire Season: Field Notes from a Wilderness LookoutRating: 4 out of 5 stars4/5 (142)

- Come Back, Como: Winning the Heart of a Reluctant DogFrom EverandCome Back, Como: Winning the Heart of a Reluctant DogRating: 3.5 out of 5 stars3.5/5 (10)

- Spoiled Rotten America: Outrages of Everyday LifeFrom EverandSpoiled Rotten America: Outrages of Everyday LifeRating: 3 out of 5 stars3/5 (19)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 3.5 out of 5 stars3.5/5 (35)

- The Light Eaters: How the Unseen World of Plant Intelligence Offers a New Understanding of Life on EarthFrom EverandThe Light Eaters: How the Unseen World of Plant Intelligence Offers a New Understanding of Life on EarthNo ratings yet

- The Lives of Bees: The Untold Story of the Honey Bee in the WildFrom EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildRating: 4.5 out of 5 stars4.5/5 (44)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeFrom EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeRating: 4.5 out of 5 stars4.5/5 (700)

- Braiding Sweetgrass: Indigenous Wisdom, Scientific Knowledge and the Teachings of PlantsFrom EverandBraiding Sweetgrass: Indigenous Wisdom, Scientific Knowledge and the Teachings of PlantsRating: 4.5 out of 5 stars4.5/5 (1427)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldFrom EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldRating: 4.5 out of 5 stars4.5/5 (19)

- When the Sahara Was Green: How Our Greatest Desert Came to BeFrom EverandWhen the Sahara Was Green: How Our Greatest Desert Came to BeRating: 4.5 out of 5 stars4.5/5 (6)