Professional Documents

Culture Documents

Trivalent Vs Hexavalent

Uploaded by

Arvind KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trivalent Vs Hexavalent

Uploaded by

Arvind KumarCopyright:

Available Formats

BLTPS-19

Sales Engineering

Technical Paper Series

resistance, self-healing, and paint adhesion. One other

Hexavalent vs. Trivalent Chromates: issue that must be addressed is how you tell the difference

Why must we change, and what are the between the two finishes.

differences? • Color Variability – In many cases customers are

th

On February 28 , 2006 OSHA published a final standard purchasing the yellow or gold version of zinc

addressing occupational exposure to hexavalent chromium dichromate. This color change is created during the

(Federal Register # 71:10099–10385). The standard was hexavalent chromate conversion process, which also

published in agreement with a timetable set forth by the greatly improves corrosion resistance. With the move

U.S. Court of Appeals, and covers exposure to hexavalent to trivalent chrome the conversion process will no

chromium (CR(VI) in general industry, construction and longer generate a color change, and color must be

shipyards. This standard was deemed necessary by OSHA added by using a dye. The use of a dye makes it

to reduce significant health risks posed by occupational difficult to maintain a uniform color, and UV

exposure to hexavalent chromium. exposure can eventually cause the color to fade. This

discrepancy in color can create problems when trying

The new standard significantly lowers the permissible to match existing material, or when aesthetics are

exposure limit for hexavalent chromium from 52 to 5 important. The corrosion properties are also

micrograms per cubic meter of air. The standard also sacrificed, as the die has no corrosion resistance

covers methods for controlling exposure when working properties. The product becomes no more than a clear

with hexavalent chromes, including proper ventilation, zinc finish that has been dyed yellow.

respiratory protection, protective clothing, etc.

• Corrosion Resistance – Under salt spray tests the

As stated above this standard will drastically restrict trivalent chromate provides approximately 36

exposure limits to hexavalent chromium. This in turn has hours of protection. A topcoat can be added to

forced the plating industry to react in one of two ways. increase corrosion resistance to similar levels

Option one, the industry could terminate the use of achieved by hexavalent chromes (120+ hours).

hexavalent chromes altogether, and change over to The amount of topcoat coverage directly affects

trivalent chromium. Although this option completely the corrosion resistance of the product, and

eliminates the use of hexavalent chrome, it does have its currently no industry standards exist that mandate

drawbacks, which we will discuss later in this document. topcoat thickness. This means the topcoat could

Option two is for the plating companies to take protective vary, and so will the corrosion resistance. The

measures to limit the exposure of their employees to topcoat also creates other barriers, such as

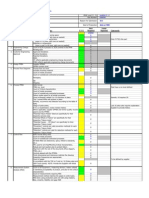

hexavalent chromes, and continue to supply the same increased cost, and the inability to paint. Figure

compound they have for years. This would require them to 2 compares the corrosion resistance of hexavalent

use both engineering methods and personal protective vs. trivalent yellow.

equipments to limit employee exposure to hexavalent

chromes. Figure 2

So what is the difference between trivalent and hexavalent

chromium? Both trivalent and hexavalent chromium are

conversion coatings added to the plating process to

increase finish performance. Both are aqueous solutions,

and are applied in the same manner. The only difference is

the starting material Cr3 vs. Cr6, and the performance

properties of then new conversion coating.

Now that we’ve discussed the coating process, let’s detail

the performance difference between the two conversion Trivalent Yellow B-Line Dura-Green Hexavalent Yellow

coatings. Some of the major differences between the two after 118 hours after 600 hrs after 600 hrs

chromium conversions are color variability, corrosion

Cooper B-Line, Inc. ٠ 509 West Monroe Street ٠ Highland, IL 62249 USA ٠ Phone: 618-654-2184 ٠ Fax: 618-654-1917 ٠ Email: blineus@cooperbline.com

© 2003 Cooper B-Line, Inc.

BLTPS-19

outperforms zinc chromate, pre-galvanized, and other

• Self-Healing Properties – The trivalent chromate industry green paints. Figure 2 shows B-Line’s Dura-

alone has no self-healing properties. This can be Green epoxy compared to the current hexavalent yellow

improved with the addition of a topcoat, but still zinc finish and the new trivalent yellow zinc. It is obvious

only provides about 33% of the self-healing in these pictures that Dura-Green is capable of not only

protection of the hexavalent chromium. The maintaining the same corrosion requirements as the current

topcoat also creates other barriers, such as hexavalent yellow, but greatly outperforms the new

increased cost, and the inability to paint. trivalent yellow.

• Identification – There is no easy way to verify Table 1

whether the products supplied are trivalent or

Hexavalent(2)

Pre-Galv G90

Dura-Green

Yellow Zinc

Yellow Zinc

hexavalent. Both are considered a yellow zinc

Trivalent

Finish Options

Industry

finish, and are similar in color. The only true way

Green

to determine the finish is through chemical

testing. Figure 3 shows both options, and as you

Corrosion

can see it is difficult to differentiate the two. 612 36 192 36 680

Resistance (Salt

(1) Hrs Hrs Hrs Hrs Hrs

Spray hrs)

Figure 3

Color Variability

Identifiable Finish

No Hex Chromes

(2)

Present

(3)

Paintable Surface

Trivalent Yellow Hexavalent Yellow

As you can see the differences between the two types of Good Fair Poor

chromate conversions are significant. Although they may (1) All salt spray (fog) tests conducted in accordance with ASTM B117

both look the same the corrosion properties, durability, and and evaluated according to ASTM D1654 Table 1 & 2. Tests re

field flexibility varies a great deal. The biggest issue of all performed and certified by an independent testing laboratory.

is how do you know what you have? Is it hexavalent, or is (2) OSHA regulates Hexavalent chrome exposure.

(3) Surface does not require cleaning prior to painting.

it trivalent? Do I need to wear protective equipment?

How corrosion resistant is the coating? Unfortunately Although the industry has an alternative product to take the

there is no good way to answer these questions in the field. place of the hexavalent yellow, the performance

capabilities are greatly reduced. Factors such as corrosion

So now that we’ve covered the differences in the finishes, resistance & color cannot be maintained with the new

what are the viable alternatives available to the market? trivalent yellow. There are also identification concerns, as

There are many material and finishes available that are the difference between the hexavalent and trivalent color

easily identifiable, and well suited for various applications. cannot be seen with the naked eye. These factors will

These alternative material and finish options include greatly reduce the long-term quality of the product, and

painted, pre-galvanized, hot-dipped galvanized, stainless may not meet your project’s aesthetic requirement. Cooper

steel and aluminum. While each material is a viable B-Line offers Dura-Green as a solution to your safety &

alternative, some such as stainless steel, hot-dipped corrosion requirements, while maintaining long-term

galvanized and aluminum may be cost prohibitive. The quality standards demanded by our customers.

best alternative from both a cost and performance

perspective would be a painted finish.

Cooper B-Line’s Dura-Green finish is an excellent

alternative that offers excellent performance

characteristics, and is extremely cost effective. Table 1

shows the performance characteristics of green compared

to other standard finishes. The Dura-Green finish

Cooper B-Line, Inc. ٠ 509 West Monroe Street ٠ Highland, IL 62249 USA ٠ Phone: 618-654-2184 ٠ Fax: 618-654-1917 ٠ Email: blineus@cooperbline.com

© 2003 Cooper B-Line, Inc.

You might also like

- Alternative For Tank Chromium Using (Brush) PlatingDocument15 pagesAlternative For Tank Chromium Using (Brush) PlatingdeerryNo ratings yet

- Catalogue Fan Coil Unit DDBDocument36 pagesCatalogue Fan Coil Unit DDBLuqmanAssaffatG80% (5)

- Asset Integrity Management PDFDocument155 pagesAsset Integrity Management PDFBouazizizi MOHAMEDNo ratings yet

- Colmonoy 69 AlloDocument4 pagesColmonoy 69 Allopushpak100% (1)

- SQD-025 PPAP ChecklistDocument7 pagesSQD-025 PPAP ChecklistMadhan RajNo ratings yet

- Naming Chemical Compounds WorksheetDocument4 pagesNaming Chemical Compounds WorksheetSam Jo100% (1)

- Astm A-1018Document5 pagesAstm A-1018daniloreaNo ratings yet

- CQI 9 4th EditionDocument1 pageCQI 9 4th Editionmirosek100% (1)

- Venkat - MoRTH 5th Revision Essential Tables For Highway Field EngineersDocument68 pagesVenkat - MoRTH 5th Revision Essential Tables For Highway Field EngineersV Venkata Narayana96% (28)

- Qip 128Document3 pagesQip 128Kevin BrownNo ratings yet

- Imparting Resistance To Storage Stain: GalvinfonoteDocument3 pagesImparting Resistance To Storage Stain: GalvinfonoteSontosh BhattacharjeeNo ratings yet

- Trivalent Passivation SystemsDocument2 pagesTrivalent Passivation SystemskarthegreNo ratings yet

- Trivalent Passivation Systems PDFDocument2 pagesTrivalent Passivation Systems PDFMuthuswamyNo ratings yet

- Case Study Independent Plating 2012Document8 pagesCase Study Independent Plating 2012alfaroq_almsryNo ratings yet

- Hard Chrome ReplacementDocument7 pagesHard Chrome ReplacementPhu, Le HuuNo ratings yet

- DacrometDocument6 pagesDacrometdavideNo ratings yet

- DacrometDocument6 pagesDacrometPeter MangalukiNo ratings yet

- EPA Chrom HazardsDocument5 pagesEPA Chrom HazardsLuis Paz Soldán GNo ratings yet

- Evaluation of Corrosion Resistance of As Sprayed Wc-Co-Cr On DH 36 Steel With Addition of 3% GnpsDocument9 pagesEvaluation of Corrosion Resistance of As Sprayed Wc-Co-Cr On DH 36 Steel With Addition of 3% GnpsTarkes DoraNo ratings yet

- TCP 3 e 6Document11 pagesTCP 3 e 6Christina Christina ChristinaNo ratings yet

- Cloverdale Tds 83021a eDocument4 pagesCloverdale Tds 83021a eErnesto Javier Martín RosabalNo ratings yet

- Maincote™ Hg-31: Waterborne Acrylic Resin For Water and Corrosion-Resistant Industrial CoatingsDocument7 pagesMaincote™ Hg-31: Waterborne Acrylic Resin For Water and Corrosion-Resistant Industrial CoatingsLong An DoNo ratings yet

- Effect of Different Types of Graphene Coatings On Friction and Wear Performance of Aluminum AlloyDocument10 pagesEffect of Different Types of Graphene Coatings On Friction and Wear Performance of Aluminum AlloyDr Praveen KumarNo ratings yet

- Zinc Nickel PlatingDocument1 pageZinc Nickel PlatingSiripongTNo ratings yet

- New Trial Paper BGasDocument2 pagesNew Trial Paper BGasmoonstar_dme100% (1)

- BPCL - 221019 PDFDocument55 pagesBPCL - 221019 PDFMaymole Boben100% (1)

- PVD Chromium Coatings Replacing Decorative Chromium ElectroplatedDocument8 pagesPVD Chromium Coatings Replacing Decorative Chromium ElectroplatedNassima JagharNo ratings yet

- PComP BrochureDocument2 pagesPComP BrochureanupamghildyalNo ratings yet

- Apollo Tricoat Tubes: Investor Presentation March 2019Document17 pagesApollo Tricoat Tubes: Investor Presentation March 2019Rahul. YadavNo ratings yet

- Chromate Conversion Coatings and Their Current AppDocument5 pagesChromate Conversion Coatings and Their Current AppDeni HermawanNo ratings yet

- CBDD Standard Paint Spec (With SW Data)Document5 pagesCBDD Standard Paint Spec (With SW Data)lightsonsNo ratings yet

- Zinc PlatingDocument2 pagesZinc PlatingErixon RamírezNo ratings yet

- CGL CoatingDocument27 pagesCGL Coatingthiru_jsr100% (1)

- GEOMETDocument4 pagesGEOMETdavideNo ratings yet

- ColorcoatŽ PE 25 DatasheetDocument2 pagesColorcoatŽ PE 25 Datasheetprimoz1No ratings yet

- Case StudiesDocument1 pageCase StudiesdurgeshwardNo ratings yet

- Brochure Corrosion Protection en 2009Document5 pagesBrochure Corrosion Protection en 2009kalkuchNo ratings yet

- Klueberfluid C-F 3 ULTRA IngleseDocument2 pagesKlueberfluid C-F 3 ULTRA Ingleseseegna100% (3)

- ALTERNATIVES To Hexavalent Chromium and Chromium PlatingDocument4 pagesALTERNATIVES To Hexavalent Chromium and Chromium PlatingClaudio SiqueiraNo ratings yet

- Product Data Sheet: Wire Rope Lubricant High ViscosityDocument2 pagesProduct Data Sheet: Wire Rope Lubricant High ViscosityGilmer CaceresNo ratings yet

- Hard Chrome Replacement by HVOF Sprayed CoatingsDocument9 pagesHard Chrome Replacement by HVOF Sprayed CoatingsR2osNo ratings yet

- Zinc Flake Vs Zinc-Nickel ComparisonDocument7 pagesZinc Flake Vs Zinc-Nickel ComparisonSon NguyenNo ratings yet

- New Blygold PoluAl BrochureDocument2 pagesNew Blygold PoluAl BrochuresabasabzNo ratings yet

- New Hydroblasting and Slurryblasting Standards IssuedDocument6 pagesNew Hydroblasting and Slurryblasting Standards IssuedCésar AugustoNo ratings yet

- Surface FinishesDocument8 pagesSurface FinishesasritaipNo ratings yet

- Paint Systems For Steel StructuresDocument7 pagesPaint Systems For Steel StructuresHermann Lowe100% (1)

- M - Graphene Coating For Corrosion ProtectionDocument6 pagesM - Graphene Coating For Corrosion ProtectionGabriel DiazNo ratings yet

- Maincote™ EC-11: Waterborne Elastomeric Acrylic Resin For Industrial Maintenance CoatingsDocument10 pagesMaincote™ EC-11: Waterborne Elastomeric Acrylic Resin For Industrial Maintenance CoatingsLong An ĐỗNo ratings yet

- Clevis Pipe Hangers, Supports and Accessories: Vogel NootDocument18 pagesClevis Pipe Hangers, Supports and Accessories: Vogel NootVIVEK MAHAJANNo ratings yet

- Chrom I TingDocument11 pagesChrom I TingAshish RawatNo ratings yet

- Astm B 449Document5 pagesAstm B 449Tuyen NguyenNo ratings yet

- HereShield TDSDocument5 pagesHereShield TDSMahdi BagheriNo ratings yet

- Shalimar Chlorokote Zinc Phosphate PrimerDocument2 pagesShalimar Chlorokote Zinc Phosphate PrimerAnujkr KumarNo ratings yet

- Carboquick 200 PDSDocument4 pagesCarboquick 200 PDSMarcelo Alejandro MarinoNo ratings yet

- Floor Care Duragreen PresentationDocument23 pagesFloor Care Duragreen PresentationMaria Eugenia CiveiraNo ratings yet

- Alumina Matrix in RefractoriesDocument5 pagesAlumina Matrix in RefractoriesSans SenNo ratings yet

- X Roc EpoxyBondDocument2 pagesX Roc EpoxyBondLakmal JayashanthaNo ratings yet

- Evaluation of Two Commercially-Available Lubricants by Means of Ring Test To AA 6061 F Aluminum AlloysDocument7 pagesEvaluation of Two Commercially-Available Lubricants by Means of Ring Test To AA 6061 F Aluminum Alloysabdul basitNo ratings yet

- X-Roc Epoxybond: Epoxy Resin Bonding AgentDocument2 pagesX-Roc Epoxybond: Epoxy Resin Bonding AgentAmr RagabNo ratings yet

- Hingewhitepaperajl 1530030565894Document4 pagesHingewhitepaperajl 1530030565894Sadeq NeiroukhNo ratings yet

- Trivalent Cromates PlatingDocument3 pagesTrivalent Cromates PlatingnimeshchanchaniNo ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- 311 Hansen Zinc PlatingDocument2 pages311 Hansen Zinc PlatingSurendra KamalNo ratings yet

- Mill Finish Anodized Finish Powder Coated Finish Super Durable Powder Coated Finish Polyvinylidene Flouride (PVDF) Finish Alodine Chromated FinishDocument27 pagesMill Finish Anodized Finish Powder Coated Finish Super Durable Powder Coated Finish Polyvinylidene Flouride (PVDF) Finish Alodine Chromated Finishedbern20005873No ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- 2023-24 - Combos Box Set CatalogueDocument36 pages2023-24 - Combos Box Set CatalogueArvind KumarNo ratings yet

- AnalysisDocument1 pageAnalysisArvind KumarNo ratings yet

- 2023-24 - Metal Pens CatalogDocument27 pages2023-24 - Metal Pens CatalogArvind KumarNo ratings yet

- Is 1570 4 1988 PDFDocument16 pagesIs 1570 4 1988 PDFArvind KumarNo ratings yet

- TALAT Lecture 3401: Forging AlloysDocument21 pagesTALAT Lecture 3401: Forging AlloysCORE MaterialsNo ratings yet

- TALAT Lecture 3401: Forging AlloysDocument21 pagesTALAT Lecture 3401: Forging AlloysCORE MaterialsNo ratings yet

- Shrinkage After WeldingDocument6 pagesShrinkage After WeldingArvind KumarNo ratings yet

- European Welding New-StandardsDocument39 pagesEuropean Welding New-StandardsJOECOOL67100% (3)

- European Welding New-StandardsDocument39 pagesEuropean Welding New-StandardsJOECOOL67100% (3)

- Eximpulse Import1557553275Document11 pagesEximpulse Import1557553275Mulsa KTGNo ratings yet

- High-Performance Longboard DesignDocument8 pagesHigh-Performance Longboard DesignFilippo ZapataNo ratings yet

- Running Projects in NPD (New Product Development) Area CTQ (Critical To Quality)Document5 pagesRunning Projects in NPD (New Product Development) Area CTQ (Critical To Quality)Mohammad AdilNo ratings yet

- Diesel Usado AnfoDocument8 pagesDiesel Usado AnfochoqolloNo ratings yet

- Sa-530 For Flattening HeightDocument10 pagesSa-530 For Flattening HeightmaheshNo ratings yet

- Wedge Wire Screens & Tubes PROGRESSDocument8 pagesWedge Wire Screens & Tubes PROGRESSPhu, Le HuuNo ratings yet

- The Future of Productivity: Wire Arc Additive Manufacturing: 3dprintDocument4 pagesThe Future of Productivity: Wire Arc Additive Manufacturing: 3dprintItziarNo ratings yet

- PT B, CH 1, Sec 1: 5.6 Scantling of GlazingDocument6 pagesPT B, CH 1, Sec 1: 5.6 Scantling of GlazingHamada AttiaNo ratings yet

- Production of FormaldehydeDocument92 pagesProduction of FormaldehydegozdebstnciNo ratings yet

- Crochet HeartsDocument4 pagesCrochet HeartsAleemah KhnNo ratings yet

- Insulation PinsDocument2 pagesInsulation PinsChandravadanNo ratings yet

- Datasheet For Metals ST 90 PCDocument2 pagesDatasheet For Metals ST 90 PCGalNo ratings yet

- Monthly Bulletin of Indices For The Price Adjustment Formulae For Construction Contracts. October 2009Document213 pagesMonthly Bulletin of Indices For The Price Adjustment Formulae For Construction Contracts. October 2009ferdinandbataraNo ratings yet

- Final Year ProjectDocument50 pagesFinal Year ProjectDanish KaiserNo ratings yet

- Pengaruh Penambahan Gelatin Terhadap Susut Masak, Daya Mengikat Air, Keempukan Dan Nilai PH Sosis Daging SapiDocument8 pagesPengaruh Penambahan Gelatin Terhadap Susut Masak, Daya Mengikat Air, Keempukan Dan Nilai PH Sosis Daging Sapidewiarum sariNo ratings yet

- The Project Report KLTDocument9 pagesThe Project Report KLTLenh LeNo ratings yet

- Ma'Aden Engineering Manual: Structural Design Criteria - Non-Process Buildings & StructuresDocument35 pagesMa'Aden Engineering Manual: Structural Design Criteria - Non-Process Buildings & StructuresMuhammad Najam AbbasNo ratings yet

- Determinacion de La Composicion PNADocument5 pagesDeterminacion de La Composicion PNACarlos VazquezNo ratings yet

- Encoded Physics and ChemDocument5 pagesEncoded Physics and ChemPrince Lancelot100% (1)

- Journal of Applied Polymer Science Volume 98 Issue 2 2005 (Doi 10.1002 - App.22097) Kishore Ravi Shankar S. Sankaran - Short-Beam Three-Point Bend Tests in Syntactic Foams. Part II - Effect of MicroDocument7 pagesJournal of Applied Polymer Science Volume 98 Issue 2 2005 (Doi 10.1002 - App.22097) Kishore Ravi Shankar S. Sankaran - Short-Beam Three-Point Bend Tests in Syntactic Foams. Part II - Effect of MicroPablo OrtegaNo ratings yet

- 0657940-60-01 Rev3 Medc Hd1 Heat Detector (HD) - A2 - EnglishDocument1 page0657940-60-01 Rev3 Medc Hd1 Heat Detector (HD) - A2 - EnglishrhomadonaNo ratings yet

- USA5892ps 10193Document5 pagesUSA5892ps 10193Mubashar HassanNo ratings yet

- Mech Malleable Iron Fittings Catalogue PDFDocument12 pagesMech Malleable Iron Fittings Catalogue PDFics companyNo ratings yet

- Telecom Cost Template - New Site Transmission WorkDocument26 pagesTelecom Cost Template - New Site Transmission WorkRanel EspinosaNo ratings yet