Professional Documents

Culture Documents

Austin 1972

Austin 1972

Uploaded by

Anonymous 61GHICZNyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Austin 1972

Austin 1972

Uploaded by

Anonymous 61GHICZNyCopyright:

Available Formats

215

Methods for Determinationof Breakage DistributionParameters

L. G. AUSTIN and P_ T_ LUCKIE

Departmmrof hfmeriat Sc5cnces. P~Irania Sra:e ihicer~ir); tirzircrx$r Park. Pa. I Li_S_A_)

(Received March 18. 1971; in x-wised form Ma>- 15, 1971)

Summary interest for a short period of time, sample the re-

sulting material, and perform a size analysis of tie

iThe distriburion of primary breakage producrs in material broken smaller than the starting size ne

laboratory mills can be estimated b-v batch grinding most convenient way of displaying the results is the

for short times_ 77wee methodr are giren for mani- cumulative breakage distribution B, defined as

pulatkzg the data, the second and third melhods follows The size range is split into a number of size

correcting for secondary breakage. _Wezhod III is intervals, often a geometric progression of sir\;es

the most accurate, but since it uses the speczjk rates and numbered 1 for the top size interval, 2 for the

of breakage of xhe uarious sizes in lhe correction second, and so on down to n, n being the size range

procedure it is necessary IO hm;e experinrenral or zero to the bottom size of tbe n- 1 interval_ Bij is

theoretical esCmn&s of these caIues_ A general then the weight fraction of material broken from

cornpurer program is given for the compwtalions. size i which falls less than the upper size of size

interval i In non-cumulative form. b:_;= BLi- Bi+ Ij

= the weight fraction broken from sizei which falls

Ih?RODUCTION into size interval i Experimentally,~ is the top size

intervak and tbe set of values Bi 1 is plotted rzrsz~

The treatment of grinding as a rate process with particle size (upper size of intemal‘i), passing throuch

the unit operation of grinding being equivalent to 1 at i=2 (see Fig 1. for example)_ This method-is

reactor design, is receiving considerable attention called the one-size fraction method.

at presentr_ As part of the size-mass balance de- An experimental variation (the tracer method)

scription of grinding it is necessary to determine involves following in similar fashion the traced

experimentally the size-mass distribution of frag- breakage products of a traced fractionzV where the

ments produced by the primary breakage of a tracing enables the material to be distinguished

narrowsizefractionofmaterial_Intbissense.primary from other material_ This has the advantage that

breakage is defined as producing smaller fragments breakage of the size of interest can be followed in a

which are remixed into the charge in the mii and mixture of other sizes, and it is not necessary to

have to wait their turn to be reselected for further produce a starting batch of material all of this size

breakage. The specific rates of breakage &) of a This technique can also sometimes be applied to

given size fraction depend on this selection-for- continuous grindin$ with the traced fraction added

breakage and are incorporated into the equations of to ?L- feed, since the traced material coming out of

grinding’ ; the objective of this note is to discuss the miff after 30 set, for example, has in effca been

methods of dete rmining the primary breakage dis- batch ground for 30 set (this assumes that different

tribution without the interference of the secondary sizes move &rough the miil at the srme rate with no

breakage of :be fragments by reselection for break- preferential classification at tbe 61 tit).

age- If the time of grind is very short so that only a few

per cent of the starting fraction is broken, then it

can be assumed that the reselection for breakaae of

THEORY the products is negligible, and a simple cala&ion

(Method I, see Appendix) can be applied HoweI-er,

The simplest waya to determine the breakage there are problems with Method LA correction has

distribution is to batch grind a sample of the size of to be made for sieving error- More importan; the

Pom-der T&l_ 5 (1971/G’?)

I_ G. AUSTIN, P. T. LUCKIE

that the specific rate of production of material of less

than size i from larger size i is not dependent on i-

Cne form of the equation of batch grinding is

dPi(t)/dr = i B,&[P,(r)-P,, r (r)] (1)

‘X i

where Pi(r) is the fraction or percentage less than the

upper size of size interval i at time t. When S$&=

function i only,

l-Pi(r)= [l-q(O)] exp(-SS,Qr) (2)

The Appendix shows how this gives

log [(l --pi(O))l(l -HO)1

Bi_l -z (3)

~~gCU-WW-~2(~)l

The major disadvantage of Method II is that the

assumption of SjBi+j= function i only is an approxi-

I””

P mation, and the method works best for the one-size

zo ,B 16 14 I2 10 B 6 4 2

fraction method [which has P2(0)= s(O), etc,=O]

SIZE WC& IHTERVALSI for short grind times. However, it is certainly an

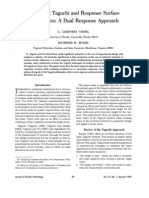

Fi_e 1. Values of S and B used to simulate%ei_eht-size-time improvement over Method I since it can be used at

distributions. longer grind times, and where the values of P,(O),

P,(O), etc. are not zero.

Method III, as formtdated in the Appendix, is the

assumption of negligible rebreakage is only good for most versatile method of calculating B values as it

short times which give only small build-up of can be used with quite large amounts of material in

products; for short times, however, it is sometimes the lower size fractions, both in the starting feed and

not possible to get accurate size analyses of the the distribution at time t, and it works when S,-B,,-

broken fractions because they are small percentages values are not approximately constant. However, it

of the total sample. Because of sieving error 6, the requires an estimate of the values of S, and it is

starting size is usually l-6 in size 1 and 6 in size 2; complex enough to require computer calculation

if S is large, the 2 material will undergo appreciable rather than hand calculation (see Appendix). If two

breakage and to avoid this it is necessary to perform or three S vaiues for different sixes are known experi-

accurate preparation of the initial size, to keep S low, mentally, interpolation from S (log scale) reT= x

which can be tedious experimentally- These prob (log scale) can be used to get the required values of S.

Iems can sometimes be overcome by performing It is the preferred method if reasonable estimates of

several tests (e.g. for grinds of 15 set, 30 set, 1 min S can be made.

etc) and extrapolating the results to near zero time,

but again this is ex_perimentalIy tedious and requires

precise size analysis_ In the continuous tracer RESULTS AND DISCUSSION

method, the minimum time at which traced material

leaves the mill may not be short enough to avoid In order to test the three methods of calculating

secondary brpakage. B, sets of simulated size distributions were generated

Method II (see Appendix) partially eliminates using postulated values of S and B, and a feed

these problems, by performing an approximate consisting of 97% in the top size interval [wZ(0)=

correction for secondary breakage_ -4s presented 0.033. The values of S and B used are shown in Fig 1,

here it is a modified form of that first used by Herbst and the size distributions generated are shown in

and Fuerstenaus_ Experimentally it is similar to Figs 2 and 3. (The value of S for an interval is

those discussed above, but the calculation method plotted ~ersuli the upper size of the interval.) The

is different_ It assumes that the expression S,B,, is a simulated size distributions were generated by

function of i only and not J PhysicaIIy, thrs means solving eqn_ (1) on a digital computers, assuming

Powder Technol, 5 (1971/Z)

DETERMINATION OF BREAKAGE DISTRIBLZION PARAMEl-ERS 217

that the B values are normalized. that %GB,_ 1 = B,_, =

B 5.3, etc. B4_, = B5_:! = Be_,, etc and so on-The three

methods of calculating B were then applied to

selectedsizedisttibutionsSincethesizedistributions

are simulated by exact computation there is no

GRINDING TIME. 30MlN experimental error in the curves and a comparison

of the calculated B values with the known B KAXS

demonstrates non-random error caused bv the

assumptions made in the method of calculation.

It will be noted that values of S and B have been

used. which have the same slope (on log-log scales)

for the smaher-size intervaIs. If this slope is z

s&S, = (0.841)=+ i’

B,, = b(0.831~‘-1’ _ i > 7

fcr the set 2 data of Fig I_ Assuming that B ~-alues

are normalized, Bij= B,_i_ E_1. and hence

SiB,j = (S,)(O_841)‘“- “(b)(O_S41)=+~‘. I >j+7

= (b)(S,)(O_S31)=+”

a .

P = function i only, not j _

a

*

,.,,,‘,,....

20 a* 16 14 l2 10

.r....

6 6 4

-.

2

Thus the data. set 2 in particular, has been chosen

SIZE I,,.%& 1NTERVAL.S~ so that the criterion necessary for Method II to apply

Fig L Wcighht-sizcdislributiox for YI 1. A calcuiarcd using BII is satisfied over part of the size range If the x-alues of

containing error_ B had been chosen such that they passed through

b = 1, then the Method II criterion would be exactly

Oi- satisfied for the set 2 data. and it would always give

I exactly the correct ralues of B from any of the size

distributions In pncti e, however, this would be an

0 1 unrealistic set of B nlues since experimental values

for balI and rod mihing have the general shapeshown

although the slope z and the value of b XT+- from

material to materiaL There are also data for other

o- milling systems in whi& the slope of the S plot I is

not close to the slope of the B plot, fl_

Considering Table I it can be seen that the three

D

methods are all reasonably satisfactory for only a

P

0

0

o-

small percentage of breakage from size intenal 1.

0

P

0

2 YIN

0 although even here Method I has significant error_

v

0 P The error would be less for S curves in vhicb S

5- 0 decreases rapidly with smaller partide size. because

0

0

P

the reIative amount of breakage from the lower size

p 0.5 YIN

intervals would then be less At approximateIy 2Opd

09 P broken from size intend 1, Method II has developed

2 P

P

significant error, which is increased for the data at

P

P

approximately40°/0 broken from size 1. Forexample,

P considering the fine material, final size interval 20.

Method II gives 29% from the 1.6 min distribution

*

P

1[ and 3.5 o/0from the 4-O min distribution, compared to

i ?o 18 16 14 12 IO 6 6 4 2

SIZE U/4& INTERVALS1 a true value of 2S”/$ When these wrong G&ES are

Fig 3. Wci&+six dktribntiom for sex 2 used to caIcuIate size distributions for 30 mitt

218 I_ G. AUSTIN. P. T. LUCKIE

TABLE I

B values for set 1 (maximum in S)

Stie True r=O.I min t=1.6 min t =4_0 min

inrenxl B

BI BII BIZI BZ BZI 8111 BZ BII BZIZ

1 1 1 1 1 1 1 1 1 1 1

2 1 1 1 1 1 1 1 1

3 0.680 0.72 0.7 068 0.75 0.71 0.680 A.80 0.73 LO

4 0.463 0.49 0.475 O-463 0.54 0.50 0.465 0.62 OS4 0.474

5 0.313 0.33 0.323 0.313 0.39 0.36 0.315 0.49 0.41 0328

6 0.212 0.23 0220 0212 029 026 0214 0.38 032 0226

7 0 146 0.16 0.152 0.146 021 0.19 0.148 0_30 025 0.156

s 0.100 011 0.105 0.1 0.16 0.14 0.101 024 0.19 cl106

9 0.088 0094 0.09 1 0.088 0.13 0.12 0.088 0.20 0.16 0.0885

10 0.079 0084 0.08 1 O-079 0.11 0.10 0.079 0.17 0.13 0.0767

11 0071 0.075 0.073 0.07 I 0.098 0.087 0.070 O-14 0.11 o-069

12 0.0635 0067 00648 0.0635 00S6 0.076 0.0632 0.12 0.097

13 0.0567 0.060 0_0578 O-0567 0.076 0.067 0.0564 0.11 0.084 0.0548

14 0.050 0_053 0.05 1 0.05 0.066 0.059 0.0498 0.094 0.073 0.0489

15 0.0445 0.047 0.0445 0.059 0.052 0.0444 0.083 0.061 0.0440

16 0.W o-w3 o.wO7 0.040 0.053 0.047 0.040 0.073 0.057 0.0398

i7 0.0357 0.038 0.0364 0.0357 0.047 0.041 0.065 0.050 0.0357

18 0.0318 0.034 0.0324 0.0318 0.042 0.037 0.03 18 0.058 0.044 0.0318

19 0.0283 0 030 0.0288 0.0283 0.037 0.033 O-0283 O-051 O-039 0.0284

20 0.0250 0.026 0.0255 0 0250 0.033 0.029 0.0250 0.045 0.035 0.0250

T_4BLE II

B values for set 2 (power function for S)

SIX T#-Ue t=O_Z min t = O-4 min t = 2.0 min

inrenxd B

Bi BZZ BZIZ BI BIZ BIZI BI BII BZIZ-

1 1 1 1 1 1 1 1 1 1 1

2 I 1 1 1 1 I 1 1 I

3 0.680 0.7 1 0.686 0.680 0.74 0.690 b.680 0.84 0.719 0.680

4 0.463 0.49 O-469 0.463 0.52 0.477 0.463 0.67 0.51 0.49

5 0.313 0.33 0319 0.313 0.36 0.329 0.314 0.52 037 0.34

6 0.212 0.23 0217 0_212 0.25 0.227 Qz13 0.40 0.27 0.23

7 0.146 0.16 0.150 0.146 0.18 0.159 0.147 030 010 0.16

8 0.100 0.11 0.103 0.100 O.I3 0.111 O_lOO 023 0.15 0.11

9 0.088 0.094 0.089 0.088 0.11 0.095 &OS8 0.19 0.12 O-091

10 0.079 0.084 0.080 0.079 O-093 O-082 0.079 a15 0.095 0.080

11 0.07 1 0.075 0.07 1 0.071 0.083 0.072 O-07 1 0.13 o.oso O-07 1

12 0.0635 0.067 0.0635 0.0635 0.073 O-0641 0.0635 Qll 0.067 QO64

13 0.0567 0.060 0.0567 0 0567 0.065 0~0570 0.0567 0.099 0.060

14 0.05aJ 0.053 0.0500 9-0500 O-057 QO502 0_0500 a087 0_052 0.051

15 O-0445 O~Gl7 ODl4.5 O-0445 0.051 0.0446 0_0445 O-077 O-Q46 OXM6

16 O-0400 0.032 0.0400 O.O?.MJ O-046 0.0400 0.01oo 0.068 O-041 CO41

17 0.0357 0.037 0.0357 0.0357 0.041 0.0357 0.0357 0.061 0.036 0.037

18 Q0318 0.034 a0318 0.0318 0.036 0.0318 0.0318 O-054 0.032 O-033

19 0.0283 O-030 0.0283 a0283 O-032 0.0283 011283 0.048 0.0285 O-029

20 0.0250 0.026 0.0250 0.0250 0.029 O-0250 a0250 o.cJ43 QO253 O-026

p2 8.32% 25% =4%

DEERMINATION OF BREAKAGE DISTRIBUTION PARAMETERS 219

grinding the error in the final interval is very error). This result means that it is no longer necesmry

pronounced (see Fig 2). Method III is quite satis- to prepare a batch of material closely sieved to size 1

factory for aII three times It is our experience that to run a test; any reasonable starting material can

accurate size distributions can be obtained at about be used providing the size analysis is accurately

3040% broken out without elaborate experimental determined This _yeatly reduces sample preparation

procedures, but that below 20% it ‘becomes necessary time_ However, rt must be remembered that the

to run several careful tests to get a good average or simulated data used normalized B values. whereas

get data which can be extrapolated to zero time_ we have many experimental examples where this is

Considering Table II, Method II is satisfactory not a valid assumption The advantage of the one-

even at approximately 65 o/0broken out. Method III size fraction method app!ied for a small deFee of

is also satisfactory_ It is concluded that when the breakage is that the BII or BIII values are predomi-

parameters are of the form of set 2 Method II can be nantly produced by breaka_? from size interval I_

applied, requiring no preliminary knowledge of S If a wide starting size distnbution is used, the B

values. values calculated are weighted means of the sire

Our current practice is to use Method II to get a intervalsinvolved and it is not possible to distinguish

first estimate of B values, use these to estimate S Bi., from Biw2 from Biw3_etc’_

values by back-calcuIation’, and use these estimates

of S to calculate B by Method III. If the two sets of B

values are in agreement, satisfactory S and B values CONCLUSIONS

have been obtained_ If not, the Method III B values

are used to recalculate S values Three methods are presented for determining

Table III shows Methods II and III applied to breakage distribution parameters, based on different

calculate B from a starting distribution which is not approximations of varying complexity_ Method III

all of size 1, ground for a relatively short period of is generally more satisfactory than Method IL and

time (4 min). Even in this case, the BIII values Method I is only applicable under special conditions

accurately regenerated the size distributions and are However, Method III requires an estimate of the

satisfactory (the BII values are again radically in values of specific rates of breakage_

REFERESCES

TABLE III

I L G. Austin, K. J. Rdd and P. T. Luclic, Woriirhop on Grinding

B values for Set 1 calculated from non-single size feed

Circuirs. PemqIr4mia Stare Unirersir_r, &fay JO-IA 1970:

I_ G. Austin. Theory and Pracrice of Grkdinu. Chynber of

Size t=4min TIlLI?

ia?rzal dfine& Johannesburg. Smah Afnka. _4& 17-Y; i970. -

B

2 R P_ Gardner and L_ G. AnSin. in H. Rumpfand D_ B.zkrcns

P(O) P I41 BII BIII

(eds), In ElarGpean symp_ i%?rH&em Vcrlq chunic

1 1 I 1 I 1

u’cinhdm. 196L p_ 217.

3 D. E K&all, ZL J. Reid and C J. RcsxuicL Pmrdcr Technol

2 0.415 0.047 1 1 1

1 (5) (1968) 291.

3 0308 0534 0.78 (1680 Q680

4 J. A Hcrbst and D. W_ Fucmcna~~. Trans. AI.%f& MI (196s)

4 0.239 0.449 0.64 O-47 0.463

538.

O_lS7 0382 054 0313

z 5 P. T. Luckx and I, G. Austin, A review in~rodoction IO rhc

z a148 0327 a47 021’

7 0.117 solorion of rho grinding upations by digital wmpuution,

0279 0.40 u15 (L146

0.093 0.237 0.M 0.106

Afirsrpksci &g_, (in press).

8 0.100

6 R R Klimpcl and L_ G.Fcaszin. I&. Eaq_ Ckznz Frmdpmenmk,

9 GO77 Ozcu 02.9 GO90 GOSS

9 (2) (197C) 230.

10 O-065 Gl?S 025 GO78 GO79

7 L_ G. Austin and V_ tC_ B-ktia, Expcrimmral muhods for

11 GO.55(5) GISO 021 GO69 GO71

grinding srudia in taborator~; mills, Powder TechrwL, 5

12 0.018 0.129 0.18 0.061 O-0635

(1971/72) 261.

13 GO41 (5) 0.111 0.15 GOSS GO567

14 O-036 Go96 Q13 0049 a050

15 O-032 Cl084 0.11 a044 Qcu45 APPENDIX: CALCUIATION OF B V_4LUES FROW

16 0*028 GO73 0.094 0.040 OD4Oo WEIGH-l--SIZE DISl-RIBUI’lONS AT SHORT TIMES OF

17 0.025 O-065 o*Os 1 0.036 a0357 E4TCH GRINDING

18 a022 O-057 a071 a032 GO318

19 GO197 o_osO GO63 (1029 ao2s3

20 0.0175 acus GO55 GO25 QO250

First approximation I Method I

The experimental technique is to start with a

Powder TechnoL. 5 (1971/R)

220 L. G. AUSTIN, P. T. LUCKIE

charge which is almost entirely in the top size than s& i (size i being the top sim of interval i)_ This

interval. A sample of this is resieved, and it is gives an analytical solution to the equation of batch

generally found that a certain fractional amount, 6 grinding since S$&= constant for given value of i

say, will pass through into the second size interval

Thus the starting charge is actually I-Pi(t)=[l-I$(O)]exp[-SjBijt],jc i @3)

wl(0)= l--8 Applying this for short grinding times of a feed

i,‘l (0) = 8 primarily in the top size fraction,

6 is called the sieving error.

If the grinding time is very small, the breakage l-p,(t)=[l-Pi(O)] exp(-Bi_rSrt)

products will undergo negligible rebreakage. Then, Assuming that the initial distribution at time zero is

sieving of a sample which has been ground will give 1-iiinsize 1,thenPz(0)=6

w,(t), wz(t), _._, etc. and

weight arriving size 2 l-P2(t)=(l-6)exp(-S,t)

b

‘** = weight out of size 1 -S,t=ln[(l-p=(t))l(l-a)]

Let the fractional weight broken out of size 1 be Aw,

-BB,_,S,t -ln[(l-Pi(t))/(l-E(O))]

Aw = wr (0) - \Vr (t) (Al)

hzcu -SKoMl -pi@))1

The weight arriving in size 2 (A4)

% = log[(1-P~(0))/(l-P~(t))]

= W&)-6 Equation (A4) is the working equation.

Then, For small degrees of grinding, the values of P,(t)

will be small for the one-size fraction method [except

b 2,1 = [wz(rj-6]/Aw

for Pr (t) = 1, of course] and

Further, since ~(3,0), w(4,0), etc are negligible

Bi.1 2: [p;(t)-p;(O)]/[p,(t)_bl

b,., = w,(r)/Aw, etc. N Pi(t)/Aw D i > 3

In terms of B, Thus the two methods give identical results at

B 3. 1 = cumulative fraction below sufficiently low times of grinding_

I

Third approximation I Method III

= ii_ wi (t)/ AW

This method requires as input an estimate of the

rate constants of breakage, although the estimate

= Ps (t)/Atv

need not be very accurate_ The estimate is obtained

Similarly, from experimental data on rates of breakage’ ; for

B, 1 = P; (t)/Aw, i>3 example, the S curves in Fig 1 can be constructed

from appropriate rate measurements, so that the

= pi (t)/ CFZ(tj- pZ toI1 6-1 values of S fcr the various size intervals can be

Note: B,_, = 1. B,?, = 1. Equation (42) is the estimated by interpolation.

working equation. In principle, the size distribution produced at

some time of grinding from a specified feed is a

Second approximation: Method II

unique resuh of the S and B parameters, and know-

In some cases it is diflicult to get accurate data at

ing S, B can be back-calculated However, the algebra

very short times of grinding. Then it is necesmry to

correct for rebreakage of the primary breakage of the back-computation is non-tractabIe, except for

the two top size intervals 1 and 2 For these two

products The starting point is the approximation

intervals, the fractional amounts broken to less than

that S(y) B(x, yj=function of nyonly, which for size

intervals in geometric progression can be put as size i in time t of grinding are:

I SjBi,i=function i only. Physically, this means that “fraction less than size i from size 1” _

the rate of breakage to less than size i depends only

on the fractional amount of material greater than =Bisl[w,(0)-Wl(t)] 7 i > 1

size & not on the mean size of the material greater = Bi,l Aw (A3

Powder TechnoL 5 (197 ly;rz)

DETERMINATION OF BREAKAGE DISlRIBUTION PARAMEI-ERS 221

Traction less than size i from size 2” Now the fractional amount below the upper size

of siz 3 produced during grinding is clearly the sum

cBi.2 r

0

S,wx(t)dt of contributions from sixe 1 and 2, and hence

&(r)-P’(O)= 13,_,Aw+Ar

=Bi.lAz > is-2 646) or

Now wz(t) is known from the Reid solution B xl= P~(~)-~~P)-~I/Aw WC9

In the same way,

(emsa’- emsz’)wl (0) + esS2’ w2 (0) (A7)

Thus

l-e-s1z _ l-e-S2’ Now if&Z&normalized, BLi=Bi_j_,; ifit is not, this

AZ=& can be used as an approximation for the one size

s2 >

Sl

fraction method at short grind times because the

value of&(t) is dominated by B,_, and the error in

+w2(0)(

Q-==‘)] setting Be_2 = E& is negligible Then

and substituting for S, b,. 1w1 (O)/(S, -S,) from eqn.

(A7) where B,_ 1 is known from eqn. (AlO).

-s2rw2(0) emsIr 1 -e--s=r \ In general

w2(0-e 1 -

Ax=& e-S’t_e-SZ’

s, - s, 1

tw,(O) (y==)]

Since l-exp(-S,r)=Aw/w,(O),and l-exp(-SS,t)

= l-(~-Aw/w,(~)~=‘~‘, where the solution marches down from i=4_

To summarize, the required data are I values of S,

A = H’.(~)--W2WU-~Y [l_(l_-y__d] wl(0)=l-P=(O). A\~=~c,(O)--w,(t)=P,(r)-P,(O),

2

A+(l-@---I and values of s(t), P,(r), ___ P,(r); P,(O), P,(O), ---

+[l-(l--)=jw2(0) (AS) P,(O). A2 is calculated using eqns (AS), (A!3); hence,

B 3_l is calculated from eqn- (AlO); hence, the

where for printing convenience values of BiLI are calculated from eqn (All),

starting with z=4 and working down.

A = Aw/w r (0) (A%

and COMPUTATION

r = S,t/In [l/(1 - Aw/w, (0))] Wa)

Solving most of the equations developed to

A2 has the physical significance of the amount simulate a comminution process or estimating the

broken from the second in:ervaI, and is calculated parameters of the simulating equations requires, or

from eons- (AS), 6% @a)- is made more convenient by, the pro& T gofa

Similar use of the Reid solution for the third, computing device The more common method used

fourth, etc intervals becomes intractable, and today is to write a program of solution and solve it

therefore the amount broken out of the jth interval on a digital computer_ Research into this unit

is approximated by a simple linear mean rate: operation at The Pennsylvania State University has,

of course, generated its own set of computer pro-

“fractional amount broken to less than s&z i from

grams These programs are written in FORTRAN

breakage ofj material” N BiiSjt[wj(0)+wi(t)]/3,

lV language without resorting to esoteric system

i>j>3

capabilities such as mixed mode, variable dimension

Thk is an excchent approximation for short grind statements, etc. and hence should execute without

times where w#) varies almost linearly with time alteration on most existing computer systems These

Pm&T T&z_ 5 (1971/72)

222 L. G. AUSTIN. P-T. LUCKIE

pro_- have been written and documented as SUBROUTINE BFUXC (PO, PT, ST, N,

subroutines, a technique employed by IBM for their I,==, B)

scientific progr amming packages Users of these DIMENSION PO(l), PT(i), ST(l), B(1)

programs need to provide a main program which B(l)= 1.0

inputs the required data, calls the subroutine and B(2)= 1.0

outputs the requested data. Dl = PT(2)- PO(2)

IF(KEY.EQ.l) GO TO 10

Subroutine BFUNC ALPHA=Dl/(l.O- PO(2))

Purpose : BETA=ALOG(l.O-ALPHA)

To develop cumulative interval breakage function IF(KEY_EQ_2) GO TO 10

values which give the proportion of material GAMh&+=l_O--MP (-ST(2))

broken out of size 1 which falls below size I, where R = ST(2)/BETA

1 is numerically less than or equal to I, 1 repre- D2=((PT(2)--T(3)-(LO-GAMMA)*(PO

senting the largest size interval_ (2)-PO(3)))/(ALPHA-GAMMA)*

Usage : (GAMMA+R*ALPHA)+GAMMA*

CALL BFUNC (PO, PT, ST, N, KEY, B) (POW- PO(3))YDl

Description of parameters: DlDl=Dl+Dl

PO--An input vector of size N containing the 10 DO 40 1=3,N

cumulative feed decimal fraction less than IF(KEV_EQ_2) GO TO 30

size I. B(I)=(PT(I)- PO(I))/Dl

PT-An input vector of size N containing the IF(KEY_EQ.1) GO TO 40

cumulative product decimal fraction less 11=1-l

than size I, after batch grinding for T units B(I)=B(I)-B(Il)*D2

of time. IF(Il.EQ.2) GO TO 40

ST-An input vector of size N containing the B(I)=B(I)*DlDl

product of the intervd selection function DO 20 J=3,11

value and the grinding time; i.e., S(I)*T. K=I-J+l

N-The number of size intervals_ 20 B(I)=B(I)-B(K)*ST(J)*(PO(J)- PO(J+ I)+

KEY-Input code indicating the tyPe of B values PT(J)- PT(J + 1))

to be calculated B(I)=B(I)/DlDl

1-B (I) values GOT040

2-B (II) valaes 30 B(I)=ALOG((l.O- PT(I))/(l.O- PO(I)))/

3-B (III) values. BETA

B-An output vector of size N containing the 40 CONTINUE

cumulative interval breakage vahres. RETURN

Remarks : END

Values for the input vector, ST, are only required

for KEY = 3.

Subroutines and function subprograms ra:qJired I

None.

Method :

Solutions of the comminution equations.

Powder TechnoL, 5 (1971/72)

You might also like

- F.C. Bonde-. Comminution Theory PDFDocument11 pagesF.C. Bonde-. Comminution Theory PDFLM100% (1)

- Randstad2040 Structural VisionDocument41 pagesRandstad2040 Structural VisionAna Maria Fernandez MaldonadoNo ratings yet

- From Israel To DamascusDocument52 pagesFrom Israel To DamascusSteve OBrienNo ratings yet

- Introduction To Human Resources ManagementDocument23 pagesIntroduction To Human Resources ManagementashusinghputputNo ratings yet

- (Novo) An Alternative Solution To The Grinding Equation in CumulativeDocument5 pages(Novo) An Alternative Solution To The Grinding Equation in CumulativeThayrone Zé Marmita NicksonNo ratings yet

- A Process Capability Index Sensitive To SkewnessDocument13 pagesA Process Capability Index Sensitive To SkewnessJuan Posada GNo ratings yet

- An Alternative Method For Programming Mill Models: Leonard G. Austin, Heechan ChoDocument5 pagesAn Alternative Method For Programming Mill Models: Leonard G. Austin, Heechan ChoDirceu NascimentoNo ratings yet

- A General Model For Semi-Autogenous and Autogenous MillingDocument20 pagesA General Model For Semi-Autogenous and Autogenous MillingRAVI1972No ratings yet

- Estimating The Cut (Ds0) Sizeof Classifiers Without Product Particle-SizemeasurementDocument10 pagesEstimating The Cut (Ds0) Sizeof Classifiers Without Product Particle-SizemeasurementbehnamNo ratings yet

- Drill Holes and BlastholesDocument15 pagesDrill Holes and BlastholesKevin RiosNo ratings yet

- PAPER ORGINAL (Msr+Taguchi+Vinning+Myers+Jqtv22i1vining)Document8 pagesPAPER ORGINAL (Msr+Taguchi+Vinning+Myers+Jqtv22i1vining)RQP1029No ratings yet

- msf.465-466.163Document7 pagesmsf.465-466.163Ray AgonNo ratings yet

- 17-Chapter Manuscript-211-1-10-20181129Document13 pages17-Chapter Manuscript-211-1-10-20181129Rolly AlfeusNo ratings yet

- Pressure Transient Analysis by Using MS. Excel Sheet and Computer ProgrammingDocument13 pagesPressure Transient Analysis by Using MS. Excel Sheet and Computer ProgrammingRolly Alfeus100% (1)

- Rensselaer Polytechnic Institute, Troy, New York (U.S.A.)Document6 pagesRensselaer Polytechnic Institute, Troy, New York (U.S.A.)Kartik DuttNo ratings yet

- NASA-CR-33 Probability Functions For Random Responses - Prediction of Peaks, Fatigue Damage, and Catastrophic FailuresDocument60 pagesNASA-CR-33 Probability Functions For Random Responses - Prediction of Peaks, Fatigue Damage, and Catastrophic Failuresjason chowNo ratings yet

- Application of The Choquet Integral in Multicriteria Decision MakingDocument27 pagesApplication of The Choquet Integral in Multicriteria Decision MakingddericiNo ratings yet

- A Survey of Thresholding TechniquesDocument29 pagesA Survey of Thresholding TechniquesdieuthNo ratings yet

- Logarithmico-Normal Distribution Solids: BreakageDocument3 pagesLogarithmico-Normal Distribution Solids: BreakageLizeth Mayerly Castellanos ArciniegasNo ratings yet

- Least Cost Tolerance Allocation For Mechanical Assemblies With Automated...Document22 pagesLeast Cost Tolerance Allocation For Mechanical Assemblies With Automated...palaniNo ratings yet

- Weighted Average Operators Generated by N-Dimensional Overlaps and An Application in Decision MakingDocument6 pagesWeighted Average Operators Generated by N-Dimensional Overlaps and An Application in Decision MakingFuad EngineNo ratings yet

- Pages 42Document22 pagesPages 42Jaime Magno Gutierrez RamirezNo ratings yet

- Claims Reserving Using Tweedie'S Compound Poisson Model: BY Ario ÜthrichDocument16 pagesClaims Reserving Using Tweedie'S Compound Poisson Model: BY Ario ÜthrichAdamNo ratings yet

- Experiment 2: Determination of Poisson'S Ratio: TitleDocument4 pagesExperiment 2: Determination of Poisson'S Ratio: Titlenikhil jaiswalNo ratings yet

- Estiamando ZetaDocument6 pagesEstiamando ZetaGabriel AguirreNo ratings yet

- Statistical Process Control Optimization With Variable Sampling Interval and Nonlinear Expected LosDocument29 pagesStatistical Process Control Optimization With Variable Sampling Interval and Nonlinear Expected LosjuanivazquezNo ratings yet

- An Operational Measure For Squeezing: Home Search Collections Journals About Contact Us My IopscienceDocument46 pagesAn Operational Measure For Squeezing: Home Search Collections Journals About Contact Us My Iopsciencenawal.maftahNo ratings yet

- Brents MethodDocument12 pagesBrents MethodcharrasquidoNo ratings yet

- Regression Shrinkage and Selection Via The LassoDocument22 pagesRegression Shrinkage and Selection Via The LassopedropietrafesaNo ratings yet

- Cutoff XFEM PaperDocument19 pagesCutoff XFEM PaperFelipe LopesNo ratings yet

- Multi-Item EOQ Calculation in Presence of Warehouse Constraints: A Simulative AnalysisDocument10 pagesMulti-Item EOQ Calculation in Presence of Warehouse Constraints: A Simulative AnalysisAgung WicaksonoNo ratings yet

- Co Variance ShrinkageDocument9 pagesCo Variance ShrinkageEttore TruccoNo ratings yet

- CalcI Integral AppsDocument50 pagesCalcI Integral AppsdarnaNo ratings yet

- Minimum Error ThresholdingDocument7 pagesMinimum Error ThresholdingAnonymous ZM6JiBMoOTNo ratings yet

- Open Pit Production Planning Using Controlled Pushbacks and AggregatesDocument11 pagesOpen Pit Production Planning Using Controlled Pushbacks and AggregatesFrancisco CabreraNo ratings yet

- 3d Segmentation of The Mouse Spleen in Microct Via Active ContouDocument4 pages3d Segmentation of The Mouse Spleen in Microct Via Active ContouJanice AbrahamNo ratings yet

- Six-Port Complex Permittivity MeasurementsDocument3 pagesSix-Port Complex Permittivity MeasurementsWalter Santiago Campos ArandaNo ratings yet

- JRS Numerical Schemes For Optical Soliton Propagation Analysis A Test ComparisonDocument5 pagesJRS Numerical Schemes For Optical Soliton Propagation Analysis A Test ComparisonjrosouzaNo ratings yet

- Bowing BOPP DocumentDocument5 pagesBowing BOPP DocumentKarl ThomasNo ratings yet

- TENSION MEMBERS Yielding Shear LagDocument28 pagesTENSION MEMBERS Yielding Shear LagEhsan WasimNo ratings yet

- XavierDocument11 pagesXavierRogério JuniorNo ratings yet

- Multimodel Modelization and Stabilization of A BioreactorDocument5 pagesMultimodel Modelization and Stabilization of A BioreactorkaramaNo ratings yet

- Formation Characterization: Well and Reservoir Testing: 2-1. Evolution of A TechnologyDocument25 pagesFormation Characterization: Well and Reservoir Testing: 2-1. Evolution of A TechnologyodremanjNo ratings yet

- DESIGN Glauz - SSRC - 2018Document12 pagesDESIGN Glauz - SSRC - 2018Tri huỳnhNo ratings yet

- Modeling of Nevada Sand Behavior Using CHSOIL: February 2011Document9 pagesModeling of Nevada Sand Behavior Using CHSOIL: February 2011Zhenhe SongNo ratings yet

- Ecole Polytechnique: Centre de Math Ematiques Appliqu EES Umr Cnrs 7641Document22 pagesEcole Polytechnique: Centre de Math Ematiques Appliqu EES Umr Cnrs 7641harshal161987No ratings yet

- Ortogonal Experimental Plans For A Wind Turbine Blade DesignDocument10 pagesOrtogonal Experimental Plans For A Wind Turbine Blade DesignCosmin DiaconuNo ratings yet

- BSH 004 2007 - 001 PDFDocument8 pagesBSH 004 2007 - 001 PDFJakesNo ratings yet

- Ahmadi 2008 Dynamic Properties of Filled RubberDocument19 pagesAhmadi 2008 Dynamic Properties of Filled RubberKenanNo ratings yet

- A Heterogeneous One-Dimensional Model For Non-Adiabatic Fixed Bed Catalytic ReactorsDocument7 pagesA Heterogeneous One-Dimensional Model For Non-Adiabatic Fixed Bed Catalytic ReactorsBamrung SungnoenNo ratings yet

- Degradation Testing and AnalysisDocument47 pagesDegradation Testing and AnalysisCarlos Bathuel Ramirez P.No ratings yet

- On Design Margin For Process System With Parameter UncertaintyDocument5 pagesOn Design Margin For Process System With Parameter Uncertaintyra9622No ratings yet

- Mpi I 97 1 010Document9 pagesMpi I 97 1 010Anant ChhajwaniNo ratings yet

- 5.1 Modeling Periodic Behaviour (JSM)Document4 pages5.1 Modeling Periodic Behaviour (JSM)RyanNo ratings yet

- Errors Log or GammaDocument4 pagesErrors Log or Gammapraneed gamageNo ratings yet

- Spectral Methods MILHDBK5JDocument15 pagesSpectral Methods MILHDBK5JRickNo ratings yet

- IJCER (WWW - Ijceronline.com) International Journal of Computational Engineering ResearchDocument6 pagesIJCER (WWW - Ijceronline.com) International Journal of Computational Engineering ResearchInternational Journal of computational Engineering research (IJCER)No ratings yet

- Drill-Holes and Blast-Holes: Serge Antoine Séguret and Sebastian de La FuenteDocument14 pagesDrill-Holes and Blast-Holes: Serge Antoine Séguret and Sebastian de La FuenteRizkyy Rachmalya ZainalNo ratings yet

- Using The Gaussian Elimination Method For Large Banded Matrix EquationsDocument75 pagesUsing The Gaussian Elimination Method For Large Banded Matrix EquationsLucas SantosNo ratings yet

- A Double Roll Crusher AppliedDocument7 pagesA Double Roll Crusher AppliedAnonymous bmFsuvNo ratings yet

- Fe For Retaining WallDocument4 pagesFe For Retaining WallSerpanaNo ratings yet

- Disturbance Attenuation in A SITO Feedback Control System: ACC02-IEEE1415Document20 pagesDisturbance Attenuation in A SITO Feedback Control System: ACC02-IEEE1415faridrahmanNo ratings yet

- CSAT Formulae Bookle by Amit GargDocument33 pagesCSAT Formulae Bookle by Amit Gargrahulpatel00978No ratings yet

- Effectiveness of Online Class To The Learning of The Bread and Pastry Production StudentsDocument30 pagesEffectiveness of Online Class To The Learning of The Bread and Pastry Production StudentsChristian Cj SamonteNo ratings yet

- Practice Too EnoughDocument4 pagesPractice Too EnoughSHEYLA ESTEFANY FERRUA JAVIERNo ratings yet

- Angky Geradhika Januareza: Education LevelDocument2 pagesAngky Geradhika Januareza: Education LevelGeo Sanchis HutapeaNo ratings yet

- VocabForIELTS PED SpellingRulesDocument1 pageVocabForIELTS PED SpellingRulesMihai BalanNo ratings yet

- R26 ECE Ingles PDFDocument20 pagesR26 ECE Ingles PDFBruninho AzevedoNo ratings yet

- TCL Regular ExpressionsDocument5 pagesTCL Regular ExpressionsVeeranjaneyulu DhikondaNo ratings yet

- Appendix B: Business Plan Template: Applied Health StrategiesDocument34 pagesAppendix B: Business Plan Template: Applied Health StrategiesfaradayzzzNo ratings yet

- Micro Focus Security Arcsight Logger: Configuration and Tuning Best PracticesDocument44 pagesMicro Focus Security Arcsight Logger: Configuration and Tuning Best PracticesBrice TOSSAVINo ratings yet

- OHS in Front Office ServicingDocument46 pagesOHS in Front Office ServicingEdwin Soriano87% (15)

- ISO 45001 Technical Guide - 0Document10 pagesISO 45001 Technical Guide - 0Essam El-DesoukyNo ratings yet

- Data Sheet Milk Reception Unit.1 enDocument2 pagesData Sheet Milk Reception Unit.1 enBoricean Gheorghita100% (1)

- 61JSK-4400 Jack Screw Kit Installation Instructions - English H14727PADocument4 pages61JSK-4400 Jack Screw Kit Installation Instructions - English H14727PAnader0123No ratings yet

- Tyco Insertion-ExtractionToolsDocument4 pagesTyco Insertion-ExtractionToolsChung LeNo ratings yet

- Net SAML2 Service Provider FrameworkDocument43 pagesNet SAML2 Service Provider FrameworkojmojnovNo ratings yet

- How To Resolve Costing ErrorsDocument38 pagesHow To Resolve Costing ErrorsNathanNo ratings yet

- 1.2. All Four Biomolecules V2Document112 pages1.2. All Four Biomolecules V2Clàudia VicenteNo ratings yet

- Tvet System Governance 20180625Document13 pagesTvet System Governance 20180625Soil Water EngineeringNo ratings yet

- 2012 Business - Riverview Trial With SolutionsDocument31 pages2012 Business - Riverview Trial With SolutionsArpit KumarNo ratings yet

- Calculus 3.1Document11 pagesCalculus 3.1blackjack95129No ratings yet

- Worksheet No. 2 - Ch-2-PolynomialsDocument2 pagesWorksheet No. 2 - Ch-2-PolynomialsAishi GuptaNo ratings yet

- Intelligent Electromagnetic Flowmeter: Working PrincipleDocument20 pagesIntelligent Electromagnetic Flowmeter: Working PrincipleABDUL GHAFOORNo ratings yet

- Chemical Resistance of Plastics and Elastomers Used in Pipeline ConstructionDocument80 pagesChemical Resistance of Plastics and Elastomers Used in Pipeline ConstructionMagin Idelfonso TorreblancaNo ratings yet

- 9500 MPR Installation Test and Turn Up - Module 1 - Product - Ed07Document38 pages9500 MPR Installation Test and Turn Up - Module 1 - Product - Ed07Reza RaamNo ratings yet

- What Is DesulfurizationDocument20 pagesWhat Is DesulfurizationYash NandurkarNo ratings yet

- Ethernet Cable - Color Coding DiagramDocument4 pagesEthernet Cable - Color Coding DiagramArchie KinsNo ratings yet

- ModulationDocument15 pagesModulationPoongodiNo ratings yet