Professional Documents

Culture Documents

OTEC2

OTEC2

Uploaded by

Anshul YadavOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OTEC2

OTEC2

Uploaded by

Anshul YadavCopyright:

Available Formats

NAME: ANTESH JAIN

BRANCH: ELECTRICAL ENGINEERING

ROLL NO: 2016031011

OCEAN THERMAL ENERGY CONVERSION

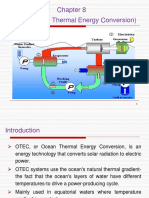

INTRODUCTION: Most of the electricity we use comes from heat engines of one kind or

another. A heat engine is a machine that cycles between two different temperatures, one hot and

one cold, usually extracting heat energy from a fuel of some kind.

In OTEC, we use the temperature difference between the hot surface of the ocean and the cooler,

deeper layers beneath to drive a heat engine in a broadly similar way—except that no fuel is

burned: we don't need to create a difference in temperature by burning fuel because a temperature

gradient exists in the oceans naturally! Since the temperature difference is all-important, we need

the biggest vertical, temperature gradient we can possibly find (at least 20° and ideally more like

30–40°). In practice, that means a place where the surface waters are as hot as we can find and the

deep waters (perhaps 500–1000m or 1000–3000ft beneath ) are as cold as possible.

WORKING: There are essentially two different kinds of OTEC plant.

Closed cycle: In closed-cycle OTEC, there is a long, closed loop of pipeline filled with a

fluid such as ammonia, which has a very low-boiling point (−33°C or 28°F). (Other fluids,

including propane and various low-boiling refrigerant chemicals, have also been

successfully used for transporting heat in OTEC plants.) The ammonia never leaves the

pipe: it simply cycles around the loop again and again, picking up heat from the ocean,

giving it up to the OTEC power plant, and returning as a cooled fluid to collect some more.

Open cycle: In open-cycle OTEC, the sea water is itself used to generate heat without any

kind of intermediate fluid.

You might also like

- Shell & Tube Heat Exchanger - PresentationDocument17 pagesShell & Tube Heat Exchanger - Presentationtantri.hellyantiNo ratings yet

- Project Report On: Solar Thermoelectric Coolers (Peltier Cooler)Document22 pagesProject Report On: Solar Thermoelectric Coolers (Peltier Cooler)Shashwat RawatNo ratings yet

- Ocean Thermal Energy ConversionDocument13 pagesOcean Thermal Energy ConversionRandroxRNo ratings yet

- Ocean Thermal Energy ConversionDocument43 pagesOcean Thermal Energy ConversionMaitry DaveNo ratings yet

- Thermodynamic analysis of geothermal heat pumps for civil air-conditioningFrom EverandThermodynamic analysis of geothermal heat pumps for civil air-conditioningRating: 5 out of 5 stars5/5 (2)

- Case Study Report On: Pyre 202 - Wind Energy, Tidal Energy and OtecDocument15 pagesCase Study Report On: Pyre 202 - Wind Energy, Tidal Energy and OtecsundarNo ratings yet

- Ocean Thermal Energy Conversion and How It Works: Jeremy FeakinsDocument11 pagesOcean Thermal Energy Conversion and How It Works: Jeremy FeakinszartashaNo ratings yet

- CH 9 OTECDocument6 pagesCH 9 OTECscharichNo ratings yet

- A Technical Paper Presentation On: Ocean Thermal Energy ConversionDocument20 pagesA Technical Paper Presentation On: Ocean Thermal Energy ConversionsaurabhNo ratings yet

- Ocean Thermal Energy ConversionDocument20 pagesOcean Thermal Energy ConversionAthisayaraj RajNo ratings yet

- Power Plant Engineering 160100082 - Assignment - 2Document12 pagesPower Plant Engineering 160100082 - Assignment - 2Vidushi VinodNo ratings yet

- Nes Module IIIDocument12 pagesNes Module IIIVenuNo ratings yet

- OotecDocument12 pagesOotecLouie Jay Gitgitin SalvañaNo ratings yet

- Documenttopdf Trial Version, To Remove This Mark, Please Register This SoftwareDocument10 pagesDocumenttopdf Trial Version, To Remove This Mark, Please Register This Softwareranga247No ratings yet

- Documenttopdf Trial Version, To Remove This Mark, Please Register This SoftwareDocument11 pagesDocumenttopdf Trial Version, To Remove This Mark, Please Register This Softwareranga247No ratings yet

- Chapter - 5 OTECDocument12 pagesChapter - 5 OTECsahitNo ratings yet

- Otec Power Plant: NcercDocument22 pagesOtec Power Plant: NcercVimi WilsonNo ratings yet

- Ocean Thermal Energy ConversionDocument10 pagesOcean Thermal Energy ConversionRaviteja RokzNo ratings yet

- Introduction To Ocean Thermal Energy ConversionDocument5 pagesIntroduction To Ocean Thermal Energy ConversiondalerNo ratings yet

- Ocean Thermal EnergyDocument23 pagesOcean Thermal EnergyNAGMANI59No ratings yet

- Thermo OTECDocument15 pagesThermo OTECzikri annuurNo ratings yet

- OTEC (Ocean Thermal Energy Conversion)Document10 pagesOTEC (Ocean Thermal Energy Conversion)Farhan asifNo ratings yet

- Presentation On Ocean Thermal Energy ConvertionDocument23 pagesPresentation On Ocean Thermal Energy ConvertionAtal SahaNo ratings yet

- Close&Hybrid OTECDocument26 pagesClose&Hybrid OTECJohn Jay AbinalNo ratings yet

- 16eemme023 Seminar ReportDocument9 pages16eemme023 Seminar ReportShreya RathoreNo ratings yet

- Presentation ++Document15 pagesPresentation ++36.Praphull DesaleNo ratings yet

- OTEC - Ocean Thermal Energy Conversion: by Maria Bechtel and Erik NetzDocument12 pagesOTEC - Ocean Thermal Energy Conversion: by Maria Bechtel and Erik NetzrodrigoflaNo ratings yet

- Cean Hermal Nergy Onversion: O T E CDocument18 pagesCean Hermal Nergy Onversion: O T E CHappy PatelNo ratings yet

- OTECDocument14 pagesOTECTALLURI LAKSHMI PRASANNANo ratings yet

- Technical ReportDocument2 pagesTechnical ReportAyman Al-SabqiNo ratings yet

- Ocean Thermal Energy ConversionDocument15 pagesOcean Thermal Energy Conversion36.Praphull DesaleNo ratings yet

- Ocean EnergyDocument15 pagesOcean EnergyJASWANT SINGHNo ratings yet

- HereDocument3 pagesHereBilly Joe BreakfastNo ratings yet

- RER Mod5@AzDOCUMENTS - inDocument13 pagesRER Mod5@AzDOCUMENTS - inMizan SalimNo ratings yet

- Ocean Thermal Energy Conversion (OTEC) Uses TheDocument1 pageOcean Thermal Energy Conversion (OTEC) Uses TheSumiNo ratings yet

- Technical Fact SheetDocument1 pageTechnical Fact SheetAyu Fitriyah WahyuniNo ratings yet

- Presented By: Anirban Karmakar (E.E) Roll No. 20Document20 pagesPresented By: Anirban Karmakar (E.E) Roll No. 20Mayank GuptaNo ratings yet

- Ocean Thermal Energy Conversion (OTEC)Document8 pagesOcean Thermal Energy Conversion (OTEC)Vanne Jo PajoNo ratings yet

- Ocean Thermal Energy ConversionDocument14 pagesOcean Thermal Energy ConversionRahul Kumar YadavNo ratings yet

- Ocean Thermal Energy Conversion (Otec)Document4 pagesOcean Thermal Energy Conversion (Otec)Sarvani ShettigarNo ratings yet

- Ocean Energy Conversion Methods: Arshad Babu. U M7B Roll No: 7457 TKMCE KollamDocument32 pagesOcean Energy Conversion Methods: Arshad Babu. U M7B Roll No: 7457 TKMCE KollamgaviNo ratings yet

- Ocean Thermal Energy Conversion: International Journal of Energy and Power EngineeringDocument4 pagesOcean Thermal Energy Conversion: International Journal of Energy and Power EngineeringKemas Ganesha MahendraNo ratings yet

- Ocean Power: Ed Lemery, Brooke Scatchard, Nate TrachimowiczDocument19 pagesOcean Power: Ed Lemery, Brooke Scatchard, Nate TrachimowiczGanesh Kumar100% (1)

- Presentation 3-2Document4 pagesPresentation 3-2Vighnesh BhatNo ratings yet

- Ocean Thermal Energy Conversion: By-Snehanshu Das 7 Sem, B.TechDocument20 pagesOcean Thermal Energy Conversion: By-Snehanshu Das 7 Sem, B.TechJeanNo ratings yet

- Energy From The Oceans: (OTEC, Tides, Waves, and Small Hydroelectric)Document55 pagesEnergy From The Oceans: (OTEC, Tides, Waves, and Small Hydroelectric)Patel NikhilNo ratings yet

- Tutorial Questions On Heat Ex ChangersDocument3 pagesTutorial Questions On Heat Ex ChangersPuneet Garg100% (1)

- Ocean Thermal Energy ConversionDocument17 pagesOcean Thermal Energy ConversionVamsi Pelluru100% (1)

- An Energy Efficient Hybrid System of Solar Powered Water Heater and Adsorption Ice MakerDocument7 pagesAn Energy Efficient Hybrid System of Solar Powered Water Heater and Adsorption Ice MakerAjith KrishnanNo ratings yet

- Ocean Thermal Energy ConversionDocument16 pagesOcean Thermal Energy ConversionFIFA Lords & LegendsNo ratings yet

- AGOJO - Ocean Thermal Energy ConversionDocument14 pagesAGOJO - Ocean Thermal Energy ConversionCarren MarquezNo ratings yet

- Ocean Thermal EnergyDocument19 pagesOcean Thermal EnergyabdulzubairNo ratings yet

- Solar Water Heater With Shell and Helical Coiled Tube Heat Exchanger As A Storage TankDocument11 pagesSolar Water Heater With Shell and Helical Coiled Tube Heat Exchanger As A Storage TankKarimaNo ratings yet

- Chap - 5 Second Law of Thermodynamics - Lectureand Pro 2Document41 pagesChap - 5 Second Law of Thermodynamics - Lectureand Pro 2Mulugeta WoldeNo ratings yet

- Vivek Chand OTECDocument20 pagesVivek Chand OTECvivek chand100% (1)

- What Is OTEC What Is OTECDocument7 pagesWhat Is OTEC What Is OTECkalyniNo ratings yet

- Engr 211 K Thermodynamics Homework # 1: C H C H 3 3Document2 pagesEngr 211 K Thermodynamics Homework # 1: C H C H 3 3dbNo ratings yet

- Rer Mod 5Document14 pagesRer Mod 5rahulNo ratings yet