Professional Documents

Culture Documents

Effect of PWHT Mechanical Properties of Weld Metals PDF

Effect of PWHT Mechanical Properties of Weld Metals PDF

Uploaded by

bacabacabacaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of PWHT Mechanical Properties of Weld Metals PDF

Effect of PWHT Mechanical Properties of Weld Metals PDF

Uploaded by

bacabacabacaCopyright:

Available Formats

Effects of Post Weld Heat Treatment (PWHT) Temperature

on Mechanical Properties of Weld Metals for High-Cr

Ferritic Heat-Resistant Steel

Genichi TANIGUCHI*1, Ken YAMASHITA*1

*1 Welding Process Dept., Technical Center, Welding Business

Welded joints of high-Cr ferritic heat-resistant steel, ASTM in the actual implementation.1), 2) In connection

A335 Gr. P91, were subjected to post weld heat treatment with selecting welding consumables, chemical

(PWHT) to improve mechanical properties and to reduce constituents, such as Mn and Ni, that lower the Ac1

residual stress. We have measured the Ac1 of weld metals transformation point are regulated.3) However, not

for Gr. P91 steel, containing varying amounts of Mn+Ni, much has been done to validate the applicability of

and have examined the effects of PWHT temperatures on this control and regulation to the weld metals from

the mechanical properties of each weld metal. The upper the aspect of mechanical properties.

limits of the PWHT temperature for the respective weld In this study, two types of weld metals for Gr. P91

metals are considered. steel, containing different amounts of Mn+Ni, were

mainly used to study the change of their mechanical

Introduction properties during PWHTs performed at temperatures

exceeding their Ac1 transformation points. The upper

High-Cr ferritic heat-resistant steel is a material limit of the PWHT temperature allowable for each

that, along with austenitic heat-resistant steel, has weld metal is considered.

long been studied and utilized. This ferritic steel has

a smaller coefficient of thermal expansion compared 1. Experimental method

with the austenitic heat-resistant steel and exhibits

excellent creep rupture strength thanks to, among 1.1 Tested materials

other things, the addition of Nb, V and N. Therefore,

this steel is widely used in thermal power plants The materials tested were the weld metals

that run and stop repeatedly, in accordance with the TRUSTARC TM, note) CM-9Cb (hereinafter "CM-9Cb")

power demand, in an environment of steam at high and TRUSTARC CM-95B9 (hereinafter "CM-95B9").

temperature and pressure. The steel ASTM A335 Gr. Both are Kobe Steel's covered electrodes for Gr. P91

P91 is a typical high-Cr ferritic heat-resistant steel and steel. The CM-9Cb has been used for over 20 years,

is applied particularly to large diameter thick-walled mainly in thermal power plants in Japan. On the other

pipes such as the main steam pipes in thermal power hand, CM-95B9 is a covered electrode that meets the

plants. American Welding Society (AWS) standard, A5.5

The welded joints of Gr. P91 steel are generally E9015-B9: 2006, and features a lower content of Mn

subjected to post weld heat treatment (hereinafter and Ni in the weld metal, compared with CM-9Cb. In

referred to as "PWHT") to reduce residual stress and the following description, the weld metal of CM-9Cb

to improve the performance of the weld. If the PWHT is referred to as "A", and that of CM-95B9 is referred

is conducted at an appropriate temperature and to as "B".

time, the welded joint exhibits favorable mechanical Fig. 1 shows the shape of the welding groove

properties. However, if the PWHT temperature configuration. Plates of JIS G3106 SM490A were used

is too low, the weld metal exhibits inadequate for the test. Prior to the test, each groove surface

toughness due to insufficient tempering effect. On

the other hand, if the PWHT temperature is too

high, the tensile strength at ambient and elevated

temperatures becomes insufficient due to excessive

tempering effect. Especially in cases where the PWHT

temperature exceeds the Ac1 transformation point of

the weld metal, the weld metal undergoes reverse

transformation, which results in a microstructure

containing fresh martensite with high strength and Fig. 1 Groove configuration and pass sequences

low toughness. This microstructure deteriorates

the performance of the welded joint. To avoid these note )

TRUSTARC ( ) is a trademark of Kobe

problems, the PWHT temperature is controlled Steel.

33 KOBELCO TECHNOLOGY REVIEW NO. 32 DEC. 2013

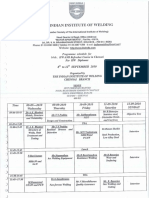

Table 1 Welding conditions equipped with an LED device. The heating rate of

the specimen was 10℃/min up to 600℃ and was 5℃/

min in the temperature range from 650 to 1,050℃, the

range in which reverse transformation is expected to

occur. On the other hand, a carbon steel containing

0.19mass%C was used as a standard sample to

verify the validity of the measurement result. For this

verification, comparisons were made between the Ac1

was provided with three layers of buttering welding transformation point measured and the A1 point that

using respective welding consumables tested and is roughly derived from the Fe-C phase diagram.

machined smoothly so as to prevent the fluctuation

of the chemical composition due to dilution by the 1.4 Mechanical properties evaluation of weld metal

base material. Table 1 shows the welding conditions

inside the groove. The mechanical properties evaluated were tensile

strength at room temperature, Charpy impact

1.2 PWHT conditions absorbed energy at 20℃ and the creep rupture time

at 600℃ (applied stress:108MPa and 147MPa).

Each specimen for mechanical properties The specimens, in accordance with AWS A5.5, were

evaluation was subjected to PWHTs. For weld metal prepared from each weld metal after the PWHT for

A, the PWHTs were conducted at five temperatures: the room temperature tensile test and Charpy impact

i.e., 670, 730, 760, 790 and 820℃. For weld metal B, test. Each creep rupture specimen had a diameter

PWHTs were conducted at four temperatures; i.e., ofφ6.0mm with extensometer limb and was taken

720, 760, 800 and 850℃. The holding time for each in the direction parallel to the welding direction and

PWHT was 4 hrs. The lower control limit for the from a location at the center of the bead width and of

PWHT temperature was 300℃, while the heating the plate thickness.

rate and cooling rate above the lower control limit

temperature were 55℃/h or lower. 1.5 Observation on the state of carbonitride

precipitation and the extracted residue analysis

1.3 Measurement of Ac1 transformation points of

weld metals A transmission electron microscopy (TEM)

study was conducted on the precipitation state of

In order to measure the Ac1 transformation carbonitride after the PWHT. Each TEM observation

point, a solid cylindrical specimen of φ8 66mm sample was taken from a cross-section vertical to the

was taken from each weld metal, as-welded. Each welding direction at the center of the bead width and

specimen was taken in the direction parallel to the of the plate thickness. The observation was conducted

welding direction and from a location at the center by an extraction replica technique. Extracted residue

of the bead width and of the plate thickness. The Ac1 analysis was conducted to identify the amount and

transformation point is defined as the temperature at composition of carbonitride, using a solid cylindrical

which the austenitic phase starts to form during the specimen ofφ8×20mm. Each specimen was taken

heating process. A general method for measuring from the same location as the TEM observation sample,

the Ac1 transformation point involves detecting the but in the direction parallel to the welding direction.

expansion and contraction of the specimen during

the phase transformation.4) This type of measurement 2. Experimental results and discussion

technique, however, often yields measurement

values that vary significantly, because its accuracy 2.1 The chemical compositions of weld metals

depends on the method of the expansion/contraction

measurement and the measurement conditions. Table 2 shows the chemical compositions of weld

Therefore, a preliminary study was conducted to metals A and B, as well as that of the carbon steel used

verify the validity of the method adopted in this as the standard sample for the measurement of Ac1

study for measuring the Ac1 transformation point.5) transformation point. The amounts of Mn+Ni in the weld

The measurement method adopted involves heating a metals were 2.49 mass% for A and 1.38 mass% for B.

specimen by induction in a high vacuum atmosphere

of approximately 10-3 Pa, and detecting the diameter 2.2 Ac1 transformation point of weld metals

change of the specimen during the heating, using

a non-contact high-precision measuring system Table 3 shows the Ac1 transformation points

KOBELCO TECHNOLOGY REVIEW NO. 32 DEC. 2013 34

Table 2 Chemical compositions of testing materials

Table 3 Measurement results for Ac1

Fig. 2 Relationship between PWHT temperature and

mechanical properties of weld metal A at RT

measured. The Ac1 transformation point of the 0.19

mass%C carbon steel, used as the standard sample,

was found to be 732℃. This temperature agrees well

with the A1 transformation point of approximately

727℃ derived from the Fe-C system phase diagram.

This result verifies the reliability of the method used

to measure the Ac1 transformation point in the present

study; i.e., the method involving heating a specimen

by induction in a high vacuum atmosphere, and

detecting the change in the diameter of the specimen

using a non-contact high-precision measuring system

with an LED device.

The Ac1 transformation points of weld metals A

and B, measured in accordance with this method, were Fig. 3 Relationship between PWHT temperature and

733℃ and 785℃, respectively. These measurement mechanical properties of weld metal B at RT

results are hereinafter used as the Ac1 transformation

points of the respective weld metals. equal to the lower-limit strength value specified for

the steel at the PWHT temperature of 800℃. At 850℃,

2.3 Effect of PWHT temperature on mechanical 0.2% proof strength at room temperature drops

properties of weld metals below the lower-limit strength value specified for the

steel.

Fig. 2 and Fig. 3 show the relationships between The absorbed energy of weld metal A increases

the PWHT temperature and mechanical properties with rising PWHT temperature until the temperature

at room temperature of the weld metals A and B, reaches 760℃, but decreases when the PWHT

respectively. Also included in each figure is the temperature exceeds 760℃. The absorbed energy of

strength of Gr. P91 steel specified by ASTM. weld metal B, on the other hand, increases with rising

The room-temperature tensile strength of weld PWHT temperature and appears to reach a maximum

metal A decreases with rising PWHT temperature at a PWHT temperature between 800℃ and 850℃.

until the PWHT temperature reaches 760℃, but Fig. 4 shows the relationship between the PWHT

increases when the PWHT temperature exceeds temperature and creep rupture time of weld metals

760℃. The room-temperature tensile strength of weld A and B. When the applied stress is low (108MPa),

metal B, on the other hand, decreases monotonically the creep rupture times of both weld metals A and B

with rising PWHT temperature and becomes almost become shorter with rising PWHT temperature. The

35 KOBELCO TECHNOLOGY REVIEW NO. 32 DEC. 2013

shows the reverse transformation ratios of weld

metals A and B. Each reverse transformation ratio

was determined from the temperature vs. expansion/

contraction curve obtained by the Ac1 transformation

point measurement. For each of weld metals A and

B, the ratio of the reverse transformation to the

austenitic phase is rather small in the temperature

range immediately above the Ac1 transformation

Fig. 4 Relationship between PWHT temperature and 600℃ point, which makes the amount of fresh martensite

creep rupture time of weld metals A and B precipitated in the cooling process small and not

enough to cause the reversal of the mechanical

creep rupture time of weld metal B decreases abruptly properties. On the other hand, as the PWHT

at PWHT temperatures exceeding 800℃. When the temperature rises, the reverse transformation ratio

applied stress is high (147MPa), the creep rupture increases, increasing the amount of fresh martensite

time of weld metal A shortens with rising PWHT with high strength and low toughness. This is

temperature until the temperature reaches 790℃, considered to have caused the reversal phenomena

but, in contrast to this, above 790℃, it lengthens. described above. Meanwhile, unlike weld metal A,

The creep rupture time of weld metal B, on the other weld metal B did not show any reversal of mechanical

hand, shortens with rising PWHT temperature and properties even when the PWHT temperature

decreases abruptly at PWHT temperatures exceeding greatly exceeded its Ac1 transformation point and

760℃. the reverse transformation ratio became sufficiently

In the case of weld metal A, a reversal large. This phenomenon cannot simply be explained

phenomenon was observed, at a boundary of the by the reverse transformation ratio alone. For an

PWHT temperature, in each mechanical property, explanation, two assumptions were considered;

i.e., the room-temperature tensile strength, absorbed i.e., the precipitation of low C fresh martensite and

energy and creep rupture time under high applied the precipitation of ferrite phase6). The former, in

stress. This phenomenon is considered to be particular, was considered on the basis of the fact

caused by fresh martensite precipitated at PWHT that weld metal B has a smaller amount of Mn + Ni

temperatures exceeding the Ac1 transformation compared with weld metal A. When the amount of

point. Fresh martensite is formed from the austenitic Mn + Ni is small, only a small amount of solid solute

phase that is formed at temperatures exceeding the C is generated in the austenitic phase by the reverse

Ac1 transformation point, undergoing martensitic transformation. As a result, low C fresh martensite

transformation in the cooling process. The primary that is relatively soft is considered to precipitate in the

objective of PWHT is tempering; however, the fresh cooling process.

martensite is not tempered and exhibits high strength The following experiment was conducted to

and low toughness. This is considered to have caused verify these assumptions. The specimens for the Ac1

the reversal phenomena in the mechanical properties. transformation point measurement were prepared

There are two facts that should be noted. The first from weld metals A and B, both as-welded.

fact is that the reversal of the mechanical properties Each specimen was held for 1h at a temperature

of weld metal A occurs at temperatures higher than approximately 30℃ higher than its respective Ac1

its Ac1 transformation point. This fact is roughly transformation point and was subjected to the cooling

explained by the reverse transformation ratio. Fig. 5 process at a cooling rate of 2℃/min. The temperature

Fig. 5 Relationship between temperature and reverse transformation ratio of weld metals A and B

KOBELCO TECHNOLOGY REVIEW NO. 32 DEC. 2013 36

vs. expansion/contraction curve was measured the middle of the photograph. This white structure

during the cooling process to confirm the precipitated corresponds to the area of concentrated blue in

phase. Fig. 6 shows the results. Weld metal A exhibits the KAM image of weld metal B shown in Fig. 8,

a linear expansion behavior, an indication of fresh which indicates that the lattice strain of this area is

martensite formation, at around 400℃. Weld metal B, significantly smaller than that of the structure in

on the other hand, exhibits another linear expansion the surrounding area. This implies that the white

behavior, an indication of third phase precipitation, structure observed in weld metal B may possibly be

at around 750℃. Fig. 7 shows the microstructures of ferrite. The identification of this precipitate phase will

weld metals A and B after this test, and Fig. 8 shows be pursued further.

the Kernel Average Misorientation (KAM) images of The second fact that should be noted is that weld

the respective fields. The KAM images are obtained metal A shows a reversal in the relationship between

by electron backscatter diffraction (EBSD) analysis PWHT temperature and creep rupture time under

and provide measures of crystal misorientation and high applied stress, which, however, is not the

lattice strain. A KAM image represents the average case for the low applied stress. This is considered

crystal misorientations between a pixel and the to have been caused by the difference between

nearest neighboring pixels in the image, and displays the deformation behavior of the creep rupture test

the crystal misorientation distribution in the observed specimens under high stress and that under low

field. Martensite has a large lattice strain in its crystal stress.7) In other words, when a high stress is applied,

lattice, enabling the KAM image to discriminate deformation occurs throughout the entire specimen.

between ferrite and martensite in the microstructure. Fresh martensite, with highly dense dislocations

Comparing weld metals A and B in Fig. 7, it can be in its crystal grain, contributes to the prolonged

seen that the microstructure of weld metal B has a creep rupture time. On the other hand, under a low

coarse white texture in the perpendicular direction in applied stress, deformation preferentially occurs

in the vicinity of prior austenitic grain boundaries.

Hence, the fresh martensite is considered not to have

contributed to the prolonged creep rupture time.

The above results confirm that the upper limit

of allowable PWHT temperature is governed by

the mechanical properties, rather than by the Ac1

transformation point.

2.4 Effect of PWHT temperature on the precipitation

Fig. 6 Phase transformation temperature of weld metals A state and composition of carbonitride precipitation

and B during cooling process

in weld metals

An investigation was made regarding the effect

of PWHT temperature on the precipitation state

and precipitate amount/composition of carbonitride

in weld metal A. Fig. 9 shows the TEM images of

weld metal A after PWHT at each temperature. No

Fig. 7 Microstructures of weld metals A and B after phase

transformation temperature analysis

Fig. 8 KAM images of weld metals A and B after phase Fig. 9 TEM images of weld metal A after PWHT at different

transformation temperature analysis temperatures

37 KOBELCO TECHNOLOGY REVIEW NO. 32 DEC. 2013

Fig.11 Creep rupture strengths of weld metals A and B after

PWHT at different temperatures

mechanical properties is considered to be important

in determining the PWHT temperature.

Fig.10 Analysis of extracted residues of weld metal A after

Fig.11 shows the creep rupture strengths of weld

PWHT at different temperatures

metals A and B. The creep master curve for the Gr. P91

steel welded joint is also included. From the results,

significant difference was found in the precipitation and now assuming that the weld metal is required

amount and distribution of carbonitride between the to have a creep rupture strength that is equal to or

PWHT temperatures of 670℃ and 760℃. However, greater than that of the welded joint, the upper limits

it was clearly observed that the precipitates of of the PWHT temperatures for weld metals A and B

intragranular carbonitride are more thinly distributed become 760℃ and 800℃ respectively.

at 790℃, and the lath carbide on grain boundaries has If the PWHT temperature of 760℃ is used for weld

been coarsened at 820℃. metal A, the weld metal exhibits a favorable toughness

Extracted residue analysis was conducted to with its tensile strength at room temperature fully

quantitatively compare the precipitation amount of satisfying the specification for Gr. P91 steel. In the

carbonitride at the respective PWHT temperatures. case where the PWHT temperature of 800℃ is used

Fig.10 shows the analysis results. It is confirmed that for weld metal B, the weld metal exhibits a favorable

the elements Cr, Mo, V and N all decrease abruptly toughness; however, its room-temperature tensile

when the PWHT temperature exceeds 760℃. This strength has only a small margin against the Gr. P91

is considered to have been caused by the increased steel specification, as described above.

PWHT temperature promoting the dissolution of After the comprehensive consideration of

carbonitride into the matrix to form a solid solution. mechanical properties based on the above results,

the upper limits of the PWHT temperatures for weld

3. The upper limit PWHT temperature allowable for metals A and B are concluded to be 760℃ and 800℃,

each weld metal respectively.

The Ac1 transformation points of weld metals A Conclusions

and B were measured and found to be 730℃ and

780℃, respectively. If the construction standard Two types of weld metals were prepared using

that stipulates that the PWHT temperature must be CM-9Cb and CM-95B9, Kobe Steel's covered

lower than the Ac1 transformation point is followed, electrodes designed for ASTM A335 Gr. P91 steel.

the upper limits of the PWHT temperature for The weld metals are mainly characterized by their

weld metals A and B should be approximately different Mn + Ni content. Each of them was subjected

730℃ and 780℃, respectively. However, the PWHT to post weld heat treatment (PWHT) at temperatures

temperature of 730℃ provides weld metal A above its Ac1 transformation point to study its

with tempering insufficient to achieve the desired mechanical properties after the heat treatment. There

mechanical properties. In the case of weld metal was discussion concerning the upper limit of the

B, on the other hand, the PWHT temperature of PWHT temperature allowable for each of the weld

780℃ makes the room-temperature tensile strength metals. The results show that the amount of Mn+Ni

almost equal to the lower limit value of the standard for the CM-9Cb weld metal was 2.49mass%, and the

for Gr. P91 steel, which raises a concern that the Ac1 transformation point was 733℃. In accordance

margin against the specification becomes too small. with the construction standard stipulating that

Thus, a PWHT temperature selected merely on the the PWHT temperature must be lower than the Ac1

basis of the Ac1 transformation point may not transformation point, the upper limit of the PWHT

be practical. Comprehensive contemplation of temperature should be 730℃; however, on the basis

KOBELCO TECHNOLOGY REVIEW NO. 32 DEC. 2013 38

of the evaluation results for mechanical properties, References

a PWHT temperature of up to 760℃ is judged to be

allowable. 1) ASME B31.1. POSTWELD HEAT TREATMENT. 2001, 132.1,

p.87.

The amount of Mn + Ni for the CM-95B9 weld metal 2) Thermal and Nuclear Power Engineering Society. The

was 1.38mass% and Ac1 transformation point was interpretation for the technical standard for thermal power

785℃. If the standard described above is followed, plant [Chapter 10, Welding][handbook] (Revision H19).

the upper limit of the PWHT temperature should be 2009, p.159.

780℃; however, on the basis of the evaluation results 3) AWS A5.5/A5.5M. 2006. p.8.

4) ASTM 1033-4. Standard Practice for Quantitative

for mechanical properties, a PWHT temperature of Measurement and Reporting of Hypoeutectoid Carbon and

up to 800℃is judged to be allowable. Low-Alloy Steel Phase Transformations.

The above findings indicate that the PWHT 5) Chen Liang et al. Effect of PWHT temperature and

temperature for a weld metal of high Cr ferritic mechanical properties of High-Cr ferritic heat-resistant steel

heat-resistant steel should not be determined merely weld metal. Welding in the World. 2012, Vol.56, January-

February (1-2).

on the basis of the Mn + Ni content and/or the Ac1 6) T. Tokunaga, et al. Phase transformation behavior of Gr. 91

transformation point, but rather should take into ferritic steel around the Ac1 temperature. CAMP-ISIJ. 2008,

consideration the mechanical properties, including Vol.21, p.1066.

creep rupture performance. 7) H. Kushima et al. Degradation of Mod. 9Cr-1Mo Steel during

The present paper studying the upper limit of the Long-term Creep Deformation. TETSU-TO-HAGANE (in

Japanese). 1999, Vol.85, No.11, p. 57.

PWHT temperature focuses only on the weld metals.

However, more comprehensive research should be

done to evaluate the actual welded joints, and this

would include a study of the base material and the

heat-affected zone of the base material.

39 KOBELCO TECHNOLOGY REVIEW NO. 32 DEC. 2013

You might also like

- Asnt Level 1 Thermography Course ManualDocument45 pagesAsnt Level 1 Thermography Course Manualchitturi jagadish100% (1)

- TWI Specification CSWIP 3.2 PDFDocument27 pagesTWI Specification CSWIP 3.2 PDFKhalilahmad Khatri100% (2)

- BGAS-MCQ-Exam QuestionsDocument11 pagesBGAS-MCQ-Exam QuestionsShanmuga Navaneethan100% (5)

- Extraction of Caffeine From Tea - Lab ReportDocument11 pagesExtraction of Caffeine From Tea - Lab ReportRibka Kristania Hadhiwaluyo50% (4)

- Heat-Treatment of High Carbon Steel Wire - PatentingDocument4 pagesHeat-Treatment of High Carbon Steel Wire - Patentingعزت عبد المنعم100% (1)

- SNT-TC-1A 2020 ChangesDocument33 pagesSNT-TC-1A 2020 ChangesShanmuga Navaneethan100% (6)

- IWE-Welding Inspection BookDocument540 pagesIWE-Welding Inspection BookShanmuga NavaneethanNo ratings yet

- Quick Start Guide For CrystalExplorer17 - CrystalExplorer WikiDocument10 pagesQuick Start Guide For CrystalExplorer17 - CrystalExplorer WikiMarjanSplitNo ratings yet

- Litreature Review On Vitamin CDocument14 pagesLitreature Review On Vitamin CPredeswaran Ponniah100% (2)

- Effects of PWHT Temperature On Mechanical Properties PDFDocument11 pagesEffects of PWHT Temperature On Mechanical Properties PDFA K SinghNo ratings yet

- Temper Bead Welding 36036664Document9 pagesTemper Bead Welding 36036664sv1xv100% (1)

- Influence of Heat Input and Post-Weld Heat Treatment On Boiler Steel P91 (9Document10 pagesInfluence of Heat Input and Post-Weld Heat Treatment On Boiler Steel P91 (9Hatem RagabNo ratings yet

- Panduan BeasiswaDocument7 pagesPanduan BeasiswaAmalia Tri WNo ratings yet

- The Influence of Niobium and Aging Treatment in The 18% Ni Maraging SteelDocument8 pagesThe Influence of Niobium and Aging Treatment in The 18% Ni Maraging SteelGopala Rao ThellaputtaNo ratings yet

- The Effect of Repeated Post-Weld Heat Treatment On Low-Carbon Steel ASTM A216WCBDocument5 pagesThe Effect of Repeated Post-Weld Heat Treatment On Low-Carbon Steel ASTM A216WCB78858799No ratings yet

- The Mechanical Properties and Microstructures of 9% Chromium Steel P92 WeldmentsDocument23 pagesThe Mechanical Properties and Microstructures of 9% Chromium Steel P92 WeldmentspkguptaqaqcNo ratings yet

- 01 - A CCT Diagram For An Offshore Pipeline Steel of X70 TypeDocument6 pages01 - A CCT Diagram For An Offshore Pipeline Steel of X70 TypeŞarîngă George AlexandruNo ratings yet

- New Ultra High Strength Steel Grades For Hot StampingDocument10 pagesNew Ultra High Strength Steel Grades For Hot StampingAndress SsalomonnNo ratings yet

- Kim 2018Document26 pagesKim 2018Muhammad Rizki Gorbyandi NadiNo ratings yet

- CA 6NM CastingsDocument11 pagesCA 6NM CastingsvasanthiNo ratings yet

- 1-S2.0-Flash Butt Welding Application On 16MnCr5 Chain Steel and Investigations of Mechanical Properties-MainDocument9 pages1-S2.0-Flash Butt Welding Application On 16MnCr5 Chain Steel and Investigations of Mechanical Properties-MainHARIMETLYNo ratings yet

- Materials and Design: B.C. Shang, Z.M. Yin, G. Wang, B. Liu, Z.Q. HuangDocument5 pagesMaterials and Design: B.C. Shang, Z.M. Yin, G. Wang, B. Liu, Z.Q. HuangAntonio Alonso Diaz ArriagaNo ratings yet

- Metals-09-00939 OKDocument14 pagesMetals-09-00939 OKRebeca Francis Moran CamposNo ratings yet

- Chapter 5 Quantitative Prediction of C-MN Steel Weld Metal MicrostructureDocument18 pagesChapter 5 Quantitative Prediction of C-MN Steel Weld Metal MicrostructureXimena Mercedez Palacios PortalNo ratings yet

- Effects of Heat Striaghening in Structural SteelDocument12 pagesEffects of Heat Striaghening in Structural SteelAnish XmenNo ratings yet

- 508 2293 5 PB PDFDocument9 pages508 2293 5 PB PDFarjun prajapatiNo ratings yet

- Effect of Controlled Rolling/controlled Cooling Parameters On Microstructure and Mechanical Properties of The Novel Pipeline SteelDocument10 pagesEffect of Controlled Rolling/controlled Cooling Parameters On Microstructure and Mechanical Properties of The Novel Pipeline SteelamnajamNo ratings yet

- Effect of 1110dified Heat Treatl11ent On Mechanical Properties of 300M SteelDocument7 pagesEffect of 1110dified Heat Treatl11ent On Mechanical Properties of 300M SteelRoberto GiménezNo ratings yet

- Enhancement of Mechanical Properties of Low Carbon Dual Phase Steel Via Natural AgingDocument19 pagesEnhancement of Mechanical Properties of Low Carbon Dual Phase Steel Via Natural AgingMoin ANo ratings yet

- Structural SteelsDocument5 pagesStructural SteelsijazNo ratings yet

- A 1033 - 04 Qtewmzm - PDFDocument14 pagesA 1033 - 04 Qtewmzm - PDFTiến Lượng NguyễnNo ratings yet

- Metals 10 00099 v2 PDFDocument23 pagesMetals 10 00099 v2 PDFarjun prajapatiNo ratings yet

- Thermomechanical Processing of Pipeline Steels With A With A Reduced MN ContentDocument9 pagesThermomechanical Processing of Pipeline Steels With A With A Reduced MN ContentBuchan65No ratings yet

- Austentite Steel Thermal StabilizationDocument17 pagesAustentite Steel Thermal StabilizationArangamar KumaranNo ratings yet

- A618 PDFDocument4 pagesA618 PDFSadashiva sahooNo ratings yet

- Mechanical Properties of Biomedical Co-33Cr-5Mo-0.3N Alloy at Elevated TemperaturesDocument7 pagesMechanical Properties of Biomedical Co-33Cr-5Mo-0.3N Alloy at Elevated TemperaturesDeva RajNo ratings yet

- Some Aspects of Metallurgical Assessment of Boiler Tubes-Basic Principles and Case StudiesDocument10 pagesSome Aspects of Metallurgical Assessment of Boiler Tubes-Basic Principles and Case StudiesmsdoharNo ratings yet

- The in Uence of Welding Parameters On The Joint Strength of Resistance Spot-Welded Titanium SheetsDocument8 pagesThe in Uence of Welding Parameters On The Joint Strength of Resistance Spot-Welded Titanium Sheetskaliappan45490100% (1)

- Comparative Evaluation of Temperature Distribution in Gtaw and FSW Joints of Aa 5059 Aluminium AlloyDocument9 pagesComparative Evaluation of Temperature Distribution in Gtaw and FSW Joints of Aa 5059 Aluminium AlloyBabu NarayananNo ratings yet

- 02 Effect of Chemical Composition and ProcessingDocument49 pages02 Effect of Chemical Composition and ProcessingAli MoussaNo ratings yet

- Experimental Setup For Jominy EndDocument6 pagesExperimental Setup For Jominy Enddeva mandavgadeNo ratings yet

- Evaluation of The Heat Transfer Coefficient at The Metal-Mould Interface During FlowDocument4 pagesEvaluation of The Heat Transfer Coefficient at The Metal-Mould Interface During FloweidelsayedNo ratings yet

- Volchok 22Document4 pagesVolchok 22amitkkambleNo ratings yet

- Acom85 - 4 High Temperature Behaviour of The Austenitic SS UNS S30815 (253 MA) & Weldments PDFDocument16 pagesAcom85 - 4 High Temperature Behaviour of The Austenitic SS UNS S30815 (253 MA) & Weldments PDFpipedown456No ratings yet

- Effects of Tempering and PWHTDocument10 pagesEffects of Tempering and PWHTfaisalNo ratings yet

- Yang 2013Document10 pagesYang 2013mohamadNo ratings yet

- Creep and Life Assessment of Engineering Components in Power Plants and Process IndustriesDocument30 pagesCreep and Life Assessment of Engineering Components in Power Plants and Process IndustriesThomas TuckerNo ratings yet

- Material Science & EngineeringDocument27 pagesMaterial Science & EngineeringzulfikarNo ratings yet

- Roqtuf PDFDocument6 pagesRoqtuf PDFLeonidio CamposNo ratings yet

- Titipan ZahraDocument7 pagesTitipan ZahraDikaAfriandiNo ratings yet

- Evaluation of Creep Properties of Steel P92 and Its Welded JointDocument4 pagesEvaluation of Creep Properties of Steel P92 and Its Welded Jointmahmoud_allam3No ratings yet

- Brazing Allloy Cusil ABADocument12 pagesBrazing Allloy Cusil ABADheeraj SharmaNo ratings yet

- Intercritical Heat Treatment Effect PDFDocument6 pagesIntercritical Heat Treatment Effect PDFmuthu_g6942No ratings yet

- 1 Effect of The Intercritical Annealing Temperature On The Mechanical Properties of 10 PCT MN Multi-Phase Steel PDFDocument8 pages1 Effect of The Intercritical Annealing Temperature On The Mechanical Properties of 10 PCT MN Multi-Phase Steel PDFJulio Hernandez MartinezNo ratings yet

- A601010111 PDFDocument11 pagesA601010111 PDFMahmoud Ahmed AlyNo ratings yet

- A Finite Element Analysis For The Least Temperature Rise in A Hot Torsion Test SpecimenDocument14 pagesA Finite Element Analysis For The Least Temperature Rise in A Hot Torsion Test SpecimenkotakamalsNo ratings yet

- Physical and Numerical Modelling of Heat Treatment The Precipitation-Hardening Complex-Phase Steel (CP)Document4 pagesPhysical and Numerical Modelling of Heat Treatment The Precipitation-Hardening Complex-Phase Steel (CP)rodrigosiqueiraNo ratings yet

- Creep and Creep Damage Assessment in P91 Weld JointsDocument12 pagesCreep and Creep Damage Assessment in P91 Weld JointsDeepakNo ratings yet

- Carbon Content of Steel - ReportDocument13 pagesCarbon Content of Steel - ReportGurpreet KalsiNo ratings yet

- Analisis Por Elementos FinitosDocument6 pagesAnalisis Por Elementos FinitosEnriqueGDNo ratings yet

- Microstructural Characterization, Strengthening and Toughening Mechanisms of A Quenched and Tempered Steel Effect of Heat Treatment ParametersDocument22 pagesMicrostructural Characterization, Strengthening and Toughening Mechanisms of A Quenched and Tempered Steel Effect of Heat Treatment ParametersAlmerindo JuniorNo ratings yet

- OF UP: Apparatus For Measuring Thermal Conductivity Metals To 600 CDocument13 pagesOF UP: Apparatus For Measuring Thermal Conductivity Metals To 600 Cnova wahyuniNo ratings yet

- Metals 13 01301Document11 pagesMetals 13 01301iqbal haiderNo ratings yet

- Influence of Heat Treatment On Microstructure and Properties of Gx12Crmovnbn9-1 Cast SteelDocument6 pagesInfluence of Heat Treatment On Microstructure and Properties of Gx12Crmovnbn9-1 Cast SteelSankar GaneshNo ratings yet

- Thermit Welding of Chromium Vanadium RailsteelDocument8 pagesThermit Welding of Chromium Vanadium Railsteelsantu_23No ratings yet

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- Control and Analysis in Iron and SteelmakingFrom EverandControl and Analysis in Iron and SteelmakingRating: 3 out of 5 stars3/5 (2)

- Nace Ampp CP1 EpgDocument16 pagesNace Ampp CP1 EpgShanmuga Navaneethan0% (1)

- Valve ListDocument10 pagesValve ListShanmuga NavaneethanNo ratings yet

- Ut-Aws D1.5Document21 pagesUt-Aws D1.5Shanmuga NavaneethanNo ratings yet

- Material Grades ChartDocument2 pagesMaterial Grades ChartShanmuga NavaneethanNo ratings yet

- Personnel Qualification Record ListDocument1 pagePersonnel Qualification Record ListShanmuga NavaneethanNo ratings yet

- QC Observation of EPC ProjectsDocument1 pageQC Observation of EPC ProjectsShanmuga Navaneethan0% (1)

- Welding Master Piece Hand Written VishaljiDocument61 pagesWelding Master Piece Hand Written VishaljiShanmuga NavaneethanNo ratings yet

- Bgas Gr.2 CertificateDocument1 pageBgas Gr.2 CertificateShanmuga NavaneethanNo ratings yet

- Monthly Report FormatDocument47 pagesMonthly Report FormatShanmuga Navaneethan100% (1)

- Positive ParentingDocument31 pagesPositive ParentingShanmuga NavaneethanNo ratings yet

- Piping QC PocketBook Navaneethan SundaramDocument25 pagesPiping QC PocketBook Navaneethan SundaramShanmuga NavaneethanNo ratings yet

- NDT-Acceptance Various CodesDocument17 pagesNDT-Acceptance Various CodesShanmuga NavaneethanNo ratings yet

- RT-Procedure-Native File - For Easy Edit Urgent Doc Submission PurposeDocument19 pagesRT-Procedure-Native File - For Easy Edit Urgent Doc Submission PurposeShanmuga NavaneethanNo ratings yet

- Petronics - Musafah-AbudhabiDocument1 pagePetronics - Musafah-AbudhabiShanmuga NavaneethanNo ratings yet

- UT - L2 For L3 ExamDocument139 pagesUT - L2 For L3 ExamShanmuga Navaneethan0% (1)

- Asnt India Section Yearbook 2020Document37 pagesAsnt India Section Yearbook 2020Shanmuga NavaneethanNo ratings yet

- CSWIP TWI - Latest NotesDocument115 pagesCSWIP TWI - Latest NotesShanmuga Navaneethan100% (1)

- Cold Bending of 3LPP-Flowline PipesDocument2 pagesCold Bending of 3LPP-Flowline PipesShanmuga NavaneethanNo ratings yet

- Api 510 MCQDocument126 pagesApi 510 MCQShanmuga Navaneethan100% (1)

- NDE Personnel QualificationDocument316 pagesNDE Personnel QualificationShanmuga Navaneethan100% (1)

- Oil Debate Chromatography PPT 2Document17 pagesOil Debate Chromatography PPT 2Eridha TriwardhaniNo ratings yet

- Evjen PDFDocument5 pagesEvjen PDFTommyKMerinoAlamaNo ratings yet

- 2021 Ansys Upm Masters Degree CatalogueDocument50 pages2021 Ansys Upm Masters Degree CatalogueGiovanny GarcNo ratings yet

- Horror Movie Pitch Deck by SlidesgoDocument55 pagesHorror Movie Pitch Deck by SlidesgoAnh BùiNo ratings yet

- Grados de HPCDocument3 pagesGrados de HPCpops3No ratings yet

- 1005 Syn LabDocument7 pages1005 Syn LabMuhammad Ubaid Ur RehmanNo ratings yet

- The Laws of The Moon's Motion According To GravityDocument62 pagesThe Laws of The Moon's Motion According To GravityMay JdaNo ratings yet

- Geophysical InvestigationDocument20 pagesGeophysical InvestigationHrishikeshShahaneNo ratings yet

- Chapter 3 FinalDocument41 pagesChapter 3 FinalTamirat NemomsaNo ratings yet

- Tutorial Absorption 2022Document27 pagesTutorial Absorption 2022Mars Studio0% (1)

- Nanobiochar and Biochar Based NanocompositesDocument12 pagesNanobiochar and Biochar Based NanocompositesJaini FakhrudinNo ratings yet

- Modeling and Simulation of A Co-Current Rotary Dryer Under Steady ConditionsDocument8 pagesModeling and Simulation of A Co-Current Rotary Dryer Under Steady ConditionsVinh Do ThanhNo ratings yet

- Long Quiz.. Exogenic ProcessDocument3 pagesLong Quiz.. Exogenic ProcessSheryl Lou AngelesNo ratings yet

- A Review of Cement Testing Apparatus and Methods Under CO2 Environment and Their Impact On Well Integrity Prediction - Where Do We StandDocument24 pagesA Review of Cement Testing Apparatus and Methods Under CO2 Environment and Their Impact On Well Integrity Prediction - Where Do We StandXuning WuNo ratings yet

- Chapter 4 AXial Loading MemberDocument20 pagesChapter 4 AXial Loading Memberk.ghanemNo ratings yet

- Plasma Ball ActivityDocument1 pagePlasma Ball ActivitySoumajit SenNo ratings yet

- Physics: Cambridge International Examinations General Certificate of Education Ordinary LevelDocument8 pagesPhysics: Cambridge International Examinations General Certificate of Education Ordinary Levelmstudy123456No ratings yet

- Slide-7 MulurDocument40 pagesSlide-7 MulurAbrianto akuanNo ratings yet

- Raman Scattering 8. Raman ScatteringDocument35 pagesRaman Scattering 8. Raman ScatteringSankarNo ratings yet

- Review On Graphene and Its Derivatives Synthesis Methods and Potential Industrial ImplementationDocument18 pagesReview On Graphene and Its Derivatives Synthesis Methods and Potential Industrial ImplementationThúy DuyNo ratings yet

- Introduction To X Ray Diffraction PDFDocument21 pagesIntroduction To X Ray Diffraction PDFShahbaz AhmedNo ratings yet

- EMTL 250 Module 2 2017Document27 pagesEMTL 250 Module 2 2017Mwongera MwaraniaNo ratings yet

- Alloy Datasheet Guidebook 09 20181Document87 pagesAlloy Datasheet Guidebook 09 20181Shankar PediredlaNo ratings yet

- Silylation Overview FLUCADocument45 pagesSilylation Overview FLUCARosamaria Garcia HernandezNo ratings yet

- Electrochemical Biosensors: - Potentiometric Biosensors - Amperometric Biosensors - Impedimetric BiosensorsDocument18 pagesElectrochemical Biosensors: - Potentiometric Biosensors - Amperometric Biosensors - Impedimetric BiosensorsutkuyavuzNo ratings yet

- Targeted Drug Delivery SystemsDocument48 pagesTargeted Drug Delivery SystemsSasidhar Rlc100% (1)

- A New Theory For The Negative Difference Effect in Magnesium PDFDocument6 pagesA New Theory For The Negative Difference Effect in Magnesium PDFMd SyazwanNo ratings yet