Professional Documents

Culture Documents

CAGI Data Sheet - 2209 PDF

Uploaded by

Shiro EmiyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CAGI Data Sheet - 2209 PDF

Uploaded by

Shiro EmiyaCopyright:

Available Formats

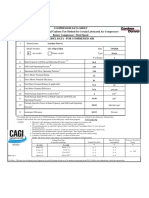

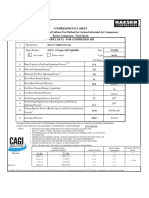

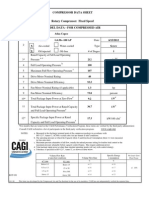

COMPRESSOR DATA SHEET

Rotary Compressor: Fixed Speed

MODEL DATA - FOR COMPRESSED AIR

1 Manufacturer: Sullair Corp

Model Number: 2209 Date: February 7, 2012

2 X Air-cooled Water-cooled Type: Screw

X Oil-injected Oil-free # of Stages: 1

a, e a,e

3* Rated Capacity at Full Load Operating Pressure 127 acfm

b b

4 Full Load Operating Pressure 125 psig

c c

5 Maximum Full Flow Operating Pressure 125 psig

6 Drive MotorNominal Rating 30 hp

7 Drive Motor Nominal Efficiency 94.1 percent

8 Fan Motor Nominal Rating (if applicable) 1 hp

9 Fan Motor Nominal Efficiency 85.5 percent

e e

10* Total Package Input Power at Zero Flow 8.3 kW

Total Package Input Power at Rated Capacity and

11 kWd

Full Load Operating Pressured 27.8

Specific Package Input Power at Rated Capacity and

12* e kW/100 cfme

Full Load Operating Pressure 21.9

*For models that are tested in the CAGI Performance Verification Program, these items are verified by the third party administrator.

Consult CAGI websitefor a list of participants in the third party verification program: www.cagi.org

NOTES: a. Measured at the discharge terminal point of the compressor package in accordance with

ISO 1217, Annex C; ACFM is actual cubic feet per minute at inlet conditions.

b. The operating pressure at which the Capacity (Item 3) and Electrical Consumption (Item 11) were measured

for this data sheet.

c. Maximum pressure attainable at full flow, usually the unload pressure setting for load/no load control or the

maximum pressure attainable before capacity control begins. May require additional power.

d. Total package input power at other than reported operating points will vary with control strategy.

e. Tolerance is specified in ISO 1217, Annex C, as shown in table below:

Volume Flow Rate Specific Energy

No Load / Zero Flow

at specified conditions Volume Flow Rate Consumption Power

m3 / min ft3 / min

% %

Below 0.5 +/- 7 +/- 8

Below 15

0.5 to 1.5 +/- 6 +/- 7 +/- 10%

15 to 50

1.5 to 15 +/- 5 +/- 6

50 to 500

Above 15 +/- 4 +/- 5

ROT 030 Above 500

5/11 R7 This form was developed by the Compressed Air and Gas Institute for the use of its members. CAGI has not independently verified the reported data.

You might also like

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Compressor Data Sheet: Chicago PneumaticDocument1 pageCompressor Data Sheet: Chicago PneumaticAlex Daniel Nepomuceno JorgeNo ratings yet

- Compressor Data Sheet Rotary Compressor: Fixed Speed: Gardner DenverDocument1 pageCompressor Data Sheet Rotary Compressor: Fixed Speed: Gardner DenverRamon SanhuezaNo ratings yet

- CAGI Rotdata ISO1217 Annex CDocument1 pageCAGI Rotdata ISO1217 Annex Csvengoto9No ratings yet

- Rotary Compressor Data Sheet with Key SpecsDocument1 pageRotary Compressor Data Sheet with Key SpecsSURYANo ratings yet

- Up6s 30 125Document1 pageUp6s 30 125Eddie SantillánNo ratings yet

- CAGI Data Sheet L250-340hp-125psi-Water 7-9-20Document1 pageCAGI Data Sheet L250-340hp-125psi-Water 7-9-20Heba MohamedNo ratings yet

- CAGI QRS 15 HP (125psi) tcm332 - 3524075 1272440482Document1 pageCAGI QRS 15 HP (125psi) tcm332 - 3524075 1272440482Alex Daniel Nepomuceno JorgeNo ratings yet

- ROTARY COMPRESSOR SPEC SHEETDocument1 pageROTARY COMPRESSOR SPEC SHEETahmad_394661978No ratings yet

- Rotary Compressor Fixed Speed Data SheetDocument1 pageRotary Compressor Fixed Speed Data SheetJohn TheodorouNo ratings yet

- CAGI Data Sheet L11-15hp-125psi-Air 7-9-20Document1 pageCAGI Data Sheet L11-15hp-125psi-Air 7-9-20Jorge Enrique Salas RoblesNo ratings yet

- Rs37i A200 PDFDocument1 pageRs37i A200 PDFMohammadAlAmeenNo ratings yet

- Cagi-000715 - 00 - ST709 AcDocument1 pageCagi-000715 - 00 - ST709 AcEloy Armando Rodriguez PazNo ratings yet

- CAGI RS37i-A125Document1 pageCAGI RS37i-A125Marco ChablaNo ratings yet

- RS37i A125Document1 pageRS37i A125Cay MartínezNo ratings yet

- SM 15-115-125-AC-460V-CAGI-Datasheet - 46-37534Document1 pageSM 15-115-125-AC-460V-CAGI-Datasheet - 46-37534rigoberto alvaNo ratings yet

- Up6 40 125Document1 pageUp6 40 125erickNo ratings yet

- RS11i A125Document1 pageRS11i A125rigoberto alvaNo ratings yet

- GA90-125 - 125 Psi 2020Document1 pageGA90-125 - 125 Psi 2020Eloy Armando Rodriguez PazNo ratings yet

- Up 6 50pe 125Document1 pageUp 6 50pe 125mahdiNo ratings yet

- Cagi Data Sheets 7509ps Ac 20080401Document1 pageCagi Data Sheets 7509ps Ac 20080401AllinUrbinaGoicocheaNo ratings yet

- Compressor data sheet details key specsDocument1 pageCompressor data sheet details key specsDiiani AmayaNo ratings yet

- GA 132 - 125psig (8.6bar) - Air CooledDocument1 pageGA 132 - 125psig (8.6bar) - Air CooledGleidson AnteroNo ratings yet

- Ga 250-125Document1 pageGa 250-125Gustavo RodriguesNo ratings yet

- Compressor data sheet released June 2020Document1 pageCompressor data sheet released June 2020Phil NorvalNo ratings yet

- SAV-500 125 Psi EAY DATA SHEET UnloadDocument1 pageSAV-500 125 Psi EAY DATA SHEET UnloadricardoNo ratings yet

- Compressor Data Sheet: Ingersoll Rand H100A - 125 PsigDocument1 pageCompressor Data Sheet: Ingersoll Rand H100A - 125 PsigAnonymous mZEUquNo ratings yet

- G160 - 145psig - Air CooledDocument1 pageG160 - 145psig - Air CooledВладислав СередаNo ratings yet

- ZR200-150 - 150 Psi - Water-CooledDocument1 pageZR200-150 - 150 Psi - Water-CooledVictor MonteNo ratings yet

- Rs160i A145Document1 pageRs160i A145gustavo rodriguesNo ratings yet

- BSD40 - 175 AC tcm9 21216Document1 pageBSD40 - 175 AC tcm9 21216ANDRESNo ratings yet

- Compressor Data Sheet Centrifugal Compressor: Model Data - For Compressed AirDocument1 pageCompressor Data Sheet Centrifugal Compressor: Model Data - For Compressed AiracildeNo ratings yet

- Model Data - For Compressed Air Atlas Copco Compressors, Inc GA 18 Pack 1Document1 pageModel Data - For Compressed Air Atlas Copco Compressors, Inc GA 18 Pack 1manuel solano gomezNo ratings yet

- Compresor Quincy QGV100Document1 pageCompresor Quincy QGV100Luis LoredoNo ratings yet

- Variable Frequency Drive Rotary Compressor Data SheetDocument1 pageVariable Frequency Drive Rotary Compressor Data SheetcmpuckNo ratings yet

- ALL AMN ALL en 1812 ALL Newsletter11 CAGIDatasheetDocument10 pagesALL AMN ALL en 1812 ALL Newsletter11 CAGIDatasheetCursed RonyNo ratings yet

- CAGI Data Sheet SAV-200hp-EAU-125psi-Water 6-26-20 PDFDocument1 pageCAGI Data Sheet SAV-200hp-EAU-125psi-Water 6-26-20 PDFCarlos MNo ratings yet

- Compressor Data Sheet: Atlas Copco GA45-125 APDocument1 pageCompressor Data Sheet: Atlas Copco GA45-125 APWaqar DarNo ratings yet

- S100-2 100psi 072011Document1 pageS100-2 100psi 072011Air Repair, LLCNo ratings yet

- GA200 Hybrid Air Cooled 150PSI 445Document2 pagesGA200 Hybrid Air Cooled 150PSI 445agus03leoNo ratings yet

- Epe500 2saDocument1 pageEpe500 2saMiguel Anibal Mejia BravoNo ratings yet

- SX7.5 160 AC 460V CAGI Datasheet tcm9 360810Document1 pageSX7.5 160 AC 460V CAGI Datasheet tcm9 360810Yasmine ياسمينNo ratings yet

- Compressor Data Sheet Rotary Compressor: Fixed Speed Model Data - For Compressed AirDocument1 pageCompressor Data Sheet Rotary Compressor: Fixed Speed Model Data - For Compressed AirchrsolvegNo ratings yet

- Rotary compressor data sheetDocument1 pageRotary compressor data sheetEnd SoonNo ratings yet

- 10 KVA Perkins Diesel Generator Set - Non EPA - 50Hz TP-P10-T1-50Document5 pages10 KVA Perkins Diesel Generator Set - Non EPA - 50Hz TP-P10-T1-50Daniel OkereNo ratings yet

- Compressor Data Sheet Rotary Compressor: Fixed Speed Model Data - For Compressed AirDocument1 pageCompressor Data Sheet Rotary Compressor: Fixed Speed Model Data - For Compressed AirlguzmandNo ratings yet

- Rotary Compressor Data SheetDocument1 pageRotary Compressor Data SheetByron PanchiNo ratings yet

- Hoja Cagi Ga 30-125 Psi Atlas CopcoDocument1 pageHoja Cagi Ga 30-125 Psi Atlas CopcoCarlos FerreraNo ratings yet

- G140X G140QXDocument7 pagesG140X G140QXKhawaja Kashif QadeerNo ratings yet

- Compressor Data Sheet Rotary Compressor: Fixed Speed Model Data - For Compressed AirDocument1 pageCompressor Data Sheet Rotary Compressor: Fixed Speed Model Data - For Compressed Airmarabest30% (1)

- Compressor Data Sheet: Atlas CopcoDocument1 pageCompressor Data Sheet: Atlas CopcoherrerafaridNo ratings yet

- CT155-CT170S (50 HZ)Document3 pagesCT155-CT170S (50 HZ)NADER KAMELNo ratings yet

- Compressor Data Sheet Federal Uniform Test Method For Certain Air Compressors Not ApplicableDocument1 pageCompressor Data Sheet Federal Uniform Test Method For Certain Air Compressors Not ApplicablehansNo ratings yet

- KP-F D XXGV OperationManual EDocument7 pagesKP-F D XXGV OperationManual EabathunNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Capek Characteristic ModesDocument82 pagesCapek Characteristic ModesAnthony NguyenNo ratings yet

- POD Tutorial: Proper Orthogonal Decomposition ExplainedDocument22 pagesPOD Tutorial: Proper Orthogonal Decomposition ExplainedAfiorNo ratings yet

- IXL - British Columbia Grade 9 Math CurriculumDocument5 pagesIXL - British Columbia Grade 9 Math Curriculumpkgarg_iitkgpNo ratings yet

- Cross Laminated TimberDocument32 pagesCross Laminated TimberRobertŠargačNo ratings yet

- Spe - 57313 Gas Lift Optimization Efforts and ChallengesDocument9 pagesSpe - 57313 Gas Lift Optimization Efforts and ChallengesAldo EstebanNo ratings yet

- MIND SM en Servicemanual VS800 h39439-31 enDocument70 pagesMIND SM en Servicemanual VS800 h39439-31 enashfaqNo ratings yet

- Examples Bolted ConnectionsDocument16 pagesExamples Bolted Connectionsaisha nakato100% (2)

- CVH 99Document294 pagesCVH 99Halil AKSUNo ratings yet

- Hypothermia & HyperthermiaDocument21 pagesHypothermia & HyperthermiaIRENE MAE SAN JUANNo ratings yet

- Since 1940: General CatalogDocument32 pagesSince 1940: General CatalogFernanda ContursiNo ratings yet

- Column Design With P-DeltaDocument2 pagesColumn Design With P-DeltaAKSNo ratings yet

- Origin&Evolution of MagmasDocument47 pagesOrigin&Evolution of MagmasVictor V IeNo ratings yet

- Nasa PI Day ProblemsDocument21 pagesNasa PI Day ProblemsLKKNo ratings yet

- Percentage CalculatorDocument4 pagesPercentage Calculatorapi-162641823No ratings yet

- 2.1 Perimeter Varios Shapes Measure and Calculate Activity Sheet 2Document12 pages2.1 Perimeter Varios Shapes Measure and Calculate Activity Sheet 2Aarti PadiaNo ratings yet

- Casting Brochure 0Document12 pagesCasting Brochure 0makdangNo ratings yet

- Newton's Second Law of Motion: The Atwood MachineDocument4 pagesNewton's Second Law of Motion: The Atwood MachineEarl Mathew DangcalanNo ratings yet

- GSI Brief HisDocument73 pagesGSI Brief HisSimhachalam TerliNo ratings yet

- Is 1904 1986Document24 pagesIs 1904 1986mttaibNo ratings yet

- 2 66kV Isolator R3 Jan13Document33 pages2 66kV Isolator R3 Jan13akhilesh205No ratings yet

- Refinery Process Design Notes - For IITGDocument193 pagesRefinery Process Design Notes - For IITGLakshmi Devineni100% (3)

- WWW Cuemath Com Distance FormulaDocument8 pagesWWW Cuemath Com Distance FormulaᏗᏕᎥᎷ ᏗᏝᎥNo ratings yet

- Control SystemsDocument161 pagesControl SystemsDr. Gollapalli NareshNo ratings yet

- Sa121 128Document2 pagesSa121 128Abhijit KerkarNo ratings yet

- HelicalDocument8 pagesHelicalAnamiya BhattacharyaNo ratings yet

- Chapter 5 - ProbabilityDocument97 pagesChapter 5 - ProbabilityPoison IveeNo ratings yet

- 258 PDFDocument47 pages258 PDFMichelle ArredondoNo ratings yet

- Load Cell Controller (Sh-1000b Manual (En) )Document25 pagesLoad Cell Controller (Sh-1000b Manual (En) )김성화No ratings yet

- Sample of Research ReportDocument6 pagesSample of Research Reportapi-314423329No ratings yet

- Pune Institute of Computer Technology: Subject: Fiber Optic CommunicationDocument68 pagesPune Institute of Computer Technology: Subject: Fiber Optic CommunicationHarshal JadhavNo ratings yet