Professional Documents

Culture Documents

Use of Plastic in A Concrete To Improve Its Properties: Research Paper

Use of Plastic in A Concrete To Improve Its Properties: Research Paper

Uploaded by

Dipali Dewangan0 ratings0% found this document useful (0 votes)

14 views3 pagesOriginal Title

137.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views3 pagesUse of Plastic in A Concrete To Improve Its Properties: Research Paper

Use of Plastic in A Concrete To Improve Its Properties: Research Paper

Uploaded by

Dipali DewanganCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

International Journal of Advanced Engineering Research and Studies E-ISSN2249–8974

Research Paper

USE OF PLASTIC IN A CONCRETE TO IMPROVE ITS

PROPERTIES

Raghatate Atul M.

Address for Correspondence

A.S. Polytechnic, Pipri Dist: Wardha, Maharashtra- 442001, India

ABSTRACT

Plastic bags which are commonly used for packing, carrying vegetables, meat etc creates a serious environmental problem.

Plastic bag last in environment up to 1000 years because of plastic bag last so long the number of plastic bag accumulated

increases each year. Disposal of large quantity of plastic bag may cause pollution of land, water bodies and air.

The proposed concrete which is made up by adding plastic in concrete may help to reuse the plastic bag as one of the

constituent’s material of concrete, to improve the certain properties of concrete. The properties of concrete containing

varying percentages of plastic were tested for compressive strength and Split tensile strength and shows that an appreciable

improvement in tensile strength of concrete can be achieved by introducing cut pieces of plastic bags.

KEYWORDS: Compressive Strength Split Tensile Strength, Plastic Bag, And Environmental Problems.

INTRODUCTION Cement used for the test was ordinary Portland

Generation of plastic waste is one of the fastest cement of 43 grade confirming to IS 8112- 1989.

growing areas. Every year more than 500 billion Various test were carried out, result of which shown

plastic bags are used (nearly one million bag per in Table.1.0

minute). Hundreds of thousands of sea turtles, whales Fine Aggregate

and other marine mammals die every year from Natural river sand was used as fine aggregate. The

eating discarded plastic bag for mistaken food. On properties of sand were determined by conducting

land many animals suffer from similar fate to marine tests as per IS2386 (Part- I). The results are shown in

life. Collection, hauling ad disposal of plastic bag Table.1.2

waste creates an additional environmental impact. In Coarse aggregate

a landfill or in environment, Plastic bags take up to Crushed granite stones obtained from local quarries

1000 year to degrade. were used as a coarse aggregate. The maximum size

Many researches were conducted to use industry by of coarse aggregate used was 20 mm. The properties

products such as fly ash, silica of concrete. of aggregate were determined by conducting test as

R.Lakshmi and S. Nagan suggested the use of E- per IS: 2386 (Part – III). The results are tabulated in

Plastic particles along with fly ash to improve the Table.1.3

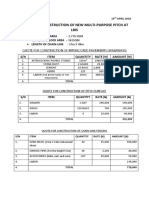

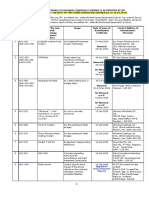

properties of concrete. Dr. M. Shivraja used the coir Table 1.2: Properties of Fine Aggregate

fibers as concrete composites for disaster prone

structures. Flume, glass cullet, coir fibers, e-plastic

waste in concrete to improve the properties

RESEARCH SIGNIFICANCE

Plastic bags which are used for carrying goods

become a waste after use and create environmental Table 1.3: Properties of Coarse Aggregate

problems. Large amount of plastic waste produced

every year. Recycle and reused of plastic require vast

manpower and processing cost thus the very small

amount of plastic recycled and reused and rest going

into landfills, incinerators and dumps.

Here author suggested the use of these plastic bags

pieces in a concrete as a plastic fiber to improve the

properties of concrete. Use of plastic has a dual Water

advantage cost of material is low also it solve the Portable water free from impurities and salt used for

problem of disposal of plastic up to some extent. casting and curing the concrete blocks as per IS –

MATERIALS 456-2000.

Cement Plastic

Table 1.1: Properties of Cement Pieces Polyethylene bag shown in fig.1.1, which are

commonly used for the packaging and carrying goods

are used in concrete

Fig. 1.1: Polyethylene bags

Concrete Mixes

Control mix concrete and modified concrete with

varying percentages of pieces of waste plastic bags

were presented in Table. All the mixes prepared are

IJAERS/Vol. I/ Issue III/April-June, 2012/109-111

International Journal of Advanced Engineering Research and Studies E-ISSN2249–8974

according to M 20 grade of concrete with w/c ratio

0.45.

Fig.1.2:Concrete blocks with plastic pieces

Compressive Strength Test Fig.1.4: Variation of 28 days compressive strength

Compressive strength test were carried out on 150 with various percentage of plastic

mm X 150 mm X 150 mm specimen for that three

cube were prepared for each mix. Strength of each

cube was evaluated after 3, 7 and 28 days

respectively. Test was carried out as per IS 14858:

2000. Result of compressive strength test was

presented in Table.1.4

Fig.1.5: Variation of tensile strength

Split Tensile Strength

Tensile strength is one of the basic and important

properties of concrete. Concrete is very good in

compression but weak in tension and this is one of

the drawbacks of concrete. Split tensile strength test

were carried out on a cylindrical specimen 150 mm in

mm in diameter and 300 m long. Specimen shall be

tested after 3, 7, and 28 days respectively. Result of

split tensile test was presented in Table.1.5

Fig.1.6: Variation of 28 days tensile strength with

various percentage of plastic

CONCLUSION

Based on the Experimental result following points are

summarized with regard to effect of plastic on the

properties of concrete

• Compressive strength of concrete is affected

RESULT AND DISCUSSION by addition of plastic pieces and it goes on

Compressive Strength decreasing as the percentage of plastic

The 3 days, 7 days and 28 days compressive strength increases addition of 1 % of plastic in

result were presented in Table.1.4.As shown in fig concrete causes about 20% reduction in

1.3 & fig 1.4 the compressive strength of concrete strength after 28 days curing.

goes on reducing with increase in percentage of • The splitting tensile strength obserarvation

plastic pieces but the rate of reducing compressive shows the improvement of tensile strength

strength is very low. of concrete. Up to 0.8 % of plastic

This reduction in strength is may be due reduction in improvement of strength recorded after that

bonding due introduction of plastic pieces. addition of strength of concrete decreases

Tensile Strength with addition of plastic.

Result of Split tensile strength after 3 days, 7 days,

• Thus it is conclude that the use plastic can

and 28 days were presented in

be possible to increase the tensile strength of

Table.1.5.Improvement in splitting tensile strength

concrete.

after addition of plastic pieces in concrete was

• From the above discussion it is identified

observed which show in graph

that the use of plastic can be possible to

improve the properties of concrete which

can act as a one of the plastic disposal

method.

REFERENCES

1. R.Lakshmi, S. Nagan, “Utilization of waste E plastic

particles in cementitious mixtures” Journal of Structural

Engineering,Vol.38, No. 1, April – May 2011, pp. 26-

35

2. P.Muthupriya, K. Subramanian, B.G. Vishuram,

“Experimental investigation on high performance

reinforced concrete column with silica fume and fly ash

as admixtures” Journal of Structural

Fig.1.3: Variation of compressive strength

IJAERS/Vol. I/ Issue III/April-June, 2012/109-111

International Journal of Advanced Engineering Research and Studies E-ISSN2249–8974

Engineering,Vol.38, No. 1, April – May 2011, pp. 46-

59

3. Dr. M. Sivaraja “Application of coir fibers as concrete

composites for disaster prone structures” submitted to

Central Institute of Coir Technology.

IJAERS/Vol. I/ Issue III/April-June, 2012/109-111

You might also like

- Experimental Investigation On Waste-Plastic Reinforced Concrete BrickDocument5 pagesExperimental Investigation On Waste-Plastic Reinforced Concrete BrickInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Polyethylene Terephthalate (PET) WasteDocument5 pagesPolyethylene Terephthalate (PET) WasteleniucvasileNo ratings yet

- Trmaxx Series Safety Valves PDFDocument2 pagesTrmaxx Series Safety Valves PDFArturo Treviño MedinaNo ratings yet

- Minor Project Synopsis Civil FinalDocument9 pagesMinor Project Synopsis Civil FinalAceNo ratings yet

- Use of Plastic Waste in Bituminous Road ConstructionDocument5 pagesUse of Plastic Waste in Bituminous Road ConstructionIJSTE100% (1)

- A Review Paper On Replacement of Fine AggregateDocument5 pagesA Review Paper On Replacement of Fine AggregateIJRASETPublicationsNo ratings yet

- BQ Steel Bridge Revision 4Document9 pagesBQ Steel Bridge Revision 4Anonymous UUw70xirblNo ratings yet

- Waste PlasticDocument18 pagesWaste PlasticAshwath100% (1)

- Experimental Study On Strength Behaviour of Plastic Sand BricksDocument4 pagesExperimental Study On Strength Behaviour of Plastic Sand Brickstesfalem kiros100% (1)

- Plastic Mixed Reinforced ConcreteDocument10 pagesPlastic Mixed Reinforced ConcreteUmange RanasingheNo ratings yet

- Study of Strength Property of Concrete Using Waste Plastics and Steel FiberDocument3 pagesStudy of Strength Property of Concrete Using Waste Plastics and Steel FibertheijesNo ratings yet

- Article 1Document11 pagesArticle 1Vinod KanapathyNo ratings yet

- My Final ReportDocument20 pagesMy Final Reportg.amruthaNo ratings yet

- Evaluation_of_Stabilized_Soil_Blocks_with_the_inclusion_of_Plastic_Fibre_as_Sustainable_Building_MaterialDocument6 pagesEvaluation_of_Stabilized_Soil_Blocks_with_the_inclusion_of_Plastic_Fibre_as_Sustainable_Building_Materialolivierm197No ratings yet

- Experimental Investigation On The Properties of Concrete Containing Post-Consumer Plastic Waste As Coarse Aggregate ReplacementDocument9 pagesExperimental Investigation On The Properties of Concrete Containing Post-Consumer Plastic Waste As Coarse Aggregate ReplacementZasiah TafheemNo ratings yet

- Bricks 41-June-798Document8 pagesBricks 41-June-798Noel100% (1)

- An Experimental Study On Waste Plastic Aggregate Based Concrete - An Initiative Towards Cleaner EnvironmentDocument5 pagesAn Experimental Study On Waste Plastic Aggregate Based Concrete - An Initiative Towards Cleaner Environmentshalom napoleonNo ratings yet

- Experimental Investigation of Waste Plastic Fiber in Reinforced Cement Concrete Using Recycled Coarse AggregateDocument12 pagesExperimental Investigation of Waste Plastic Fiber in Reinforced Cement Concrete Using Recycled Coarse AggregateInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Recycled Plastic Used in Concrete Paver BlockDocument3 pagesRecycled Plastic Used in Concrete Paver BlockInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Utilization of Waste Polythene As Low Cost and Eco-Friendly Material in PPC ConcreteDocument5 pagesUtilization of Waste Polythene As Low Cost and Eco-Friendly Material in PPC ConcreteEditor IJTSRDNo ratings yet

- ProjectDocument22 pagesProjectSrikanth S SanamoNo ratings yet

- Strength DurabilityDocument6 pagesStrength Durability19TUCV038 SHUHAIL AKTHAR.ANo ratings yet

- Penetration DecreaseDocument5 pagesPenetration DecreaseBeatrice KunguNo ratings yet

- Pet Fiber Reinforced ConcreteDocument5 pagesPet Fiber Reinforced ConcreteJames HermoNo ratings yet

- Thesis ProposalDocument7 pagesThesis ProposalMEHIDE HASANNo ratings yet

- Experimental Investigation On Reinforced Concrete With Plastic FiberDocument6 pagesExperimental Investigation On Reinforced Concrete With Plastic FiberIJRASETPublicationsNo ratings yet

- Experimental Study On Concrete Using Glass Powder and Granite PowderDocument5 pagesExperimental Study On Concrete Using Glass Powder and Granite PowderijaertNo ratings yet

- WPFRC 7Document13 pagesWPFRC 7Tesema LegeseNo ratings yet

- Concrete With Recycled Plastic WasteDocument11 pagesConcrete With Recycled Plastic WasteWilliam RuizNo ratings yet

- 321-Article Text-520-1-10-20190425Document12 pages321-Article Text-520-1-10-20190425Ahmed khushalNo ratings yet

- Effect of Addition of Polymer On The Properties of Waste Plastic Fibre Reinforced Concrete-An Experimental InvestigationDocument9 pagesEffect of Addition of Polymer On The Properties of Waste Plastic Fibre Reinforced Concrete-An Experimental InvestigationIJMERNo ratings yet

- Partial Replacement of Coarse Aggregates by ExpandedDocument4 pagesPartial Replacement of Coarse Aggregates by ExpandedInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Category.:-: Company Name.:-. Problem Code.:-. Team Leader Name:-. College Code.Document7 pagesCategory.:-: Company Name.:-. Problem Code.:-. Team Leader Name:-. College Code.Karthepan visionsNo ratings yet

- Utilization of E - Waste and Plastic Bottle Waste-LibreDocument9 pagesUtilization of E - Waste and Plastic Bottle Waste-LibreDorin OgradăNo ratings yet

- An Overview On Characteristic Strength of Concrete by Using Plastic FibreDocument6 pagesAn Overview On Characteristic Strength of Concrete by Using Plastic FibreIJRASETPublicationsNo ratings yet

- Shear Strength Improvementof Black Cotton Soil Reinforcedwith Waste Plastic Bottle StripsDocument15 pagesShear Strength Improvementof Black Cotton Soil Reinforcedwith Waste Plastic Bottle StripsLaura MuñozNo ratings yet

- Report Black BookDocument54 pagesReport Black BookSanket ChaudhariNo ratings yet

- Properties of Hardened Concrete Bricks Containing Expanded Polystyrene BeadsDocument9 pagesProperties of Hardened Concrete Bricks Containing Expanded Polystyrene BeadsrabikantNo ratings yet

- Proposal CorrectionDocument14 pagesProposal CorrectionjanithaNo ratings yet

- Performance of Partially Replaced Plastic Bottoles (Pet) As Coarse Aggregate in Producing ConcreteDocument10 pagesPerformance of Partially Replaced Plastic Bottoles (Pet) As Coarse Aggregate in Producing ConcreteShakil Bin AzizNo ratings yet

- Strength and Durability Properties of Plastic - Formatted PaperDocument6 pagesStrength and Durability Properties of Plastic - Formatted Papershalom napoleonNo ratings yet

- Utilization of Waste Plastics As A Fiber in Concrete: January 2017Document6 pagesUtilization of Waste Plastics As A Fiber in Concrete: January 2017Excel MigsNo ratings yet

- 1 PBDocument7 pages1 PBTondiNo ratings yet

- Ijaiem 2015 05 15 28 PDFDocument9 pagesIjaiem 2015 05 15 28 PDFASSISTANT ENGINEER HQNo ratings yet

- Experimental Study On Flexural and Impact Behavior of Ferrocement SlabsDocument11 pagesExperimental Study On Flexural and Impact Behavior of Ferrocement SlabsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Properties of Self-Compacting Lightweight Concrete Containing Recycled PDFDocument10 pagesProperties of Self-Compacting Lightweight Concrete Containing Recycled PDFAniel DiasNo ratings yet

- 11 X October 2023Document35 pages11 X October 2023Sohail ShaikhNo ratings yet

- Studies On The Improvement of Characteristics of Bitumen With Use of Waste PlasticDocument6 pagesStudies On The Improvement of Characteristics of Bitumen With Use of Waste PlasticAnurag TiwariNo ratings yet

- Structural Characteristics of Concrete Produced With Coal Ash and Jute Fibre For Sustainable EngineeringDocument9 pagesStructural Characteristics of Concrete Produced With Coal Ash and Jute Fibre For Sustainable EngineeringEmmanuel OgunjioforNo ratings yet

- Green Concrete Using Plastic Waste1Document3 pagesGreen Concrete Using Plastic Waste1sugunavidiyadar100% (1)

- Experimental Study On Paver Blocks Utilize in Pet FibresDocument7 pagesExperimental Study On Paver Blocks Utilize in Pet FibresijaertNo ratings yet

- Pengaruh Penggunaan Botol Plastik Polyethylene Terephthalate (Pet) Sebagai Tambahan Serat Terhadap Kekuatan BetonDocument8 pagesPengaruh Penggunaan Botol Plastik Polyethylene Terephthalate (Pet) Sebagai Tambahan Serat Terhadap Kekuatan BetonSafii NurtNo ratings yet

- Effect of PET Bottle Pieces and Waste Wrapper Fibe PDFDocument8 pagesEffect of PET Bottle Pieces and Waste Wrapper Fibe PDFjuan paulo tenias domenechNo ratings yet

- Study On Experimental Behavior of Plastic Based Fiber As Secondary Reinforcement in Concrete PavementDocument13 pagesStudy On Experimental Behavior of Plastic Based Fiber As Secondary Reinforcement in Concrete PavementIJRASETPublicationsNo ratings yet

- To Investigate The Mechanical Properties of Concrete by Partial Replacement of Cement With Ceramic Tiles Waste Powder and Addition of Jute FiberDocument10 pagesTo Investigate The Mechanical Properties of Concrete by Partial Replacement of Cement With Ceramic Tiles Waste Powder and Addition of Jute FiberIJRASETPublicationsNo ratings yet

- Waste Plastic Bags For Cheap Houses Mixed Concrete Solutions (Limbah Kantong Plastik Untuk Campuran Beton Solusi Rumah Murah)Document10 pagesWaste Plastic Bags For Cheap Houses Mixed Concrete Solutions (Limbah Kantong Plastik Untuk Campuran Beton Solusi Rumah Murah)salehunesNo ratings yet

- 17 1 31 1 10 20170503 PDFDocument10 pages17 1 31 1 10 20170503 PDFJhijin Zhee Namja HaengbokhaeyoNo ratings yet

- An Experimental Study On Strength Behaviour of Cement Concrete With Use of Plastic FibreDocument6 pagesAn Experimental Study On Strength Behaviour of Cement Concrete With Use of Plastic FibreJefrey PeraltaNo ratings yet

- Use of Waste Plastic in Concrete Mixture As Aggregate ReplacementDocument4 pagesUse of Waste Plastic in Concrete Mixture As Aggregate ReplacementIJAERS JOURNALNo ratings yet

- Experimental Study On Concrete With Plastic Waste and Master GeliniumDocument9 pagesExperimental Study On Concrete With Plastic Waste and Master GeliniumInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Influence of Continuous Plastic Fibers Reinforcement Arrangement in Concrete StrengthenedDocument9 pagesInfluence of Continuous Plastic Fibers Reinforcement Arrangement in Concrete StrengthenedIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- A1LDocument9 pagesA1LariyaNo ratings yet

- Concrete Strategy - Transgulf Readymix Concrete Company - Machinery, Plant - PMV Middle EastDocument18 pagesConcrete Strategy - Transgulf Readymix Concrete Company - Machinery, Plant - PMV Middle EastrbewalesNo ratings yet

- CENG7051 Column Modified 2016Document70 pagesCENG7051 Column Modified 2016abadittadesseNo ratings yet

- Quote For Construction of New Multi-Purpose Pitch at LbisDocument2 pagesQuote For Construction of New Multi-Purpose Pitch at LbisOLUMAYOWA OMOTOSONo ratings yet

- ASCE710W - Wind AnalysisDocument3 pagesASCE710W - Wind AnalysisJomo-Rhys GilmanNo ratings yet

- Chapter 1 - 31 - 40Document10 pagesChapter 1 - 31 - 40MOHD ZAINUDIN JENALNo ratings yet

- Geometry of FoundationsDocument27 pagesGeometry of Foundationsmunishant1No ratings yet

- ACP SuperCorDocument16 pagesACP SuperCorHaryo WidodoNo ratings yet

- 19ASC303A Assignment 7 PDFDocument3 pages19ASC303A Assignment 7 PDFRD412No ratings yet

- A7 Curing and Sealing Brochure B36Document6 pagesA7 Curing and Sealing Brochure B36Orisa IntanNo ratings yet

- A G Chehab PHD Thesis (Civil Engineering) PDFDocument265 pagesA G Chehab PHD Thesis (Civil Engineering) PDFURINo ratings yet

- AssefaKidan EthDocument113 pagesAssefaKidan Ethseret GideyNo ratings yet

- 159 Accrediated Expired As On 28042022Document15 pages159 Accrediated Expired As On 28042022Rushiraj PatelNo ratings yet

- Non-Destructive Testing: Characteristics and Comparison Between MethodsDocument12 pagesNon-Destructive Testing: Characteristics and Comparison Between MethodsdayalramNo ratings yet

- Geometric and Pavement Design of RaodwatDocument56 pagesGeometric and Pavement Design of RaodwatFelicien SinabubaragaNo ratings yet

- Man and Environment Relationship Case StudyDocument13 pagesMan and Environment Relationship Case StudyChinmay TirthakarNo ratings yet

- Ecox2: Recycled Impact Sound Reduction Underlayment For LVT Plank FlooringDocument1 pageEcox2: Recycled Impact Sound Reduction Underlayment For LVT Plank Flooringstefan cirlanaruNo ratings yet

- Postal Book Soil Engg.: Package Mechanics FoundationDocument12 pagesPostal Book Soil Engg.: Package Mechanics Foundation20je0565 Miran ShaikhNo ratings yet

- S.No. S1 S2 S3 Average Sand Particle Size (MM) Percentage of Mix (Plastic - Sand) Percentage of Coconut Fiber (%)Document2 pagesS.No. S1 S2 S3 Average Sand Particle Size (MM) Percentage of Mix (Plastic - Sand) Percentage of Coconut Fiber (%)Awais KhanNo ratings yet

- CT - Media - Kit - 2020 - Non Tenant RateDocument10 pagesCT - Media - Kit - 2020 - Non Tenant Ratereko_selengeNo ratings yet

- Design of Earthen and Concrete Gravity Dam at Dalhore, RawalpindiDocument96 pagesDesign of Earthen and Concrete Gravity Dam at Dalhore, RawalpindiKai Pascal AlibassaNo ratings yet

- Water Resources - Exam PackDocument27 pagesWater Resources - Exam Packdevanand.r.mahesh123No ratings yet

- Aerodynamic Optimisation On Building ShapesDocument17 pagesAerodynamic Optimisation On Building ShapesNijandhan Hari100% (3)

- Madrigal Business Park (Com-Unity)Document45 pagesMadrigal Business Park (Com-Unity)James Romulus 2113No ratings yet

- Control of Water Discharge and Level by SyphonsDocument10 pagesControl of Water Discharge and Level by SyphonsSujeet KumarNo ratings yet

- Exp 3 WeirsDocument11 pagesExp 3 WeirsAshrafNamamuTeratas100% (1)

- 7 Atterberg LimitDocument41 pages7 Atterberg Limitkim suarezNo ratings yet

- Cantilever Beam Bending TestDocument12 pagesCantilever Beam Bending TestLogan Dabuma100% (1)