0% found this document useful (0 votes)

1K views29 pagesInjection Moulding Guide

This document provides information about injection molding, including:

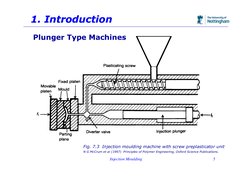

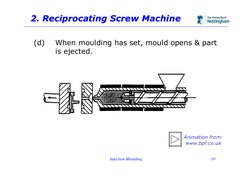

- The principles of injection molding involve melting a thermoplastic, forcing the melt into a closed mold, and allowing the component to cool before ejection.

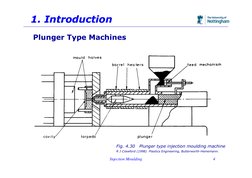

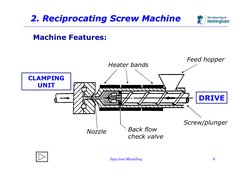

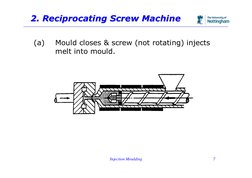

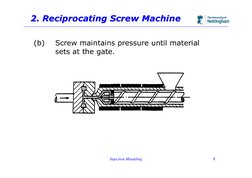

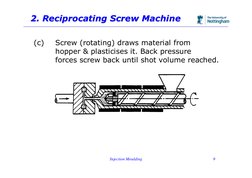

- Reciprocating screw machines are commonly used. They feature a screw and barrel to plasticize the material and an injection unit to force the melt into the mold.

- Proper mold design is important, with features like gates, vents, cooling channels, and appropriate dimensions to ensure proper filling and minimize defects.

- Calculations can provide estimates for the minimum injection pressure required to fill a part based on flow rate and geometry, as well as the clamping force needed to

Uploaded by

zulkefli-abdullah-8044Copyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views29 pagesInjection Moulding Guide

This document provides information about injection molding, including:

- The principles of injection molding involve melting a thermoplastic, forcing the melt into a closed mold, and allowing the component to cool before ejection.

- Reciprocating screw machines are commonly used. They feature a screw and barrel to plasticize the material and an injection unit to force the melt into the mold.

- Proper mold design is important, with features like gates, vents, cooling channels, and appropriate dimensions to ensure proper filling and minimize defects.

- Calculations can provide estimates for the minimum injection pressure required to fill a part based on flow rate and geometry, as well as the clamping force needed to

Uploaded by

zulkefli-abdullah-8044Copyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd