Professional Documents

Culture Documents

Bs EN 806

Uploaded by

Comofco GibraltarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bs EN 806

Uploaded by

Comofco GibraltarCopyright:

Available Formats

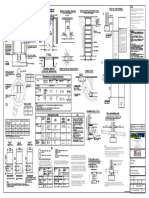

Drainage pumped system calculation - Option 1

Amount of wastewater to be pumped: 6,72 l/s

General data we can know are:

Geometrical height

Drive height: 9,22 metre.

Length of the pipe 22,29 metre.

internal pipe diameter: 80 mm.

Nº gate valves: 1

Nº valves: 1

Nº 90º elbows: 3

Sump pit calculation

Qp = 1,25 · Flow rate 8,4 l/s

Vp = 0,3 Qp (l/s) being Qp pump capacity (l/s)

Vp= 2,52 m³ = 2520 Litre

Note: Starting from the level that results between the ground level to the upper generatrix of

the pipe and adding the recommended levels, we obtain the height of the sump pit. With this

data we can only calculate the area of it, which results from the formula: litre / height of the

pit.

Sump pit area = litre/sump pit height

Pit heigth = 1,91 m

Pit area = 2,52 m² = Pit of 1,79 m of diameter

Sump pit characteristics

P´I : 0,91m

H= Hr+Pc

H: Manometric height (m)

Hr: Drive height

PI: 1 m Pc: Pressure loss (pipes, valves, elbows ...)

PI: Immersion depth (m)

Sump pit depth: 1,91m

Sump pit diameter: 1,80m

Calculation operations of the facility:

2. Pressure loss in Drive:

Pipe length: 22,29 metre

Singular losses: 10 metre (gate valve)

10 metre (valve)

15 metre (3nº bends of 90 °)

Equivalent piping length: 57,29 metre

With this value you can get lost in mca across the board losses. That is, 6,72 l/s in a pipe of 80

mm. diameter corresponding to 2,62 metre per 100 linear metre of pipe of given

characteristics. Then, 2,62 x 57,29/100 = 1,50 m.c.a

Then:

Total head = Drive´s pressure loss + Drive heigth = 1.50 +

9,22 = 10,72 mca

The appropriate flow rate of the pump must be of 8,4 l/s and the pumping

impulse height must be at least of 10,72 m.c.a

You might also like

- ROEDIGER 2007 RoeVac Vacuum Sewer System PDF Presentation PDFDocument69 pagesROEDIGER 2007 RoeVac Vacuum Sewer System PDF Presentation PDFmanuelNo ratings yet

- HepworthDocument147 pagesHepworthldbautista2005No ratings yet

- Geberit Piping Systems Catalogue 2010/2011Document95 pagesGeberit Piping Systems Catalogue 2010/2011Catalin Frincu0% (1)

- ESP CAlDocument1 pageESP CAlMohammed Sayeem ShabuddinNo ratings yet

- Teh 1096 PDFDocument48 pagesTeh 1096 PDFIrfan AbbasiNo ratings yet

- Geberit TrapsDocument32 pagesGeberit TrapsCatalin FrincuNo ratings yet

- Swimming Pool Calculation-April 3Document1 pageSwimming Pool Calculation-April 3Efren CahatianNo ratings yet

- Scupper DrainDocument216 pagesScupper DrainMunzuara AktherNo ratings yet

- Thread Chart - BSPT + NPTDocument12 pagesThread Chart - BSPT + NPTMd EtNo ratings yet

- Geberit HDPE Piping Systems Catalogue 2011/2012Document83 pagesGeberit HDPE Piping Systems Catalogue 2011/2012IvanSmith100% (1)

- Flash Card - AspeDocument36 pagesFlash Card - Aspesunil_v5No ratings yet

- Pipe Sizing NomogramDocument1 pagePipe Sizing NomogramAleksandarSashaStankovichNo ratings yet

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesDocument42 pagesOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesayaNo ratings yet

- BS 1610Document2 pagesBS 1610Comofco GibraltarNo ratings yet

- BS 1610Document2 pagesBS 1610Comofco GibraltarNo ratings yet

- Geberit Sanitary Catalogue 2017 2018Document348 pagesGeberit Sanitary Catalogue 2017 2018Po MoNo ratings yet

- Albion Butterfly ValveDocument28 pagesAlbion Butterfly ValveZein MubarakNo ratings yet

- Brochure B1500 All Fire PumpsDocument4 pagesBrochure B1500 All Fire Pumpseng_elbarbaryNo ratings yet

- Anti Vortex Plate AssemblyDocument1 pageAnti Vortex Plate AssemblyQubit SizedNo ratings yet

- BORplus Product GuideDocument20 pagesBORplus Product GuideSarmad AftabNo ratings yet

- Geberit Drainage BrochureDocument6 pagesGeberit Drainage BrochureCzar LRNo ratings yet

- Sizing of InterceptorDocument11 pagesSizing of InterceptorLorence GabayanNo ratings yet

- Pool Calculation GuideDocument30 pagesPool Calculation Guideolomizana100% (2)

- SD Qatar Product CatalougeDocument36 pagesSD Qatar Product CatalougeRichard Beldua50% (2)

- Water Sizing Fixture Units WorksheetDocument13 pagesWater Sizing Fixture Units Worksheetike4546No ratings yet

- 3-Gaseous Systems Calculations.Document3 pages3-Gaseous Systems Calculations.AyaEzzNo ratings yet

- Prezentare CIBSE PT EN806Document56 pagesPrezentare CIBSE PT EN806danateoNo ratings yet

- Hepworth ProfileDocument19 pagesHepworth Profilediljamchris100% (1)

- Oil-Water Separator according to EN 858Document11 pagesOil-Water Separator according to EN 858Senghou MeasNo ratings yet

- Swimming PoolDocument13 pagesSwimming PoolM ANo ratings yet

- Geberit bs12056 Drainage Design Without CompromiseDocument64 pagesGeberit bs12056 Drainage Design Without CompromiseKushalKallychurnNo ratings yet

- AED Design Requirements - Jockey Pumps - Mar09Document5 pagesAED Design Requirements - Jockey Pumps - Mar09rogel_gana100% (1)

- Project Standard Specification: Jacuzzi 15491 - Page 1/5Document5 pagesProject Standard Specification: Jacuzzi 15491 - Page 1/5adel rihanaNo ratings yet

- Exhaust Fan SelectionDocument81 pagesExhaust Fan Selectionprabhuselva22100% (1)

- BS 5955-6Document21 pagesBS 5955-6Fenner ElectromechanicalNo ratings yet

- Parking Garage Ventlation1Document2 pagesParking Garage Ventlation1MOHAMED ELKHASHABNo ratings yet

- Unit 3-Fire Safety: Portable Fire Fighting Equipment - (Write Short Notes On Portable Equipment-2010)Document21 pagesUnit 3-Fire Safety: Portable Fire Fighting Equipment - (Write Short Notes On Portable Equipment-2010)Navya chowdaryNo ratings yet

- Wet Riser Stage 2 (Above)Document1 pageWet Riser Stage 2 (Above)ZamzuriNo ratings yet

- Technical Brochures AW HT 0031 0071 enDocument50 pagesTechnical Brochures AW HT 0031 0071 endouslasNo ratings yet

- Siphonic Roof Drainage Systems: Understanding PrimingDocument0 pagesSiphonic Roof Drainage Systems: Understanding PrimingDedy KristiantoNo ratings yet

- Upvc Catch Basin Submittal - CosmoplastDocument30 pagesUpvc Catch Basin Submittal - CosmoplastAburvaraj0% (1)

- N2 Generator CalculationDocument9 pagesN2 Generator CalculationBagus PrambudiNo ratings yet

- HVWS SystemDocument1 pageHVWS Systemabhinay02meNo ratings yet

- Catalogue: Made in GermanyDocument313 pagesCatalogue: Made in GermanytrofihomeNo ratings yet

- Tips on Water Storage and Pumps in Fountain Design Part 2Document2 pagesTips on Water Storage and Pumps in Fountain Design Part 2Anh Đức NguyễnNo ratings yet

- Case Study Siphonic Roof Drains MarshallDocument2 pagesCase Study Siphonic Roof Drains MarshalldanateoNo ratings yet

- PP Push-Fit Drainage Solutions Catalogue: "Superior German Quality"Document31 pagesPP Push-Fit Drainage Solutions Catalogue: "Superior German Quality"holoNo ratings yet

- Ato Abdulkader Residence Plumbing DesignDocument15 pagesAto Abdulkader Residence Plumbing Designdawitggg0% (1)

- (BS en 15239-2007) - Ventilation For Buildings. Energy Performance of Buildings. Guidelines For Inspection of Ventilation Systems.Document48 pages(BS en 15239-2007) - Ventilation For Buildings. Energy Performance of Buildings. Guidelines For Inspection of Ventilation Systems.january1969No ratings yet

- Lindab PascalDocument20 pagesLindab PascalruisengoNo ratings yet

- Hydraulic Calculation: Automatic Fire Sprinkler SystemDocument6 pagesHydraulic Calculation: Automatic Fire Sprinkler SystemJoeven JagocoyNo ratings yet

- Ventilation Design Guide for Electrical RoomsDocument8 pagesVentilation Design Guide for Electrical RoomsphilipyongNo ratings yet

- Fire Fighting Pumps: FeaturesDocument3 pagesFire Fighting Pumps: FeaturesReyza PrasetyoNo ratings yet

- NFPA 820 Wastewater Treatment Facility Area ClassificationsDocument36 pagesNFPA 820 Wastewater Treatment Facility Area ClassificationsKarim El ShamashergyNo ratings yet

- Chilled Water TreatmentDocument10 pagesChilled Water TreatmentacmvorgNo ratings yet

- Weil Pump Flow and Basin Sizing Calculator (EDocFind - Com)Document15 pagesWeil Pump Flow and Basin Sizing Calculator (EDocFind - Com)mohdnazirNo ratings yet

- Ms KRT 2553 804 10 14Document40 pagesMs KRT 2553 804 10 14sharandeep1112No ratings yet

- Fire DRY HydrantsDocument4 pagesFire DRY HydrantsAbdullah RamadanNo ratings yet

- Air Duct CalculatorDocument6 pagesAir Duct CalculatorrakeshamechNo ratings yet

- Flow Measurement through Venturi and Orifice MetersDocument5 pagesFlow Measurement through Venturi and Orifice MetersRaghavanNo ratings yet

- Experiment 2 - Estimating The Frictional Loss in A Pipe FlowDocument3 pagesExperiment 2 - Estimating The Frictional Loss in A Pipe Flowf20221047No ratings yet

- Title: Orificemeter AimDocument4 pagesTitle: Orificemeter AimPrashant GiriNo ratings yet

- Norma A.070 ComercioDocument2 pagesNorma A.070 ComercioComofco GibraltarNo ratings yet

- Domestic Water CalculationDocument8 pagesDomestic Water CalculationComofco GibraltarNo ratings yet

- 7.standard Specification For Bateries and ChargerDocument15 pages7.standard Specification For Bateries and ChargerComofco GibraltarNo ratings yet

- Manhole Type B and Inspection ChamberDocument1 pageManhole Type B and Inspection ChamberComofco GibraltarNo ratings yet

- Difusion AireDocument25 pagesDifusion AireComofco GibraltarNo ratings yet

- 1.specifications For Outdoor Oil Immersed TransformersDocument47 pages1.specifications For Outdoor Oil Immersed TransformersComofco GibraltarNo ratings yet

- Specification for Public Health InstallationDocument14 pagesSpecification for Public Health InstallationComofco GibraltarNo ratings yet

- HVAC Standard SpecDocument26 pagesHVAC Standard SpecComofco GibraltarNo ratings yet

- 6.standards Specifications For Power and Control CablesDocument18 pages6.standards Specifications For Power and Control CablesComofco GibraltarNo ratings yet

- Uk Building Regulations 2010 - Drainage & Disposal - BR - PDF - Ad - H - 2010Document64 pagesUk Building Regulations 2010 - Drainage & Disposal - BR - PDF - Ad - H - 2010Daniel KakuruNo ratings yet

- Standard Elec SpecDocument27 pagesStandard Elec SpecComofco GibraltarNo ratings yet

- Pressure Loss Air ConditioningDocument6 pagesPressure Loss Air ConditioningComofco GibraltarNo ratings yet

- En 1610Document2 pagesEn 1610Comofco GibraltarNo ratings yet

- Accoustic Perfomance and Pressure LossDocument4 pagesAccoustic Perfomance and Pressure LossComofco GibraltarNo ratings yet

- Uk Building Regulations 2010 - Drainage & Disposal - BR - PDF - Ad - H - 2010Document64 pagesUk Building Regulations 2010 - Drainage & Disposal - BR - PDF - Ad - H - 2010Daniel KakuruNo ratings yet

- Uk Building Regulations 2010 - Drainage & Disposal - BR - PDF - Ad - H - 2010Document64 pagesUk Building Regulations 2010 - Drainage & Disposal - BR - PDF - Ad - H - 2010Daniel KakuruNo ratings yet

- Uk Building Regulations 2010 - Drainage & Disposal - BR - PDF - Ad - H - 2010Document64 pagesUk Building Regulations 2010 - Drainage & Disposal - BR - PDF - Ad - H - 2010Daniel KakuruNo ratings yet

- BS 1610Document3 pagesBS 1610Comofco GibraltarNo ratings yet

- En 1610Document1 pageEn 1610Comofco GibraltarNo ratings yet

- BS 1610Document3 pagesBS 1610Comofco GibraltarNo ratings yet

- Uk Building Regulations 2010 - Drainage & Disposal - BR - PDF - Ad - H - 2010Document64 pagesUk Building Regulations 2010 - Drainage & Disposal - BR - PDF - Ad - H - 2010Daniel KakuruNo ratings yet