Professional Documents

Culture Documents

Manual Overlay Welding PDF

Manual Overlay Welding PDF

Uploaded by

sheikmoinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Overlay Welding PDF

Manual Overlay Welding PDF

Uploaded by

sheikmoinCopyright:

Available Formats

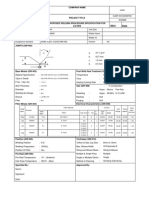

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

WPS No. OL-3 WPS Revision No. 0 PQR No. OL-3 PQR Revision No. 0

Application Corrosion-Resistant Overlay Service Sour Welding Material Inconel 625

BASE METAL FILLER METAL

P-No. 1 BM Thickness Range 6.0 mm - unlimited Spec. No. (SFA) A5.11

Material Specification A516, A283, A515, API 5L Gr. B, A36 AWS No. (Class.) ENiCrMo-3

(typical)

Size of Filler Metal 3.2

Other carbon steel

SAW Electrode-Flux (Class.) N/A

WELD METAL

Chem. Elem. Electrode / Flux Trade Name Inconel 112

0.15 max. C, 38 min. Ni, 12 min. Cr, 6 min. Mo, 40

max. Fe SAMS S/N 20-484-340

Deposit Thickness 1.6 mm minimum PREHEAT

Preheat Temp. 10 C

JOINT SKETCH

Interpass Temp. 177 C

POST WELD HEAT TREATMENT

weld overlay Temperature Range None

1 layer only Time Range N/A

30-50% bead overlap Heating Rate N/A

Cooling Rate N/A

POSITION

A Position All Welding Progression V-UP

GAS

Shielding Gas (Type) N/A

Flow Rate N/A

TECHNIQUE & ELECTRICAL CHARACTERISTICS

Tungsten Electrode Size and Type N/A Orifice or Gas Cup Size N/A

String or Weave Bead Stringer Multiple or Single Layer Single

Initial & Interpass cleaning (Brushing, Grinding, etc.) Brushing & Grinding

FILLER

LAYER PROCESS METAL SIZE POLARITY AMP VOLT TRAVEL SPEED SEQUENCE/COMMENTS

1 SMAW ENiCrMo-3 3.2 DCRP 65-90 22-26 use only 3.2 mm dia. electrode

SPECIFIC INSTRUCTIONS & DETAILS

1. Single layer only

2. For improved corrosion resistance, use procedure OL-4 (two layer technique).

Department Consulting Services Department Revision Date November 24, 1998

Approval Restrictions None

Copyright©Saudi Aramco 2009. All rights reserved.

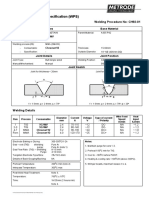

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

WPS No. OL-4 WPS Revision No. 0 PQR No. OL-4 PQR Revision No. 0

Application Corrosion-Resistant Overlay Service Sour Welding Material Inconel 625

BASE METAL FILLER METAL

P-No. 1 BM Thickness Range 6.0 mm - unlimited Spec. No. (SFA) A5.11

Material Specification A516, A283, A515, API 5L Gr. B, A36 AWS No. (Class.) ENiCrMo-3

(typical)

Size of Filler Metal 3.2

Other carbon steel

SAW Electrode-Flux (Class.) N/A

WELD METAL

Chem. Elem. Electrode / Flux Trade Name Inconel 112

0.10 max. C, 50 min. Ni, 17 min. Cr, 8 min. Mo, 20

max. Fe SAMS S/N 20-484-340

Deposit Thickness 3.0 mm minimum PREHEAT

Preheat Temp. 10 C

JOINT SKETCH

Interpass Temp. 177 C

POST WELD HEAT TREATMENT

weld overlay Temperature Range None

2 layers minimum Time Range N/A

30-50% bead overlap Heating Rate N/A

Cooling Rate N/A

POSITION

A

Position All Welding Progression V-UP

GAS

Shielding Gas (Type) N/A

Flow Rate N/A

TECHNIQUE & ELECTRICAL CHARACTERISTICS

Tungsten Electrode Size and Type N/A Orifice or Gas Cup Size N/A

String or Weave Bead Stringer Multiple or Single Layer Single

Initial & Interpass cleaning (Brushing, Grinding, etc.) Brushing & Grinding

FILLER

LAYER PROCESS METAL SIZE POLARITY AMP VOLT TRAVEL SPEED SEQUENCE/COMMENTS

1 SMAW ENiCrMo-3 3.2 DCRP 65-90 22-26 use only 3.2 mm dia. electrode

2 SMAW ENiCrMo-3 3.2 DCRP 65-90 22-26

SPECIFIC INSTRUCTIONS & DETAILS

Department Consulting Services Department Revision Date November 24, 1998

Approval Restrictions None

Copyright©Saudi Aramco 2009. All rights reserved.

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

WPS No. OL-6 WPS Revision No. 0 PQR No. OL-6 PQR Revision No. 0

Application Corrosion-Resistant Overlay Service Sour Welding Material 316L Stainless Steel

BASE METAL FILLER METAL

P-No. 1 BM Thickness Range 6.0mm-unlimited Spec. No. (SFA) A5.4

Material Specification A516, A283, A515, API 5L Gr. B, A36 AWS No. (Class.) E316L

(typical)

Size of Filler Metal 3.2

Other carbon steel

SAW Electrode-Flux (Class.) N/A

WELD METAL

Chem. Elem. Electrode / Flux Trade Name N/A

16 min. Cr, 10 min. Ni, 2 min. Mo

SAMS S/N 20-484-698

Deposit Thickness 3.0 mm minimum PREHEAT

Preheat Temp. 10 C

JOINT SKETCH

Interpass Temp. 177 C

POST WELD HEAT TREATMENT

weld overlay Temperature Range None

2 layers minimum Time Range N/A

30-50% bead overlap Heating Rate N/A

Cooling Rate N/A

POSITION

A

Position All Welding Progression V-UP

GAS

Shielding Gas (Type) N/A

Flow Rate N/A

TECHNIQUE & ELECTRICAL CHARACTERISTICS

Tungsten Electrode Size and Type N/A Orifice or Gas Cup Size N/A

String or Weave Bead Stringer Multiple or Single Layer Single

Initial & Interpass cleaning (Brushing, Grinding, etc.) Brushing & Grinding

FILLER

LAYER PROCESS METAL SIZE POLARITY AMP VOLT TRAVEL SPEED SEQUENCE/COMMENTS

1 SMAW E316L 3.2 DCRP 70-100 22-26 use only 3.2 mm dia. electrode

2 SMAW E316L 3.2 DCRP 70-100 22-26

SPECIFIC INSTRUCTIONS & DETAILS

Department Consulting Services Department Revision Date November 24, 1998

Approval Restrictions None

Copyright©Saudi Aramco 2009. All rights reserved.

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

WPS No. OL-8 WPS Revision No. 0 PQR No. OL-8 PQR Revision No. 0

Application Hardfacing Overlay Service Sour Welding Material Stellite 6

BASE METAL FILLER METAL

P-No. 8 BM Thickness Range 6.0-25.4mm Spec. No. (SFA) A5.13

Material Specification 304, 304L, 316, 316L stainless steel AWS No. (Class.) ECoCr-A

(typical)

Size of Filler Metal 3.2

Other

SAW Electrode-Flux (Class.) N/A

WELD METAL

Chem. Elem. Electrode / Flux Trade Name Stellite 6

0.7 min. C, 40 min. Co, 20 min. Cr, 3 min. W,

25 max. Fe, 3 max. Ni SAMS S/N 20-117-315

Deposit Thickness 1.6 mm minimum PREHEAT

Preheat Temp. 10 C

JOINT SKETCH

Interpass Temp. 250 C

POST WELD HEAT TREATMENT

weld overlay Temperature Range None

1 layer only Time Range N/A

30-50% bead overlap Heating Rate N/A

Cooling Rate N/A

POSITION

A Position All Welding Progression V-UP

GAS

Shielding Gas (Type) N/A

Flow Rate N/A

TECHNIQUE & ELECTRICAL CHARACTERISTICS

Tungsten Electrode Size and Type N/A Orifice or Gas Cup Size N/A

String or Weave Bead Stringer Multiple or Single Layer Single

Initial & Interpass cleaning (Brushing, Grinding, etc.) Brushing & Grinding

FILLER

LAYER PROCESS METAL SIZE POLARITY AMP VOLT TRAVEL SPEED SEQUENCE/COMMENTS

1 SMAW ECoCr-A 3.2 DCRP 90-130 22-26 use only 3.2 mm dia. electrode

SPECIFIC INSTRUCTIONS & DETAILS

Department Consulting Services Department Revision Date November 24, 1998

Approval Restrictions None

Copyright©Saudi Aramco 2009. All rights reserved.

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

WPS No. OL-9 WPS Revision No. 0 PQR No. OL-9 PQR Revision No. 0

Application Corrosion-Resistant Overlay Service Sour Welding Material 309 Stainless Steel

BASE METAL FILLER METAL

P-No. 1 BM Thickness Range 6.0 mm - unlimited Spec. No. (SFA) A5.4

Material Specification A516, A283, A515, API 5L Gr. B, A36 AWS No. (Class.) E309

(typical)

Size of Filler Metal 3.2

Other carbon steel

SAW Electrode-Flux (Class.) N/A

WELD METAL

Chem. Elem. Electrode / Flux Trade Name N/A

20 min. Cr, 11 min. Ni

SAMS S/N 20-485-410

Deposit Thickness 3.0 mm minimum PREHEAT

Preheat Temp. 10 C

JOINT SKETCH

Interpass Temp. 177 C

POST WELD HEAT TREATMENT

weld overlay Temperature Range None

2 layers minimum Time Range N/A

30-50% bead overlap Heating Rate N/A

Cooling Rate N/A

POSITION

A

Position All Welding Progression V-UP

GAS

Shielding Gas (Type) N/A

Flow Rate N/A

TECHNIQUE & ELECTRICAL CHARACTERISTICS

Tungsten Electrode Size and Type N/A Orifice or Gas Cup Size N/A

String or Weave Bead Stringer Multiple or Single Layer Single

Initial & Interpass cleaning (Brushing, Grinding, etc.) Brushing & Grinding

FILLER

LAYER PROCESS METAL SIZE POLARITY AMP VOLT TRAVEL SPEED SEQUENCE/COMMENTS

1 SMAW E309 3.2 DCRP 65-90 22-26 use only 3.2 mm dia. electrode

2 SMAW E309 3.2 DCRP 65-100 22-26

SPECIFIC INSTRUCTIONS & DETAILS

Department Consulting Services Department Revision Date November 24, 1998

Approval Restrictions None

Copyright©Saudi Aramco 2009. All rights reserved.

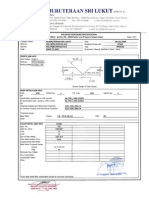

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

0 P1-9 0

WPS No. P1-BU1 WPS Revision No. PQR No. PQR Revision No.

Application Weld Build-Up Service Sour Welding Material E7018

BASE METAL FILLER METAL

P-No. 1 BM Thickness Range 4.8mm-203mm A5.1

Spec. No. (SFA)

A105, A350, A694, A707 L3 & L5, A216 WCB

Material Specification AWS No. (Class.) E7018

(typical)

Size of Filler Metal 3.2, 4.0

all carbon steel materials (garde B through X60)

Other

SAW Electrode-Flux (Class.) N/A

WELD METAL

Electrode / Flux Trade Name N/A

Chem. Elem. N/A

SAMS S/N 20-483-071/074

Deposit Thickness 203 mm maximum PREHEAT

Preheat Temp. 20 C if WT<25mm, 121 C if WT>25mm

JOINT SKETCH

Interpass Temp. 315 C

POST WELD HEAT TREATMENT

weld buildup Temperature Range None

1 or 2 layers (as required) Time Range N/A

grind smooth Heating Rate N/A

Cooling Rate N/A

POSITION

A Position All Welding Progression V-UP

GAS

Shielding Gas (Type) N/A

Flow Rate N/A

TECHNIQUE & ELECTRICAL CHARACTERISTICS

Tungsten Electrode Size and Type N/A Orifice or Gas Cup Size N/A

String or Weave Bead Stringer Multiple or Single Layer Single or multiple

Initial & Interpass cleaning (Brushing, Grinding, etc.) Brushing & Grinding

FILLER

LAYER PROCESS METAL SIZE POLARITY AMP VOLT TRAVEL SPEED SEQUENCE/COMMENTS

1, 2 SMAW E7018 3.2 DCRP 90-120 22-26

alt. SMAW E7018 4.0 DCRP 120-160 22-26

SPECIFIC INSTRUCTIONS & DETAILS

Grind flush and smooth with contour of the original surface.

Department Consulting Services Department Revision Date March 28, 2000

Approval Restrictions None

Copyright©Saudi Aramco 2009. All rights reserved.

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

0 P*04 0

WPS No. P8-BU1 WPS Revision No. PQR No. PQR Revision No.

Application Weld Build-Up Service Sour Welding Material 316L Stainless Steel

BASE METAL FILLER METAL

P-No. 8 BM Thickness Range 4.8mm-50.8mm A5.4

Spec. No. (SFA)

316, 316L Stainless Steel

Material Specification AWS No. (Class.) E316L

(typical)

Size of Filler Metal 3.2

Other

SAW Electrode-Flux (Class.) N/A

WELD METAL

Electrode / Flux Trade Name N/A

Chem. Elem. Cr 17% min, Ni 11% min.

SAMS S/N 20-484-698

Deposit Thickness 40 mm maximum PREHEAT

Preheat Temp. 20 C if WT<25mm, 121 C if WT>25mm

JOINT SKETCH

Interpass Temp. 315 C

POST WELD HEAT TREATMENT

weld buildup Temperature Range None

1 or 2 layers (as required) Time Range N/A

grind smooth Heating Rate N/A

Cooling Rate N/A

POSITION

A Position All Welding Progression V-UP

GAS

Shielding Gas (Type) N/A

Flow Rate N/A

TECHNIQUE & ELECTRICAL CHARACTERISTICS

Tungsten Electrode Size and Type N/A Orifice or Gas Cup Size N/A

String or Weave Bead Stringer Multiple or Single Layer Single or multiple

Initial & Interpass cleaning (Brushing, Grinding, etc.) Brushing & Grinding

FILLER

LAYER PROCESS METAL SIZE POLARITY AMP VOLT TRAVEL SPEED SEQUENCE/COMMENTS

1, 2 SMAW E8018-C1 3.2 DCRP 90-120 22-26

alt. SMAW E8018-C1 4.0 DCRP 120-160 22-26

SPECIFIC INSTRUCTIONS & DETAILS

Grind flush and smooth with contour of the original surface.

Department Consulting Services Department Revision Date February 23, 2000

Approval Restrictions None

Copyright©Saudi Aramco 2009. All rights reserved.

SAUDI ARAMCO

WELDING PROCEDURE SPECIFICATIONS

0 P1-21 0

WPS No. P1-BU2 WPS Revision No. PQR No. PQR Revision No.

Application Weld Build-Up Service Non-Sour Welding Material E8018-C1

BASE METAL FILLER METAL

P-No. 1 BM Thickness Range 4.8mm-203mm A5.5

Spec. No. (SFA)

A333 Gr 6, A537 Cl. 1 & 2

Material Specification AWS No. (Class.) E8018-C1

(typical)

Size of Filler Metal 3.2, 4.0

Other

SAW Electrode-Flux (Class.) N/A

WELD METAL

Electrode / Flux Trade Name N/A

Chem. Elem. N/A

SAMS S/N 20-483-541/543

Deposit Thickness 203 mm maximum PREHEAT

Preheat Temp. 20 C if WT<25mm, 121 C if WT>25mm

JOINT SKETCH

Interpass Temp. 315 C

POST WELD HEAT TREATMENT

weld buildup Temperature Range None

1 or 2 layers (as required) Time Range N/A

grind smooth Heating Rate N/A

Cooling Rate N/A

POSITION

A Position All Welding Progression V-UP

GAS

Shielding Gas (Type) N/A

Flow Rate N/A

TECHNIQUE & ELECTRICAL CHARACTERISTICS

Tungsten Electrode Size and Type N/A Orifice or Gas Cup Size N/A

String or Weave Bead Stringer Multiple or Single Layer Single or multiple

Initial & Interpass cleaning (Brushing, Grinding, etc.) Brushing & Grinding

FILLER

LAYER PROCESS METAL SIZE POLARITY AMP VOLT TRAVEL SPEED SEQUENCE/COMMENTS

1, 2 SMAW E8018-C1 3.2 DCRP 90-120 22-26

alt. SMAW E8018-C1 4.0 DCRP 120-160 22-26

SPECIFIC INSTRUCTIONS & DETAILS

Grind flush and smooth with contour of the original surface.

Department Consulting Services Department Revision Date March 28, 2000

Approval Restrictions None

Copyright©Saudi Aramco 2009. All rights reserved.

You might also like

- WQT ProcedureDocument28 pagesWQT ProcedureAnant Rubade100% (1)

- Repair Welding Temper BeadDocument9 pagesRepair Welding Temper BeadwilliamjdtNo ratings yet

- Weld Fit Up Inspection Employee TrainingDocument10 pagesWeld Fit Up Inspection Employee TrainingBadiuzzama Azmi100% (2)

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium Weldingvishal bailur50% (2)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- What Is Stellite SteelDocument11 pagesWhat Is Stellite SteelRathnakrajaNo ratings yet

- Metrode Welding Duplex & Superduplex Stainless SteelsDocument18 pagesMetrode Welding Duplex & Superduplex Stainless SteelsClaudia Mms50% (2)

- Asme Viii QC ManualDocument70 pagesAsme Viii QC Manualneurolepsia3790No ratings yet

- Manual Structural WeldingDocument12 pagesManual Structural WeldingwalitedisonNo ratings yet

- Hastelloy C-276 WeldingDocument4 pagesHastelloy C-276 WeldingClaudia MmsNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Temper Bead Welding WPS and PQRDocument27 pagesTemper Bead Welding WPS and PQRSandeep Parmar100% (3)

- Procedure For Post Weld Heat Treatment (PWHT PROCEDURE)Document10 pagesProcedure For Post Weld Heat Treatment (PWHT PROCEDURE)Senthil Kumaran100% (2)

- WPS-PQR (Er309l Mo)Document4 pagesWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Mock UP Procedure Rev ADocument6 pagesMock UP Procedure Rev AFauzan Rusmayadi Reharder100% (1)

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingaamirtec301100% (2)

- WPSDocument1 pageWPSNidhinkorothNo ratings yet

- Duplex Ss WPSDocument8 pagesDuplex Ss WPSVinu Raveendran100% (1)

- Welding Procedure Specification "WPS": O O O ODocument1 pageWelding Procedure Specification "WPS": O O O OAli MoosaviNo ratings yet

- WPS FormatDocument1 pageWPS FormatAbdullah AnsariNo ratings yet

- Post Weld Heat Treatment ProcedureDocument15 pagesPost Weld Heat Treatment ProcedureSamer Bayati100% (1)

- 202 1sp 0 Saw Cs CsDocument8 pages202 1sp 0 Saw Cs CskrishimaNo ratings yet

- Super Duplex Stainless SteelDocument1 pageSuper Duplex Stainless SteelUma Shankar100% (2)

- Weld Overlay Procedure For InconelDocument3 pagesWeld Overlay Procedure For InconelArash Mohamadi100% (3)

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- Multiple PQR QualificationDocument4 pagesMultiple PQR QualificationKarthikeyan ShanmugavelNo ratings yet

- Repair ProcedureDocument6 pagesRepair ProcedureTomy GeorgeNo ratings yet

- PQRDocument2 pagesPQRalokbdas100% (1)

- Material SelectionDocument58 pagesMaterial SelectionSivareddy InduriNo ratings yet

- Effect of Heat InputDocument9 pagesEffect of Heat InputshrikantajitNo ratings yet

- Pwps Asme Gtaw & SmawDocument2 pagesPwps Asme Gtaw & SmawMuhammad Fitransyah Syamsuar Putra100% (1)

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenNo ratings yet

- WpsDocument2 pagesWpssamer8saifNo ratings yet

- Corespondent A Standard e Material eDocument7 pagesCorespondent A Standard e Material eionijhonnieNo ratings yet

- PWHT ProcedureDocument11 pagesPWHT Proceduretbmari100% (15)

- P91 Repair With NiCrDocument76 pagesP91 Repair With NiCrElias KapaNo ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- Amigos Technical Services (S) Pte LTD Post Weld Heat Treatment ProcedureDocument12 pagesAmigos Technical Services (S) Pte LTD Post Weld Heat Treatment Procedurevsnaiduqc50% (2)

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- Hydro Test ProcedureDocument9 pagesHydro Test ProcedureAdeel QaiserNo ratings yet

- Repair and Buttering ProcedureDocument14 pagesRepair and Buttering Proceduremohd as shahiddin jafri100% (3)

- Welding Repair ProcedureDocument6 pagesWelding Repair ProcedureTrương Định50% (4)

- Scan Preheat and PWHT ProcedureDocument11 pagesScan Preheat and PWHT ProcedureGandhi Kusuma100% (1)

- ABS Acceptance of Filler Metals To AWSDocument2 pagesABS Acceptance of Filler Metals To AWSgeorgekc77No ratings yet

- DIN - ASME - STANDARD - HeadsDocument3 pagesDIN - ASME - STANDARD - HeadsHong Dae YoonNo ratings yet

- Weld OverlayDocument4 pagesWeld OverlayInfoNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- ASTM GradesDocument4 pagesASTM GradesSaurabh MundheNo ratings yet

- Wqt-Visual-Mag - BS 2Document24 pagesWqt-Visual-Mag - BS 2KyNo ratings yet

- PWHTDocument9 pagesPWHTshervinyNo ratings yet

- FCAW Overlay WPSDocument2 pagesFCAW Overlay WPSAsad Bin Ala Qatari100% (1)

- BS 970 En8dDocument1 pageBS 970 En8dsumeetsaini88No ratings yet

- 625 Overlay WeldingDocument9 pages625 Overlay Weldingdaviesgang360100% (2)

- Pipeline Weld Joint & Ragiograph Film Numbering SystemDocument9 pagesPipeline Weld Joint & Ragiograph Film Numbering Systemgst ajah100% (2)

- WPS & PQRDocument7 pagesWPS & PQRRanjan KumarNo ratings yet

- Astm 1018Document9 pagesAstm 1018Vyn VynNo ratings yet

- Wps PQR PDFDocument35 pagesWps PQR PDFquality unifab83% (6)

- Table K-1 Allowable Stresses in Tension For Metals For Chapter IXDocument2 pagesTable K-1 Allowable Stresses in Tension For Metals For Chapter IXricardoNo ratings yet

- A Comparison of ISO 15614 Part 1 and ASME IXDocument3 pagesA Comparison of ISO 15614 Part 1 and ASME IXsusanwebNo ratings yet

- Wps 316L Gtaw R00Document3 pagesWps 316L Gtaw R00Richard Periyanayagam100% (3)

- Wps FormatDocument12 pagesWps FormatGohilakrishnan ThiagarajanNo ratings yet

- KSL Wps PQR 012 DuplexDocument33 pagesKSL Wps PQR 012 DuplexJunaidi Minhat100% (6)

- Typical Material Specifications For Major Component PartsDocument9 pagesTypical Material Specifications For Major Component PartsSampath KumarNo ratings yet

- Oxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupsDocument6 pagesOxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupssanketNo ratings yet

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- PQR For 32 MM PlateDocument1 pagePQR For 32 MM PlateMuhammed MubeenNo ratings yet

- p22MNVMB MN Gtaw+Smaw (Pipe)Document2 pagesp22MNVMB MN Gtaw+Smaw (Pipe)abidaliabid1No ratings yet

- Fab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FSDocument2 pagesFab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FSabidaliabid1100% (1)

- SsDocument2 pagesSsy4nuarNo ratings yet

- Assembly2 Caster Complete 1Document1 pageAssembly2 Caster Complete 1lianaNo ratings yet

- Reducer M-F An912 - NPTDocument7 pagesReducer M-F An912 - NPTDaniel SantacruzNo ratings yet

- Aço China - Cross Reference SteelDocument12 pagesAço China - Cross Reference SteelPaulo BaltorNo ratings yet

- Section II Par T A Fer Rous Material Specifications Sa 451 To End 2019 Asme Boiler and Pressure Vessel Code An International Code PDF Free - 6Document1 pageSection II Par T A Fer Rous Material Specifications Sa 451 To End 2019 Asme Boiler and Pressure Vessel Code An International Code PDF Free - 6洛霖No ratings yet

- Astm B 30 06a Standard Specification For Copper Alloys in inDocument13 pagesAstm B 30 06a Standard Specification For Copper Alloys in inpablojorgesilvaNo ratings yet

- SS 304 6MMDocument1 pageSS 304 6MMRavi MehtaNo ratings yet

- Specifications of Aluminum MaterialsDocument2 pagesSpecifications of Aluminum MaterialsTony C.No ratings yet

- Fundamental Studies On The Mechanism of Ultrasonic WeldingDocument56 pagesFundamental Studies On The Mechanism of Ultrasonic WeldingStupinean LarisaNo ratings yet

- Alberg Cutting Tool 2002 PDFDocument28 pagesAlberg Cutting Tool 2002 PDFApichat1967No ratings yet

- BỘ TIÊU CHUẨN THÉP TƯƠNG ĐƯƠNG - STEEL STANDARD EQUIPVALENTDocument12 pagesBỘ TIÊU CHUẨN THÉP TƯƠNG ĐƯƠNG - STEEL STANDARD EQUIPVALENTLưu DuyNo ratings yet

- CMI WeldingChartsDocument1 pageCMI WeldingChartsnitinNo ratings yet

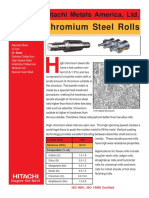

- Chromium Steel Rolls: Hitachi Metals America, LTDDocument2 pagesChromium Steel Rolls: Hitachi Metals America, LTDHariNo ratings yet

- Carbide End Mill Feeds and Speeds TuffCut XR 177 MetricDocument1 pageCarbide End Mill Feeds and Speeds TuffCut XR 177 MetricIlham FadillahNo ratings yet

- Exp LoopDocument37 pagesExp Loopreach_arindomNo ratings yet

- Plant Name & CodeDocument16 pagesPlant Name & CodeDevnarayam SahuNo ratings yet

- Hitesh Metal (India) Introduction & Profile 1.2.18 PDFDocument5 pagesHitesh Metal (India) Introduction & Profile 1.2.18 PDFHMI MumbaiNo ratings yet

- Europe Germany France Italy Belgium Sweden U.K. Canada India Japan USA Internation AlDocument6 pagesEurope Germany France Italy Belgium Sweden U.K. Canada India Japan USA Internation AlOsvaldo Meza100% (1)

- Martensitic SS Alloy Materials PDFDocument1 pageMartensitic SS Alloy Materials PDFImtiyaz AliNo ratings yet