Professional Documents

Culture Documents

Vessel Supports

Uploaded by

OscarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vessel Supports

Uploaded by

OscarCopyright:

Available Formats

1.

EQUIPMENT SUPPORTS

Legs supports to be adopted for vertical vessels having diameter not exceeding 1600 mm and the

maximum tangent-to-tangent length is less than 3200 mm and the maximum length of leg is less

than 1600 mm.

Skirt-to-vessel junction weld where length to diameter ratio is 18 and larger, shall be checked by

inspection before welding. The root pass and the last pass shall be examined to avoid cracks.

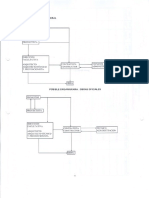

3.4.1 SUPPORT SKIRTS

Support skirls are often used for tall vertical vessels. It might be difficult to know whether a

vessel shall be regarded as tall or short, but the ASME Code gives a very precise and useful way

of carrying out the classification. A short vertical vessel is simply limited by the dimensions and

ratios shown in Fig. 3.3.

D< 1.80 m

L/D<5

H/D<2

Fig. 3.3 Dimensions limiting short vertical vessels.

Support skirts are usually connected to a base ring resting on a concrete foundation. They can

cither be cylindrical or conical and attached to the vessel by a butted or a lapped weld. The bulled

weld should blend smoothly into the knuckle portion of the head, while the lapped weld is

attached to the cylindrical portion of the head. The two different types are illustrated in Fig. 3.4

and Fig. 3.5.

You might also like

- Chapter 4 09Document22 pagesChapter 4 09zhangjlNo ratings yet

- 3.1 Metal ReinforcementDocument26 pages3.1 Metal ReinforcementAbestano JadeNo ratings yet

- Estimate Lesson 4 RSBDocument28 pagesEstimate Lesson 4 RSBBCXC LLAM100% (1)

- Thumb Rules For Steel&Concrete DesignDocument11 pagesThumb Rules For Steel&Concrete DesigngvgbabuNo ratings yet

- Solution To AssignmentsDocument7 pagesSolution To AssignmentsMayank ShrivastavaNo ratings yet

- WWPA Framing BasicsDocument6 pagesWWPA Framing BasicsjphughesNo ratings yet

- Article - Structural BoltsDocument6 pagesArticle - Structural Boltsing_weroNo ratings yet

- Reinforcing Steel ReferenceDocument19 pagesReinforcing Steel ReferenceMary Emalaine SerranoNo ratings yet

- 07cb0663-d04c-4864-955d-bf609dc759c1Document6 pages07cb0663-d04c-4864-955d-bf609dc759c1x620100% (1)

- CRSI Rebar Lap Splice Design GuidelinesDocument1 pageCRSI Rebar Lap Splice Design GuidelinesTos HernandoNo ratings yet

- CASINGDocument24 pagesCASINGPavan KumarNo ratings yet

- Placing Reinforcing BarsDocument5 pagesPlacing Reinforcing BarsYudhi PranataNo ratings yet

- TrussesDocument39 pagesTrussesKentDemeterio100% (1)

- CraneDocument19 pagesCranedeua2004No ratings yet

- Reinforcement Detailing Guide for Concrete StructuresDocument6 pagesReinforcement Detailing Guide for Concrete StructurescherogonyaNo ratings yet

- Radial Gate AnalysisDocument16 pagesRadial Gate AnalysisAkshay Badhani100% (1)

- NAFI Joint Design 3 (2001) - Bolts, Coach Screws & Timber ConnectorsDocument16 pagesNAFI Joint Design 3 (2001) - Bolts, Coach Screws & Timber Connectorssteveh49No ratings yet

- Hilok Hitigue InstallationDocument16 pagesHilok Hitigue Installationtbiris0% (1)

- 30 Rules For Good Connections.5Document4 pages30 Rules For Good Connections.5chipchipperson100% (1)

- Marine Anchor Design GuideDocument28 pagesMarine Anchor Design GuideKevin SaaVedra CastañedaNo ratings yet

- Placing Reinforcing Bars - tcm45-344165Document5 pagesPlacing Reinforcing Bars - tcm45-344165x620No ratings yet

- Design Consideration of Column According To Aci CodeDocument17 pagesDesign Consideration of Column According To Aci CodeFayyazAhmadNo ratings yet

- Reinforcing Steel and Wire Fabric GuideDocument1 pageReinforcing Steel and Wire Fabric GuideSardarNo ratings yet

- Predilla Assignment Module 3Document15 pagesPredilla Assignment Module 3Justine PredillaNo ratings yet

- Specifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionDocument12 pagesSpecifying Bolt Length For High-Strength Bolts: Manual of Steel Constructionpreds1717No ratings yet

- Specifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionDocument12 pagesSpecifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionalbertoxinaNo ratings yet

- Building As Human Shelter: King Post Top Chord Web MembersDocument4 pagesBuilding As Human Shelter: King Post Top Chord Web MembersKristin Brienne Leander-RenomeronNo ratings yet

- Earthquake DesignDocument2 pagesEarthquake DesignUmange RanasingheNo ratings yet

- Do's and Dont's in Civil EngineeringDocument20 pagesDo's and Dont's in Civil EngineeringRam1028100% (1)

- Reinforced Concrete Development Lengths and Bar SplicesDocument36 pagesReinforced Concrete Development Lengths and Bar SplicesSaadan HussainNo ratings yet

- Welcome To OurDocument28 pagesWelcome To OurKh Bappi ShahriarNo ratings yet

- PSC Girder MethodologyDocument12 pagesPSC Girder MethodologySaurabh KumarNo ratings yet

- Economics For Structural Steel Plate GirdersDocument10 pagesEconomics For Structural Steel Plate Girdersthomas kilianNo ratings yet

- Naval ArchitectureDocument36 pagesNaval ArchitectureAnshuman SharmaNo ratings yet

- Civil Work Specification Part 44Document10 pagesCivil Work Specification Part 44AM MANo ratings yet

- Technical Information: 1. Hoist RopesDocument17 pagesTechnical Information: 1. Hoist RopesvikasgahlyanNo ratings yet

- Calculate Reinforcement Lap LengthsDocument10 pagesCalculate Reinforcement Lap LengthsQamar JamilNo ratings yet

- Casing Types, Functions, and ClassificationsDocument71 pagesCasing Types, Functions, and ClassificationsPeterMarkNo ratings yet

- RCC Member Design TipsDocument8 pagesRCC Member Design TipsAbhishek ChaudhariNo ratings yet

- Pipe Schedule: Welded and Seamless Wrought Steel PipeDocument10 pagesPipe Schedule: Welded and Seamless Wrought Steel PipePrasad BhosaleNo ratings yet

- Gaseous Hydrogen Piping SpecificationDocument5 pagesGaseous Hydrogen Piping SpecificationAndri DoemeriNo ratings yet

- A FEDS Structural BoltsDocument6 pagesA FEDS Structural BoltsCrimsonPoshNo ratings yet

- How Do Columns in RC Buildings Resist EarthquakeDocument2 pagesHow Do Columns in RC Buildings Resist EarthquakekooaduNo ratings yet

- Presentation On Reinforcing Detailing of RCC MembersDocument20 pagesPresentation On Reinforcing Detailing of RCC MembersprakashNo ratings yet

- Technical Section RYCO HydraulicDocument50 pagesTechnical Section RYCO Hydraulicedhy_03100% (1)

- RCC Member Design TipsDocument9 pagesRCC Member Design TipsNaren ViratNo ratings yet

- Guide For The Installation of ACSR and ACSR TW Conductors PDFDocument15 pagesGuide For The Installation of ACSR and ACSR TW Conductors PDFKevin MweneSafari100% (1)

- Connection CostsDocument3 pagesConnection CostsShajit KumarNo ratings yet

- Lec 03 - Steel - Bolt ConnectionsDocument28 pagesLec 03 - Steel - Bolt Connectionsjaffer talhaNo ratings yet

- FOUNDATION PLAN & DETAILSDocument21 pagesFOUNDATION PLAN & DETAILSIzri AndayaNo ratings yet

- SejDocument31 pagesSejShipra Mishra75% (8)

- Seccion 16 Abs SoldaduraDocument9 pagesSeccion 16 Abs SoldaduraRoberto DavilaNo ratings yet

- Anker Schroeder - Anchors For Marine StructuresDocument28 pagesAnker Schroeder - Anchors For Marine Structuresmark keijzersNo ratings yet

- A Guide to Making Your Own Fishing-Rod and TackleFrom EverandA Guide to Making Your Own Fishing-Rod and TackleRating: 5 out of 5 stars5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- CORROSION RESISTANCE Durco 2 PDFDocument8 pagesCORROSION RESISTANCE Durco 2 PDFJUAN ANTONIO HERNANDEZ SOSANo ratings yet

- Innomag-Lining 200005300307Document4 pagesInnomag-Lining 200005300307OscarNo ratings yet

- Safety Valves For Boiler Pressure VesselDocument1 pageSafety Valves For Boiler Pressure VesselOscarNo ratings yet

- Comments On PZVDocument2 pagesComments On PZVOscarNo ratings yet

- Dupont Tefzel: Chemical Use Temperature GuideDocument12 pagesDupont Tefzel: Chemical Use Temperature GuideOscarNo ratings yet

- Kitz Cast Carbon and Low Alloy Steel Gates GlobesDocument27 pagesKitz Cast Carbon and Low Alloy Steel Gates GlobesLupiNo ratings yet

- 52 Week Photography ChallengeDocument2 pages52 Week Photography ChallengeMichael Zhang100% (20)

- CALCULATION NOMINAL WALL THICKNESS OF TUBING For Project FinalDocument4 pagesCALCULATION NOMINAL WALL THICKNESS OF TUBING For Project FinalOscarNo ratings yet

- Dupont Tefzel: Chemical Use Temperature GuideDocument12 pagesDupont Tefzel: Chemical Use Temperature GuideOscarNo ratings yet

- Environmentally Safe VCI/MCI TechnologiesDocument8 pagesEnvironmentally Safe VCI/MCI TechnologiesOscarNo ratings yet

- Exercise GuideDocument2 pagesExercise Guidesyrus025No ratings yet

- Insulation Material SpecificationDocument1 pageInsulation Material SpecificationSandra FerrellNo ratings yet

- Nozzle Allowable LoadsDocument1 pageNozzle Allowable LoadsOscarNo ratings yet

- Mortgage Calculation FNT PDFDocument1 pageMortgage Calculation FNT PDFOscarNo ratings yet

- Vessel Supports PDFDocument1 pageVessel Supports PDFOscarNo ratings yet

- Wind VibrationDocument1 pageWind VibrationOscarNo ratings yet

- ThermostatDocument132 pagesThermostatOscarNo ratings yet

- Quality Assurance Plan-BendsDocument7 pagesQuality Assurance Plan-BendsOscarNo ratings yet

- Construction code pressure vesselsDocument24 pagesConstruction code pressure vesselshugo.dutillet6002100% (1)

- Project Management Report For Tank FarmDocument17 pagesProject Management Report For Tank FarmAbhik Tushar Das100% (1)

- Nozzle Allowable LoadsDocument1 pageNozzle Allowable LoadsOscarNo ratings yet

- Piping Stress AnalysisDocument51 pagesPiping Stress Analysissandygo100% (4)

- Structural Design of Steel Pipe Support StructureDocument1 pageStructural Design of Steel Pipe Support StructureOscarNo ratings yet

- C StructDesign Bendapudi Feb10Document3 pagesC StructDesign Bendapudi Feb10samvendanNo ratings yet

- IACS NDT ForginsDocument18 pagesIACS NDT Forginsflore73No ratings yet

- Piping Stress AnalysisDocument51 pagesPiping Stress Analysissandygo100% (4)

- Spec Boiler and Pressure Vessel by Federal GovernmentDocument26 pagesSpec Boiler and Pressure Vessel by Federal Governmentalizadeh2222No ratings yet

- Phased Array Ultrasonic TestingDocument26 pagesPhased Array Ultrasonic TestingOscarNo ratings yet

- Activity Code Activity Type Status Work Description - Previous Bi-Week Hours Project or Allies To Charge HoursDocument5 pagesActivity Code Activity Type Status Work Description - Previous Bi-Week Hours Project or Allies To Charge HoursOscarNo ratings yet