Professional Documents

Culture Documents

Agarbatti Project

Uploaded by

Rock RamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Agarbatti Project

Uploaded by

Rock RamCopyright:

Available Formats

Introduction:

The burning of Incense/Agarbatti in religious and social function has been

practiced in india since ancient times. Agarbatti an aromatic powder or paste on a

bamboo stick is burnt in Indian homes as a fragment fumigant and is reputed to

insecticiadal and antiseptic properties. Agarbatties are available in different colours

different perfumes. The burning time of an agarbatti can go from 15 minutes to 03

hours lower quality only charcoal powder or low quality sandalwood poder with a

mixture of 50-60 percent of wood gum powder. Cheap perfumes are also used to give

them a top note. In superior verieties, purified resins, essential oils, natural fixatives

like amber, musk and divet are used along with synthetic aromatics to improve its

quality.

Market:

Agarbatti is used by all communities and religious in india, Ceylon, Burma and

by Indians residing abord. As of today 85 foreign countries are using our agarbatties.

This industry is one of the abour intensive cottage types of industries in india and

right now Karnataka state leads in this industry, the main centre of manufacture

being mysore and bangaore due to easy availability of raw materieals. Moreover, it is

an export oriented industry and can be a good source of earning.

Process:

Al the ingredients in powder from are mixed well in the proper proporation

with water to a semi soid paste by skied labour. The raw sticks are then dried

properly and packed in suitable bundes depends on price and product offering. For

the manufacture of perfumed and raw agarbatties are dipped propery in dipping

trays. The perfumed agarbatties are packed immediaty in polythene bags and finaly in

printed cartons after proper labeling and branding.

Production Target:

Around 4560 quintals of bamboo sticks would be produced per year. This stics

would be a different size and would be sold at the rate of Rs.1,750/- per quintal. The

total sales would be around Rs.79,80,000/-.

Raw Materiels:

All the raw materiels are localy available which is a positive side follow starters.

Muli Bamboo Rs.99,000/-

Quality of Bamboo Rs.1,08,000/-

Printed Paper Box for Packaging of Rs.35,833/-

Incense sticks

Perfume, Chemicas etc Rs.78,000/-

Total Rs.3,20,833/-

Power:

At 200/200 volts, 50 Hz with AC single phase & 3 wire. The manufacturing unit

will need a total connected load of 5 KW. The annua consumption of power is

estimated at 10476 KWHrs costing Rs.20,657/-.

Water: The unit will need 550 Ltrs of Water. The Cost of drawing of water is shown in

power cost.

Manpower:

Apart from one skilled worker which can be recruited or trained the entire

manpower requirement is locally available. The number and annual cost of

manpower are given below.

Sl.No. Category of Manpower No. of Persons Annual Cost

1 Manager cum chief Chemist 1 Rs.78,000/-

2 Sales and Administrative Staffs 2 Rs.84,000/-

3 Skilled Worker (Trained) 1 Rs.60,000/-

4 Unskilled Worker 2 Rs.60,000/-

Total 6 Rs,2,82,000/-

Project Cost:

1. A) Land & Building Owned

B) Shed for office cum godown Rented

2. Machinary & Equipment

a) Bamboo cross cutting machine, Rs.1,05,000/-

bamboo forming machine & 0

equipment, drying tray

b) Hydrauic extruder & kneading M/c Rs.1,30,000/-

c) Incense stick polishing machine 1 Rs.35,000/-

No.

Sub Total Rs.2,70,000/-

d) Furniture & Fixtures Rs.75,000/-

e) Pre-operating Expenses Rs.25,000/-

3. Provision for contingencies Rs.20,000/-

4. Preliminary & Pre operative Rs.20,000/-

Expenses

Total Fixed Capital Rs.4,10,000/-

5. Working Capital (for 3 Months)

a) Raw Materials Rs.3,20,833/-

b) Power Rs.1,721/-

c) Salary & Wages Rs.23,500/-

d) Miscellaneous Expenses Rs.3,946/-

Total Project Cost Rs.7,60,000/-

Profitability: (Rs. In Thousands)

Sl. No. Description 1st Year 2nd Year 3rd Year 4th Year 5th Year

1 Capacity 60% 70% 80% 80% 80%

Utilized

2 Annual Sales 3,456 4,032 4,608 4,608 4,608

Realization

3 Annual Cost in

Rs.

a) Raw Materials 2,310 2,695 3,080 3,080 3,080

b) Power 12 14 17 17 17

Wages & 282 289 296 296 296

c) Saaries

Repair & 16 16 16 16 16

d) Maintenance

Administrative 75 79 83 87 91

e) overheads

Selling 518 605 691 691 691

f) Expenses

Description 40 40 40 40 40

g)

Intrest 61 49 36 22 7

h)

3,314 3,787 4,259 4,257 4,253

Annual Profit 142 245 349 351 355

4)

Return on 18.68% 32.24% 45.92% 46.18% 46.71%

5) Investment

Return on 4.11% 6.08% 7.57% 7.62% 7.70%

6) Sales

Cash accrual 182 285 389 391 395

7)

Annual

8) Contribution

Break Even

9) Point in

Percent

Debt servicing

10) Capacity

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

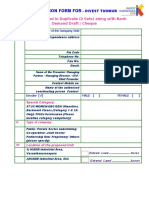

- Application Form For: To Be Submitted in Duplicate (2 Sets) Along With Bank Demand Draft / ChequeDocument5 pagesApplication Form For: To Be Submitted in Duplicate (2 Sets) Along With Bank Demand Draft / ChequeRock RamNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Project Profile GovtDocument4 pagesProject Profile GovtsudayippNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Agarbatti PDFDocument2 pagesAgarbatti PDFAntony JosephNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Agarbatti PDFDocument2 pagesAgarbatti PDFAntony JosephNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Incense Stick/ Agarbatti Manufacturing Project Report - Free Agarbatti Manufacturing Project ReportDocument14 pagesIncense Stick/ Agarbatti Manufacturing Project Report - Free Agarbatti Manufacturing Project ReportRock Ram80% (5)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- PPP Rfi Template-EnDocument15 pagesPPP Rfi Template-EnAhmedManamaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- 21 Century Literature The Face of TodayDocument1 page21 Century Literature The Face of TodayPatrick RodriguezNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Official #PapalVisitPH 2015 Liturgical BookletDocument132 pagesOfficial #PapalVisitPH 2015 Liturgical BookletTonyo Cruz100% (2)

- E9 - Review 3 - LanguageDocument3 pagesE9 - Review 3 - LanguageMai PhuongNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- People MediaDocument29 pagesPeople MediaCyberR.Domingo75% (4)

- Tugas 1 Bahasa Inggris Teknik 2019Document4 pagesTugas 1 Bahasa Inggris Teknik 2019YudhasetyaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Lim, Jr. vs. Lazaro G.R. No. 185734 July 3, 2013 J. Perlas-Bernabe Facts: Lim, Jr. Filed A ComplaintDocument53 pagesLim, Jr. vs. Lazaro G.R. No. 185734 July 3, 2013 J. Perlas-Bernabe Facts: Lim, Jr. Filed A ComplaintRoi DizonNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Life Changing Experience EssayDocument7 pagesA Life Changing Experience Essayioqyqenbf100% (2)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Ultra Vires 2019Document15 pagesUltra Vires 2019Amigo TiendaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Raad M. Hassan 305347Document4 pagesRaad M. Hassan 305347Texas WatchdogNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Defining A Partnership - The Traditional Approach Versus An InnovaDocument43 pagesDefining A Partnership - The Traditional Approach Versus An Innovajjaye5500No ratings yet

- Templates - Internship Guidelines EUTF GhanaDocument15 pagesTemplates - Internship Guidelines EUTF GhanaGetachew HussenNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Paulding County PRogress March 27, 2013Document16 pagesPaulding County PRogress March 27, 2013PauldingProgressNo ratings yet

- Railway PassDocument3 pagesRailway PassAen NdaeNo ratings yet

- Ethics VsDocument2 pagesEthics VsvaniNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Book I PDFDocument293 pagesBook I PDFUday DokrasNo ratings yet

- ORDINANCE No. 11 424 C. M. S.: Approved As TP Form and LegalityDocument9 pagesORDINANCE No. 11 424 C. M. S.: Approved As TP Form and LegalityRecordTrac - City of OaklandNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- 5.missing File CIC - DS - A - 2013 - 001788-SA - M - 138483Document9 pages5.missing File CIC - DS - A - 2013 - 001788-SA - M - 138483callcenjobsNo ratings yet

- Mythic Vistas - Medieval Player's Manual by AzamorDocument127 pagesMythic Vistas - Medieval Player's Manual by AzamorJonathan Azamor100% (2)

- Simple Spanish in A Week by PawankumarDocument37 pagesSimple Spanish in A Week by PawankumarV J Vijay YadavNo ratings yet

- Amun HekaaDocument36 pagesAmun HekaaAnonymous TSWsAH9100% (4)

- Model / Modello: WL432Document2 pagesModel / Modello: WL432Wilson HerreraNo ratings yet

- Nicholson v. Shreve ORDERDocument2 pagesNicholson v. Shreve ORDERNetNewsLedger.comNo ratings yet

- Tarp - SBMDocument8 pagesTarp - SBMJohn Dale EvangelioNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Definisi Sukses : Sukses Sangat Berkaitan Erat DenganDocument40 pagesDefinisi Sukses : Sukses Sangat Berkaitan Erat DenganphyoulifyNo ratings yet

- Department of English, Gauhati UniversityDocument49 pagesDepartment of English, Gauhati UniversityIshita RoufNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Data Flow Diagram (Music)Document12 pagesData Flow Diagram (Music)Brenda Cox50% (2)

- Class-Changing Prefixes in The English LDocument16 pagesClass-Changing Prefixes in The English LIrena PanticNo ratings yet

- Elevating Manila To Become A Global CityDocument3 pagesElevating Manila To Become A Global CityI'm YouNo ratings yet

- 1Document11 pages1Angel Marie DemetilloNo ratings yet