Professional Documents

Culture Documents

PT Procedure

Uploaded by

Arun0 ratings0% found this document useful (0 votes)

17 views12 pagesHow to perform pt

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHow to perform pt

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views12 pagesPT Procedure

Uploaded by

ArunHow to perform pt

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

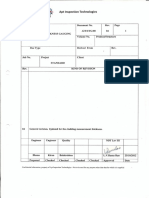

ae Apt Inspection Technologies

ait

Title

LIQUID PENETRANT EXAMNATION

Document No. Rev. | Page

AIT/LPE/00 7

Volume No. | Product/Structure

BOILER

Doe Type Derived From Rev.

Job No. Project Client _

GENERAL.

‘SPECIFICATION

Rev. KIND OF REVISION

‘This specification complies with ASME Code Sec. I; V; VIII div 1, 2007 Edition.

‘This specification complies with ASME B31.1 2004 Edition wit

included.

addenda up to Addendum 2006

17 | Updated para.8.2 Added Table 2.

16 | Updated ASME Code 2007 Edition

15 | Updated ASME 2004 Edition with Addenda up to Addendum 2006 included.

14 | Updated ASME Code Sec. I; V5 VIII div.1, 2004 Edition and 2005 Addenda.

13 | Updated ASME Code Sec. I; V3 VIII div.1, 2004 Edition.

12 _ | Updated ASME Code Sec. 1; V; VIM div.1, 2001 Edition and 2003 Addenda,

Engineer | Engineer | Quality NDT Lev

Kiran | Balakrishna L.V.Rama Rao | 25/10/2012

Checked |~ Checked | Checked | Checked | Approved Date

ae Apt Inspection Technologies

ait

Conia internation, property of Apt lnspestonTacholone Noto be us fr any purpose ther tan that fr which ie suppiod

Project Doe no. Rev. Page -

|__ sranparp AIT/LPE/00 a 2

INDEX

1. SCOPE

2. APPLICABILITY

3. GENERAL REQUIREMENTS

4. TECHNIQUES AND MATERIAL COMBINATION

- 5. OPERATIVE PROCEDURE REQUIREMENT

6. SURFACE PREPARATION

7. MATERIAL AND PENETRANT TEMPERATURE,

8. PENETRANT APPLICATION

9. EXCESS OF PENETRANT REMOVAL

10. DRYING

11. DEVELOPING

12. INTERPRETATION

13, EVALUATION OF INDICATIONS

14, ACCEPTANCE STANDARDS

15, POST -EXAMINATION CLEANING

16, CERTIFICATION

2a Apt Inspection Technologies

Alt

Project

STANDARD | __AIT/LPE/00 7

] Doe no. ev.

[Dp Re

| Page

- 3

1. SCOPE

‘This specification details the procedure to perform.a colour contrast and fluorescent liquid penetrant

‘examination of materials and welds to be used in power boiler steam generator construction.

2." APPLICABILITY.

24

23

The liquid penetrant method to be used shall full comply with the techniques described in

‘ASME code Sect. 'V Article 6 "Liquid penetrant examination", with ASME 831.1 and with

the additional requirements of this specification,

This. specification shall be used to perform, a liquid penitrant examination of tubes,

forgings, plates, weld edge preparation, formed materials welds, either in carbon. Low

alloy, ‘high ‘alloy and. nickel alloy materials Examination. shall. be performed whenever

fequired by the applicable Quality Control Plan (PCQ) and/or specification.

For paitioular production job, liquid penetrant examination shall be performed according

{o the applicable "Operative procedure" referencing the present spec. anid giving at least:

~ the materials shapes, or sizes to be examined, and the extent of the examination;

type (number. or. letter designation if available) of éach penetrant, penetrant

remover, emulsifier. and developer,

+ _ processing details for pre-examination cleaning and drying, including the cleaning

‘matefials Used and minimum time allowed for drying; :

~ processing details for applying the penetrant the. length of time that the penietrant

‘will remain on the surface (dwell.time), and the temperature of the surface and

‘Penetrant during the éxamination if outsidé 50°F (10°C) to 125°F (62°C) range;

= processing details for removing excess penetrant from the surface, and for drying

the surface before applying the developer;

= «processing details for applying the developer, and length of developing time before

interpretation;

+ processing detaiis for post-examinaition clerining.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Apt Inspection TechnologiesDocument6 pagesApt Inspection TechnologiesArunNo ratings yet

- AIT UTG ProcedureDocument6 pagesAIT UTG ProcedureArunNo ratings yet

- Green Handbook - Thermo Power Plant - JapanDocument482 pagesGreen Handbook - Thermo Power Plant - JapanteobohmNo ratings yet

- 006 Wind PowerDocument54 pages006 Wind PowerArunNo ratings yet

- l2 CP Asnt 2Document4 pagesl2 CP Asnt 2Nabeel Adeeb AlshareNo ratings yet

- Steam Turbine BasicsDocument15 pagesSteam Turbine Basicsfaisalnadim100% (1)

- ASNT Online Application Payment Methods Offered PDFDocument1 pageASNT Online Application Payment Methods Offered PDFJindarat KasemsooksakulNo ratings yet

- (Since 1987) : Einstein-TFT IIDocument16 pages(Since 1987) : Einstein-TFT IIArunNo ratings yet

- Boiler Life Assessment: L. V. Rama RaoDocument21 pagesBoiler Life Assessment: L. V. Rama RaoArunNo ratings yet

- Boiler Life Assessment: L. V. Rama RaoDocument21 pagesBoiler Life Assessment: L. V. Rama RaoArunNo ratings yet

- Boiler Life Assessment: L. V. Rama RaoDocument21 pagesBoiler Life Assessment: L. V. Rama RaoArunNo ratings yet