Professional Documents

Culture Documents

R 60 - Higher Productivity & Flexubility

Uploaded by

Aqeel AhmedOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R 60 - Higher Productivity & Flexubility

Uploaded by

Aqeel AhmedCopyright:

Available Formats

R 60 – Higher Productivity and Flexibility on

600 spinning positions

The new R 60 automated rotor spinning machine offers the accumulated productivity of up to 600

rotors. The high yarn quality achieved with the S 60 spinning box and the excellent package build ensure

maximum efficiency in downstream processes.

The energy-saving technology of the R 60 has enabled Rieter to introduce a further extension in machine

length. The first machines with 600 spinning positions are already operating successfully in a number of

spinning mills worldwide. Customers appreciate the reliability and economy of these machines.

The longest rotor spinning machine

Yarns of high quality and tenacity

The yarn quality achieved on the R 60 with the S 60 spinning box stands out in all comparisons by virtue

of its higher tenacity and regularity, as well as having fewer imperfections. This is achieved by the

innovative spinning geometry and the resulting improvement in spinning stability. These advantages are

exploited even more economically on the long machine.

Minimal energy consumption

The R 60 requires some 10 % less energy than other rotor spinning machines. The energy consumption

of rotor spinning machines depends mainly on the optimal structure of the volumetric flow of the

spinning air and losses in the power electronics. Central drives therefore still have advantages over

individual drives with large numbers of decentralized electronic components. On-going comparative

measurements by customers prove the R 60’s advantage of 10 % lower energy consumption.

Ideal flexibility

The option of independent machine sides enables the R 60 to be operated virtually as flexibly as two

machines. New safety devices even make it possible to perform maintenance and cleaning work on the

spinning positions and head and foot stock on one side in one shift, while production continues on the

other side. Maintenance on the other side of the machine can then be scheduled for another shift

without additional interruptions to production being necessary as a result.

Good for coarse-count yarns and frequent quality cuts

The option of six robots also enables production to be performed in extreme applications (short

package running times, very coarse yarns, high ends down frequencies) with maximum efficiency on a

machine with 600 spinning positions.

The high-speed automation of the R 60 manages piecing and doffing in 20 seconds. Each time thorough

rotor cleaning ensures that the spinning position can subsequently continue spinning with the highest

possible yarn quality.

In extreme applications of this kind the double capacity and performance of the tube loader is especially

useful, combined with the “independent machine sides” function.

Author:

Stephan Weidner-Bohnenberger

Head Product Management Rotor Spinning

stephan.weidner-bohnenberger@rieter.com

You might also like

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Rieter - Rotor Spinning Machine R 40Document10 pagesRieter - Rotor Spinning Machine R 40srkfan27No ratings yet

- ITMA - 2015 - Innovation in Textile Machinery SpinnningDocument68 pagesITMA - 2015 - Innovation in Textile Machinery Spinnningsureshganji06No ratings yet

- Rieter Rotor Semi r36 Brochure 3101 v1 87068 enDocument28 pagesRieter Rotor Semi r36 Brochure 3101 v1 87068 enHai PhamNo ratings yet

- J 26 Air-Jet Spinning Machine Brochure 2887-V1 en Original 75123Document24 pagesJ 26 Air-Jet Spinning Machine Brochure 2887-V1 en Original 75123A Ponmurugu PonmuruguNo ratings yet

- Rieter - Drawframes RSB-D 40 and SB-D 40Document9 pagesRieter - Drawframes RSB-D 40 and SB-D 40Kaushik Mukherjee100% (1)

- G6500 enDocument12 pagesG6500 enArifin Al HaqueNo ratings yet

- Competence in CementDocument24 pagesCompetence in CementJackson VuNo ratings yet

- Open End SpinningDocument8 pagesOpen End SpinningAmir Shahzad75% (4)

- Johndeere s690Document15 pagesJohndeere s690alaynnastaabx786No ratings yet

- Pages John DereeDocument28 pagesPages John DereearnoldmecNo ratings yet

- Servall Engineering Works PVT LTDDocument7 pagesServall Engineering Works PVT LTDRaghulNo ratings yet

- Rotor Spinning ReportDocument6 pagesRotor Spinning Reportdsethi23No ratings yet

- Gear Grinding Machines: Peripheral Systems Tooling Technology ServicesDocument8 pagesGear Grinding Machines: Peripheral Systems Tooling Technology ServicesM. AguiarNo ratings yet

- Rieter - Card C 60Document8 pagesRieter - Card C 60Marathi VideoNo ratings yet

- Brochure Slip-Ring MotorsDocument8 pagesBrochure Slip-Ring MotorsidontlikeebooksNo ratings yet

- HP Series Cone CrushersDocument12 pagesHP Series Cone CrushersPatricio Sepúlveda0% (1)

- G 35 Ring Spinning Machine Brochure 2161-v2 en 21541Document20 pagesG 35 Ring Spinning Machine Brochure 2161-v2 en 21541Aizaz ShahNo ratings yet

- 708 05 Fenner CouplingsDocument18 pages708 05 Fenner CouplingsLmf Daniel100% (1)

- Open End Spinning-SkDocument3 pagesOpen End Spinning-Skshaikat6163No ratings yet

- Parboiling Dryer PlantDocument25 pagesParboiling Dryer PlantShivaz SharmaNo ratings yet

- Harvesters: 703JH 753JH 759JHDocument18 pagesHarvesters: 703JH 753JH 759JHrossini_danielNo ratings yet

- Powerdrive x6Document7 pagesPowerdrive x6ice_PLNo ratings yet

- VX Series - English - 2019 09Document8 pagesVX Series - English - 2019 09Kiril AngelovNo ratings yet

- Brochure RZ 410Document8 pagesBrochure RZ 410Harris ChackoNo ratings yet

- Powerdrive X6: Rotary Steerable System For High-Performance Drilling and Accurate Wellbore PlacementDocument6 pagesPowerdrive X6: Rotary Steerable System For High-Performance Drilling and Accurate Wellbore PlacementClOudyo VirgílioNo ratings yet

- 364 21262 PDFDocument24 pages364 21262 PDFIonut-Catalin DimacheNo ratings yet

- J 20 Air-Jet Spinning Machine Brochure 2386-V1 en 34515Document16 pagesJ 20 Air-Jet Spinning Machine Brochure 2386-V1 en 34515Ishwar DudagiNo ratings yet

- IMM BR IR enDocument13 pagesIMM BR IR enwatnaNo ratings yet

- Caterpillar Cat Mining Shovel Excavators Spec 9a5887Document32 pagesCaterpillar Cat Mining Shovel Excavators Spec 9a5887Gholamreza GholipourNo ratings yet

- Feller John Deere 959KDocument20 pagesFeller John Deere 959KJavierRivasNeiraNo ratings yet

- 903K 909K 953K 959K Espec Dka5004 - 12-06Document20 pages903K 909K 953K 959K Espec Dka5004 - 12-06coelhoclaudiosNo ratings yet

- Sweepmaster 1200 RHDocument4 pagesSweepmaster 1200 RHM. Arif PrasetyoNo ratings yet

- Rolling 4Document2 pagesRolling 4danaandrei74No ratings yet

- Rieter G 37 Ring Spinning Machine Brochure 3218 v5 95390 enDocument28 pagesRieter G 37 Ring Spinning Machine Brochure 3218 v5 95390 enSahed MollaNo ratings yet

- Leaflet R9500p enDocument6 pagesLeaflet R9500p enDavid Lopez OaxacaNo ratings yet

- Semi-Automated Rotor Spinning Machine R 37Document28 pagesSemi-Automated Rotor Spinning Machine R 37Chaman VermaNo ratings yet

- Wt625 Testo Toty EngDocument6 pagesWt625 Testo Toty EngRazvan PredaNo ratings yet

- Fresadora RX-600e PDFDocument24 pagesFresadora RX-600e PDFEFRAIN VALLEJONo ratings yet

- NTB R9600-G8 enGB-USDocument28 pagesNTB R9600-G8 enGB-USOrso OsvaldNo ratings yet

- Cat 320d LRRDocument28 pagesCat 320d LRRt1meNo ratings yet

- Blower Power Chart Pristair Wastewater BrochureDocument2 pagesBlower Power Chart Pristair Wastewater BrochureprannoyNo ratings yet

- 4 Roadtec 600 Cummins QSXDocument24 pages4 Roadtec 600 Cummins QSXdavidNo ratings yet

- Brochure Rotor Mills enDocument12 pagesBrochure Rotor Mills enB'MAZNo ratings yet

- 305.5D CR Hydraulic ExcavatorDocument16 pages305.5D CR Hydraulic ExcavatorhansNo ratings yet

- 5 Mixer FlygtDocument8 pages5 Mixer FlygtHugo Miño Carrasco100% (1)

- Rotor SpinningDocument4 pagesRotor SpinningJasmeet SinghNo ratings yet

- CBI Annihilator ShredderDocument2 pagesCBI Annihilator ShredderHelmiNo ratings yet

- 315D CatDocument20 pages315D CatFernando Omar Arena100% (1)

- Claas Quadrant 2100 ManualDocument33 pagesClaas Quadrant 2100 Manualgraig27No ratings yet

- RE98725 - MCR Family - 2017 07 30Document2 pagesRE98725 - MCR Family - 2017 07 30insincos administrativoNo ratings yet

- 2 Mixer FlygtDocument8 pages2 Mixer FlygtHugo Miño Carrasco100% (1)

- Escavadeira CAT 320Document20 pagesEscavadeira CAT 320LucasNo ratings yet

- Router8000 5axisDocument8 pagesRouter8000 5axisDaniel AustinNo ratings yet

- Radial Piston Motors: Series 60Document32 pagesRadial Piston Motors: Series 60Ваня БойкоNo ratings yet

- Lynx 220LSYC 030615Document15 pagesLynx 220LSYC 030615Operations ManagerNo ratings yet

- Link No 71 Customer Magazine 86450 Original English 86450Document32 pagesLink No 71 Customer Magazine 86450 Original English 86450Muhammad Farooq KokabNo ratings yet

- Hydraulic Shovel: Engine Bucket Operating SpecificationsDocument32 pagesHydraulic Shovel: Engine Bucket Operating SpecificationserallatuasanNo ratings yet

- Atlas BrochureDocument2 pagesAtlas BrochureRulNo ratings yet

- Applying Energy Management in Textile Industry, Case Study: An Egyptian Textile PlantDocument8 pagesApplying Energy Management in Textile Industry, Case Study: An Egyptian Textile PlantAqeel AhmedNo ratings yet

- (99+) Improve Energy Intensity in Spinning Business - LinkedInDocument14 pages(99+) Improve Energy Intensity in Spinning Business - LinkedInAqeel AhmedNo ratings yet

- A Review On Energy Management in Textile IndustryDocument7 pagesA Review On Energy Management in Textile IndustryAqeel AhmedNo ratings yet

- Cost-Effective Energy Conservation Techniques For Textile Spinning MillsDocument14 pagesCost-Effective Energy Conservation Techniques For Textile Spinning MillsAqeel Ahmed100% (1)

- Denim ExpressDocument6 pagesDenim ExpressAqeel AhmedNo ratings yet

- Rope DyeingDocument48 pagesRope DyeingAqeel AhmedNo ratings yet

- Excellence Series - Favorite: The IndustryDocument7 pagesExcellence Series - Favorite: The IndustryAqeel AhmedNo ratings yet

- Impact of Carding Segments On Quality of Card Sliver: Practical HintsDocument1 pageImpact of Carding Segments On Quality of Card Sliver: Practical HintsAqeel AhmedNo ratings yet

- 01 How To Indent Cots & ApronsDocument1 page01 How To Indent Cots & ApronsAqeel AhmedNo ratings yet

- New Iconic Series:: Spinner's DesireDocument4 pagesNew Iconic Series:: Spinner's DesireAqeel AhmedNo ratings yet

- 3 420 P Rol Tex Det enDocument2 pages3 420 P Rol Tex Det enAqeel AhmedNo ratings yet

- 2007-4-18-An Investigation On Energy Consumption in Yarn Production With Special Reference To Ring SpinningDocument8 pages2007-4-18-An Investigation On Energy Consumption in Yarn Production With Special Reference To Ring SpinningAqeel AhmedNo ratings yet

- 2007-4-18-An Investigation On Energy Consumption in Yarn Production With Special Reference To Ring SpinningDocument15 pages2007-4-18-An Investigation On Energy Consumption in Yarn Production With Special Reference To Ring SpinningAqeel AhmedNo ratings yet

- Processing Indian Raw Cotton Special Print 2285-V1 en 31635Document19 pagesProcessing Indian Raw Cotton Special Print 2285-V1 en 31635Aqeel AhmedNo ratings yet

- I QUBEDocument2 pagesI QUBEAqeel AhmedNo ratings yet

- CompressorDocument35 pagesCompressoravinash13100% (1)

- USTER - Tap in To Free Know-How PDFDocument2 pagesUSTER - Tap in To Free Know-How PDFAqeel AhmedNo ratings yet

- Uster Countum 3Document322 pagesUster Countum 3Aqeel Ahmed95% (21)

- USTER - Tap in To Free Know-HowDocument2 pagesUSTER - Tap in To Free Know-HowAqeel AhmedNo ratings yet

- The Rieter Manual of Spinning Vol. 1-Pages 40 PDFDocument80 pagesThe Rieter Manual of Spinning Vol. 1-Pages 40 PDFAbdul RafayNo ratings yet

- Feasibility Study For Cotton Spinning MillDocument122 pagesFeasibility Study For Cotton Spinning MillNoman Ansari100% (2)

- sn74ls02 1Document3 pagessn74ls02 1Israel PalaciosNo ratings yet

- Rohde&Schwarz ESMC HF Reciever DatasheetDocument10 pagesRohde&Schwarz ESMC HF Reciever DatasheetHanseaticLeague1993No ratings yet

- HM 71 T4 (A2:6) 2,2kW 25º: General DataDocument4 pagesHM 71 T4 (A2:6) 2,2kW 25º: General Dataaqil khanNo ratings yet

- Cummins: Fault Code: 367 PID: P0370Document3 pagesCummins: Fault Code: 367 PID: P0370Enrrique LaraNo ratings yet

- Hasting CatalogDocument218 pagesHasting CatalogMM MMNo ratings yet

- Ftu bf2 2d SpecificationDocument4 pagesFtu bf2 2d SpecificationAdil BELMOUMENNo ratings yet

- Model TA Belt Alignment ControlDocument4 pagesModel TA Belt Alignment ControlRobertoNo ratings yet

- pp07 FloydDocument42 pagespp07 Floydsss0% (1)

- DC Bus ParallelingDocument20 pagesDC Bus ParallelingНебојша МитровићNo ratings yet

- Coa CH4Document6 pagesCoa CH4vishalNo ratings yet

- MML - 2012 04 22 15 28 36Document67 pagesMML - 2012 04 22 15 28 36echoCancellerNo ratings yet

- NXP S32g-Vnp-Gldbox RMDocument43 pagesNXP S32g-Vnp-Gldbox RMNikhil PunnooseNo ratings yet

- TD25 - AirConditionerServiceManualDocument80 pagesTD25 - AirConditionerServiceManualMike SmithNo ratings yet

- YLS-U Series DatasheetDocument2 pagesYLS-U Series DatasheethorseNo ratings yet

- Antenna CatalogDocument109 pagesAntenna CatalogGeoffrey AlleyneNo ratings yet

- Omron 04112019 S8VK-S24024 Datasheet (1) - 1568318 PDFDocument5 pagesOmron 04112019 S8VK-S24024 Datasheet (1) - 1568318 PDFmegatornadoNo ratings yet

- A Multi Phase Harmonic Load Flow Solution TechniqueDocument9 pagesA Multi Phase Harmonic Load Flow Solution TechniquerameshpampanaNo ratings yet

- ReymillWindmill Sta Rosa NEDocument8 pagesReymillWindmill Sta Rosa NEIssey Mari TiongcoNo ratings yet

- Kaman KD-2306 Data Sheet WebDocument4 pagesKaman KD-2306 Data Sheet WebWendy ChillyNo ratings yet

- NTD78N03 Power MOSFET: 25 V, 78 A, Single N Channel, DPAKDocument7 pagesNTD78N03 Power MOSFET: 25 V, 78 A, Single N Channel, DPAKfercikeNo ratings yet

- Dual Tone Multi Frequency (DTMF) Signal Generation and DetectionDocument7 pagesDual Tone Multi Frequency (DTMF) Signal Generation and DetectionDaNo ratings yet

- ECG1200G Technical Specification CaltalogDocument3 pagesECG1200G Technical Specification CaltalogShaaibNo ratings yet

- A Full Wave Rectifier Is A Circuit Arrangement Which Makes Use of Both Half Cycles of Input Alternating CurrentDocument9 pagesA Full Wave Rectifier Is A Circuit Arrangement Which Makes Use of Both Half Cycles of Input Alternating CurrentKaran SoniNo ratings yet

- Ia T 3 Two Marks Q & ADocument2 pagesIa T 3 Two Marks Q & ARAMESH BABU EEENo ratings yet

- Ks Ac Synchronous MotorsDocument6 pagesKs Ac Synchronous MotorsAlberto Hernandez0% (1)

- Vdocuments - MX - Mimaki cg130 FX Service ManualDocument142 pagesVdocuments - MX - Mimaki cg130 FX Service ManualCarlos PaezNo ratings yet

- EC8651 TLW R2017 Unit 1 Two MarksDocument2 pagesEC8651 TLW R2017 Unit 1 Two MarksDhanaraj PNo ratings yet

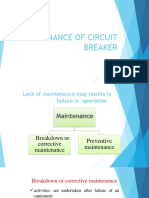

- Circuit Breaker MaintenanceDocument15 pagesCircuit Breaker MaintenanceJoyson Pereira100% (1)

- Energy Management Control Solution For Solar PV Applications Type Eos-Array LiteDocument20 pagesEnergy Management Control Solution For Solar PV Applications Type Eos-Array LitedianaNo ratings yet

- Microwave2 - Power Dividers and Directional CouplersDocument27 pagesMicrowave2 - Power Dividers and Directional CouplersKoay FTNo ratings yet