Professional Documents

Culture Documents

Model TA Belt Alignment Control

Uploaded by

RobertoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model TA Belt Alignment Control

Uploaded by

RobertoCopyright:

Available Formats

CONVEYOR COMPONENTS COMPANY

130 Seltzer Road, PO Box 167 Croswell, MI 48422 USA

PHONE: (810) 679-4211 TOLL FREE (800) 233-3233 FAX: (810) 679-4510

® Email: info@conveyorcomponents.com http:\\www.conveyorcomponents.com

MODEL TA CONVEYOR BELT ALIGNMENT CONTROL

WARNING:

DEATH or SERIOUS INJURY may occur.

Before installing or adjusting, shut down and physically lock-out the

conveyor system.

A. HOW IT WORKS

The model TA Conveyor Belt Alignment Control protects conveyor belts from damage due to

belt misalignment or runoff. These controls are used in pairs with one control placed on each

side of the conveyor belt. Each control unit can be equipped with two micro-switches to

produce signals indicating belt misalignment at two deviation points. The first signal point

could be used to indicate small belt deviation by sounding an alarm. The second signal point

could be used to guard against extreme belt runoff by shutting down the conveyor.

Each control consists of aluminum housing with a red epoxy coated roller. The roller is

adjustable up to 90 in both directions and is positioned approximately 1” from the conveyor

belt. The micro-switch actuation points are adjustable from 0 to 45 by a simple change of

the actuating cam(s). The model TA can be furnished with general purpose or explosion proof

construction. Epoxy coated housings are also available.

B. RECOMMEDED NUMBER OF UNITS

A minimum of four alignment controls is required for each conveyor belt, with one on each

side of the belt near the head and tail pulleys. For conveyors greater that 1,500 feet (457

meters) long, an additional four alignment controls may be required, evenly spaced, one on

each side of the carrying and return belt.

C. INSTALLATION INSTRUCTIONS

Model TA control units are always used in pairs with one placed on each side of the conveyor

belt, usually a pair at each of the head and tail ends of the conveyor. Additional pairs of TA

units may be placed at other points along the conveyor.

The micro-switch(es) can be wired to trigger a warning signal or be connected directly to the

motor starter circuit to stop a conveyor.

The control unit should be mounted on supports so that the roller is positioned perpendicular

to the conveyor belt, and positioned to intercept the conveyor belt at its midpoint. The roller

clamp may be loosened to pivot the roller into the proper position. The roller is 9-3/4” high,

and the point of interception should be at the 4-7/8” point. Control units should not be

mounted too close to the belt because false signals could result. In most applications, the

controls could be mounted approximately 1” from the belt, eliminating false signals while still

protecting the belt against wide deviations.

Field wiring must meet or exceed the requirements of the National Electrical Code and any

other agency or authority having jurisdiction over the installation. Conduit fittings must meet

applicable CSA and UL standards.

I1030002revH.DOC ©Copyright Conveyor Components Co. 2011 1 OF 4

D. ROLLER POSTION AND MICRO-SWITCH ACTUATION SETUP

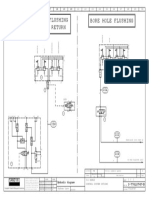

Figure 1: Control Actuation Example

The Model TA is shipped with the switch cam(s)

centered with the roller arm. During the

installation, the switch cam and the roller arm

should be re-positioned to ensure switch

actuation at the desired roller positions.

1. Roller Position

Loosen the roller clamp and pivot the roller so

that it is perpendicular to the belt at the

midpoint of the roller. Then tighten the roller

clamp.

2. Position the housing so the roller is 1” from

the edge of the conveyor belt. Then fasten

the mounting feet.

3. Switch Cam Adjustment

Lock out all power to the switch unit and

remove the cover. Use the 3/32 hex wrench

provided to loosen the #10-32 set screw on the

switch cam.

4. Pivot roller in the desired amount away from the

belt for alarm or shutdown.

5. Adjust cam in same direction as the roller will move

until the micro-switch just trips. Then lock the

setscrew.

6. Pivot the roller in the desired amount for second

trip point if needed.

7. Adjust the second cam as in step 5.

Figure 2: Roller and Belt Position

E. TECHNICAL INFORMATON

1. Individual Switch Contact Ratings:

SPDT switches: DPDT switches:

20 Amps, 125/250/480 VAC 15 Amps, 125/250 VAC

10 Amps, 125 VAC Inductive N/A

1 hp, 125 VAC 3/4 hp, 125 VAC

2 hp, 250 VAC 1 1/2 hp, 250 VAC

½ Amp, 24 VDC N/A

½ Amp, 125 VDC N/A

¼ Amp, 250 VDC N/A

Note: Special units with gold plated micro-switch contacts rated 0.1 Amps at 125 VAC.

2. Conduit opening: One ¾” NPT standard opening is built-in.

3. Actuating Arm:

Roller is red epoxy coated steel with stainless steel shaft.

Roller arm travel is 90 in both directions from vertical.

I1030002revH.DOC ©Copyright Conveyor Components Co. 2011 2 OF 4

4. External Hardware: stainless steel

5. Operating Temperature Range (ordinary locations units): -50C to 65C; -58F to 150F

6. Ambient Temperature Range (hazardous locations units): -50C to 40C; -58F to 104F

7. Enclosure Ratings:

TA-1, TA-2, TA-4, TA-5:

UL Types 3S, 4, 4X, 5 & 12; CSA Types 3S, 4, 4X & 12

TA-1X, TA-2X, TA-4X, TA-5X:

UL / CSA for Class I, Groups C & D; Class II, Groups E, F & G; Class III Hazardous

Locations

TA-1D, TA-2D, TA-4D, TA-5D:

UL Types 3S, 4, 4X, 5 & 12; Class II, Groups E, F & G; Class III Hazardous Locations

CSA Types 3S, 4, 4X & 12; Class II, Groups E, F & G; Class III Hazardous Locations

F. WIRING

Note: TWIST WIRE TOGETHER BEFORE INSERTING IN TERMINAL (ENROULEZ LES

FILS ENSEMBLE AVANT LES INTRODUITE DANS LA BORNE.).

Figure 3: SPDT 2-Switch Schematic Figure 4: DPDT 2-Switch Schematic

To properly wire to the micro-switches on the model TA, route

incoming wires over the shaft and micro-switches. Avoid

contact with the micro-switch levers and other moving parts

inside enclosure.

Figure 5: Wire Routing

I1030002revH.DOC ©Copyright Conveyor Components Co. 2011 3 OF 4

Figure 6: Terminal Identification (SPDT) Figure 7: Terminal Identification (DPDT)

G. DIMENSIONS

Figure 8: Dimensions and Mounting, Model TA-2 Shown

Figure 9: Dimensions and Roller Travel

I1030002revH.DOC ©Copyright Conveyor Components Co. 2011 4 OF 4

You might also like

- Series Switch IB-016IDocument13 pagesSeries Switch IB-016Imastelecentro100% (1)

- 641 - 2051B ManualDocument10 pages641 - 2051B ManualPirv Maria AncaNo ratings yet

- Aq SerieDocument76 pagesAq Serieharold_anilloNo ratings yet

- Bulletin 840 Float Switch and Operator Assembly InstructionsDocument8 pagesBulletin 840 Float Switch and Operator Assembly InstructionsCsr Rbi PrzNo ratings yet

- Cms Electronics BoardDocument11 pagesCms Electronics BoardLuis Fernando Becerra JimenezNo ratings yet

- 143T-449T TECO Welding House GeneralDocument9 pages143T-449T TECO Welding House GeneralChristian TorresNo ratings yet

- Warn 2.5 Owners ManualDocument16 pagesWarn 2.5 Owners ManualNorthernbearNo ratings yet

- Body Electrical SystemDocument59 pagesBody Electrical SystemLeonardo Gómez Berniga100% (1)

- Installation and Maintenance Manual for 2SA5 Series Electric ActuatorsDocument19 pagesInstallation and Maintenance Manual for 2SA5 Series Electric ActuatorsArif ShafiNo ratings yet

- Manual 2Document0 pagesManual 2Rafat ThongNo ratings yet

- VC Series: Installation Instruction - EinbauanleitungDocument12 pagesVC Series: Installation Instruction - EinbauanleitungIon VasileNo ratings yet

- MRTPDocument20 pagesMRTPStephen Crawford100% (1)

- Overhead Crane Operation ManualDocument21 pagesOverhead Crane Operation ManualParthiban Karuna83% (6)

- Barton Flotrac 308 User ManualDocument16 pagesBarton Flotrac 308 User ManualJose Fernando Davila VigoNo ratings yet

- T10 Float Level Switch: DescriptionDocument6 pagesT10 Float Level Switch: DescriptionHJNo ratings yet

- INSTALLATION BULLETIN MI0703 2PC Date 08012013 PDFDocument9 pagesINSTALLATION BULLETIN MI0703 2PC Date 08012013 PDFROYALNo ratings yet

- Yaesu G-800S / G-1000S, G-800SDX / G-1000SDXDocument15 pagesYaesu G-800S / G-1000S, G-800SDX / G-1000SDXjsslaveNo ratings yet

- HKC Elect Ric Quart Er T Urn Act Uat or 'HQ' Series Inst Ruct Ion and Maint Enance ManualDocument32 pagesHKC Elect Ric Quart Er T Urn Act Uat or 'HQ' Series Inst Ruct Ion and Maint Enance ManualFlo MarineNo ratings yet

- RET Install PDFDocument4 pagesRET Install PDFraduldelNo ratings yet

- Hyundai Elantra 1.6L Body Electrical System1Document89 pagesHyundai Elantra 1.6L Body Electrical System1MANUALES2000CLNo ratings yet

- VAHLEDocument28 pagesVAHLEAdrian M FahriNo ratings yet

- DZB200M&JDocument41 pagesDZB200M&Jvijayrockz06No ratings yet

- Maintenanceboth Q and ADocument46 pagesMaintenanceboth Q and AMMS SNo ratings yet

- VF1Document138 pagesVF1Tomás Andrés Madrid RosalesNo ratings yet

- Flex Sys Cable ReelerDocument38 pagesFlex Sys Cable ReelerAngel Sanchez VilcaNo ratings yet

- Understanding Electric Lifting BarriersDocument5 pagesUnderstanding Electric Lifting Barrierssachinsurywanshi14No ratings yet

- Il 41 100 1BDocument20 pagesIl 41 100 1Brajat_nandy5297No ratings yet

- CT-2000PLUS/PRO Series AC Motor Driver Instruction ManualDocument71 pagesCT-2000PLUS/PRO Series AC Motor Driver Instruction Manualm_shakshoki100% (2)

- Unterlagen für Röhrennetzteil FLUKE 407 DDocument41 pagesUnterlagen für Röhrennetzteil FLUKE 407 Dbass1385No ratings yet

- Body Electrical System - PDF - LIL EVODocument107 pagesBody Electrical System - PDF - LIL EVOShannon AsimNo ratings yet

- Sevcon MOS90 DC Traction and Pump Controller Datasheet1-1734225600Document41 pagesSevcon MOS90 DC Traction and Pump Controller Datasheet1-1734225600Jay Murphy100% (8)

- 9479 Inst ManualDocument8 pages9479 Inst ManualfdkaNo ratings yet

- GX30R 100RDocument53 pagesGX30R 100RSergio Garcia100% (1)

- User Manual: High Velocity AC Motor DrivesDocument38 pagesUser Manual: High Velocity AC Motor DrivesKumar HarendraNo ratings yet

- CG USTAD - M ManualDocument53 pagesCG USTAD - M ManualAshish ParasharNo ratings yet

- Speed Switches: InstructionsDocument3 pagesSpeed Switches: InstructionsmuthakkerNo ratings yet

- Al 811Document10 pagesAl 811yu3zaNo ratings yet

- Electric Linear ActuatorDocument8 pagesElectric Linear ActuatorLinweiXiaNo ratings yet

- LG L194WTDocument29 pagesLG L194WTqxbgwhvuNo ratings yet

- Point Machine FOR RAILWAY SIGNALINGDocument32 pagesPoint Machine FOR RAILWAY SIGNALINGVikas Srivastav98% (51)

- Non-excitation tap switch guideDocument23 pagesNon-excitation tap switch guidehendrias_budiNo ratings yet

- MI - 5386 - Relays PDFDocument4 pagesMI - 5386 - Relays PDFSudarshan DhumalNo ratings yet

- E-Link 1000LR Antenna Quick Install Guide 980-0200-001A - 021811 - FinalDocument2 pagesE-Link 1000LR Antenna Quick Install Guide 980-0200-001A - 021811 - FinalIsrar ZiaNo ratings yet

- Users Guide Digital Inductive Loop Sensors: MatrixDocument6 pagesUsers Guide Digital Inductive Loop Sensors: MatrixEliseu DiasNo ratings yet

- Axle CounterDocument24 pagesAxle CounterVikas Srivastav100% (9)

- HT SWITCHGEAR specification summaryDocument7 pagesHT SWITCHGEAR specification summaryIwan TristiawanNo ratings yet

- 25F-PRCServ PDFDocument38 pages25F-PRCServ PDFsindelu60No ratings yet

- GARD G6000: Installation Instructions For Swift Road BarriersDocument24 pagesGARD G6000: Installation Instructions For Swift Road BarriersShah JeeNo ratings yet

- Quantum Radio Slave 4: Operating InstructionsDocument15 pagesQuantum Radio Slave 4: Operating InstructionsVictor GarciaNo ratings yet

- Installation, Operation and Maintenance Instructions: Metalarm Series 6301 Ce Metal Detector SystemDocument12 pagesInstallation, Operation and Maintenance Instructions: Metalarm Series 6301 Ce Metal Detector SystemKarin AndersonNo ratings yet

- Displacer Type Level SwitchDocument10 pagesDisplacer Type Level SwitchKarthik Chockkalingam100% (1)

- CW-80 ManualDocument12 pagesCW-80 ManualBrian YostNo ratings yet

- Electric Actuator InstructionDocument40 pagesElectric Actuator Instructiongasm220% (1)

- Trinetics Switches Ultravac Ii200Document4 pagesTrinetics Switches Ultravac Ii200Rafat ThongNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- AlimentationDocument166 pagesAlimentationRobertoNo ratings yet

- Rexroth AmplifierDocument8 pagesRexroth AmplifierJoão Victor Teixeira FerreiraNo ratings yet

- DINSpace SNAP SpecsDocument1 pageDINSpace SNAP SpecsRobertoNo ratings yet

- Block de Control THC 560Document1 pageBlock de Control THC 560santitojose_1986No ratings yet

- Em - U2 - LINCOLN Valve Change OverDocument3 pagesEm - U2 - LINCOLN Valve Change OverRobertoNo ratings yet

- E Jumbo Only: SandvikDocument2 pagesE Jumbo Only: SandvikRobertoNo ratings yet

- Sandvik: Additional Comments For RHR Configuration 04/2015 PME D Date Updated by Change Not. Date Was Before Pcs. RevDocument1 pageSandvik: Additional Comments For RHR Configuration 04/2015 PME D Date Updated by Change Not. Date Was Before Pcs. RevRobertoNo ratings yet

- Sandvik: 05/12/14 F PME Additional Comment For Hoses 146 and 147 Date Updated by Change Not. Date Was Before Pcs. RevDocument1 pageSandvik: 05/12/14 F PME Additional Comment For Hoses 146 and 147 Date Updated by Change Not. Date Was Before Pcs. RevRobertoNo ratings yet

- SandvikDocument1 pageSandvikRobertoNo ratings yet

- Automatic Air Flushing On Rock Drill Return Bore Hole FlushingDocument1 pageAutomatic Air Flushing On Rock Drill Return Bore Hole FlushingRobertoNo ratings yet

- Sandvik: L Date Updated by Change Not. Date Was Before Pcs. RevDocument1 pageSandvik: L Date Updated by Change Not. Date Was Before Pcs. RevRobertoNo ratings yet

- Sandvik: SLU SLUDocument1 pageSandvik: SLU SLURobertoNo ratings yet

- Chapter 3 Signal Conditioning PDFDocument13 pagesChapter 3 Signal Conditioning PDFBelayneh Tadesse50% (2)

- LG MS-1146SQP-77520Document33 pagesLG MS-1146SQP-77520Angel FigueroaNo ratings yet

- Small Signal Transistors TO-39 CaseDocument1 pageSmall Signal Transistors TO-39 CasePetr ggaNo ratings yet

- MRFU Description: Huawei Technologies Co., LTDDocument14 pagesMRFU Description: Huawei Technologies Co., LTDعلي عباسNo ratings yet

- Kodak Point-of-Care CR 120/140 Systems: Service Manual For TheDocument156 pagesKodak Point-of-Care CR 120/140 Systems: Service Manual For TheRichard Gomera FernandezNo ratings yet

- Circuit Switchers: 1. Visual and Mechanical InspectionDocument3 pagesCircuit Switchers: 1. Visual and Mechanical InspectionHoneylyn IgnacioNo ratings yet

- Automatic Scorer CatalogDocument222 pagesAutomatic Scorer CatalogNathan Bukoski100% (1)

- Cpi - Cpi1004 Cmp200 Brochure e FNL CRPDDocument4 pagesCpi - Cpi1004 Cmp200 Brochure e FNL CRPDRaulNo ratings yet

- tr13 03 02 Kompletteringar Fortydligand 3.sv - enDocument57 pagestr13 03 02 Kompletteringar Fortydligand 3.sv - ensasa milosevicNo ratings yet

- Thermo Cr422 Troubleshooting ManualDocument35 pagesThermo Cr422 Troubleshooting ManualRuben DuranNo ratings yet

- Single-Phase Induction Motor Adjustable Speed Drive: Direct Phase Angle Control of The Auxiliary Winding SupplyDocument7 pagesSingle-Phase Induction Motor Adjustable Speed Drive: Direct Phase Angle Control of The Auxiliary Winding SupplyMega Firdausi NuzullaNo ratings yet

- Trainiing BeckhoffDocument45 pagesTrainiing BeckhoffĐại TrầnNo ratings yet

- 11643Document16 pages11643dfvgdfvdfvdsvsfsdasdvNo ratings yet

- Interpret AC Voltages & CurrentsDocument46 pagesInterpret AC Voltages & CurrentsKelvin LooiNo ratings yet

- Class:12 Physics Assignment 8 Topic: Electromagnetic InductionDocument3 pagesClass:12 Physics Assignment 8 Topic: Electromagnetic InductionAkshat RawatNo ratings yet

- Complete McWade Catalogue Aug 2015Document214 pagesComplete McWade Catalogue Aug 2015tedNo ratings yet

- Clevo M620ne-UDocument34 pagesClevo M620ne-UHh woo't hoofNo ratings yet

- Honeywell RC500 Hardware Planning Installaition Users GuideDocument92 pagesHoneywell RC500 Hardware Planning Installaition Users GuideakramhomriNo ratings yet

- B HRG0U22401 Electric SystemDocument9 pagesB HRG0U22401 Electric SystemJOAO BIANCHININo ratings yet

- An Adaptive Reconfigurable Rectifier For Wireless Power TransmissionDocument3 pagesAn Adaptive Reconfigurable Rectifier For Wireless Power Transmissionkavirasu1990No ratings yet

- Solenoid Valves 3/2 131: Direct Operated 3 Mounting Holes in The Body 1/4Document2 pagesSolenoid Valves 3/2 131: Direct Operated 3 Mounting Holes in The Body 1/4sks1969No ratings yet

- SYS-3010 Syringe Pump Operation Manual - V1.1Document62 pagesSYS-3010 Syringe Pump Operation Manual - V1.1bprz50% (2)

- MIL-DTL-38999 Electrical Connector SpecificationDocument159 pagesMIL-DTL-38999 Electrical Connector SpecificationJader PetrucciNo ratings yet

- Service Manual: ChassisDocument39 pagesService Manual: Chassisefrain villazonNo ratings yet

- Experion LCN Tech Spec PDFDocument27 pagesExperion LCN Tech Spec PDFjashkishoreNo ratings yet

- 1000W Driver Power Amplifier NamecDocument37 pages1000W Driver Power Amplifier NamecRoldao AlmeidaNo ratings yet

- Shaloo Rakheja, PHD - NYU Tandon School of EngineeringDocument2 pagesShaloo Rakheja, PHD - NYU Tandon School of EngineeringGurinder Pal SinghNo ratings yet

- Analysis of Stray Current Tracktoearth Potentials and SubstationDocument20 pagesAnalysis of Stray Current Tracktoearth Potentials and SubstationLaurence MichaelNo ratings yet

- Parts Mini VRFDocument5 pagesParts Mini VRFbitorrenta6bitoNo ratings yet

- E-field and H-field cell placement for solving Maxwell's equations using FDTD methodDocument7 pagesE-field and H-field cell placement for solving Maxwell's equations using FDTD methodJosNo ratings yet