Professional Documents

Culture Documents

14ND-online Ogilvie PDF

Uploaded by

american_guy10Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

14ND-online Ogilvie PDF

Uploaded by

american_guy10Copyright:

Available Formats

Online Exclusive from

PHARMACEUTICAL ENGINEERING

THE OFFICIAL TECHNICAL MAGAZINE OF ISPE

NOVEMBER/DECEMBER 2014, VOL 34, NO 6

regulatory compliance

©Copyright ISPE 2014

Life Cycle Management

www.PharmaceuticalEngineering.org

Starting Materials Selection and

Life Cycle Management

by Richard Andrews, Mike James, Luc Janssens, Paul Marshall,

Frank Montgomery, and Ron Ogilvie

This article discusses the selection of Starting Materials (SMs) for the

commercial manufacture of Active Pharmaceutical Ingredients (APIs) and

challenges and potential solutions to the selection and agreement of SMs.

S

election of Starting Materials (SM) for and regulators. The article also provides insights into how an

commercial manufacture of an Active applicant might address such challenges.

Pharmaceutical Ingredient (API) is It is important that regulators are assured that the appli-

an important matter for industry and cant has an approach to SM supply and quality management

regulators. This starting material, that assures the quality of the API across the product life-

once approved, becomes the starting cycle (i.e., from first approval and then through subsequent

point for application of current Good changes to supply).

Manufacturing Practice (cGMP), and Let’s begin by considering regulatory expectations. It is a

manufacturing process and control requirement of pharmaceutical manufacturing regulations

commitments. globally that the marketing application (or change applica-

Regulatory expectations in ICH countries for selection tion) provides information on the API manufacture, either

of SMs are provided in Q11 “Development and Manufac- as part of the submission (3.2.S) or (in some countries) by

ture of Drug Substances.” In Q11, a set of “principles” are reference to a separate master file. This API manufacturing

provided for an applicant to consider as part of justification process description starts with introduction of the proposed

of proposed SMs. These principles provide a set of consid- SMs. (EU regulators find a summary of the process used to

erations that can support the proposal of an SM, but do not make proposed SMs useful in evaluating the appropriate-

establish an algorithm for decision-making, so every ap- ness of SM controls.) Global regulations require that API

plicant who considers a process will not immediately be led be made under cGMP for supply to patients and that cGMP

to the same SM proposal. This flexibility is appropriate as is appropriately applied across the process described in

different approaches to manufacturing, supply and control the submission, i.e., SMs become the cGMP starting point.

can support different SMs and means that the SM proposal Global regulations also require manufacture be appropri-

requires justification. The justification becomes a matter ately validated for commercial supply, and validation should

for review and approval. A regulator can question proposed encompass critical aspects of the described manufacturing

SMs and may require the applicant to redefine their pro- process. Thus, the proposed SMs become the starting point

posed SM, usually earlier in the synthesis. As this decision for implementing approaches to validation.

is clearly linked to the supply of the API, the refusal of a The pharmaceutical manufacturer is responsible for

proposed SM can have significant impact on the applicant’s ensuring quality by ensuring manufacture is conducted

supply intentions and thus, is worthy of careful attention in accordance with cGMP and the product license. The

and risk management. regulatory role is to ensure the quality, safety and efficacy

This article considers the principles established in Q11 of product that reaches the patient. To appropriately ad-

and examines the implementation challenges for industry dress the accountability placed on the regulatory system, a

PHARMACEUTICAL ENGINEERING NOVEMBER/DECEMBER 2014 1

regulatory compliance

Life Cycle Management

regulator needs to be able to assess API quality/safety and API. This has the effect of ensuring “significant chemistry”

assess risks to quality/safety in API manufacture. Of course, is done to produce the API and making it less likely that

industry also needs to control the same risks and needs to impurities from structurally dis-similar SMs will be present

be “in control” of SM quality and supply. It is important to in API.

assure the regulator that such quality control is in place and Thus, behind potential “rules” lie principles that underpin

can be maintained across time and change. Such assurance what is important in selecting SMs, e.g., that the SM quality

might be provided by sharing controls placed on the SM and has little likelihood of impurities impacting on API quality.

its supply by the applicant, by being transparent why SM se- The suggestion that “SMs should be ‘X’ steps from API”

lection decisions are made and by providing information on is similar, as again significant chemistry will be conducted

how risks to quality are managed. Without such information, to convert SM to API and the isolations conducted will assist

a regulator may not have sufficient confidence in the SM to in the purge of SM-associated impurities during processing.

approve it for commercial manufacture. Even with such in- The underlying principles that there should be little likeli-

formation, the regulator may seek further assurances based hood of carry-over of unmanaged impacts to API quality

on their assessment of the balance of risks to quality and and ensuring the regulator will be provided with significant

quality controls. Providing information for assessment is a understanding of the manufacture of API and the risks that

key component in achieving approval, and without transpar- may be associated with its quality, allow proper assessment

ency, trust in the proposal and the resultant quality would be of associated controls.

harder to establish. So, deep concerns for quality management, transparency

of manufacturing information and risk assessment of impu-

No “Absolute Rules” to Guide the Process rity risks and controls are reflected into the Q11 principles,

of Selection, Justification and Acceptance and sought by regulators when assessing proposed SMs

of an SM for manufacture of a commercial API. However, providing

“Rules” are designed to be prescriptive. “Rules” could lead guiding principles makes interpretation and implementation

to regulators being obliged to accept a SM simply because more open to discussion than would “simple” (but inflexible)

it complies with “the rules” even if the proposed SM is one “rules.”

the regulator finds to be a concern. ICH determined that a Q11 makes clear that ALL the principles need to be con-

lack of absolute rules is appropriate. Instead, Q11 provided sidered to support SM selection, but that no one principle is

certain principles for consideration that allow an applicant an absolute expectation. The Q11 principles address building

to make (and regulators to review) a proposal in a case- quality in to API through development and implementation

by-case manner, that is closely related to the case-by-case of appropriate control strategies for significant materials.

selection of manufacturing steps, suppliers and controls that The Q11 principles that support SM selection are:

optimally provides for manufacture of API.

Q11 allows a material with significant pre-existing, non- • A SM will be a significant fragment of drug substance.

pharmaceutical use (a commodity material) to be a proposed • Carryover of risks to drug substance quality is of lower

SM without further justification. Therefore, one potential potential impact the further the SM is from API (in terms

“rule” could have been that “all SMs should be commercial- of number of steps or structural similarity).

ly-available” (if this concept could be simply defined). This • The control strategy for API and process needs to be

rule, however, would prevent a SM without this prior usage appropriate and to judge this, information on impurity

being considered. The rule also would mean that if an appli- potential presence and formation can be needed (even for

cant has to use only commodity materials as SMs, they could some SMs).

be “locked into” sub-optimal manufacturing routes (with • Manufacturing steps that significantly impact API im-

adverse impacts on costs, waste, environmental impact, purity profile should normally be included in S.2.2 (i.e.,

process safety, etc.) or need to use particular chemistries or after the SM).

technologies to elaborate the commodity SM to API that are • Each branch of a manufacturing process begins with one

not available to the applicant “in house.” or more SMs.

The suggestion that “SMs should be commercially- • A SM should be of defined chemical properties and struc-

available” is potentially useful as this precludes the need to ture (and be isolated).

manufacture any commodity material under cGMP to allow

for its use in pharmaceutical manufacture. And, given the Q11 guides the applicant to provide a justification for why

structural complexity of many APIs and the relative struc- each proposed SM is appropriate in light of the general

tural “simplicity” of most commodity chemicals, this rule principles. The justification can include information on the

could have the effect of keeping SMs simple and distinct ability of analytical methods to detect SM impurities; the

in structural (and probably physico-chemical) terms from fate and purge of those impurities and their derivatives in

2 NOVEMBER/DECEMBER 2014 PHARMACEUTICAL ENGINEERING

regulatory compliance

Life Cycle Management

subsequent steps and how the proposed SM specification • The applicant’s internal manufacturing capabilities. Par-

contributes to the overall control strategy. (Changes to the ticular chemistries (e.g., low temperature reactions; high

SM specification are subject to change management). pressure reactions; particular functional transformations)

This Q11 content is helpful, but as the guidance does not may be most effective for efficient API manufacture but

establish “simple rules” different companies may take differ- that the applicant cannot support in their facilities and

ent approaches to SM selection. Regulators can have ques- are only available when working in partnership with sup-

tions and challenges on a company’s SM proposal. Regulatory pliers who have specific expertise and facilities.

agencies can want to see longer regulatory syntheses than an

applicant proposes. Regulators also note information on SM • Applicant’s internal manufacturing capacity. This is a

manufacture can be important to as part of risk evaluation. finite resource and may be managed such that vital final

So, every applicant can develop proposals based on Q11 steps of all key medicines in the portfolio can be made.

principles and establish what they believe to be a justifica- Capacity analysis considers manufacturing volumes of

tion for SM selection proposals. This needs to include infor- medicines (which can change with time) and process

mation to allow regulators to reach conclusions on how risks efficiency of manufacturing routes. Furthermore, some

have been managed and a well-rationalized control strategy process steps can need dedicated plant or environmental

for impurities. treatment and all these factors have to be considered in

The expectation for consistency of decisions has been determining the optimal route and process. “Convergent”

a concern with the concepts built into ICH Q11. When ap- rather than “linear” syntheses can be favored.

plicants invest to different degrees in product and process

understanding and controls, there is a very reasonable case • Security of supply. Oftentimes, an API manufacturer will

for regulatory acceptance of differences from such appli- want > 1 source of a SM to manage efficient and secure

cants. Thus, the ideal outcome may not be consistency, but supply and will establish relationships with key suppli-

predictability about acceptability of justifications based on ers. There is no regulatory constraint on this approach,

shared knowledge, risk management and controls applied. providing each source produces API of acceptable quality.

To approach this predictability, there needs to be Dependent upon capacity and capability, this also can

transparent exchange of information and a mutual involve a “make – buy” option wherein the applicant

appreciation of what needs to be delivered from the and other suppliers make a proposed SM. This explains

management of SM supply, and maintained across why regulators can find that an applicant is making a

the product’s lifecycle. Regulators welcome pre-submis- proposed SM. This “make – buy” approach also can be

sion on starting material proposals and associated control utilized when applicant and supplier have collaborated to

strategies. develop the process to manufacture the SM. Security of

The ISPE team collected key questions that regulators supply is not as easily assured if SM comes from a single

(assessors and inspectors) and industry had on this topic. source using “trade-secret” technology.

Here we provide context to these questions and suggest

some ways that concerns might be addressed. It is hoped • Process understanding. The better an applicant un-

that this will lead to increased mutual understanding and derstands the API manufacturing process, the clearer

easier implementation of Q11 principles. becomes the understanding of which process elements

impact on API quality, and the understanding of what

Regulators may not be Aware Why SM control strategy is needed to assure quality of the API.

Selection Decisions are Made by Industry Thus, an applicant who knows little about the process

– Approaches Seem Very Variable Between may need to maintain similar materials and controls as

Companies. Can This be Explained? used in development (e.g., same SMs and specifications

It would be helpful for an applicant to provide an under- based on supply quality received), whereas an applicant

standing of why they have made SM proposals. who has invested in increased product/process knowl-

A company can have a variety of reasons in making the edge may know that significant API impurities result

proposal for a SM, as several factors are important to a com- from later processing steps. Similarly, the applicant may

pany in the finalization of the API manufacturing process. understand that certain aspects of SM quality are more

These factors include: important than others in assuring API quality and thus

the SM specification can include some attributes and not

• Availability of commercial commodity materials, which others and can establish limits wider than historical sup-

can guide SM selected during development and also iden- ply quality for some attributes, based on the applicant’s

tify suppliers who might be able to provide a later process knowledge of the purge (and fate) of SM impurities. This

“intermediate,” based on their capabilities and expertise. process knowledge also can enable the applicant to pro-

PHARMACEUTICAL ENGINEERING NOVEMBER/DECEMBER 2014 3

regulatory compliance

Life Cycle Management

pose controls on unspecified impurities in the SM above • The expectation that a commodity material be the SM

the limit expected in the API. can lead to certain processes/ chemistries being needed

within manufacturing that 1. may not be optimal for API

• Number of steps conducted under cGMP. cGMP com- manufacture; 2. may not be available to the applicant

mences from the proposed SMs. The legislative require- in their facilities; and 3. may lead to one route being

ment to manufacture under cGMP was introduced to selected over another simply on the basis of the current

assure quality of the final API. The more steps carried out catalogue of commodity chemicals.

under cGMP, potentially the higher assurance of quality.

• Building a relationship with a supplier of a commodity

• The manufacturer will select a manufacturing route to material to provide a later material in the manufacturing

seek to optimize a variety of factors – manufacturing ef- route can improve overall effectiveness and economy of

ficiency, environmental impact, and economics. manufacture.

• Support process improvement. The manufacturing • Proposal of a commercially available commodity mate-

process at initial approval may not be optimized (for rial as SM does not remove the need for the proposed SM

throughput, cost, environmental input, etc.) and the to have a suitable specification and appropriate control

manufacturer may wish to improve the process. Some de- methodology to assure API quality.

gree of regulatory flexibility may be sought by proposing

short manufacturing processes. However, this needs to • One does not always know how a commercially avail-

be balanced by considering what steps impact and what able commodity material is made. Thus, understanding

controls are necessary for API quality, which should then the needs of control methodologies in terms of impurity

be included in the regulatory synthetic pathway. The risks monitoring capabilities can be difficult. Conversely, if

to API quality are minimized when process understand- one has developed chemistry to a later intermediate (or

ing has been used to rationally select the SM. co-developed this with a supplier), one understands the

“later steps” in the SM manufacture and thus can more

Why are Commercially-Available/ readily develop control methodology/specifications.

Commodity Materials not Always Selected?

It may not be needed to propose a commercially-available • A commodity material can have multiple suppliers and

commodity SM to assure API quality, and to do so may not different quality from different supply sources. Each

allow for optimization of cost and manufacturing robust- source can have different potential impurities. This

ness. In addition, this approach could be “non-scientific” if makes quality assurance less easy and can make manu-

the generation of API critical quality attributes could be as- facturing less robust. Reliance on commodity sources can

sured by focus on later steps and by provision of controls for appear to increase supply chain security and quality but

later materials, one of which could be proposed as the SM, can have the opposite effect.

supported by appropriate justification.

“Commercial availability” may change across time – the • Even if a later intermediate comes available over time, it

chemicals industry may target non-commodity intermedi- does not mean that the “late” commercial material will

ates in pharmaceutical manufacturing as commercial op- necessarily be suitable for use as SM as it needs to both

portunities. This could bring very cost-effective and efficient meet specification and assure against, e.g., cross-contam-

new materials to the market. It would be strange if later ination risks from manufacture/supply. Thus, a SM being

manufacturers of the API should be able to adopt such later made for an applicant from a partnership with a limited

intermediates without question of the overall control and number of suppliers can be a more stable and secure

quality management approach, and it would be strange if an position than “commercial availability.”

innovator company could not also switch to such materials

as they became available (the innovator being best-posi- Of course, it can be necessary to utilize commodity materi-

tioned to understand the control needs for the later interme- als as SMs in API manufacture. This can happen when a late

diate). fragment in a convergent synthesis comes from a commod-

It would be helpful for an applicant to provide explana- ity material. There is nothing wrong with such a proposal as

tion of why they have not proposed a commercially-available long as the risks to API quality are considered and appropri-

commodity material as the proposed SM. ate specifications/control methods put in place to assure API

A company can have several reasons in choosing not to quality.

propose a commercially available commodity SM: The underlying principle is that the applicant needs to

control risks to quality and the regulators need to be able to

4 NOVEMBER/DECEMBER 2014 PHARMACEUTICAL ENGINEERING

regulatory compliance

Life Cycle Management

assess the controls put in place. When this is considered, use assure API quality. This approach may not be taken by all

of only commercially-available commodity materials as SMs applicants, but a proposal from one applicant does not need

need be no more appropriate than the proposal of a later to match that from another, it only needs to be appropriate

material as the SM. There may be no correlation between based on the knowledge the applicant has shared and the

commercial-availability and the risk to API quality. controls that the applicant has put in place to manage risks

to API quality.

Why is a Certain Number of Steps not This is best done when the latter stages of SM manu-

Always Proposed? facture are known to the applicant. The SM specification is

This “number of steps” approach is seen as a means of most meaningful when links from the impurities specified

guarding against carry-over of impurities and managing on the SM specification to the API specification are clearly

against contamination risks. It might be reasonable to have understood – i.e., which impurities purge, which progress

increased levels of concern any time a SM proposal is made to API, perhaps in modified form, and what levels should be

which does not mean that a certain number of steps (or controlled.

isolations) to API results. However, it should continue to be An applicant who presents such understanding of their

possible for an applicant to make a justification of a SM with control strategy that supports the specification of the pro-

a low number of steps to API provided risks to quality are posed SM will have gone some way to convincing the regula-

adequately addressed. After all, in a convergent synthesis, tor of the appropriateness of the SM proposed. The regulator

few steps may be used to convert commodity materials to may still have questions on how this understanding and

API and in some syntheses, a late commodity material can quality is maintained against change and how this proposed

enter a process very close to API. Both cases can be ac- supply manages cross-contamination concerns the regulator

ceptable and in both cases the focus is on the adequacy of may have. The API manufacturer can work with the SM sup-

controls and assurance of API quality and not on absolute plier to address such concerns, e.g. by ensuring that changes

step-counting. in SM manufacture are communicated from the SM supplier

It would be helpful for an applicant to provide more un- to the API manufacturer.

derstanding of why they have proposed SM closer to the API

as the proposed SM. How can Specifications/Control Strategy/

A company can have several reasons in not choosing to Quality System Manage Changes to SM

propose an earlier material as the SM. These factors include: Supply?

The acceptance of a proposed SM and its associated control

• The optimal manufacturing process is a convergent one, strategy needs to maintain quality across the product life-

and thus, commodity SMs are closer to the API. cycle. This is a significant concern, as if a process description

• A commodity material enters the process closer to the and control strategy begins with the SMs, then all changes

API. prior to this point will not be under regulatory purview.

• In a process to an API, no significant API impurities Furthermore, some changes could be significant, but

come from earlier steps/materials. Significant impurities invisible to the test methodologies applied, so materials that

result from early steps in some syntheses and later steps should fail could be passed due to the inability of control

in others – convergent syntheses can often support more methods to manage the change made. Thus, reliance on the

impurity purge in a shorter number of steps than linear control strategy may not allow the regulator to meet their

syntheses due to greater difference between SM and API responsibility to ensure quality of the medicine.

properties. This risk could exist irrespective of the length of a route

and irrespective of whether the proposed SM is commercial or

How can Specifications/Control Strategy not (indeed, a commodity SM might be most at risk from such

Manage Risk to Quality (Even for a SM not invisible changes). What needs to be considered by applicant

Separated From API by Many Steps)? and regulators alike are questions such as: 1. how can the

An applicant can invest in understanding what impurities manufacturer of API be aware of changes and manage their

should be controlled on the specification of a proposed SM. impact? 2. does the analytical methodology have the power to

This understanding can be based on knowledge of how the manage this change? and 3. is SM specification still relevant?

proposed SM is made, which potential impurities (organic An API manufacturer can establish an agreement with

materials, solvents, elemental residues) could be associated the supplier to communicate changes to SM manufacture so

with its manufacture (even by a number of potential routes that the API manufacturer can assess any risk to API qual-

of synthesis), which impurities need to be specified, which ity. The API manufacturer can evaluate the change in SM

need to be capable of monitoring by the analytical methods, manufacture for any new potential impurities that may be

and what levels of impurities can be accepted in the SM to present and evaluate whether the analytical methodologies

PHARMACEUTICAL ENGINEERING NOVEMBER/DECEMBER 2014 5

regulatory compliance

Life Cycle Management

remain valid to assure SM quality. If the analytical methods With time, it has been recognized that this is not essen-

are unsuitable, then new methodologies should be devel- tial, as the control strategy applied to a chiral SM, and down-

oped, so that the change can be properly evaluated. If the stream intermediates and API, can assure the API’s chiral

analytical methods are able to detect new potential impuri- quality. This allows for use of “chiral pool” SMs (sugars and

ties and the post-change SM continues to meet specification, amino acids, etc.), and for products of resolutions (enzy-

the change is likely to have no impact on API quality. If there matic or chemical) to be accepted as SMs when supported

are new detected impurities in the post-change SM, it may by suitable controls. This flexibility supports innovation, as

be that the material should not be used until it is understood industry can then adopt different approaches to produce

if the new impurities lead to any significant change in API the chiral SM, providing the SM specification continues to

quality. Where there are changes to the SM specification or assure quality of the SM and API – e.g. a SM resulting from

the analytical methods this should be communicated to the chiral resolution (with a 50% loss of the unwanted enan-

regulators. tiomer) can be optimized to a route where the chirality is

Regulations require that the company quality authority established in other ways (e.g. asymmetric hydrogenation),

is independent of the manufacturing responsibility and that leading to more efficient API manufacture.

there is a professional and independent quality authority

within a company to oversee the proper working of such Does Proposed SM Need to be Before the

documented change management processes. First Use of Mutagenic Reagents?

A regulator needs to know the applicant is in control of such

How Can Manufacturing Route Risk risks to API quality. Mutagenic impurities can be seen as

Assessment Support SM Selection potentially critical quality attributes and thus, regulators

Decision? can expect that steps that use/generate mutagenic materials

An applicant thinking rationally about what SMs to propose, should be on the regulated process. Good process design can

knowing regulators might be hoping for at least “X” steps, however look to use/generate mutagenic materials early in

and a solid rationale for anything less, should bring their manufacturing (precisely to lessen the likelihood of carry-

understanding of the process to bear on the SM justification over to API).

and present the knowledge about what impacts API quality Again, it may not be essential for steps using/generating

to the regulator. mutagenic materials to be on the described manufacturing

An applicant can understand which API manufacturing process provided the control strategy adequately manages

steps lead to significant API impurities. The applicant can risk.

share this knowledge with the regulator as part of the SM The quality of a proposed SM (e.g., an aromatic amine)

justification. The applicant also can understand what the can be controlled with respect to mutagenic potential

(potential) SM impurity profile is and how the SM impuri- impurities (e.g., precursor aromatic nitro compound) by

ties are handled by the API manufacturing process – Do analytical method and as need be by specification. Again, the

they purge? Where? How much? Are they converted to other applicant can with knowledge of the manufacturing process

materials downstream? of the proposed SM, build necessary controls into the SM

The applicant who understands the potential SM impu- specification. In this case, the mutagenic impurity can be

rity profile is well placed to establish appropriate methods controlled at the SM either at the required API limit or at

for SM control and best placed to develop the manufactur- a limit that purges to the necessary API limit. (Note that a

ing process for the API to build in processing operations mutagenic impurity introduced early may be purged during

that can remove impurities as the manufacturing process subsequent processing and may not have the potential to

proceeds. With this knowledge, an applicant may be able to impact API quality.)

propose a SM with no potential impurities that carry-over

to API, or propose a SM which has carryover, but where the How can GMP Risks Associated With the

downstream control and qualification needs are managed. use of a SM That Enters a Manufacturing

Process at a Late Stage be Managed?

Does Proposed SM Need to be Before the Short routes from SMs to API may increase cGMP risks to

Point of Introduction of Chirality? API quality by carry-over of “unknown” impurities (or con-

Chirality is a critical quality attribute of many active taminants from manufacture of the proposed SM).

substances. Regulators have considered that the step that Such risks can be managed by agreeing with the supplier

establishes the API’s chiral quality should be on the regu- to, e.g., establish appropriate cleaning/cross-contamination

lated process description and that the SM should be before management procedures during manufacture. An API can be

introduction of chirality. manufactured by the applicant from a SM produced by a sup-

ply partner under such an agreement (that can also include

6 NOVEMBER/DECEMBER 2014 PHARMACEUTICAL ENGINEERING

regulatory compliance

Life Cycle Management

change communication), and together with an appropriate Hopefully, the consideration here of key questions that

control strategy, this can be a suitable manufacturing strategy. arise from API SM proposals enable improved communica-

Having a supply agreement with a SM manufacturer does tion that supports smoother discussion of API SM proposals.

not, however, provide the basis for a SM proposal. Quality management of pharmaceuticals is of paramount

There is no presumption that subsequent API suppliers importance to all stakeholders, including patients, and

entering the market (say for supply of a generic product) managing SM quality plays a foundational role in assuring

should have the same agreed SM as the original product. quality of medicines.

Approval should be on the basis of how that supplier man-

ages risks to API quality from their proposed manufacturing Authors

supply chain. Richard Andrews, UK MHRA

Mike James, GlaxoSmithKline

Summary

There are a number of factors to be considered in API SM Luc Janssens, Johnson & Johnson

selection and justification. This selection decision can Paul Marshall, UK MHRA

be approached in a case-by-case manner using scientific Frank Montgomery, AstraZeneca

understanding and the quality system to manage risks. This

flexibility is well-supported by the Q11 principles. These Ron Ogilvie, Pfizer

provide useful guidance and can lead to effective SM selec-

tion, provided the spirit of these principles is appropriately

applied.

PHARMACEUTICAL ENGINEERING NOVEMBER/DECEMBER 2014 7

You might also like

- Guideline Supplier Qualification - Dec09FINALDocument34 pagesGuideline Supplier Qualification - Dec09FINALbach2007No ratings yet

- Risk Assessment in Automated Manufacturing Practices 2Document0 pagesRisk Assessment in Automated Manufacturing Practices 2venki_beeNo ratings yet

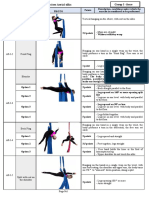

- Aerial Yoga Manual 2018 Third Edition ADocument156 pagesAerial Yoga Manual 2018 Third Edition Atito1628100% (8)

- Aerial Yoga Manual 2018 Third Edition ADocument156 pagesAerial Yoga Manual 2018 Third Edition Atito1628100% (8)

- Quality Manual TemplateDocument34 pagesQuality Manual Templatesakib445100% (3)

- Fundamentals of An Environmental Monitoring ProgramDocument71 pagesFundamentals of An Environmental Monitoring Programtito1628No ratings yet

- Technical Guide Change ControlDocument42 pagesTechnical Guide Change Controltito1628No ratings yet

- Technical Guide Change ControlDocument42 pagesTechnical Guide Change Controltito1628No ratings yet

- Process Safety ManagementDocument28 pagesProcess Safety ManagementIndranil Hatua93% (14)

- EU-GMP.2014 - Annex - 20 (Quality Risk Management)Document25 pagesEU-GMP.2014 - Annex - 20 (Quality Risk Management)bvsc77035No ratings yet

- The Aerial Sling Manual: Prev Iew Prev IewDocument13 pagesThe Aerial Sling Manual: Prev Iew Prev Iewtito1628100% (1)

- File-Download Environmental MonitoringDocument8 pagesFile-Download Environmental Monitoringppremala86No ratings yet

- FPH-HP Install Manual V2.8Document38 pagesFPH-HP Install Manual V2.8steve67% (3)

- PQLI Control Strategy Model and ConceptsDocument10 pagesPQLI Control Strategy Model and ConceptspakdekroNo ratings yet

- Guideline Supplier Qualification - Dec09FINALDocument34 pagesGuideline Supplier Qualification - Dec09FINALsksingh82100% (3)

- Avoiding Errors With The Batch Release ProcessDocument11 pagesAvoiding Errors With The Batch Release ProcessAnthony CollierNo ratings yet

- Guideline Supplier Qualification - Dec09FINALDocument35 pagesGuideline Supplier Qualification - Dec09FINALflongNo ratings yet

- 2.10 Risk-Based Qualification For The 21st CenturyDocument7 pages2.10 Risk-Based Qualification For The 21st CenturyJorge Humberto HerreraNo ratings yet

- Applying ICH Q8 (R2), Q9, and Q10 Principles To CMC ReviewDocument5 pagesApplying ICH Q8 (R2), Q9, and Q10 Principles To CMC Reviewvg_vvgNo ratings yet

- Appendix 1 Compulsory Exercises Aerial Silk Eng 2018Document23 pagesAppendix 1 Compulsory Exercises Aerial Silk Eng 2018tito1628100% (6)

- Guideline Supplier Qualification - Contract Labs Final - Jan 2012Document22 pagesGuideline Supplier Qualification - Contract Labs Final - Jan 2012nsk79in@gmail.com100% (1)

- Lighthouse Environmental Monitoring Systems and Regulatory ComplianceDocument40 pagesLighthouse Environmental Monitoring Systems and Regulatory ComplianceHasni MoezNo ratings yet

- GMP in Pharmaceutical Industry: Global cGMP & Regulatory ExpectationsFrom EverandGMP in Pharmaceutical Industry: Global cGMP & Regulatory ExpectationsRating: 5 out of 5 stars5/5 (2)

- Alberto Villoldo Book PDFDocument120 pagesAlberto Villoldo Book PDFtito1628100% (3)

- Appendix 2 Compulsory Exercises Aerial Hoop 2018 EngDocument28 pagesAppendix 2 Compulsory Exercises Aerial Hoop 2018 Engtito1628100% (1)

- Guideline Supplier QualificationDocument21 pagesGuideline Supplier QualificationHamid HamidNo ratings yet

- FP5007 Sop GMP 1Document32 pagesFP5007 Sop GMP 1silvanaanggraeniNo ratings yet

- Quality Risk Management SopDocument9 pagesQuality Risk Management Sopselinasimpson1301100% (1)

- Sistemas A320Document115 pagesSistemas A320Juan Pablo Montoya MNo ratings yet

- X-Ray GuidelinesDocument76 pagesX-Ray GuidelinesanggabianzNo ratings yet

- Anatomy of ContaminationControlDocument19 pagesAnatomy of ContaminationControlVinay PatelNo ratings yet

- Change Management: Common Failures and A Checklist For ImprovementDocument5 pagesChange Management: Common Failures and A Checklist For ImprovementPerry BurtonNo ratings yet

- Cleaning Validation Guidelines - A Complete ListDocument11 pagesCleaning Validation Guidelines - A Complete ListSanjay SharmaNo ratings yet

- The Formalized Risk Assessment For Excipients - GenialDocument22 pagesThe Formalized Risk Assessment For Excipients - Genialtito1628No ratings yet

- GXP Compliance in Pharmaceutical Industry PDFDocument6 pagesGXP Compliance in Pharmaceutical Industry PDFGyana SahooNo ratings yet

- Pharmaceutical Quality Management System (QMS) Questions and AnswersFrom EverandPharmaceutical Quality Management System (QMS) Questions and AnswersNo ratings yet

- APIC RSM Auditing - 201802 PDFDocument23 pagesAPIC RSM Auditing - 201802 PDFAl RammohanNo ratings yet

- IJPR1303238Document18 pagesIJPR1303238yaminiaravindNo ratings yet

- Annex2TRS 981Document32 pagesAnnex2TRS 981anandhra2010No ratings yet

- GMP and Regulations: Good Manufacturing PracticeDocument10 pagesGMP and Regulations: Good Manufacturing PracticeCelia Caroline Neves Faria de SousaNo ratings yet

- API SM Part 1Document7 pagesAPI SM Part 1Ronaldo JanglinNo ratings yet

- Quality Risk Management and The Draft Annex 1 Revision - What To ExpectDocument6 pagesQuality Risk Management and The Draft Annex 1 Revision - What To ExpectGovindaRajulaReddy M.VNo ratings yet

- Supplier Qualification Guideline APICDocument34 pagesSupplier Qualification Guideline APICnataarajan praveenNo ratings yet

- Pharmaceutical Quality SystemDocument8 pagesPharmaceutical Quality SystemRainMan75No ratings yet

- 4 Key Considerations When Engaging A New GMP Contract Service ProviderDocument5 pages4 Key Considerations When Engaging A New GMP Contract Service ProviderMina Maher MikhailNo ratings yet

- White Paper - Regulatoy ComplianceDocument14 pagesWhite Paper - Regulatoy ComplianceMinh LêNo ratings yet

- Smart Review of Marketing Authorisation Applications and Product Lifecycle Management: Future and ChallengesDocument8 pagesSmart Review of Marketing Authorisation Applications and Product Lifecycle Management: Future and ChallengesRAPPORTS DE PHARMACIENo ratings yet

- Future-Proofing Pharmaceutical Analytical Method Development With An AQbD ApproachDocument6 pagesFuture-Proofing Pharmaceutical Analytical Method Development With An AQbD ApproachrbmoureNo ratings yet

- Compliance Program Guidance Manual Chapter - 45 Biological Drug Products Inspection of Biological Drug Products (CBER) 7345.848Document57 pagesCompliance Program Guidance Manual Chapter - 45 Biological Drug Products Inspection of Biological Drug Products (CBER) 7345.848ana_mondekarNo ratings yet

- State of Total Quality Management in Pharmaceutical Industry Literature ReviewDocument4 pagesState of Total Quality Management in Pharmaceutical Industry Literature ReviewwoeatlrifNo ratings yet

- CXG - 021e CRITERII MICROBIOLOGICE PDFDocument4 pagesCXG - 021e CRITERII MICROBIOLOGICE PDFdorinutza280No ratings yet

- Why Are Cgmps So Important?Document13 pagesWhy Are Cgmps So Important?Adeliza MortallaNo ratings yet

- Contamination - Control - in - and - Out - of - The - Cleanroom - Full - ArticleDocument3 pagesContamination - Control - in - and - Out - of - The - Cleanroom - Full - ArticlesigalrusNo ratings yet

- 7.01 CAMs QSE Dec13 v2 1Document48 pages7.01 CAMs QSE Dec13 v2 1dutoitlouwNo ratings yet

- FDA - QSR (Quality System Regulation)Document4 pagesFDA - QSR (Quality System Regulation)camohunter71No ratings yet

- Lecture 5 - 6 & 7 - 2022-1Document20 pagesLecture 5 - 6 & 7 - 2022-1Koki KingNo ratings yet

- Experiment No. Title Date 1: Definition of Good Pharmacy PracticeDocument457 pagesExperiment No. Title Date 1: Definition of Good Pharmacy Practice10 Adarsh GuptaNo ratings yet

- Method Qualification vs. Validation - What Does That Mean Now?Document3 pagesMethod Qualification vs. Validation - What Does That Mean Now?António FerreiraNo ratings yet

- The FDA and Worldwide Current Good Manufacturing Practices and Quality System Requirements Guidebook for Finished PharmaceuticalsFrom EverandThe FDA and Worldwide Current Good Manufacturing Practices and Quality System Requirements Guidebook for Finished PharmaceuticalsNo ratings yet

- 1 - QS RegDocument4 pages1 - QS RegNathan GoodpastureNo ratings yet

- CA2 Leupron Ans KunalDocument12 pagesCA2 Leupron Ans Kunalvaishanavib2000No ratings yet

- 24 IM Review Est DataDocument7 pages24 IM Review Est DataNader SedighiNo ratings yet

- Aksu 2019 Chapter 2Document23 pagesAksu 2019 Chapter 2Angel GarciaNo ratings yet

- The Quality System Regulation: Flexibility of The GMPDocument6 pagesThe Quality System Regulation: Flexibility of The GMPtrungthanhnguyen_83No ratings yet

- Good Manufacturing Practices (GMP)Document5 pagesGood Manufacturing Practices (GMP)sai vaibhavNo ratings yet

- Michigan - October 30 2019 Guidance - Medical - FINAL.TESTING - GUIDE - 634575 - 7-UnlockedDocument33 pagesMichigan - October 30 2019 Guidance - Medical - FINAL.TESTING - GUIDE - 634575 - 7-UnlockedadamscavoneNo ratings yet

- 9437 Risk-Based-El WebDocument5 pages9437 Risk-Based-El WebRavi KanthNo ratings yet

- Manual of Policies and Procedures Center For Drug Evaluation and Research MAPP 5017.2 Rev. 1Document10 pagesManual of Policies and Procedures Center For Drug Evaluation and Research MAPP 5017.2 Rev. 1Md. Yousuf BhuiyanNo ratings yet

- Regulatory Affairs in Biotech IndustryDocument29 pagesRegulatory Affairs in Biotech IndustryG.Bhavana 4GM20BT018No ratings yet

- The FDA and Worldwide Quality System Requirements Guidebook for Medical DevicesFrom EverandThe FDA and Worldwide Quality System Requirements Guidebook for Medical DevicesNo ratings yet

- Company - Business Form: Business System Management Review TemplateDocument12 pagesCompany - Business Form: Business System Management Review Templatetito1628No ratings yet

- Paper Fitness ClubDocument6 pagesPaper Fitness Clubtito1628No ratings yet

- A Historical View of Human Resource ManagementDocument12 pagesA Historical View of Human Resource Managementtito1628No ratings yet

- Logical PositivismDocument30 pagesLogical Positivismangela danzalanNo ratings yet

- Tcs Book FinalDocument16 pagesTcs Book FinalAbinash MohantyNo ratings yet

- Mathematics8 q4 Mod5 BasicConceptsOfProbability v2Document26 pagesMathematics8 q4 Mod5 BasicConceptsOfProbability v2Ella Turla100% (1)

- Whats New 10Document730 pagesWhats New 10mikadoturkNo ratings yet

- E12 VoGr Unit 7 - For StudentsDocument5 pagesE12 VoGr Unit 7 - For StudentsNGỌC TRẦN BẢO0% (1)

- D14 Updated 24 Dec 2007 PDFDocument14 pagesD14 Updated 24 Dec 2007 PDFVinayak SanghaniNo ratings yet

- Rigstoreef Impact or Enhancement On Marine Biodiversity 2157 7625 1000187Document9 pagesRigstoreef Impact or Enhancement On Marine Biodiversity 2157 7625 1000187tavis80No ratings yet

- Resume of Arif MohiuddinDocument2 pagesResume of Arif MohiuddinMohammad Arif MohiuddinNo ratings yet

- MISUMI - Mold Plastic Injection Standard ComponentDocument1 pageMISUMI - Mold Plastic Injection Standard Componentgemilang metalindoNo ratings yet

- DrBela - 2608 - 17639 - 1 - Lecture 1 2021 Introduction To Qualitative ResaerchDocument20 pagesDrBela - 2608 - 17639 - 1 - Lecture 1 2021 Introduction To Qualitative ResaerchShahzaman Murtaza KhuhroNo ratings yet

- RRL FileDocument5 pagesRRL FileRalp James TilosNo ratings yet

- Assignment in CpE As A DisciplineDocument2 pagesAssignment in CpE As A DisciplineElaine Seroyla AgaraoNo ratings yet

- List of Pre-Owned Vehicles For Sale - 09.23.22Document21 pagesList of Pre-Owned Vehicles For Sale - 09.23.22adFWSVNo ratings yet

- PostProcessing BruyereDocument45 pagesPostProcessing BruyereThirugnanam DhandayuthapaniNo ratings yet

- Dywidag Post Tensioning Catalogue 6Document1 pageDywidag Post Tensioning Catalogue 6PrateekNo ratings yet

- Tutorial Letter 201/0/2019: Becoming A TeacherDocument10 pagesTutorial Letter 201/0/2019: Becoming A TeacherEsau KotsoaneNo ratings yet

- Evaluation of Tenders and Selection of Preferred BidderDocument3 pagesEvaluation of Tenders and Selection of Preferred Biddercute_prabudassNo ratings yet

- Color Change Desiccant MSDSDocument5 pagesColor Change Desiccant MSDSAmir RahbariNo ratings yet

- Particles of The Standard ModelDocument198 pagesParticles of The Standard ModelDan Vasiliu100% (2)

- Coding Decoding Study NotesDocument10 pagesCoding Decoding Study NotesDhanashree ShahareNo ratings yet

- Book Review - The Cambridge Guide To Second Language AssessmentDocument3 pagesBook Review - The Cambridge Guide To Second Language AssessmentWeijia WangNo ratings yet

- MT8000 User Manual WinView HMI EazyBuilderDocument428 pagesMT8000 User Manual WinView HMI EazyBuilderhiloactive100% (2)

- Used To, Would, Be Used ToDocument7 pagesUsed To, Would, Be Used ToFisnik SulejmaniNo ratings yet

- Cover Letter & Resume Baba NiangDocument4 pagesCover Letter & Resume Baba NiangBabacar NiangNo ratings yet

- Safety Data Sheet: Product Name: MOBIL RARUS 826Document10 pagesSafety Data Sheet: Product Name: MOBIL RARUS 826Escobar ValderramaNo ratings yet

- Department of Education: Weekly Home Learning Plan English Quarter 1 Sept 13-Oct 8, 2021Document5 pagesDepartment of Education: Weekly Home Learning Plan English Quarter 1 Sept 13-Oct 8, 2021Adrian PanganNo ratings yet

- Practice Test (1-10)Document40 pagesPractice Test (1-10)tamNo ratings yet

- EthicsDocument73 pagesEthicsMiechaellaNo ratings yet