Professional Documents

Culture Documents

23-02 Trial Cut For Turning PDF

Uploaded by

David BumbaloughOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

23-02 Trial Cut For Turning PDF

Uploaded by

David BumbaloughCopyright:

Available Formats

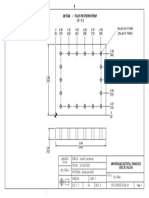

23-02 Trial Cut for Turning

Trial cut in CNC programming can have many forms. By definition, a trial cut is a physical cut that uses the cur-

rent tool to make a single - and measurable - test cut, before the actual machining begins. This test cut is part of the

CNC program, and must not interfere with the final cutting contour in any way. Trial cut is an actual cut on the

part, but has some specific characteristics:

1. The trial cut can be enabled or disabled by the CNC machine operator, as needed

2. The result of the trial cut can be measured

3. The part can be machined to final size during normal program processing

4. The trial cut programming method can be used for milling or turning

The 23-02 programming exercise shows a simple, yet powerful application of a block skip function.

ò Objective:

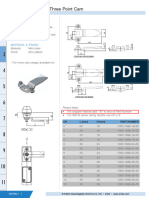

In this exercise, make a trial cut on the diameter for a fairly tight final tolerance, which is - in this case - applied

to the 44 mm diameter. The purpose of the trial cut is to adjust the wear offset before the actual cut, so the turning

(or boring) tool will complete the finish cut within the specified tolerance.

For the purposes of this exercise, the 65 mm diameter is clamped in a chuck and T01 will be used for roughing,

T03 for finishing, including the trial cut.

2X 0.1x45°

R4 Ø65

Ø44+0.03

-0.00

0

47

72

METRIC

Peter Smid CNC Programming Handbook 23-02 [ 1 ]

You might also like

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Tortort Manufacturing 80% Milled Receivers AK47Document6 pagesTortort Manufacturing 80% Milled Receivers AK47David BumbaloughNo ratings yet

- VOLVO 240 Engines d20 d24 ReconditioningDocument80 pagesVOLVO 240 Engines d20 d24 ReconditioningMyselvf100% (3)

- Omf751 - Lean Six Sigmaunit-1Document38 pagesOmf751 - Lean Six Sigmaunit-1culverts0% (1)

- 23-02 Trial Cut For Turning PDFDocument1 page23-02 Trial Cut For Turning PDFDavid BumbaloughNo ratings yet

- Training VibrasiDocument91 pagesTraining VibrasikarimNo ratings yet

- Clearance Angle Calculation: R0.375 0.02x45° TYPDocument1 pageClearance Angle Calculation: R0.375 0.02x45° TYPDavid BumbaloughNo ratings yet

- IAC Unit IIIDocument125 pagesIAC Unit IIISayamNo ratings yet

- Cleanroom Systems Ultratech Precision: Insulated PanelsDocument24 pagesCleanroom Systems Ultratech Precision: Insulated PanelsmacNo ratings yet

- Scaling Objective FunctionDocument6 pagesScaling Objective FunctionOSCARDELTANo ratings yet

- 64Mb H-Die (x32) SDRAM Specification: Revision 1.3 February 2004Document12 pages64Mb H-Die (x32) SDRAM Specification: Revision 1.3 February 2004Luis AntunesNo ratings yet

- Dimensions: INY360D-F99-2I2E2-5MDocument3 pagesDimensions: INY360D-F99-2I2E2-5MGabriel FlorNo ratings yet

- Groove - Rounded Corners: Ø38 MM Aluminum BarDocument1 pageGroove - Rounded Corners: Ø38 MM Aluminum BarDavid BumbaloughNo ratings yet

- BushingsDocument36 pagesBushingsHoangNo ratings yet

- Trig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDocument1 pageTrig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDavid BumbaloughNo ratings yet

- 30-06 Cutter Radius Offset - Part 2Document1 page30-06 Cutter Radius Offset - Part 2David BumbaloughNo ratings yet

- MACROSDocument1 pageMACROSJulieth CardenasNo ratings yet

- Kistler 1Document8 pagesKistler 1felixpluspetrol2No ratings yet

- Blend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDocument1 pageBlend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDavid BumbaloughNo ratings yet

- 1113984-23 Touch Probes en PDFDocument64 pages1113984-23 Touch Probes en PDFNjaziZollumiNo ratings yet

- Proposal Purchasing New Equipment Mictrack Series 4000Document8 pagesProposal Purchasing New Equipment Mictrack Series 4000joni Mart SitioNo ratings yet

- AaewawDocument3 pagesAaewawtamacahyaNo ratings yet

- Calculation of Swirl Angle Using CFD: Harsh R. Patel Faizanali M. SaiyedDocument3 pagesCalculation of Swirl Angle Using CFD: Harsh R. Patel Faizanali M. SaiyedEditor IJRITCCNo ratings yet

- Developing The "Right" Modularization Decisions For Mining Modules in ChinaDocument28 pagesDeveloping The "Right" Modularization Decisions For Mining Modules in ChinaKhaled GameaNo ratings yet

- Probes HeidenhainDocument64 pagesProbes HeidenhainfbalestrinNo ratings yet

- Smart Setting Motion Tools (EN)Document12 pagesSmart Setting Motion Tools (EN)Alexandrina BugaNo ratings yet

- Yvm 3 ByocilpDocument12 pagesYvm 3 ByocilpDavidNo ratings yet

- Jan, Jantx, Jantxv,: Single Channel OptocouplersDocument4 pagesJan, Jantx, Jantxv,: Single Channel OptocouplersDorelNo ratings yet

- VN-Unilube Unloading Facility - 26aug2015Document30 pagesVN-Unilube Unloading Facility - 26aug2015billNo ratings yet

- Mec531: Engineering Design 1: Part A: Mechanical Design ProcessDocument32 pagesMec531: Engineering Design 1: Part A: Mechanical Design ProcessqistinaNo ratings yet

- Experiment 2Document7 pagesExperiment 2bobcrysto100% (2)

- BI6182130001 Amplifiere Valve Asembly 2Document38 pagesBI6182130001 Amplifiere Valve Asembly 2Juan Chavez ViladegutNo ratings yet

- SAHC2012 262 Cucchi Tiraboschi Antico BindaDocument10 pagesSAHC2012 262 Cucchi Tiraboschi Antico Bindafanta calcioNo ratings yet

- UndergradthesisDocument9 pagesUndergradthesisSubhasreeNo ratings yet

- Cluster 1 RecommendDocument6 pagesCluster 1 RecommendBrandon HansonNo ratings yet

- Maintenance Standards Table 2. Tightening TorquesDocument10 pagesMaintenance Standards Table 2. Tightening TorquesAmri AnwarNo ratings yet

- User's Manual of Haiwell Classic PLC Temperature & Humidity ModuleDocument23 pagesUser's Manual of Haiwell Classic PLC Temperature & Humidity ModuleMayte GomezNo ratings yet

- Gde01 03 039 ADocument1 pageGde01 03 039 Aluca.laniNo ratings yet

- ZigBee-based Irrigation System For Home GardensDocument4 pagesZigBee-based Irrigation System For Home GardensManuel GuijarroNo ratings yet

- SyllabusDocument3 pagesSyllabusVijay Praveen P M IPNo ratings yet

- Adobe Scan 12 Sep 2023Document1 pageAdobe Scan 12 Sep 2023salebratoNo ratings yet

- Tool Function Q+A: # Answer 1Document2 pagesTool Function Q+A: # Answer 1David BumbaloughNo ratings yet

- Touch Probes enDocument44 pagesTouch Probes enMonteagudoNo ratings yet

- Department of Mechanical Engineering Me1355 - Cad/Cam Lab Year: III Year Semester: VIDocument6 pagesDepartment of Mechanical Engineering Me1355 - Cad/Cam Lab Year: III Year Semester: VIT.V.B.BabuNo ratings yet

- Msme Technology CentersDocument94 pagesMsme Technology Centersnishad saifiNo ratings yet

- Week3 DecisionmatrixDocument2 pagesWeek3 Decisionmatrixapi-370350376No ratings yet

- #EMKA-PACIFIC 2023 Catalogue - 1000-1588-H-LDocument1 page#EMKA-PACIFIC 2023 Catalogue - 1000-1588-H-Lasidin2509No ratings yet

- Advt Final PDF 2022 99202254905PM-1Document27 pagesAdvt Final PDF 2022 99202254905PM-1Praveen SinghNo ratings yet

- National Skill Competitions: Category: Manufacturing & Engineering TechnologyDocument11 pagesNational Skill Competitions: Category: Manufacturing & Engineering Technologyivan bernardNo ratings yet

- 2019 Summer Model Answer Paper (Msbte Study Resources) PDFDocument19 pages2019 Summer Model Answer Paper (Msbte Study Resources) PDFNiranjan SalunkeNo ratings yet

- Chapter One 1.1brief HistoryDocument6 pagesChapter One 1.1brief HistoryKaleab EndaleNo ratings yet

- Cavity Type DD: 1 Machining NotesDocument2 pagesCavity Type DD: 1 Machining NotesAhmed EldessoukyNo ratings yet

- MTT 243 CNC Turning Lab IDocument9 pagesMTT 243 CNC Turning Lab Iwongkw5557No ratings yet

- CAD/CAM Viva-Voce Questions (SVSCE Edition)Document4 pagesCAD/CAM Viva-Voce Questions (SVSCE Edition)goldencometNo ratings yet

- RedLine Lathe Tool Catalog NAT 06142018 PDFDocument73 pagesRedLine Lathe Tool Catalog NAT 06142018 PDFAndres Felipe Rodriguez MartinezNo ratings yet

- Hydraulic Calculation Using Pipenet V - 1.8Document222 pagesHydraulic Calculation Using Pipenet V - 1.8soetrisno898No ratings yet

- Datasheet 80010922Document7 pagesDatasheet 80010922slavunNo ratings yet

- TOD 36T Eng VersionDocument17 pagesTOD 36T Eng VersionTim SmithNo ratings yet

- CAD Systems in Mechanical and Production EngineeringFrom EverandCAD Systems in Mechanical and Production EngineeringRating: 4.5 out of 5 stars4.5/5 (3)

- Gun Control and The Founding Fathers Intent - The - Truth - and - JusticeDocument9 pagesGun Control and The Founding Fathers Intent - The - Truth - and - JusticeDavid BumbaloughNo ratings yet

- This Little Weed Is One of The Most Useful Medicines On The PlanetDocument6 pagesThis Little Weed Is One of The Most Useful Medicines On The PlanetDavid BumbaloughNo ratings yet

- Tomato Fertilizer - How To Feed Your Plants For The Ultimate HarvestDocument11 pagesTomato Fertilizer - How To Feed Your Plants For The Ultimate HarvestDavid BumbaloughNo ratings yet

- 12 Plants You'Ll Want in Your SHTF Garden - SurvivopediaDocument21 pages12 Plants You'Ll Want in Your SHTF Garden - SurvivopediaDavid BumbaloughNo ratings yet

- The Complete Guide To Growing Corn in Containers - Garden and HappyDocument17 pagesThe Complete Guide To Growing Corn in Containers - Garden and HappyDavid BumbaloughNo ratings yet

- How To Become Untrackable - Part 1 - SurvivopediaDocument12 pagesHow To Become Untrackable - Part 1 - SurvivopediaDavid Bumbalough100% (1)

- Scaling Function Q+A: # Answer 1Document2 pagesScaling Function Q+A: # Answer 1David BumbaloughNo ratings yet

- Exercises After Abdominal SurgeryDocument5 pagesExercises After Abdominal SurgeryDavid BumbaloughNo ratings yet

- Feedrate Q+A: # Answer 1Document2 pagesFeedrate Q+A: # Answer 1David BumbaloughNo ratings yet

- HK94, MP5, Parts KitsDocument6 pagesHK94, MP5, Parts KitsDavid BumbaloughNo ratings yet

- Blend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDocument1 pageBlend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDavid BumbaloughNo ratings yet

- Providers - PrivacytoolsDocument7 pagesProviders - PrivacytoolsDavid BumbaloughNo ratings yet

- 15-01 Reference Points - MillDocument1 page15-01 Reference Points - MillDavid BumbaloughNo ratings yet

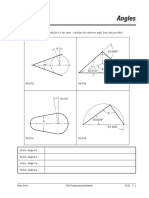

- Angles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDocument1 pageAngles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDavid BumbaloughNo ratings yet

- 44-01 Machining With TailstockDocument1 page44-01 Machining With TailstockDavid BumbaloughNo ratings yet

- Scaling Exercise: Use T01 Ø20 End MillDocument1 pageScaling Exercise: Use T01 Ø20 End MillDavid BumbaloughNo ratings yet

- Verifying Programs Q+A: # Answer 1Document2 pagesVerifying Programs Q+A: # Answer 1David BumbaloughNo ratings yet

- 49-01 Documenting Programs Q+A PDFDocument1 page49-01 Documenting Programs Q+A PDFDavid BumbaloughNo ratings yet

- 49-01 Documenting Programs Q+ADocument1 page49-01 Documenting Programs Q+ADavid BumbaloughNo ratings yet

- 53-02 Locators PDFDocument1 page53-02 Locators PDFDavid BumbaloughNo ratings yet

- 53-03 Contour Points 1Document1 page53-03 Contour Points 1David BumbaloughNo ratings yet

- 53-04 Contour Points 2Document1 page53-04 Contour Points 2David BumbaloughNo ratings yet

- 46-01 Horizontal MachiningDocument1 page46-01 Horizontal MachiningDavid BumbaloughNo ratings yet

- CNC Machining Q+A: # Answer 1Document2 pagesCNC Machining Q+A: # Answer 1David BumbaloughNo ratings yet

- Unknown Radius: Chine Shop MagazineDocument1 pageUnknown Radius: Chine Shop MagazineDavid BumbaloughNo ratings yet

- Blend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDocument1 pageBlend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDavid BumbaloughNo ratings yet

- 20-02 Rapid Motion FormulasDocument2 pages20-02 Rapid Motion FormulasDavid BumbaloughNo ratings yet

- Trig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDocument1 pageTrig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDavid BumbaloughNo ratings yet

- 19-01 Tool LengthDocument1 page19-01 Tool LengthDavid BumbaloughNo ratings yet