Professional Documents

Culture Documents

Experiment # 01: Introduction To Metallurgy Lab and To Study Its Layout"

Uploaded by

yasir mahmoodOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experiment # 01: Introduction To Metallurgy Lab and To Study Its Layout"

Uploaded by

yasir mahmoodCopyright:

Available Formats

Experiment # 01

Introduction to metallurgy lab and to study its layout"

Metallurgy lab of Mechanical Engineering Department contains

the following apparatus:

1. Cut off Machine:-

This apparatus is used to cut the specimen according to the

required shape. We cannot examine the whole material under

microscope so that's why we cut the specimen into small pieces so that

they can be easily examined. Coolant used in this machine is water

mixed with oil.

2. Microscope:-

Microscope is used to study the surface of the specimen. It is used

to notice the roughness of the surface and to check the percentage of

white and black portion of the surface.

3. Mounting Press:-

If the specimen is kept freely then there are chances of corrosion

and other damages to its surface. To prevent the specimen from these

damages, the specimen is preserved in the mounting press.

4. Polishing Wheels:-

Initially surface of the surface is very rough. If it is examined

under microscope then a lot of roughness and valleys can be observed.

To remove this roughness the specimen is kept on the polishing wheel

(firstly using P1 180 grinding paper) and polished for some time. Then

it is again observed under microscope. There is still roughness in the

surface which can be removed by using P 240, P 300, P 500, P 600 and

at last P 800. Then fine polishing of the specimen is carried out which

make the specimen like mirror.

5. Universal Testing Machine:-

It is used to test the tensile and compressive stresses of materials.

The UTM present in the Metallurgy Lab has the ability to heat or cool

the specimen up to required temperature and then find the properties

required.

It is named after the fact that it is used for this purpose all over the

world. It is a standard for the whole Universe, the results obtained

through Universal Testing Machine will be same any where in the

world. It mainly consists of two parts, which are described below:

1. Loading Unit:

This unit of UTM apply load on the test specimen. The

test specimen is clamped in the jaws and load is applied on it. This unit

is placed on a table below which “hydraulic system” is fixed. If

compressive load is to be applied then the table moves up ward and

vice versa.

2. Control Unit

This unit controls the motion of jaws and application of

load of the loading unit.

6. Automatic Polishing Apparatus:-

This apparatus is used for the automatic polishing of the

specimen. There is no need of changing grinding paper for polishing.

7. Micro wicker:-

It is used to find out the hardness of the specimen.

8. Furnace:-

It is electrically run. It is used to heat the specimen to certain

temperature. The temperature for the specimen is selected on the basis

of percentage of carbon present in the specimen.

9. Hand Grinder:-

It is used to perform spark test on the specimen.

10. Universal Hardness Testing Machine:-

There are three tests for finding hardness of the specimen. This

apparatus is used to perform all the three tests on the specimen.

You might also like

- Universal Testing Machine PDFDocument4 pagesUniversal Testing Machine PDFJoy Genieva67% (3)

- Automata Standardized PartsDocument36 pagesAutomata Standardized Partsapi-23533765475% (4)

- Full Lab 5 Mom and HydraulicDocument9 pagesFull Lab 5 Mom and HydraulicEzanie IzyanNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- STM Lab ManualDocument36 pagesSTM Lab ManualAmrut Raj PurohitNo ratings yet

- METALLURGY & MATERIAL SCIENCE Lab Manual PDFDocument44 pagesMETALLURGY & MATERIAL SCIENCE Lab Manual PDFRewat SachdevaNo ratings yet

- Me136p Exp1 Physical Study of Universal Testing MachineDocument15 pagesMe136p Exp1 Physical Study of Universal Testing MachineJohn Henry SalvadoNo ratings yet

- Metallurgy Practicum ModuleDocument9 pagesMetallurgy Practicum ModuleJundi AbdillahNo ratings yet

- Metallography Exp.Document6 pagesMetallography Exp.Nedjmah LechehebNo ratings yet

- ME - 194 Engineering Materials SessionalDocument45 pagesME - 194 Engineering Materials SessionalAsif AhnafNo ratings yet

- Fatigue Testing of MaterialsDocument10 pagesFatigue Testing of MaterialsInocent FarrukhNo ratings yet

- Metallurgy & Material Science Lab ManualDocument42 pagesMetallurgy & Material Science Lab ManualrameshNo ratings yet

- Basic Equipment in Material TestingDocument2 pagesBasic Equipment in Material TestingGian Aizel JavierNo ratings yet

- Universal Testing Machinepdf CompressDocument4 pagesUniversal Testing Machinepdf CompressJoshua Miguel BunoNo ratings yet

- MOS Lab Manual - NewDocument41 pagesMOS Lab Manual - NewPavan Kalyan SuryavamshiNo ratings yet

- MOS Manual w-19Document57 pagesMOS Manual w-19Ghulam MuhyudinNo ratings yet

- Mom Practical Theory ContentDocument33 pagesMom Practical Theory ContentZaky MuzaffarNo ratings yet

- AMT 2 Dipak PhokeDocument20 pagesAMT 2 Dipak PhokeAVINASH BHUSARENo ratings yet

- Practical 15,16,17,21Document11 pagesPractical 15,16,17,21Muhammad AwaisNo ratings yet

- Al Mgreport (NagasakiUniversity)Document36 pagesAl Mgreport (NagasakiUniversity)huychungngNo ratings yet

- Fatigue TestDocument2 pagesFatigue Testunam123No ratings yet

- Module 3. Mechanical TestingDocument13 pagesModule 3. Mechanical TestingPearl Alexandra FabitoNo ratings yet

- HMT Pinjore HaryanaDocument12 pagesHMT Pinjore HaryanaAnurag KumarNo ratings yet

- Assignment 2 CMDocument7 pagesAssignment 2 CMAhmad RazaNo ratings yet

- Impact TestDocument4 pagesImpact TestKumar SamreshNo ratings yet

- Materials Testing Laboratory Laboratory Exercise No. 1 Inspection of The Materials & Testing LaboratoryDocument10 pagesMaterials Testing Laboratory Laboratory Exercise No. 1 Inspection of The Materials & Testing LaboratoryRejoice SamboNo ratings yet

- Experiment No.8Document5 pagesExperiment No.8sahil thakurNo ratings yet

- Strength of Material Lab ManualDocument31 pagesStrength of Material Lab ManualAnonymous mRBbdopMKfNo ratings yet

- Bab IiiDocument7 pagesBab IiiWahyu Haidar PratamaNo ratings yet

- Fatigue SomDocument13 pagesFatigue SomOmed HajiNo ratings yet

- HMTDocument6 pagesHMTHarshmani GuptaNo ratings yet

- Metal Detection Procedure in ApparelDocument4 pagesMetal Detection Procedure in ApparelLe Gia PhucNo ratings yet

- Ael I ManualDocument29 pagesAel I ManualNivedita kNo ratings yet

- 200 LEVEL Strength of MaterialsDocument17 pages200 LEVEL Strength of MaterialsOkeke TochukwuNo ratings yet

- Trinity Amelung KC4 - Service ManualDocument34 pagesTrinity Amelung KC4 - Service ManualNasser Anappara100% (1)

- Utm PDFDocument5 pagesUtm PDFFaisal NaeemNo ratings yet

- List NDT Techniques Commonly Used For Inspecting and ComponentsDocument12 pagesList NDT Techniques Commonly Used For Inspecting and ComponentscollinsNo ratings yet

- Exp1 CH PDFDocument7 pagesExp1 CH PDFhabiba jamilNo ratings yet

- Glass and Ceramic Testing and QualityDocument36 pagesGlass and Ceramic Testing and QualitySief MohyNo ratings yet

- Mos Lab ManualDocument71 pagesMos Lab ManualAtul GaurNo ratings yet

- Column Buckling TestDocument2 pagesColumn Buckling Testunam123No ratings yet

- MPT Examination 3Document4 pagesMPT Examination 3EdAlmNo ratings yet

- Layout of Transportation Engineering LabDocument8 pagesLayout of Transportation Engineering LabDallas HubbardNo ratings yet

- Welding MachineDocument6 pagesWelding MachineMamata ShakyaNo ratings yet

- Universal Testing MachineDocument28 pagesUniversal Testing MachineMarc Anthony de VillaNo ratings yet

- Engineering Materials: Lab AssignmentDocument9 pagesEngineering Materials: Lab AssignmentASAD ULLAHNo ratings yet

- Mos Lab Manul by Abhidhesh YadavDocument45 pagesMos Lab Manul by Abhidhesh YadavabhiNo ratings yet

- Introduction of Timken Extreme Pressure Tester From Labmen20191024Document5 pagesIntroduction of Timken Extreme Pressure Tester From Labmen20191024Lawrence LeeNo ratings yet

- Lathe Machine Lab ReportDocument5 pagesLathe Machine Lab ReportEdgar ThorpeNo ratings yet

- Ce 8381som Lab ManualDocument31 pagesCe 8381som Lab ManualAERO JPR50% (2)

- STSZ 8Document6 pagesSTSZ 8Edgard GinesNo ratings yet

- Surface GrindingDocument6 pagesSurface GrindingAnonymous YkDJkSqNo ratings yet

- Testing of MaterialsDocument21 pagesTesting of MaterialsFaizan SolankiNo ratings yet

- PROFAB ESR 1580X2.0 Manual - 2017Document16 pagesPROFAB ESR 1580X2.0 Manual - 2017Kevin VargheseNo ratings yet

- Esra 300a OprDocument15 pagesEsra 300a OprAlexeyNo ratings yet

- Integrating Vibration and Oil Analysis For Machine Condition MonitoringDocument10 pagesIntegrating Vibration and Oil Analysis For Machine Condition MonitoringAnda WahyudiNo ratings yet

- Manual For Sandblasting MachineDocument9 pagesManual For Sandblasting MachineKamel NaitNo ratings yet

- Discuss The Device, Process and Application of The Following Non-Destructive Testing Methods: A. Software TestingDocument5 pagesDiscuss The Device, Process and Application of The Following Non-Destructive Testing Methods: A. Software TestingMobile LegendsNo ratings yet

- Nature of WorkDocument33 pagesNature of WorkshivajiNo ratings yet

- MM3100-Transmission Electron Microscopy-1: 1 Slow-Speed Diamond CutterDocument4 pagesMM3100-Transmission Electron Microscopy-1: 1 Slow-Speed Diamond CutternewteamNo ratings yet

- SOM Lab ManualDocument32 pagesSOM Lab ManualMuhammad Junaid100% (1)

- 20004O CRTi2 4.5 Specification Summary JULY 2020Document4 pages20004O CRTi2 4.5 Specification Summary JULY 2020Muhammad SaiedNo ratings yet

- PV 3919 enDocument6 pagesPV 3919 enerik0007No ratings yet

- BOWSTRINGDocument14 pagesBOWSTRINGRoshini KannuriNo ratings yet

- FESTO Cylinder model DNC กระบอกลมเฟสโต้Document66 pagesFESTO Cylinder model DNC กระบอกลมเฟสโต้Parinpa Ketar100% (2)

- ACMEE 2023 - 15th International Machine Tools ExhibitionDocument16 pagesACMEE 2023 - 15th International Machine Tools ExhibitionSandeep SNo ratings yet

- Socket - EM-DUO 120/15 - 5600461: Key Commercial DataDocument4 pagesSocket - EM-DUO 120/15 - 5600461: Key Commercial DataJavier CuzcoNo ratings yet

- 0702 Pnuematic Component Symbols - ASCO PDFDocument2 pages0702 Pnuematic Component Symbols - ASCO PDFShilpa Kamath100% (1)

- Report 2021Document59 pagesReport 2021Bhushan LoharNo ratings yet

- System No. HW-D-0256: (UL/cUL)Document2 pagesSystem No. HW-D-0256: (UL/cUL)ibrahimNo ratings yet

- KP Iom - en - R2 PDFDocument25 pagesKP Iom - en - R2 PDFJose Lorenzo RefelinoNo ratings yet

- Concrete Mix Design Proposal Mix - 33Document3 pagesConcrete Mix Design Proposal Mix - 33Ruwan Sampath WickramathilakaNo ratings yet

- Operating Instructions: Motor Diaphragm Metering Pump Alpha AlpcDocument40 pagesOperating Instructions: Motor Diaphragm Metering Pump Alpha AlpcChan Chi Wong PenNo ratings yet

- Annex B Currently Recommended Illuminance Cate-Gories and Values For Industrial Lighting Design (Target Maintained Levels)Document3 pagesAnnex B Currently Recommended Illuminance Cate-Gories and Values For Industrial Lighting Design (Target Maintained Levels)Rahul MandalNo ratings yet

- (32"-Sawl Bare Pipe) : Quality Assurance Plan / Inspection Test Plan (For Sour Service Application)Document18 pages(32"-Sawl Bare Pipe) : Quality Assurance Plan / Inspection Test Plan (For Sour Service Application)Gordon LongforganNo ratings yet

- Cold Stack Design - Pipelines, Piping and Fluid Mechanics Engineering - Eng-Tips PDFDocument3 pagesCold Stack Design - Pipelines, Piping and Fluid Mechanics Engineering - Eng-Tips PDFDeepak DubeyNo ratings yet

- Industrial Refrigeration: Components and ControlsDocument1,094 pagesIndustrial Refrigeration: Components and ControlsSudharshan ReddyNo ratings yet

- Indeco Kataloog PDFDocument9 pagesIndeco Kataloog PDFDian IdawatiNo ratings yet

- Underground Cable Laying WebDocument7 pagesUnderground Cable Laying WebbryedvilNo ratings yet

- Ce 601 Set C PDFDocument9 pagesCe 601 Set C PDFJade Paul D. BesanaNo ratings yet

- Well Control Equipment PDFDocument104 pagesWell Control Equipment PDFAlexander ToyoNo ratings yet

- Calculation of Secondary Superheater 01.02.2012 00Document45 pagesCalculation of Secondary Superheater 01.02.2012 00brintopvNo ratings yet

- Ketentuan Detail Tulangan Pada Struktur Beton Bertulang Sesuai SNI 2847-201X. HAKI Medan 20.07.2019 PDFDocument223 pagesKetentuan Detail Tulangan Pada Struktur Beton Bertulang Sesuai SNI 2847-201X. HAKI Medan 20.07.2019 PDFRio FandiNo ratings yet

- Aqt-275 DSDocument1 pageAqt-275 DSPedro EstradaNo ratings yet

- Freeboard CalculationDocument45 pagesFreeboard CalculationgksahaNo ratings yet

- Clicking, or Cutting Upper LeathersDocument4 pagesClicking, or Cutting Upper LeathersVishnu TejaNo ratings yet

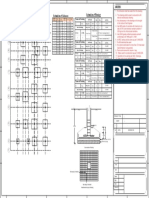

- Schedule of Footing Schedule of Columns: A B C D EF G HDocument1 pageSchedule of Footing Schedule of Columns: A B C D EF G HSimantaSonowalNo ratings yet

- Lines GP Travel Motor 349D.Document3 pagesLines GP Travel Motor 349D.Enso E Rosales FNo ratings yet

- STEEL RULES - English PDFDocument6 pagesSTEEL RULES - English PDFpinoNo ratings yet

- Metraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)Document4 pagesMetraflex Fireloop™: Down Have The 180 Return Supported. (See Installation Instructions.)CESAR VELEZNo ratings yet