Professional Documents

Culture Documents

Technical Information Sheet Radial Ball Bearings Life and Load Ratings ENB 04 0637 PDF

Technical Information Sheet Radial Ball Bearings Life and Load Ratings ENB 04 0637 PDF

Uploaded by

MIRCEA1305Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Information Sheet Radial Ball Bearings Life and Load Ratings ENB 04 0637 PDF

Technical Information Sheet Radial Ball Bearings Life and Load Ratings ENB 04 0637 PDF

Uploaded by

MIRCEA1305Copyright:

Available Formats

TECHNICAL INFORMATION

Life and Load Ratings – Radial Ball Bearings

Bearing Life

When bearings rotate, the inner and outer rings and rolling elements are constantly loaded. This

produces material fatigue and eventually bearing failure. The total number of revolutions before a

failure occurs is called the basic rating life

Life of individual bearings varies considerably, even if they are of the same size, same material, same

heat treatment and are under the same operating conditions.

Statistically, the total number of revolutions reached or exceeded by 90% of a sufficiently large group of

apparently identical bearings before the first evidence of material fatigue occurs is called the basic

rating life.

Load Ratings

Manufacturers of ball bearings typically publish Load Ratings for each bearing they produce. The

methods used to calculate ratings can vary from manufacturer to manufacturer. However, both ABMA

and ISO have published standards related to load ratings.

ABMA Std. 9 – Load Ratings and Fatigue Life for Ball Bearings

ABMA Std. 12.1 and 12.2 – Instrument Ball Bearings

ISO 76 – Static Load Ratings

SO 281 – Dynamic Load Ratings and Rating Life

With regard to load ratings, one thing to remember is - static load ratings (Cor) and dynamic load

ratings (Cr) are formulated on completely different premises and have no direct relationship to one

another.

Dynamic load ratings are determined by bearing geometry, number and size of balls, bearing pitch

diameter, and ring and ball material. This load rating is used in conjunction with the actual applied radial

load to calculate bearing fatigue life.

The static load rating relates to limiting loads applied to non-rotating bearings. The static load rating

depends on the maximum contact stress between the balls and either of the two raceways. It is affected

by material, number and size of balls, raceway curvatures, raceway depths, and contact angles. It is

also based on using clean, high quality bearing steel with typical hardness levels of 58-64 HRC for

rings and 60-65 HRC for balls.

Based on the above, for a given bearing, a change in the pitch circle can impact the dynamic load

rating, and a change in the ball diameter or ball quantity can impact both load ratings. Changing all of

these variables at the same time (depending on what the actual changes are) can result in the dynamic

capacity moving in one direction and the static capacity moving in the opposite direction (when

compared to the original configuration).

AST Bearings LLC “Value Beyond the Part™” U.S. Toll Free (800) 526‐1250

115 Main Road Headquarters (973) 335‐2230

Montville, NJ 07045‐9299 www.ASTBearings.com Fax (973) 335‐6987

© Copyright 2011 AST Bearings LLC – All rights reserved. DOCUMENT NO. ENB-04-0637

.

TECHNICAL INFORMATION

Basic Dynamic Load Rating Cr

The basic dynamic load rating of a bearing with rotating inner ring and stationary outer ring is that load

of constant magnitude and size which a sufficiently large group of apparently identical bearings can

endure for a basic rating life of one million revolutions.

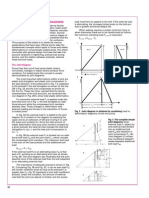

Life Formula

The equation for the basic rating life for dynamically loaded ball bearings is as follows

L10= (Cr/P)3 X 106 (Revolution)

L10h = 16667 / n · (Cr/P)3 (hours)

Where:

L10 = Basic rating life

Cr = Basic dynamic load rating (N)

n= R.P.M (revolution per minute)

L10h = Basic rating life in operating hours

P = Equivalent load (N)

Examples of rating life L10 h values

OPERATING CONDITIONS BASIC RATING LIFE L10h

Infrequent operation 500

Short or intermittent operation. Failure has little effect on function 4000 ~ 8000

Intermittent operation. Failure has significant effect on function 8000 ~ 12000

8 hours of non‐continuous operation 12000 ~ 20000

8 hours of continuous operation 20000 ~ 30000

24 hours continuous operation 40000 ~ 60000

24 hours of guaranteed trouble free operation 100000 ~ 200000

Adjusted Life Formula

The above life formula is for general use. In cases where a reliability of over 90% is required and where

influences apart from load and speed or operating frequency should be taken into account for the rating

life, ISO 281, 1990 gives an extended life formula:

Lna= a1 x a2 x a3 x (Cr/P)3 x 106 (Revolution)

Where:

Lna = Adjusted rating life in millions with a reliability of (100-n)% (n= the reliability rate)

Cr = Basic dynamic load rating (N)

P= Equivalent dynamic load rating (N)

a1=Factor for a reliability other than 90%

a2=Factor for non-conventional materials

a3=Factor for non-conventional operating conditions, in particular lubrication

AST Bearings LLC “Value Beyond the Part™” U.S. Toll Free (800) 526‐1250

115 Main Road Headquarters (973) 335‐2230

Montville, NJ 07045‐9299 www.ASTBearings.com Fax (973) 335‐6987

© Copyright 2011 AST Bearings LLC – All rights reserved. DOCUMENT NO. ENB-04-0637

.

TECHNICAL INFORMATION

Reliability Factor a1

When a reliability of over 90% is required, the corresponding factor should be selected from the

following table

Reliability 90 91 92 93 94 95 96 97 98 99 99.6 99.9

a1 1 0.92 0.84 0.77 0.64 0.62 0.53 0.44 0.33 0.21 0.1 0.037

Material Factor a2

Improvement in manufacturing techniques for raw material and for heat treatment of components has

led to an extended fatigue life for bearings. AST’s standard bearing materials are a superior quality of

vacuum degassed steel leading to an extended life for bearings. The basic load ratings have been

established by taking this longer life into consideration. This gives an increase in the operating life in

hours of a factor of 2.2 and a factor of 1.3 for the load carrying capacity. The material factor a2=1.

Operating Conditions Factor a3

This is an adjustment factor to meet non-conventional operating conditions for lubrication, temperature

and load, Under good lubrication conditions with a permanent oil film between rolling elements and

rings, the factor a3=1. In unfavorable conditions (dm·n ≤ 10000) a factor a3 < 1 must be selected.

dm (mean bearing diameter ) = (D+d)/2

n= the operating speed

At temperatures above 120⁰C, greater dimensional changes occur and the material hardness

deteriorates which affects the bearing life.

The operating factor ft for temperature can be taken from the following table

BEARING

TEMPERATURE ⁰C 120 150 175 200 225 250 275 300

TEMPERATURE

FACTOR ft 1 0.9 0.85 0.75 0.65 0.6 0.52 0.45

Basic Static Load Rating Cor

The Basic Static Load Rating applies to bearings where rotating motion does not occur or occurs only

infrequently. The Basic Load Ratings and calculation methods are based on methods described in ISO

281 and in ISO Recommendations NR.76, taking into account the current level of bearing technology.

Excessive static load causes brinelling at the contact point between the rolling element and raceway.

As a standard of permissible static load, the basic load rating Cor for radial bearings is specified as

follows:

Maximum contact pressure at the contact point between rolling element and bearing ring to be

4200 MPa and total permanent deformation of the bearing of approximately 1/10,000th of the

rolling element’s diameter.

Basic static load rating for stainless steel is 80% of that for standard bearing steel

AST Bearings LLC “Value Beyond the Part™” U.S. Toll Free (800) 526‐1250

115 Main Road Headquarters (973) 335‐2230

Montville, NJ 07045‐9299 www.ASTBearings.com Fax (973) 335‐6987

© Copyright 2011 AST Bearings LLC – All rights reserved. DOCUMENT NO. ENB-04-0637

.

TECHNICAL INFORMATION

Equivalent Dynamic Bearing Load "P"

Load conditions on bearings are usually a combination of radial and axial loads, In order to

establish the equivalent radial load with definite force and direction we use the following

formula:

P=XFr+YFa (N)

Where:

Fr= Radial load (N)

Fa=Axial load (N)

X=Radial load factor

Y=Axial load factor

D=Ball diameter (mm)

Radial load factor and axial load factor

Fa/Fr ≤ e Fa/Fr > e

Fa/(ZD2) e

X Y X Y

0.172 0.19 1 0 0.56 2.3

0.345 0.22 1 0 0.56 1.99

0.689 0.26 1 0 0.56 1.71

1.03 0.28 1 0 0.56 1.55

1.38 0.3 1 0 0.56 1.45

2.07 0.34 1 0 0.56 1.31

3.45 0.38 1 0 0.56 1.15

5.17 0.42 1 0 0.56 1.04

6.89 0.44 1 0 0.56 1

This table applies to radial ball bearings with a bore diameter up to 10mm, and thin type ball bearings with a bore

diameter up to 50 mm, consult with AST’s Engineering team for calculations for other types of bearings.

AST Bearings LLC “Value Beyond the Part™” U.S. Toll Free (800) 526‐1250

115 Main Road Headquarters (973) 335‐2230

Montville, NJ 07045‐9299 www.ASTBearings.com Fax (973) 335‐6987

© Copyright 2011 AST Bearings LLC – All rights reserved. DOCUMENT NO. ENB-04-0637

.

You might also like

- How Unbalance Affects Bearing LifeDocument8 pagesHow Unbalance Affects Bearing Lifeagrocel_bhv5591No ratings yet

- Troubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreFrom EverandTroubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreNo ratings yet

- Development of The Project ProposalDocument40 pagesDevelopment of The Project Proposalnotruwan100% (3)

- Eth - 7000024824 - Electrical BoqDocument55 pagesEth - 7000024824 - Electrical BoqAnkit VaswaniNo ratings yet

- Dynam IC Stab I Lity 0 F Rotor-Bearing Systfjms: Gunte - RDocument231 pagesDynam IC Stab I Lity 0 F Rotor-Bearing Systfjms: Gunte - Radel jcsiNo ratings yet

- Composite Design and TheoryDocument203 pagesComposite Design and Theoryapi-3700351100% (6)

- Flyer Rolling Bearing AnalysisDocument4 pagesFlyer Rolling Bearing AnalysisBikash Ranjan SahooNo ratings yet

- Bearing CalculationDocument10 pagesBearing CalculationAniket SankpalNo ratings yet

- Plain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryDocument4 pagesPlain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryShadin Asari ArabaniNo ratings yet

- How Long Will A Bearing Last? Standardized Life Equations Help To AnswerDocument3 pagesHow Long Will A Bearing Last? Standardized Life Equations Help To AnswervijaykhandgeNo ratings yet

- Bearing Lifecycle CalculationsDocument5 pagesBearing Lifecycle CalculationsKunal PatelNo ratings yet

- Bearing SelectionDocument6 pagesBearing SelectiondaryonoNo ratings yet

- Sample Construction ScheduleDocument10 pagesSample Construction Scheduleyusuf abdinasirNo ratings yet

- Goulds Model 3700/3710: High Temperature/High Pressure Process Pumps Designed and Built To Meet Requirements of API-610Document40 pagesGoulds Model 3700/3710: High Temperature/High Pressure Process Pumps Designed and Built To Meet Requirements of API-610sebasNo ratings yet

- The Effect of Unbalance On Bearing LifeDocument8 pagesThe Effect of Unbalance On Bearing LifejaypallaNo ratings yet

- Biblio MotorsDocument11 pagesBiblio MotorsMuhammad KaleemNo ratings yet

- Product Catalog - USDocument166 pagesProduct Catalog - USamijoski6051No ratings yet

- The Sulzer Oil-Free Labyrinth Piston CompressorDocument9 pagesThe Sulzer Oil-Free Labyrinth Piston CompressorAlex Kulik100% (1)

- Bearings LifeDocument4 pagesBearings Lifecastingforge4875No ratings yet

- Single-Stage Steam TurbinesDocument8 pagesSingle-Stage Steam Turbinesfouzi gherNo ratings yet

- Welding of Hollow Structural Sections PDFDocument5 pagesWelding of Hollow Structural Sections PDFManuel Gomez FariasNo ratings yet

- Electro HydraulicsDocument21 pagesElectro Hydraulicssandeep5No ratings yet

- Radial Thrust BRG Case StudiesDocument14 pagesRadial Thrust BRG Case StudiesRajagopal100% (1)

- Certified Quality Engineer Problem Bank 4Document36 pagesCertified Quality Engineer Problem Bank 4jackanddiane1No ratings yet

- Torsional Vibration of Turbomachinery - Duncan N. Walker PDFDocument136 pagesTorsional Vibration of Turbomachinery - Duncan N. Walker PDFkolle_sdestefa100% (1)

- Rotor Dynamics 1Document14 pagesRotor Dynamics 1Marco NeveNo ratings yet

- I ALERT2 Application GuideDocument48 pagesI ALERT2 Application Guidemynor8josh8juarezNo ratings yet

- S0300-BB-MAN-010 - Underwater CuttingDocument200 pagesS0300-BB-MAN-010 - Underwater Cuttingsandeep5No ratings yet

- At Least TWO Questions From Each Part.: (06 Marks)Document2 pagesAt Least TWO Questions From Each Part.: (06 Marks)nvnrevNo ratings yet

- 7977 8cd2Document2 pages7977 8cd2Pete Pompes0% (1)

- Eim Grade 12 TosDocument8 pagesEim Grade 12 TosCASTOR JAVIER100% (1)

- CIBO (Boilers) Energy Efficiency HandbookDocument64 pagesCIBO (Boilers) Energy Efficiency HandbookwanjgitNo ratings yet

- Maximum Rivet Pitch Study 20111115Document18 pagesMaximum Rivet Pitch Study 20111115Jatin KhuranaNo ratings yet

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionFrom EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo ratings yet

- Pit Ot Tube Pump TechnologyDocument12 pagesPit Ot Tube Pump TechnologymariasofiarossiNo ratings yet

- BHS行星齿轮箱简介Document17 pagesBHS行星齿轮箱简介davidwang85120% (1)

- Type OHH Pump API610 9 Ed. (ISO 13709) : File Name / OHH Sales Presentation - PPT 11/21/2001 1Document20 pagesType OHH Pump API610 9 Ed. (ISO 13709) : File Name / OHH Sales Presentation - PPT 11/21/2001 1Jorge OportoNo ratings yet

- Bolt Joint-DiagramsDocument6 pagesBolt Joint-Diagramskulov1592No ratings yet

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionFrom EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNo ratings yet

- Five Basic Errors in Shaft AlignmentDocument5 pagesFive Basic Errors in Shaft AlignmentiosalcidoNo ratings yet

- Ra00823 0706 SPCDocument553 pagesRa00823 0706 SPCsandeep5100% (1)

- Osha3722 PDFDocument2 pagesOsha3722 PDFTharaka Perera100% (1)

- Tender9 Vol II o II Pig Launcher and Receiver by MeconDocument31 pagesTender9 Vol II o II Pig Launcher and Receiver by MeconVeena S VNo ratings yet

- PreviewpdfDocument89 pagesPreviewpdfJonathan Jimenez JardonNo ratings yet

- GGBS in Concrete PDFDocument64 pagesGGBS in Concrete PDFLý HuyNo ratings yet

- Gear FatigueDocument12 pagesGear Fatigueismail_69No ratings yet

- Packing Installation FlowserveDocument2 pagesPacking Installation FlowserveMachineryengNo ratings yet

- e PDFDocument42 pagese PDFNicolás González GuerreroNo ratings yet

- Casting Cost EstimatingDocument27 pagesCasting Cost Estimatingsandeep5No ratings yet

- Catalog KingcoleDocument33 pagesCatalog Kingcoleg_casalinuovo19812344No ratings yet

- Operation c950 PDFDocument50 pagesOperation c950 PDFsandeep5100% (2)

- Dawson Downie Lamont LTDDocument2 pagesDawson Downie Lamont LTDwarehouse cikalongNo ratings yet

- Power Stream Couplings-Specn SheetsDocument6 pagesPower Stream Couplings-Specn SheetsAmol PatkiNo ratings yet

- Fristam PumpsDocument16 pagesFristam PumpsWinNo ratings yet

- Amarinth Technical Bulletin API 610 VS4 Compared To VS1 RevADocument3 pagesAmarinth Technical Bulletin API 610 VS4 Compared To VS1 RevAStephen BeasleyNo ratings yet

- 5275 PDFDocument28 pages5275 PDFLevi BriceñoNo ratings yet

- Jensen Mixer Series 600 IOM 2010Document24 pagesJensen Mixer Series 600 IOM 2010SergioNo ratings yet

- LMV 311 Poster - 091316 PDFDocument1 pageLMV 311 Poster - 091316 PDFDelio Manuel Moreno AyazoNo ratings yet

- Illustration and Analysis of Seal Face Damage PatternsDocument12 pagesIllustration and Analysis of Seal Face Damage PatternsЭдуардс КеистерсNo ratings yet

- Rotordynamic Capabilities in ANSYS Mechanical PDFDocument3 pagesRotordynamic Capabilities in ANSYS Mechanical PDFFarzad SadrNo ratings yet

- Magnetic Drive Pumps Product GuideDocument32 pagesMagnetic Drive Pumps Product GuideJean-francois RosierNo ratings yet

- Instruction For Installation Guidelines Vertical Turbine Pump PDFDocument27 pagesInstruction For Installation Guidelines Vertical Turbine Pump PDFWilliam Berrospi Garcia100% (1)

- Centrifugal Pumps - Piping Installation Design & Hydraulic System Calculation by AFT Fathom and PIPE-FLO SoftwareDocument84 pagesCentrifugal Pumps - Piping Installation Design & Hydraulic System Calculation by AFT Fathom and PIPE-FLO SoftwareHadi VeyseNo ratings yet

- A Computer Program For The Aerodynamic Design of Axisymmetric and Planar Nozzles For Supersonic and Hypersonic Wind TunnelsDocument151 pagesA Computer Program For The Aerodynamic Design of Axisymmetric and Planar Nozzles For Supersonic and Hypersonic Wind TunnelsBlackFootNo ratings yet

- Dimension Tolerance For Shaft BasisDocument13 pagesDimension Tolerance For Shaft Basissafa shaikhNo ratings yet

- s33x UpgradeDocument15 pagess33x UpgradeAlexandre Borges BorgesNo ratings yet

- PCS1001548400010 01enDocument1 pagePCS1001548400010 01enrfm23100% (1)

- Coupling PDFDocument68 pagesCoupling PDFmmkattaNo ratings yet

- OHH OHHL E00697 (Pump Zulzer)Document6 pagesOHH OHHL E00697 (Pump Zulzer)Jose Sosa CojNo ratings yet

- Balance LineDocument0 pagesBalance Linewsjouri2510No ratings yet

- Welding IntroductionDocument23 pagesWelding IntroductionRaghu ChowdaryNo ratings yet

- Ansi-Hi 9-8-1998Document77 pagesAnsi-Hi 9-8-1998billyderosierNo ratings yet

- Bolts Torque CalculatorDocument2 pagesBolts Torque CalculatorguravdrNo ratings yet

- Catalogo NTNDocument222 pagesCatalogo NTNHugo Zavala Toledo100% (1)

- Bearing Life Calculation - Bearing Loads & Speeds - American Roller BearingDocument7 pagesBearing Life Calculation - Bearing Loads & Speeds - American Roller BearingNNOUBAIHNo ratings yet

- Bearing Tech PDFDocument6 pagesBearing Tech PDFmurali036No ratings yet

- ST EPSBeltDrive Eng09Document1 pageST EPSBeltDrive Eng09sandeep5No ratings yet

- Design and Fabrication of Magnetic Couplings in Vacuum RobotsDocument8 pagesDesign and Fabrication of Magnetic Couplings in Vacuum Robotssandeep5No ratings yet

- Design of Hot Forging Process of Parts With Complex Geometry in Digital EnvironmentDocument4 pagesDesign of Hot Forging Process of Parts With Complex Geometry in Digital Environmentsandeep5No ratings yet

- Zitech PLC ProcessDocument1 pageZitech PLC Processsandeep5No ratings yet

- Actuators WDocument15 pagesActuators Wsandeep5No ratings yet

- Pro - Intralink Awareness SessionDocument26 pagesPro - Intralink Awareness Sessionsandeep5No ratings yet

- Computer Aided Micro Mechanism DesignDocument5 pagesComputer Aided Micro Mechanism Designsandeep5No ratings yet

- Diecasting Vs Other ProcessesDocument1 pageDiecasting Vs Other Processessandeep5No ratings yet

- Tds of Takelac W Series 1 3Document2 pagesTds of Takelac W Series 1 3Wang WJNo ratings yet

- Masterflow 928 Spec PDFDocument8 pagesMasterflow 928 Spec PDFDavid Toyohashi BioGenNo ratings yet

- Is 9459Document13 pagesIs 9459Anonymous mcHqIfbnV1No ratings yet

- Mouser EnclosectionDocument33 pagesMouser EnclosectionalltheloveintheworldNo ratings yet

- Royal Plaza DraftDocument4 pagesRoyal Plaza Draftssjk2008No ratings yet

- Action Plan For Brigada Eskwela 2014Document1 pageAction Plan For Brigada Eskwela 2014janice alquizarNo ratings yet

- Boxbolt Hollow Profile Fastener: Galvanized Steel, Blue Passivated (A2K) Hot-Galvanized Steel Stainless Steel A4Document1 pageBoxbolt Hollow Profile Fastener: Galvanized Steel, Blue Passivated (A2K) Hot-Galvanized Steel Stainless Steel A4Audrius VitkauskasNo ratings yet

- Ducted Central Heating and Air Circulation SystemDocument4 pagesDucted Central Heating and Air Circulation SystemsamsujNo ratings yet

- Checklist For The Inspection of Overhead Travelling CraneDocument1 pageChecklist For The Inspection of Overhead Travelling CraneMaged ObaidNo ratings yet

- Prezentacija Za GermanijaDocument20 pagesPrezentacija Za GermanijamgjorNo ratings yet

- MANUAL PVCC ValveDocument216 pagesMANUAL PVCC ValvePratik SinghNo ratings yet

- Bending Strength of Deep Corrugated Steel Panels PDFDocument34 pagesBending Strength of Deep Corrugated Steel Panels PDFAmol GoleNo ratings yet

- Module ArchitectsDocument14 pagesModule Architectsmurad_ceNo ratings yet

- SBS5411 1819 02Document48 pagesSBS5411 1819 02Thanh Hoang TranNo ratings yet

- BS EN 752-4 Annex BDocument4 pagesBS EN 752-4 Annex BAnatoly RapoportNo ratings yet

- Drilled Shaft Soil Excavation LogDocument1 pageDrilled Shaft Soil Excavation LogG-SamNo ratings yet

- Assab PortDocument5 pagesAssab PortAlemu RegasaNo ratings yet