0% found this document useful (0 votes)

140 views4 pagesWorkforce Planning and Cost Analysis

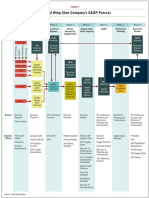

The document outlines a production planning model with the goal of minimizing total costs. It includes inputs like workforce size, production rates, costs per shirt for regular and overtime production. The model tracks inventory levels and costs like hiring, firing, inventory holding over multiple months. It aims to determine the optimal workforce levels and production quantities to meet a forecasted demand while staying under budget.

Uploaded by

Uchenna 'Bonex' OgbonnaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

140 views4 pagesWorkforce Planning and Cost Analysis

The document outlines a production planning model with the goal of minimizing total costs. It includes inputs like workforce size, production rates, costs per shirt for regular and overtime production. The model tracks inventory levels and costs like hiring, firing, inventory holding over multiple months. It aims to determine the optimal workforce levels and production quantities to meet a forecasted demand while staying under budget.

Uploaded by

Uchenna 'Bonex' OgbonnaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

- Monthly Production and Cost Analysis: This section outlines the monthly breakdown of production variables and cost factors, highlighting decision variables, starting workforce, and inventory costs.

- Supplementary Cost Data: Provides additional data focusing on inventory and overtime capacities required for production adjustments.