Professional Documents

Culture Documents

Problems Sheet-Machine Tools-2015-16 PDF

Problems Sheet-Machine Tools-2015-16 PDF

Uploaded by

Divyanshu YadavOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Problems Sheet-Machine Tools-2015-16 PDF

Problems Sheet-Machine Tools-2015-16 PDF

Uploaded by

Divyanshu YadavCopyright:

Available Formats

1

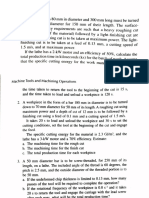

MACHINE TOOLS

LATHE:

1) Estimate the machining time to turn MS Rod from 4 cm dia to 3.5 cm dia for a length

of 15 cm in a single cut. Assume cutting speed 30 m/min. feed 0.4 mm/ rev.

Ans. 1.58 min

2) Find the time required to turn a 60mm dia rod into the

dimensions shown, take cutting speed as 20 m/ min. f = 1.2

mm/ rev. All cuts are 3mm deep. Ans. 3.23 min

3) Find the time for threading on 3 cm spindle of M.S for length

of 15 cm. The no. of threads to be cut are 3 / cm. The lathe runs at 88 rpm. Assume Approach

and over travel are 0.5 cm each and no. of cuts for M.S. are 7. Ans. 3.85 min

4) Estimate the boring time to enlarge a spindle bore from diameter 30 mm to diameter 40

mm for a length of 100 mm taking cutting speed as 30 m/min, feed 0.01 cm/rev. All cuts are

2mm deep.

a) 3.2 min b) 10.7 min c) 3.7 min d) 4.2 min Ans: B

5) A through hole of diameter 20 mm has to be drilled in a lathe in a rectangular plate of size

500 x 400 x 50 mm. Drills of diameter 10 mm and 20 mm are available. Assuming that the

cutting speed is 10 m/min and the feed for drill is 0.2 mm/rev, calculate the drilling time.

Neglect approach and over travel. Maximum material cut at a time cannot exceed 10 mm.

a) 1.6 min b) 13 min c) 16 min d) 2.4 min Ans: D

6) A round plate of diameter 500 mm has to be faced on both sides to reduce it thickness

from 30 mm to 20 mm. Depth of cut is 3 mm. Estimate the machining time. Cross feed is

0.05 cm/rev and plate rotates at 500 rpm.

a) 1 min b) 2 min c) 4 min d) 3 min Ans: C

7) A square plate of size 300 x 300 mm has to be faced on both sides to reduce it thickness

from 50mm to 40mm in two cuts per side. Cross feed is 0.05 cm/rev, plate rotates at 200 rpm.

a) Estimate the machining time a neglecting corner lengths

a) 1.5 min b) 6 min c) 3 min d) 9 min Ans: B

b) Estimate the machining time including corner lengths

a) 8.5 min b) 2.1 min c) 4.3 min d) 12.7 min Ans: A

8) The roughing speed and finishing speed for turning a job are 30 m/min and 60 m/min. The

respective feeds are 0.24 mm/rev and 0.1mm/rev. The max depth of cut is 2 mm and min

depth of cut is 0.75 mm. Take material constant is 1600 N/mm2. Calculate the power required

for roughing and finishing in watts.

Ans. Roughing Power = 384 W, Finishing Power = 120 W

PREVIOUS QUESTIONS:

9. For cutting double start screw threads of pitch 2mm on a lathe, the thread cutting tool

should have a feed of _______ Ans. 4 mm/rev

Dr. G. R. C. PRADEEP Email: grcpradeep@gmail.com

2

10. Determine the transformation ratio (TR) of the gear train connecting the spindle and lead

screw of 4 TPI required to cut 1mm pitch screw threads on a centre lathe. Ans. 20/127

11. Calculate a simple gear train to cut right hand threads of 1mm pitch on a lathe with lead

screw of 3mm pitch. Ans. 20/60 with one idler

12. A non standard thread of pitch 3.175mm is cut on a lathe having lead screw of pitch

6mm. A change gear set is provided with lathe having following teeth: 20, 30, 40, 50, 60, 70,

80, 90,100, 110, 120, 127. The correct pairs of change gears (a/b x c/d) is ______

Ans. a/b x c/d = 127/40 x 20/120

13. Find the angle at which the compound rest should be set to turn a taper on a work piece

having a length of 200 mm, diameters, 45 mm and 35 mm. Ans. 1.50

14. Find the amount of offset of tail stock required to turn a taper of length 400 mm when the

diameters at the ends are 60 and 40 respectively. Ans. 10 mm

15. A medium carbon steel work piece is turned on a lathe at 50 m/min cutting speed,

0.8mm/rev feed and 1.5 mm depth of cut. What is MRR. Ans. 60000mm3/min

16. A shaft of length 90 mm has a tapered portion of length 55 mm. The diameter of the taper

is 80 mm at one end and 65 mm at the other. If the taper is made by tailstock set over method,

the taper angle and the set over respectively are.

(a) 15032′ & 12.16mm (b) 18 032′ & 15.66mm (c) 11022′ & 10.26mm (d) 10032′ & 14.46mm

Ans. (a)

SHAPER:

1) In a shaper work, the length of the stroke is 200 mm. No. of double strokes per min. is 30

and ratio of return time to cutting time is 2:3 find the cutting speed. Ans. 10 m/min

2) Find the time required for taking a complete cut on a plate 600 x 900

mm, if the cutting speed is 9 m / min. The return time to cutting time

ratio is 1:4, feed is 3mm, clearance at each end is 75mm.

Ans. 31.25 min

3) Also find for the above problem Time required by cutting stroke, Return stroke time, and

No. of double strokes required to complete the job.

Ans. Time required by cutting stroke = 0.083 min

Return stroke time = 0.021 min

No. of double strokes required to complete the job = 300

4) Calculate the power in shaping a steel plate with a depth of cut 2.8 mm, cutting speed 65

m /min. Feed rate is 0.4mm and constant for HP conversion is 79 x 10-6 Ans. 5.75 H.P

PREVIOUS QUESTIONS:

5. If the number of double strokes per minute in a shaper is calculated by (0.643 x Cutting

speed in m/min) per length of stroke in m, the return speed is faster than cutting speed by

_____ Ans. Faster by 40%

Dr. G. R. C. PRADEEP Email: grcpradeep@gmail.com

3

6. The quick return mechanism used in a shaper has a rocker arm drive of length 200mm. If

the crank radius is 50 mm and the offset between crank centre and rocker arm pivot is 20

mm, length of the stroke is __________ Ans. 1m

7. A 600 symmetrical V tool is used in shaping a work piece with a depth of cut of 0.1 mm

and feed of 0.1 mm/stroke. The theoretical peak to valley height, in mm, of the surface

produced is ___

a) 0.043 b) 0.067 c) 0.086 d) None Ans: C

8. A work piece of 2000 mm length and 300 mm width was machined by a planning

operation with the feed set at 0.3 mm/stroke. If the machine tool executes 10 double strokes /

min, the planning time for a single pass will be _______

a) 50 min b) 100 min c) 200 min d) 220 min Ans: B

9. A cast iron block of 200 mm length is being shaped in a shaping machine with a depth of

cut of 4 mm, feed 0.25 mm/stroke, and the tool principal cutting edge angle of 300. Number

of cutting strokes per minute is 60. Using specific energy for cutting as 1.49 J/mm3, the

average power consumption in watts is _____ Ans. 298 W

DRILLING:

1) At what speed a 20mm dia drill will run for cutting steel at 25 m /min surface speed?

Ans. 398 RPM

2) A hole of 40mm dia and 50mm depth is to be drilled in a M.S. component. The cutting

speed is 65m /min. feed rate is 0.25 mm /rev. Calculate a) Machining time b) material

removal rate. Assume approach and O.T. = 3mm.

Ans. a) 0.5 min b )163.4 cm3.min

3) Blind holes of dia 10 mm are to be drilled up to a depth of 50 mm at a speed of 600 rpm

and feed 0.2 mm/rev. Point angle of drill is 1200. Machining time per hole is ____

Ans. 0.44 min.

PREVIOUS QUESTIONS:

4. A drilling machine has to be designed with 8 spindle speeds ranging between 120 to 1200

rpm. The 5th spindle speed is ________ Ans N5 = 447 rpm

5. A component requires a hole which must be with in the two limits of 25.03 and 25.04 mm

diameter. Which of the following statements about reamer size are correct?

1. Reamer size cannot be below 25.03mm

2. Reamer size cannot be above 25.04mm

3. Reamer size can be 25.04mm

4. Reamer size can be 25.03mm Ans. 1&2

6. A hole of 30 mm dia is to be produced by reaming. The min, dia. Possible is 30.00mm and

max. dia. possible is 30.05mm. Which of the statement are correct?

1. The min. dia. of the reamer can be less than 30mm

2. The min. dia. of the reamer cannot be less than 30mm

3. The max. dia. of the reamer can be more than 30.05mm

4. The max. dia. of the reamer must be less than 30.05mm Ans. 2 & 4

Dr. G. R. C. PRADEEP Email: grcpradeep@gmail.com

4

MILLING:

1) Estimate the time required to prepare a square prism on a milling machine from a round

block 90 mm in length and 40mm in dia, feed 25 mm / minute. Set up & Indexing time is

15 min. Added table travel = 10 mm. Ans. 31 min

2) Estimate the milling time to cut 60 teeth on a gear blank of 60 mm thick, feed 35 mm /

minute and take set up time as 10 min. Assume table travel = 10 mm. Ans. 130 min

3) A slot is to be made on a milling machine with the help of a peripheral cutter, revolving at

120 rpm. Find the time required to prepare the slot in two cuts, if it is 2 cm deep and 10 cm

long with a cutter of 8 cm dia. Assume feed as 0.5mm/rev. Neglect Over travel and assume

clearance at exit is 0.5 cm. Ans. 4.38 min

4) A 20x5 cm. C.I. surface is to be faced on a milling machine with a face cutter having a dia

of 10 cm. and 16 teeth. The cutting speed and feed are 50 m / min. and 5 cm / min.

Determine the milling time for a roughing cut, rpm of cutter and feed per tooth.

Ans. Time taken = 4.135 min.; RPM, N = 159 rpm; ft = 0.002 cm / tooth

5) A CNC vertical milling machine has to cut a straight slot of 10 mm width, 2mm depth b/w

(0,0) and (100,100) on XY plane (Dimensions in mm) with a cutter of dia 10mm. Feed rate is

50 mm/min. Milling time in seconds is __________. Ans. 175.7 sec

PRACTICE PROBLEMS:

6) A hexagonal prism is to be made in a milling machine from a round bar of diameter 60

mm and 100 mm length. The feed is 30 mm/min and set up time is 2 min per face. Estimate

the machining time. Assume added table travel 10 mm.

a) 24 min b) 20 min c) 32 min d) 34 min Ans: D

7) A splined shaft having 5 splines is to be produced in horizontal milling m/c. The spline slot

dimensions are 100 x 15 x 3 mm. If feed is 25 mm/min, estimate the machining time

assuming setup time is 15 min. Neglect over travel. Cutter dia is 15mm

a) 21.2 min b) 36.2 min c) 20 min d) None Ans: B

8) A work piece of 100 x 50 x 25 mm has to be machined using a face milling cutter of

diameter 60 mm and 20 teeth to reduce the thickness to 15 mm. The feed per tooth is 0.03

mm/tooth. The cutter rotates at 150 rpm. The depth of cut cannot exceed 5 mm.

a) 2.52 min b) 1.26 min c) 1.1 min d) None Ans: A

9) A work piece of 200x150x50mm is to be machined using a face milling cutter of Ф 50 mm

and 20 teeth to reduce the thickness to 45mm. The depth of cut cannot exceed 5 mm. Added

table travel is 10mm. The feed per tooth is 0.02mm/tooth. The cutting speed is 50 m/min

a) Determine the RPM of the cutter

a) 1000 b) 320 c) 250 d) None Ans: B

b) Determine the milling time.

a) 5 min b) 1.7 min c) 3.4 min d) None Ans: A

10) Data for a slab milling operation are given below:

Length of WP = 200 mm, Cutter Dia = 100 mm

Dr. G. R. C. PRADEEP Email: grcpradeep@gmail.com

5

No. of teeth = 4, Cutter speed = 100 rpm

Feed = 200 mm / min, Depth of cut = 2 mm

Total clearance at entry and exit = 5mm. Neglect over travel.

a) Mean undeformed chip thickness is _____________

b) Machining time for single pass in sec is __________

Ans. a) tavg = 71 µm b) T = 66 sec

11) A side and face cutter of 125 dia has 10 teeth. It operates at cutting speed 14m/min with

table traverse 100 mm/min. Feed per tooth of cutter is _____________ Ans. ft = 0.28 mm

12) One brand of milling m/c has following index plates.

Plate 1:- 15, 16, 17, 18, 19, 20, hole circles; Plate 2:- 21, 23, 27, 29, 31, 33, hole circles

To make 28 teeth by simple indexing, what plate is suitable?

Ans. Plate 2:- 1 full revolution + 9 holes in 21 hole circle.

NTM:

PREVIOUS QUESTIONS: (ECM)

1) During the electrochemical machining (ECM) of iron (atomic weight = 56, valency = 2) at

current of 1000A with 90% current efficiency, the MRR was observed to be 0.26 gm/s. If

Titanium (atomic weight = 48, valency = 3) is machined by the ECM process at the current of

2000A with 90% current efficiency, the expected MRR in gm/s will be ----- Ans.0.2984 gm/s

2) Electrochemical machining is performed to remove material from an iron surface of

20 mm x 20 mm under the following conditions: Inter electrode gap = 0.2 mm; Supply

voltage (DC) = 12 V; Atomic weight of iron = 55.85, Valency of iron = 2; Specific resistance

of electrolyte = 2 ohm-cm; Faraday’s constant = 96540 coulombs; the MRR in gm/s will be --

Ans. 0.3471 g/sec.

3) While removing material from iron (atomic weight = 56, valency = 2, density = 7.8 g/cc)

by ECM, a MRR of 2 cc/min is desired. The current required for achieving this MRR is ------

Ans. 896.07 Amp

4) A researcher conducts ECM on a binary alloy (Density= 6000 kg/m3) of iron (atomic

weight = 56, valency = 2) and metal P (atomic weight = 24, valency = 4). Faradays constant

= 96500 coulombs /mole. Volumetric MRR of the alloy is 50 mm3/sec at a current of 2000A.

The percentage of metal P in the alloy is -------- Ans. 25.48 %

5) Estimate the MRR (in cc/s) of an alloy containing 18% cobalt, 62% Nickel, 20%

Chromium during ECM with a current of 500A. Density of alloy is 8.28 g/cc. The following

data is available:

Metal Gram Atomic Weight Valency

Co 58.93 2

Ni 58.71 2

Cr 51.99 6 Ans. MRR = 1.24 x 10-2 cc/s

PRACTICE PROBLEMS: (ECM)

Dr. G. R. C. PRADEEP Email: grcpradeep@gmail.com

6

6) Calculate the MRR and electrode feed rate in the ECM of an iron surface that is 25mm x

25mm in cross section using Nacl in water as electrolyte. The gap between tool and work

piece is 0.25 mm. Supply voltage is 12V DC. Specific resistance of electrolyte is 3 Ω-cm

Valency of iron =2, Atomic weight = 55.85, Density = 7860 kg/m3.

Ans. a) Metal Removal Rate = 0.0368 cm3/sec. b) Electrode feed rate = 3.53 mm/min

7) In ECM operation of pure iron, an equilibrium gap of 2 mm is kept. Determine the supply

voltage, if the over voltage is 2.5V, resistivity of electrolyte is 50 Ω-mm, Set feed rate is

0.25mm/min. Z = 2, A = 56, Density = 7860 kg/m3. Ans. 13.78V

PRACTICE QUESTIONS: (EDM)

1. In a RC type generator in EDM, the maximum charging voltage is 80 V and the charging

capacitor is 100 µF. Determine spark energy. Ans. 0.32 J/cycle

2. If in a RC type generator in EDM, to get an idle time of 500 µs for open circuit voltage of

100 V and maximum charging voltage of 70 V, determine charging resistance. Assume

C = 100 µF. Ans. R = 4.15 Ω

3. For a RC type generator in EDM to get maximum power dissipation during charging

Vc = Vs x 0.716. Determine idle time for R = 10 Ω and C = 200 μF Ans. 2.51 milli sec

4. Determine on time or discharge time in EDM if Supply voltage = 100 V and Discharge

voltage= 15 V, Spark energy = 0.5 J. Generator is expected for maximum power during

charging. Machine resistance = 0.5 Ω. Ans. 0.15 milli sec

PREVIOUS QUESTIONS: (EDM)

5. A titanium sheet of 5.0mm thickness is cut by a wire edm process using a wire of 1mm dia.

A uniform spark gap of 0.5 mm on both sides is maintained during the cutting operation. If

the feed rate of the wire in to the sheet is 20mm/min, the MRR in mm3/min is _______

Ans. MRR = 200 mm3/min

6. In EDM process using RC relaxation circuit, a 12 mm dia through hole is made in steel

plate of 50 mm thickness using a graphite tool and kerosene as dielectric. Assume discharge

time is negligible. Machining is carried under following conditions. Resistance = 40Ω.

Capacitance = 20 µF, Supply voltage = 220 V, Discharge voltage = 110 V.

a) The time for one cycle in milli sec is __________

b) Average power input in KW is _____________

Ans. a) Cycle Time = 0.55 milli sec b) Average power Input = 0.22 KW.

NC MACHINES:

1. In a point to point control of NC machine, the slides are positioned by an integrally

mounted stepper motor drive. If the specification of the motor is 1 deg/pulse and pitch of the

lead screw is 3.6 mm, what is the expected positional accuracy. Ans. 10 µm.

2. A cylinder of 155 mm dia is to be reduced to 150mm dia in one turning cut with a feed of

0.15 mm/rev and cutting speed of 150 m/min on a NC lathe. What are the programmed feed

rate and MRR. Ans. Programmed feed rate = 46.2 mm/min; MRR = 56250 mm3/min

Dr. G. R. C. PRADEEP Email: grcpradeep@gmail.com

7

3. A DC servo motor is directly driving an NC table. The pitch of the lead screw of the table

is 5mm. The motor rotates at 100 rpm for an applied voltage of 10V. If the voltage speed

characteristic of the motor is linear, the applied voltage for a table speed of 3 m/min is _____.

Ans. 60V

4. In a CNC feed drive, a stepper motor with step angle of 1.80 drives a lead screw with pitch

of 2 mm. The BLU for this drive is _____. Ans. 10 µm

5. A stepper motor has 150 steps. The output shaft of the motor is directly coupled to a lead

screw of pitch 4 mm which drives the table. If the frequency of pulse supply to the motor is

200Hz, the speed of the table (mm/min) is ______ Ans. 320 mm/min

6. The total angular movement (in degrees) of a lead screw with a pitch of 5 mm to drive the

work table by a distance of 200 mm in a NC machine is _______ Ans. 144000

7. For a 3-axes CNC table, the slide along the vertical axis of the table is driven by a DC

servo motor, via lead screw nut mechanism. The lead screw has a pitch of 5 mm. This lead

screw is fitted with a relative (incremental) encoder. The BLU of the slide along the vertical

axis of the table is 0.005mm. When the table moves along the vertical axis by 9mm, the

corresponding number of pulses generated by the encoder is _______ Ans. 1800 pulses

8. A DC servo motor is coupled directly to a lead screw which drives an NC table. A digital

encoder which emits 500 pulses per revolution is mounted on the other end of the lead screw.

If the pitch of the lead screw is 5mm and the motor rotates at 600 rpm, calculate a) Linear

velocity of the table b) BLU of the NC system c) The frequency of pulses transmitted

by the encoder. Ans. a) 3 m/min b) 10 µm c) 5000 Hz

NC PART PROGRAMMING:

1) A work piece shown in the figure has to be drilled

with 3 holes at different places as shown. The depth of

hole is 10mm and the cutting tool is positioned above

the work surface. The feed rate is 200 mm/ min and

spindle rotates at 1000 rpm.

2) A work piece shown in figure has to be machined

along AB & BC in milling taking depth of cut as 5 mm.

The feed rate is 200 mm/min spindle speed is 2000

rpm, cutter dia 10 mm.

Dr. G. R. C. PRADEEP Email: grcpradeep@gmail.com

8

3) Prepare a part program for machining a rectangular contour of 200 mm x 150 mm size

from a suitable blank of 5mm thickness. Also a reamed hole of ϕ16 mm has to be made

centrally in the rectangular contour. Take feed and speed arbitrarily.

4. In finish machining of an island on a casting with CNC milling machine, an end mill of

10mm dia is used. The corner points of the island are (0, 0), (0, 30), (50, 30), (50, 0). By

applying cutter radius compensation, the trajectory of cutter will be____

Ans. (-5, -5) (55, -5) (55, 35), (-5, 35) (-5, -5)

5) Make a program in Apt for the part

shown in the figure.

6) Make a part program for the part shown using both tools of mill & drill. Assume plate

thickness of 15mm and set point at (0, 20, 0) and Z = 0 at the surface of job.

Dr. G. R. C. PRADEEP Email: grcpradeep@gmail.com

9

7) Make a program in Apt for the part shown in the figure. Assume suitable data.

8) Make a program in Apt for the part shown on the left in the figure. Assume suitable data.

Assume thickness of work piece is 6 mm.

Dr. G. R. C. PRADEEP Email: grcpradeep@gmail.com

You might also like

- Lumberlok: Timber Connectors Characteristic Loadings DataDocument12 pagesLumberlok: Timber Connectors Characteristic Loadings DataGajanthan Vethanathan0% (1)

- Sheets - Sep 2013Document13 pagesSheets - Sep 2013Mohamed OsamaNo ratings yet

- Faculty of Mechanical and Industrial Engineering (2011 E.C.)Document2 pagesFaculty of Mechanical and Industrial Engineering (2011 E.C.)Roha Engineering0% (1)

- Metal Color CodesDocument1 pageMetal Color CodesAnil Ao0% (1)

- 2 Problems Sheet Machine ToolsDocument9 pages2 Problems Sheet Machine ToolsALOKSRK0% (1)

- TUTORIALS 1 (1) - MergedDocument23 pagesTUTORIALS 1 (1) - MergedRUGERO KeslyneNo ratings yet

- 414 TutorialsDocument2 pages414 TutorialsAMOS SIFUNANo ratings yet

- Man ProDocument2 pagesMan ProlividiveNo ratings yet

- Assignment 1 2Document2 pagesAssignment 1 2Jeevan GNo ratings yet

- Manufacturing Engineering Assignment Thapar UniversityDocument5 pagesManufacturing Engineering Assignment Thapar UniversitySaurav Kumar0% (1)

- Tutorial - Topic 4Document2 pagesTutorial - Topic 4Kavish CserNo ratings yet

- AssignmentDocument2 pagesAssignmentgirma workuNo ratings yet

- AssignmentDocument2 pagesAssignmentgirma workuNo ratings yet

- Tutorial-2: Manufacturing Science and Technology-II (ME - 322)Document2 pagesTutorial-2: Manufacturing Science and Technology-II (ME - 322)Deepam ShyamNo ratings yet

- Tutorial 2Document10 pagesTutorial 2omar salahNo ratings yet

- UTA026 Manufacturing Processes Work SheetDocument3 pagesUTA026 Manufacturing Processes Work SheetGUNJAN KHULLARNo ratings yet

- Mm216 Eigenvalue EigenvalueDocument4 pagesMm216 Eigenvalue EigenvalueFurkan ŞahinNo ratings yet

- Assignment: Q.N.1. in A Turning Operation, It Was Observed That The Tool Life Was 150 Minutes When The CuttingDocument7 pagesAssignment: Q.N.1. in A Turning Operation, It Was Observed That The Tool Life Was 150 Minutes When The CuttingAnkesh KapilNo ratings yet

- Assignment 1Document4 pagesAssignment 1antonushany52No ratings yet

- Theory of Metal Cutting - NumericalsDocument2 pagesTheory of Metal Cutting - Numericalspmagrawal100% (1)

- Sheet 8Document5 pagesSheet 8mo635107No ratings yet

- MP Unit-2Document113 pagesMP Unit-2Parth MaldhureNo ratings yet

- Solution: (a) N = v/πD = 70,000 mm/80 = 279 rev/minDocument11 pagesSolution: (a) N = v/πD = 70,000 mm/80 = 279 rev/minwoihoNo ratings yet

- Sheet Metal Working& Powder MetallurgyDocument13 pagesSheet Metal Working& Powder Metallurgyanant709skNo ratings yet

- 2 Numericals Bank MP II PDFDocument7 pages2 Numericals Bank MP II PDFThenarasumohanveluNo ratings yet

- Theory of Metal Cutting Numericals PDFDocument2 pagesTheory of Metal Cutting Numericals PDFsanjayNo ratings yet

- 09 Problem Sheet 02Document2 pages09 Problem Sheet 02Shweta raiNo ratings yet

- Assign 1 2012Document2 pagesAssign 1 2012chiru1431No ratings yet

- Tutorial (Individuals) Dateline: 15/12/2011 at 5.00 PMDocument2 pagesTutorial (Individuals) Dateline: 15/12/2011 at 5.00 PMrandyooiNo ratings yet

- ME3201Document4 pagesME3201Md. Tariqul Islam MunnaNo ratings yet

- Tugas I - PM2 - A2Document1 pageTugas I - PM2 - A2Alridah SyahfitriNo ratings yet

- Example 2Document5 pagesExample 2girma workuNo ratings yet

- T, Chip Thickness 0.6 MM, RPM 590, D 100 MM, FDocument1 pageT, Chip Thickness 0.6 MM, RPM 590, D 100 MM, FZó LáNo ratings yet

- Cos Tan Here Is The Chip T 1 Si Hickness Ratio. N: R R R WDocument1 pageCos Tan Here Is The Chip T 1 Si Hickness Ratio. N: R R R WpmagrawalNo ratings yet

- Dang Tutorial 1 2 Solution (Metal Cutting) - 04112014174823135Document10 pagesDang Tutorial 1 2 Solution (Metal Cutting) - 04112014174823135Bi ChenNo ratings yet

- TA202 AssignmentsDocument1 pageTA202 AssignmentsBrajesh kumarNo ratings yet

- Sheet 5Q Manufacturing Processes 1Document1 pageSheet 5Q Manufacturing Processes 1Ahmed Rabie Abd ElazeemNo ratings yet

- Virtual Buce 3Document92 pagesVirtual Buce 3Ralph Edward Santiago Moran100% (1)

- Calculation Manufacturing ProcessDocument18 pagesCalculation Manufacturing ProcessEncik MaaNo ratings yet

- Problem Set 1Document5 pagesProblem Set 1riyaNo ratings yet

- Lecture 5 Lathe Speed and FeedDocument14 pagesLecture 5 Lathe Speed and FeedYAWARNo ratings yet

- Piping Course MaterialDocument29 pagesPiping Course MaterialLOKESHNo ratings yet

- Tutorial Problems in Machining TimeDocument2 pagesTutorial Problems in Machining TimeDHANASEKAR K IV A 9023No ratings yet

- Chapter 5 Milling Machine-Calculation Problems-11 May 2022Document11 pagesChapter 5 Milling Machine-Calculation Problems-11 May 2022ShuhadaNo ratings yet

- HW4 2013 Solution Heat TransferDocument5 pagesHW4 2013 Solution Heat TransferAlbert StarkNo ratings yet

- Cutting Force Thrust ForceDocument1 pageCutting Force Thrust ForcepmagrawalNo ratings yet

- Me 014Document2 pagesMe 014Jimmy JindalNo ratings yet

- Cutting Speed Feed For Milling MachineDocument21 pagesCutting Speed Feed For Milling MachineKeerthi Kumar100% (1)

- Taller Calculo de Parametros de CorteDocument4 pagesTaller Calculo de Parametros de CorteWendy Paola Rodriguez PerezNo ratings yet

- Stevens ME 560 HW 4Document4 pagesStevens ME 560 HW 4Dominique SmoyerNo ratings yet

- Problem Sheet Metal Machining and Cutting Conditions 2016Document3 pagesProblem Sheet Metal Machining and Cutting Conditions 2016Muhammad imranNo ratings yet

- Mid-Term Test: Material and Metal ProcessingDocument8 pagesMid-Term Test: Material and Metal ProcessingekanandaardiansyahNo ratings yet

- Lect 8Document13 pagesLect 8shashankmay18No ratings yet

- Assignment 4 Due: May 15, 2020 MachiningDocument1 pageAssignment 4 Due: May 15, 2020 MachiningngouoNo ratings yet

- Bulk Problems PDFDocument5 pagesBulk Problems PDFSatyasankar LgNo ratings yet

- ME6005/Process Planning & Cost Estimation Year/sem:IV/VIIDocument10 pagesME6005/Process Planning & Cost Estimation Year/sem:IV/VIIvengadeshNo ratings yet

- 03 Cutting Conditions - MILLING - EXDocument9 pages03 Cutting Conditions - MILLING - EXNicolle Gil RamosNo ratings yet

- انتاج ٢Document9 pagesانتاج ٢khaledfarrag281No ratings yet

- Introduction WindshieldDocument2 pagesIntroduction WindshieldShafiq AhmadNo ratings yet

- Cooling Water Problems & Solutions PDFDocument35 pagesCooling Water Problems & Solutions PDFShafiq Ahmad100% (3)

- Ch-11 NC CNC DNC FMS Automation and RoboticsDocument143 pagesCh-11 NC CNC DNC FMS Automation and RoboticsShafiq AhmadNo ratings yet

- I.C EngineDocument154 pagesI.C EngineShafiq AhmadNo ratings yet

- Grainger Catalog 401Document1 pageGrainger Catalog 401sam_wolf009No ratings yet

- Catalog: Clodfelter Bridge and Structures International, IncDocument28 pagesCatalog: Clodfelter Bridge and Structures International, Incjsyun0831No ratings yet

- V370Document30 pagesV370ulfatNo ratings yet

- Kenna MetalDocument2 pagesKenna MetalArshadAliNo ratings yet

- Safety WireDocument8 pagesSafety WirenormalNo ratings yet

- تأثير تركيز النيكل على مقاومة التأكسد الدوري لسبيكةDocument7 pagesتأثير تركيز النيكل على مقاومة التأكسد الدوري لسبيكةSalem GarrabNo ratings yet

- Tipe ChipDocument3 pagesTipe ChipHary RespatiNo ratings yet

- The Axle Housing For A Skid-Steer Loader: A Design Study in Ductile Cast IronDocument28 pagesThe Axle Housing For A Skid-Steer Loader: A Design Study in Ductile Cast Ironbeibox100% (1)

- Effects of Alloying Elements in SteelDocument3 pagesEffects of Alloying Elements in SteelRudraman Singh0% (1)

- Catalogo Yg-1 2009 - CarburoDocument33 pagesCatalogo Yg-1 2009 - Carburo13pimoNo ratings yet

- Wires For Submerged Arc Welding of Creep Resistant Steels: Copper Coated Low Alloy Steel Solid WiresDocument6 pagesWires For Submerged Arc Welding of Creep Resistant Steels: Copper Coated Low Alloy Steel Solid WiresDeepak BhatiNo ratings yet

- Sheet Metal Selection For Different Applications: Dr.N.Ramani NTTFDocument99 pagesSheet Metal Selection For Different Applications: Dr.N.Ramani NTTFSachin JadhavNo ratings yet

- Mep Online FinalDocument35 pagesMep Online FinalAkhilvjohnNo ratings yet

- Is 8329 1994Document30 pagesIs 8329 1994Madanlal Varada86% (7)

- A 897 - A 897M - 02 Qtg5ny9bodk3ts1sruqDocument11 pagesA 897 - A 897M - 02 Qtg5ny9bodk3ts1sruqrolando cuadro blancoNo ratings yet

- Katanka SAE1006 SAE1008 ENDocument1 pageKatanka SAE1006 SAE1008 ENPhong ThanhNo ratings yet

- Contern A SteelDocument2 pagesContern A Steelssmith2007No ratings yet

- CA3SN-G Cold Rolled SteeDocument2 pagesCA3SN-G Cold Rolled SteeFaizan QadirNo ratings yet

- Mineral Deposits Part 1Document5 pagesMineral Deposits Part 1Samantha Mhae LegaspiNo ratings yet

- Materiale Dhe Perpunim Termik Chapter11Document48 pagesMateriale Dhe Perpunim Termik Chapter11durimfcbNo ratings yet

- Industrial Tools and Solutions PDFDocument113 pagesIndustrial Tools and Solutions PDFandresboy123100% (1)

- Weld-Defects A - TWI PDFDocument97 pagesWeld-Defects A - TWI PDFMKPashaPasha100% (2)

- Product Brochure ZincalumeDocument2 pagesProduct Brochure ZincalumeizamNo ratings yet

- MCQ For Welding ShopDocument6 pagesMCQ For Welding Shopsudhir guptaNo ratings yet

- Asme IxDocument132 pagesAsme IxAhmed Shaban Kotb100% (1)

- ASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFDocument7 pagesASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFJA KNo ratings yet

- Aquazinc Water Based Zinc Flake Coating by Dip Spin ProcessDocument3 pagesAquazinc Water Based Zinc Flake Coating by Dip Spin Processkdhakane9460No ratings yet

- MSS Standards ListDocument3 pagesMSS Standards Listtsrinivasan5083No ratings yet