100% found this document useful (3 votes)

2K views17 pagesTank D101-1 Repair Procedure Guide

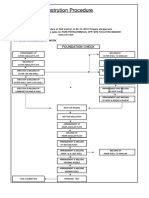

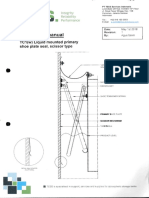

This document outlines procedures for repairing and cleaning Tank D101-1 for RH PetroGas. It includes specifications for the tank, a work methodology, preparation steps, and applicable standards. The tank repair will involve replacing the seal, annular plate, and some bottom plates. The pontoon, deck plates, and accessories will also be repaired or replaced. Welding will be used to fix corrosion on the shell plates and wind girder. Procedures will follow API and ASME standards.

Uploaded by

Andreas SchlagerCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (3 votes)

2K views17 pagesTank D101-1 Repair Procedure Guide

This document outlines procedures for repairing and cleaning Tank D101-1 for RH PetroGas. It includes specifications for the tank, a work methodology, preparation steps, and applicable standards. The tank repair will involve replacing the seal, annular plate, and some bottom plates. The pontoon, deck plates, and accessories will also be repaired or replaced. Welding will be used to fix corrosion on the shell plates and wind girder. Procedures will follow API and ASME standards.

Uploaded by

Andreas SchlagerCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 17