Professional Documents

Culture Documents

SOW Quantity Surveytank307

SOW Quantity Surveytank307

Uploaded by

3eswa14Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOW Quantity Surveytank307

SOW Quantity Surveytank307

Uploaded by

3eswa14Copyright:

Available Formats

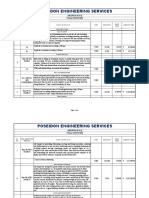

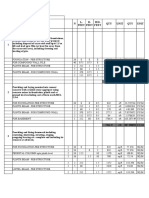

SOW Quantity SurveyTank 307 Contract #GUP - EC - 23-001

Dated 11/12/2023

Project : Repair of TANK # 307 Dia. : 61 m

Quantity surveyed

Quantity

Serial Estimated SOW Unit Contract Item NO. SOW description as contract on contract Unit Remarks

surveyed

description

Open necessary access at Tank shell to

1 Open Access door 3 SQ.M ITEM # 32 handle piping, plates, reweld and apply SQ.M

heat treatment if needed

Replace and compact oily sand layers

underneath bottom according to the

2 Remove and Replace Oily sand 2930.57 SQ.M ITEM# 4 specification of oily sand (layer thickness SQ.M

from 50 to 80 mm). Gupco will provide

oily sand.

Apply internal painting system according

3 Sandblasting and painting underneath bottom plates 2932.86 SQ.M ITEM# 49 to company specification including SQ.M

sandblasting and washing

Supply and Re-bottoming tank plate

Replace bottom plates completely 6 mm

4 2685.56 SQ.M ITEM # 8 -amount shall be added for each 2 mm

SQ.M

increment

supply material, fabricate and replace

new

5 Replace Annular plates 280.72 SQ.M ITEM # 9 annular plates completely 8 mm. SQ.M

-amount shall be added for each 2 mm

increment.

Supply material, fabricate and replace

sheet(s) from Tank roof 6mm thickness

6 Replace corroded plate of roof 18 SQ.M ITEM # 18 Partially SQ.M

Apply N.D.T (vacuum box test) on bottom Apply N.D.T on all welding phasaes:

7 5000 M.L ITEM # 48 M.L

welds vacuum Box test

Close Man-way, Clean out Door Flanges for Close Man-way, Clean out Door

8 354 Dim.Inch ITEM # 45 Dim.Inch

applying hydro- test Flanges for applying hydro- test

Supply, Fabricate ,Installsteel structure for roof Supply, Fabricate ,Installsteel

handrail and wind breaker structure for tank roof

9 900 kg ITEM # 46 kg

Open necessary access at tank roof for Open necessary access at tank roof

inspection and re-weld (open five windows at for inspection and re-weld

10 the upper deck for inspection and repair) outer 67.5 SQ.M ITEM # 33 SQ.M

pontoon

Sandblasting and painting tank externally Apply external painting system according

11 194.5 SQ.M ITEM# 50 to company specification including SQ.M

sandblasting and washing

Apply fiberglass lining system for tank

bottom and water zone of shell

completely including sandblasting and

12 Apply Fiberglass 3161.7 SQ.M ITEM # 52 painting primer - lining thickness 3000 SQ.M

micron (thick film)

Welding Longitudinal Welds at tank Roof,

13 Weld up Longitudinal Welds 3500 FT ITEM # 47 FT

Shell and bottom

14 Excavation 191.5 Qubic meter ITEM E-1 Excavation Qubic meter

Casting Concrete jackets Casting Concrete jackets

15 57.4 SQ.M ITEM E-4 SQ.M

16 Backfilling 191.5 Qubic meter ITEM E-2 Backfilling Qubic meter

Supply material, 4" sch 80 107

fabricate, replace and Supply material, fabricate, replace and

17 M.L ITEM # 42 M.L

install internal and install internal and external pipes

external pipes 6" sch 40 86

Supply material, 6" 28

Supply material, fabricate, replace and

18 fabricate, replace and EACH ITEM # 43

install Fittings

EACH

install Fittings 4" 54

19 Check and evaluate tank shell roudness – out of 1 Each D-DIAM 61-1 Check and evaluate tank shell Each

service roudness – out of service

Dismantling of existing pantograph mechanical Dismantling of existing pantograph

20 seal 1 Each D- DIAM 61 - 5 mechanical seal Each

Supply pantograph mechanical seal Supply pantograph mechanical seal

21 1 Each D- DIAM 61-6 Each

Install pantograph mechanical seal Install pantograph mechanical seal

22 1 Each D- DIAM61 - 9 Each

demolish existing extra bottom layer demolish existing extra bottom layer

23 2920 SQ.M ITEM # 3 SQ.M

G.O.S Onshore Projects Rep. Petromaint Site Manager

Name

Signature

Date

You might also like

- 2806C-E18+workshop+manual pdf+CATERPILLAR+C18Document192 pages2806C-E18+workshop+manual pdf+CATERPILLAR+C18Jhon Hever Benitez100% (27)

- ESTIMATE Water Tank - 30 KLDocument36 pagesESTIMATE Water Tank - 30 KLsurendramaharjan100% (1)

- Retaning Wall BOQDocument5 pagesRetaning Wall BOQMuhammadWazimAkram100% (1)

- Infrastructure Works Sewerage Works: All Quantities Marked Provisional Are Subjected To RemeasurementDocument2 pagesInfrastructure Works Sewerage Works: All Quantities Marked Provisional Are Subjected To RemeasurementSyahmi AbdullahNo ratings yet

- Final BUA BOQ Tender - OB Plot and Podium - 03.09.21Document11 pagesFinal BUA BOQ Tender - OB Plot and Podium - 03.09.21Jaysukh N SapraNo ratings yet

- A Competitive Analysis of Airline IndustryDocument8 pagesA Competitive Analysis of Airline Industryalexantsy27No ratings yet

- LG Multi F 3828a20097w 1Document254 pagesLG Multi F 3828a20097w 1Claudiu RaduNo ratings yet

- Client's Guide To Design and BuildDocument9 pagesClient's Guide To Design and BuildDarren Dela Cruz100% (1)

- BEC-HSE-L2 - Lock Out Tag Out ProceduresDocument12 pagesBEC-HSE-L2 - Lock Out Tag Out ProceduresZakariyaNo ratings yet

- Triple Pier - Pile IRC 112Document93 pagesTriple Pier - Pile IRC 112Praveen CyssanNo ratings yet

- Box Culvert EstimateDocument13 pagesBox Culvert EstimateAnand Soni100% (1)

- Web AccessDocument37 pagesWeb AccessHard A CodeNo ratings yet

- Sr. No. Description Quantity Unit Rate (PKR) Amount (PKR) : KW&SB New 100Mgd Pump House at DhabejiDocument2 pagesSr. No. Description Quantity Unit Rate (PKR) Amount (PKR) : KW&SB New 100Mgd Pump House at DhabejigreatwellwisherNo ratings yet

- Slab-Top Moment Support at Column FaceDocument19 pagesSlab-Top Moment Support at Column FaceRohit PhadatareNo ratings yet

- Technical Evaluation-C2 After CACDocument31 pagesTechnical Evaluation-C2 After CACTewodros TadesseNo ratings yet

- Sewerage CalculatorDocument5 pagesSewerage CalculatorKarthikeyan SankarrajanNo ratings yet

- List of Documents For ISO 17021Document2 pagesList of Documents For ISO 17021neelureddy100% (4)

- 07-01 MafDocument5 pages07-01 MafJuan Roberto López BetanzosNo ratings yet

- Management Control System Unit 1QBDocument6 pagesManagement Control System Unit 1QBSagar Yadav100% (1)

- 275-103-044 Installation Guide REV BDocument14 pages275-103-044 Installation Guide REV BJohan MonguaNo ratings yet

- 2A - Excavation and Earth WorkDocument312 pages2A - Excavation and Earth WorkChathura AbhimanaNo ratings yet

- 13-KU-TWK-50-CM-WMS-2163 - 0 - Method of Statement For BackfillingDocument13 pages13-KU-TWK-50-CM-WMS-2163 - 0 - Method of Statement For BackfillingAvak NishanNo ratings yet

- Karimpor Marrage Hall EstimateDocument33 pagesKarimpor Marrage Hall Estimatesampaplanbm01No ratings yet

- Pipe MeasurementDocument2 pagesPipe MeasurementBipin PatilNo ratings yet

- Boiler EstimateDocument40 pagesBoiler EstimatesurendramaharjanNo ratings yet

- Estimating Assignment FinalDocument78 pagesEstimating Assignment FinalsheenbergNo ratings yet

- 03 - ConcreteDocument3 pages03 - ConcreteJohnclaude ChamandiNo ratings yet

- Construction of Theatre in Chulaimbo HospitalDocument42 pagesConstruction of Theatre in Chulaimbo HospitalJoshuaNo ratings yet

- Qunatity - NagalandDocument18 pagesQunatity - NagalandManoj AhirwarNo ratings yet

- Bill No. 6 - External Work (ZJ Table) - 17 Feb 2021 - RMH ContohDocument8 pagesBill No. 6 - External Work (ZJ Table) - 17 Feb 2021 - RMH ContohIlman YusofNo ratings yet

- Al Ain Distribution Company (Aadc) : JM 0209 SubstationDocument2 pagesAl Ain Distribution Company (Aadc) : JM 0209 SubstationRyo DavisNo ratings yet

- Preliminary Estimate On Bengal Dhaba Park: Lake Town Park - Boq Summary of CostsDocument9 pagesPreliminary Estimate On Bengal Dhaba Park: Lake Town Park - Boq Summary of CostsDas EnterpriseNo ratings yet

- BOQ SampleDocument14 pagesBOQ SampleAhmad DaherNo ratings yet

- Ananya BOQ 12.06.2023Document6 pagesAnanya BOQ 12.06.2023Shubhadip MondalNo ratings yet

- Boq For Asphalt Roads & Parking 1Document8 pagesBoq For Asphalt Roads & Parking 1Ahmed AlnuamanNo ratings yet

- Boq For Tyco RoofDocument3 pagesBoq For Tyco Roofragu ramanNo ratings yet

- Material Take-Off List: RemarksDocument1 pageMaterial Take-Off List: Remarks龙琦No ratings yet

- Construction of Theatre in Chulaimbo HospitalDocument18 pagesConstruction of Theatre in Chulaimbo HospitalJoshuaNo ratings yet

- K.P.W. FORM 23: Government of Kerala Local Self Government DepartmentDocument9 pagesK.P.W. FORM 23: Government of Kerala Local Self Government Departmentaneeshp_420% (5)

- Al Ain Distribution Company (Aadc) : JM 0223 SubstationDocument2 pagesAl Ain Distribution Company (Aadc) : JM 0223 SubstationRyo DavisNo ratings yet

- Comparative StatementDocument8 pagesComparative Statementshashirajhans2140No ratings yet

- Jay Mata Di CHSLDocument6 pagesJay Mata Di CHSLrohitbhosle5971203No ratings yet

- Kubs-Bill 8 - Ancillary BuildingsDocument47 pagesKubs-Bill 8 - Ancillary BuildingsSharkeela ShukriNo ratings yet

- 0503223-01-CIV-BOQ-1021-AB (Laundry Shed BOQ Comparision)Document6 pages0503223-01-CIV-BOQ-1021-AB (Laundry Shed BOQ Comparision)CCCCCCC100% (1)

- Material Take-Off List: RemarksDocument2 pagesMaterial Take-Off List: Remarks龙琦No ratings yet

- DBM OfficeDocument76 pagesDBM OfficeSrija RoyNo ratings yet

- 1.HQ Building - 03.01.2022 - STR - Compound Wall AbDocument2 pages1.HQ Building - 03.01.2022 - STR - Compound Wall Abnitesh.salvi12No ratings yet

- Boq of Fire StationDocument8 pagesBoq of Fire StationKANWARNo ratings yet

- SGGP Reference No: P0116-TAK-P01-0200-01Document6 pagesSGGP Reference No: P0116-TAK-P01-0200-01Jabel Oil Services Technical DPTNo ratings yet

- BOQ Civil Formation - Works CTP11 WDFCC R0Document2 pagesBOQ Civil Formation - Works CTP11 WDFCC R0kalpesh bhagatNo ratings yet

- Alan Sir - Master Qty2Document5 pagesAlan Sir - Master Qty2SuvithaNo ratings yet

- Imlibun - Bill - Ra - 03Document179 pagesImlibun - Bill - Ra - 03Anil PuvadaNo ratings yet

- Pipe Loading AnalysisDocument2 pagesPipe Loading Analysislim kang haiNo ratings yet

- Is 3583Document7 pagesIs 3583Anonymous i6zgzUvNo ratings yet

- SB PHLC 2LDocument4 pagesSB PHLC 2LjayNo ratings yet

- 5th R.A. Stanford Una - 25.04.2018Document202 pages5th R.A. Stanford Una - 25.04.2018Gaurav SharmaNo ratings yet

- Estimate DetailsDocument3 pagesEstimate DetailsParchuri PraveenNo ratings yet

- Bill of Quantities Development Works and Services (Boq Based)Document6 pagesBill of Quantities Development Works and Services (Boq Based)Krishiv ChanglaniNo ratings yet

- PRICED (R) - FBC Finishing PackageDocument1 pagePRICED (R) - FBC Finishing PackagejatinNo ratings yet

- Page 1 of 104Document104 pagesPage 1 of 104shalfarida5No ratings yet

- Toyota Gujrat Motors Civil Works BoqDocument3 pagesToyota Gujrat Motors Civil Works BoqJahanzeb KhanNo ratings yet

- Item RateDocument4 pagesItem Ratettk qsNo ratings yet

- Sri Lakshmi Venkateswara Fabricators: #49, Belmar Estate, Mattaih Main Road, Rukmin Nagar, Nagasandra Post, Banagalore-73Document3 pagesSri Lakshmi Venkateswara Fabricators: #49, Belmar Estate, Mattaih Main Road, Rukmin Nagar, Nagasandra Post, Banagalore-73Sai JaganNo ratings yet

- Boq-Alphas Projects-Karanam IndustriesDocument6 pagesBoq-Alphas Projects-Karanam IndustriesswapnilNo ratings yet

- Al Ain Distribution Company (Aadc) : KB 0002 SubstationDocument2 pagesAl Ain Distribution Company (Aadc) : KB 0002 SubstationRyo DavisNo ratings yet

- Retaining Wall Typical Details (7.0M Max. Height) (TYPE 2)Document4 pagesRetaining Wall Typical Details (7.0M Max. Height) (TYPE 2)will tingNo ratings yet

- RCC Slab 2'Document121 pagesRCC Slab 2'Nuwan AththanayakaNo ratings yet

- Storm QtyDocument97 pagesStorm QtykanagarajodishaNo ratings yet

- 02-MAIN-VILLA-MID UNIT-final Price-19-12-2019 PSCCDocument3 pages02-MAIN-VILLA-MID UNIT-final Price-19-12-2019 PSCCjatinNo ratings yet

- Final Estimation For Rate PreparationDocument5 pagesFinal Estimation For Rate PreparationmanojNo ratings yet

- On S.Q.C.Document38 pagesOn S.Q.C.mba2009-10100% (1)

- IBEF Report Feb 2019Document27 pagesIBEF Report Feb 2019VKNo ratings yet

- RahulDocument4 pagesRahulEr Suraj KumarNo ratings yet

- Design ThinkingDocument25 pagesDesign Thinkingnathalie13991No ratings yet

- Tybms Sem5 LSCM Nov18Document3 pagesTybms Sem5 LSCM Nov18chirag guptaNo ratings yet

- Delivery Challan 1Document2 pagesDelivery Challan 1Antwon CharlesNo ratings yet

- The History of SQL Server and Relational DatabasesDocument5 pagesThe History of SQL Server and Relational DatabasesgopimarenNo ratings yet

- Kannad 406 SurvivalDocument56 pagesKannad 406 Survivalmarco,100% (2)

- ToR & Concept Paper RMT.0599 Issue 1Document37 pagesToR & Concept Paper RMT.0599 Issue 1Mik AeilNo ratings yet

- SCMDocument48 pagesSCMkiruba kiruNo ratings yet

- World Bank Infrastructure NoteDocument16 pagesWorld Bank Infrastructure NoteGaryaqaan Muuse YuusufNo ratings yet

- Java EE ApplicationDocument11 pagesJava EE ApplicationPooja PancholiNo ratings yet

- Weekly Highlight Report - 18th October 2019Document2 pagesWeekly Highlight Report - 18th October 2019Anonymous qaI31HNo ratings yet

- ICAT Report Cover Template-NewDocument6 pagesICAT Report Cover Template-NewClarenceNo ratings yet

- S86 Skid-Steer Loader (Specs & Features) - Bobcat CompanyDocument4 pagesS86 Skid-Steer Loader (Specs & Features) - Bobcat CompanyAnirudh RamprasadNo ratings yet

- Maintenance Patterns and Fmea AnalysisDocument11 pagesMaintenance Patterns and Fmea AnalysisAdaaNo ratings yet

- Queueing Theory PDFDocument10 pagesQueueing Theory PDFDavid LeeNo ratings yet

- Model 1030 Model 1030: Tedea-HuntleighDocument3 pagesModel 1030 Model 1030: Tedea-HuntleighEong Huat Corporation Sdn BhdNo ratings yet

- DD Env 10080-1996 PDFDocument31 pagesDD Env 10080-1996 PDFismaeelNo ratings yet