Professional Documents

Culture Documents

Loctite 586 TDS

Uploaded by

rroxana_popaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Loctite 586 TDS

Uploaded by

rroxana_popaCopyright:

Available Formats

Technical Data Sheet

LOCTITE® 586™

October-2004

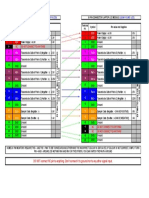

PRODUCT DESCRIPTION 100

% of Full Strength on Steel

LOCTITE® 586™ provides the following product

ss

characteristics:

a

e

75

Br

Ste

Technology Acrylic

Chemical Type Dimethacrylate ester

ate

Appearance (uncured) Red liquidLMS

rom

50

Fluorescence Positive under UV light

l

ich

tee

cd

Components One component -

ss

25

Zin

les

requires no mixing

ain

Viscosity Medium

St

Cure Anaerobic 0

Secondary Cure Activator 1min 5min 10min 30min 1h 3h 6h 24h 72h

Application Thread sealing Cure Time

Cure Speed vs. Bond Gap

LOCTITE® 586™ cures when confined in the absence of air The rate of cure will depend on the bondline gap. Gaps in

between close fitting metal surfaces. LOCTITE® 586™ is used threaded fasteners depends on thread type, quality and size.

to seal threads against water, oil and most common organic The following graph shows shear strength developed with time

on steel pins and collars at different controlled gaps and tested

materials.

according to ISO 10123.

TYPICAL PROPERTIES OF UNCURED MATERIAL 100

% of Full Strength on Steel

Specific Gravity @ 25 °C 1.12

Vapor pressure, mbar ≤2

m

5m

Flash Point - See SDS 75

0.0

m

Viscosity @ 25°C, mPa·s (cP):

5m

Falling ball "E" 4,000 to 6,000LMS

0.1

50

mm

25

0.2

TYPICAL CURING PERFORMANCE

Cure Speed vs. Substrate 0

The rate of cure will depend on the substrate used. The graph 1min 5min 10min 30min 1h 3h 6h 24h 72h

Cure Time

below shows the breakaway strength developed with time on

M10 black oxide nuts and bolts compared to different materials

and tested according to ISO 10964. Cure Speed vs. Temperature

The rate of cure will depend on the temperature. The graph

below shows the breakaway strength developed with time at

different temperatures on M10 black oxide nuts and bolts and

tested according to ISO 10964.

TDS LOCTITE® 586™, October-2004

% of Full Strength on Steel 100

Compressive Shear Strength, ISO 10123:

Steel pins and collars N/mm² 10 to 25

(psi) (1,450 to 3,625)

75

40 °C

C

Torque Augmentation

22 °

5 °C

50

Breakloose torque of an uncoated fastener will normally be 15

to 30% less than the on-torque. The effect of LOCTITE® 586™

25 on the breakloose torque is shown in the graph below.

60

Breakloose torque (N·m)

0 ™

50 586

1min 5min 10min 30min 1h 3h 6h 24h 72h E®

Cure Time TIT

LOC

40

er with

sten

Cure Speed vs. Activator 0 fa

30 M1

Where cure speed is unacceptably long, or large gaps are 6™

present, applying activator to the surface will improve cure 20 ITE® 58

tL OCT

speed. The graph below shows the breakaway strength hou

developed with time on M10 zinc dichromate steel nuts and 10 ner wit

faste

bolts using Activator 7471™ and 7649™ and tested according M10

to ISO 10964. 0

0 10 20 30 40 50

Seating torque (N·m)

100

% of Full Strength on Steel

Activator 7649™

TYPICAL ENVIRONMENTAL RESISTANCE

75 Cured for 1 week @ 22 °C

Activator 7471™

Breakloose Torque, ISO 10964, Pre-torqued to 5 N·m:

M10 zinc phosphate steel nuts and bolts

50

Hot Strength

Tested at temperature

25

100

No activator

% Strength @ 22 °C

0

1min 5min 10min 30min 1h 3h 6h 24h 72h 75

Cure Time

50

TYPICAL PROPERTIES OF CURED MATERIAL

Physical Properties:

Coefficient of Thermal Expansion, 100×10-6 25

ISO 11359-2, K-1

Coefficient of Thermal Conductivity, ISO 8302, 0.1

W/(m·K) 0

Specific Heat, kJ/(kg·K) 0.3 0 50 100 150

Temperature, °C

TYPICAL PERFORMANCE OF CURED MATERIAL Heat Aging

Adhesive Properties Aged at temperature indicated and tested @ 22 °C

After 24 hours @ 22 °C

Breakaway Torque, ISO 10964: 100

% Initial Strength @ 22 °C

M10 black oxide bolts and steel N·m ≥15LMS 120 °C

nuts (lb.in.) (≥160)

75

Prevail Torque, ISO 10964:

M10 black oxide bolts and steel N·m 25 to 55

nuts (lb.in.) (220 to 485) 50 150 °C

Breakloose Torque, ISO 10964, Pre-torqued to 5 N·m:

M10 black oxide bolts and steel N·m 25 to 55 25

nuts (lb.in.) (220 to 485)

Max. Prevail Torque, ISO 10964, Pre-torqued to 5 N·m:

M10 black oxide bolts and steel N·m 30 to 55 0

0 1000 2000 3000 4000 5000

nuts (lb.in.) (265 to 485) Exposure Time, hours

Henkel Americas Henkel Europe Henkel Asia Pacific

+860.571.5100 +49.89.320800.1800 +86.21.2891.8859

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

TDS LOCTITE® 586™, October-2004

Chemical/Solvent Resistance 1. Cured product can be removed with a combination of

Aged under conditions indicated and tested @ 22 °C. soaking in a Loctite solvent and mechanical abrasion

% of initial strength such as a wire brush.

Environment °C 100 h 500 h 1000 h

Motor oil (MIL-L-46152) 125 100 100 100 Loctite Material SpecificationLMS

LMS dated January-14, 1997. Test reports for each batch are

Unleaded gasoline 22 100 100 100

available for the indicated properties. LMS test reports include

Brake fluid 22 100 100 100 selected QC test parameters considered appropriate to

Ethanol 22 100 100 100 specifications for customer use. Additionally, comprehensive

Acetone 22 100 100 100 controls are in place to assure product quality and

Water/glycol 50/50 87 95 90 90

consistency. Special customer specification requirements may

be coordinated through Henkel Quality.

GENERAL INFORMATION

Storage

This product is not recommended for use in pure oxygen Store product in the unopened container in a dry location.

and/or oxygen rich systems and should not be selected as Storage information may be indicated on the product container

a sealant for chlorine or other strong oxidizing materials. labeling.

Optimal Storage: 8 °C to 21 °C. Storage below 8 °C or

For safe handling information on this product, consult the greater than 28 °C can adversely affect product properties.

Safety Data Sheet (SDS). Material removed from containers may be contaminated during

use. Do not return product to the original container. Henkel

Where aqueous washing systems are used to clean the Corporation cannot assume responsibility for product which

surfaces before bonding, it is important to check for has been contaminated or stored under conditions other than

compatibility of the washing solution with the adhesive. In those previously indicated. If additional information is required,

some cases these aqueous washes can affect the cure and please contact your local Technical Service Center or

performance of the adhesive. Customer Service Representative.

Conversions

This product is not normally recommended for use on plastics (°C x 1.8) + 32 = °F

(particularly thermoplastic materials where stress cracking of kV/mm x 25.4 = V/mil

the plastic could result). Users are recommended to confirm mm / 25.4 = inches

compatibility of the product with such substrates. µm / 25.4 = mil

N x 0.225 = lb

N/mm x 5.71 = lb/in

Directions for use: N/mm² x 145 = psi

For Assembly MPa x 145 = psi

1. For best results, clean all surfaces (external and internal) N·m x 8.851 = lb·in

N·m x 0.738 = lb·ft

with a LOCTITE® cleaning solvent and allow to dry. N·mm x 0.142 = oz·in

2. If the material is an inactive metal or the cure speed is too mPa·s = cP

slow, spray with Activator 7471™ or 7649™ and allow to

dry. Note:

3. Apply a 360° bead of product to the leading threads of the The information provided in this Technical Data Sheet (TDS) including

male fitting, leaving the first thread free. Force the the recommendations for use and application of the product are based

on our knowledge and experience of the product as at the date of this

material into the threads to thoroughly fill the voids. For TDS. The product can have a variety of different applications as well as

bigger threads and voids, adjust product amount differing application and working conditions in your environment that

accordingly and apply a 360° bead of product on the are beyond our control. Henkel is, therefore, not liable for the suitability

female threads also. of our product for the production processes and conditions in respect

4. Using compliant practices, assemble and wrench tighten of which you use them, as well as the intended applications and

fittings in accordance with manufacturers results. We strongly recommend that you carry out your own prior trials

recommendations. to confirm such suitability of our product.

Any liability in respect of the information in the Technical Data Sheet or

5. Properly tightened fittings will seal instantly to moderate any other written or oral recommendation(s) regarding the concerned

pressures. For maximum pressure resistance and solvent product is excluded, except if otherwise explicitly agreed and except in

resistance allow the product to cure a minimum of 24 relation to death or personal injury caused by our negligence and any

hours. liability under any applicable mandatory product liability law.

For Disassembly

1. Remove with standard hand tools. In case products are delivered by Henkel Belgium NV, Henkel

2. Where hand tools do not work because of excessive Electronic Materials NV, Henkel Nederland BV, Henkel

engagement length or large diameters (over 1"), apply Technologies France SAS and Henkel France SA please

additionally note the following:

localized heat to approximately 250 °C. Disassemble In case Henkel would be nevertheless held liable, on whatever legal

while hot. ground, Henkel’s liability will in no event exceed the amount of the

concerned delivery.

For Cleanup

Henkel Americas Henkel Europe Henkel Asia Pacific

+860.571.5100 +49.89.320800.1800 +86.21.2891.8859

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

TDS LOCTITE® 586™, October-2004

In case products are delivered by Henkel Colombiana, S.A.S. the

following disclaimer is applicable:

The information provided in this Technical Data Sheet (TDS) including

the recommendations for use and application of the product are based

on our knowledge and experience of the product as at the date of this

TDS. Henkel is, therefore, not liable for the suitability of our product for

the production processes and conditions in respect of which you use

them, as well as the intended applications and results. We strongly

recommend that you carry out your own prior trials to confirm such

suitability of our product.

Any liability in respect of the information in the Technical Data Sheet or

any other written or oral recommendation(s) regarding the concerned

product is excluded, except if otherwise explicitly agreed and except in

relation to death or personal injury caused by our negligence and any

liability under any applicable mandatory product liability law.

In case products are delivered by Henkel Corporation, Resin

Technology Group, Inc., or Henkel Canada Corporation, the

following disclaimer is applicable:

The data contained herein are furnished for information only and are

believed to be reliable. We cannot assume responsibility for the results

obtained by others over whose methods we have no control. It is the

user's responsibility to determine suitability for the user's purpose of

any production methods mentioned herein and to adopt such

precautions as may be advisable for the protection of property and of

persons against any hazards that may be involved in the handling and

use thereof. In light of the foregoing, Henkel Corporation specifically

disclaims all warranties expressed or implied, including

warranties of merchantability or fitness for a particular purpose,

arising from sale or use of Henkel Corporation’s products. Henkel

Corporation specifically disclaims any liability for consequential

or incidental damages of any kind, including lost profits. The

discussion herein of various processes or compositions is not to be

interpreted as representation that they are free from domination of

patents owned by others or as a license under any Henkel Corporation

patents that may cover such processes or compositions. We

recommend that each prospective user test his proposed application

before repetitive use, using this data as a guide. This product may be

covered by one or more United States or foreign patents or patent

applications.

Trademark usage

Except as otherwise noted, all trademarks in this document are

trademarks of Henkel Corporation in the U.S. and elsewhere. ®

denotes a trademark registered in the U.S. Patent and Trademark

Office.

Reference 2

Henkel Americas Henkel Europe Henkel Asia Pacific

+860.571.5100 +49.89.320800.1800 +86.21.2891.8859

For the most direct access to local sales and technical support visit: www.henkel.com/industrial

You might also like

- Learn SpanishDocument96 pagesLearn Spanishv155r100% (64)

- Learn SpanishDocument96 pagesLearn Spanishv155r100% (64)

- The Cooking of BrazilDocument97 pagesThe Cooking of BrazilCaroline ViannaNo ratings yet

- Citroen CX Workshop ManualDocument611 pagesCitroen CX Workshop ManualDiego Hernan Piñeiro100% (2)

- 1 Learn Spanish E-BookDocument109 pages1 Learn Spanish E-BookNataliya Vershytska0% (1)

- CIO Executive SummaryDocument8 pagesCIO Executive SummaryResumeBearNo ratings yet

- Aclu List Research Export 20160810050210Document2 pagesAclu List Research Export 20160810050210api-285701682100% (1)

- The Art of Comeback Donald TrumpDocument1 pageThe Art of Comeback Donald TrumpMoYagzud0% (2)

- ELSpanishGrammarPractice PDFDocument28 pagesELSpanishGrammarPractice PDFgeet666No ratings yet

- February Monthly Collection, Grade 5From EverandFebruary Monthly Collection, Grade 5Rating: 3 out of 5 stars3/5 (1)

- FCPP Fiberglass Coated ConcreteDocument20 pagesFCPP Fiberglass Coated ConcretemahdiNo ratings yet

- Joint Ventures Synergies and BenefitsDocument5 pagesJoint Ventures Synergies and BenefitsleeashleeNo ratings yet

- Expository Text in Reading Power PointDocument23 pagesExpository Text in Reading Power Pointrroxana_popaNo ratings yet

- Maintenance KitsDocument24 pagesMaintenance KitsIsraelNo ratings yet

- Maintenance Kits-1Document16 pagesMaintenance Kits-1Carlos RiveraNo ratings yet

- LOCTITE 586 en - GLDocument4 pagesLOCTITE 586 en - GLibrahimmcs16No ratings yet

- Loctite Fel-Pro C-102, 222 & 243Document9 pagesLoctite Fel-Pro C-102, 222 & 243Liu YangtzeNo ratings yet

- Loctite 222MS™: Product DescriptionDocument3 pagesLoctite 222MS™: Product DescriptionVaibhav ChaudharyNo ratings yet

- Literature File 181Document3 pagesLiterature File 181FERSNo ratings yet

- 620 enDocument3 pages620 enJoseph wheelerNo ratings yet

- Loctite 243: Technical Data SheetDocument6 pagesLoctite 243: Technical Data SheetMarcoNo ratings yet

- LOCTITE 243 RAIL en - GLDocument4 pagesLOCTITE 243 RAIL en - GLGheorghe Adrian SavuNo ratings yet

- Brochure of Tozen Rubber PAdsDocument1 pageBrochure of Tozen Rubber PAdsEdna TabilogNo ratings yet

- 263 NEW09-ENDocument4 pages263 NEW09-ENPaulo BertoNo ratings yet

- Loctite 603: Technical Data SheetDocument3 pagesLoctite 603: Technical Data SheetibrahimNo ratings yet

- 648 TDS PDFDocument3 pages648 TDS PDFSenthil Kumar GanesanNo ratings yet

- 243 New-EnDocument4 pages243 New-Enjaskaran singhNo ratings yet

- LOCTITE 263 THREADLOCKERDocument3 pagesLOCTITE 263 THREADLOCKERqistinaramli2024No ratings yet

- 5.CUTTING AND FILLING DETAIL MukundadaDocument1 page5.CUTTING AND FILLING DETAIL Mukundadavrteja.civilNo ratings yet

- Loctite 243™: Cone 35/2°ti at Shear Rate 129 S 350Document4 pagesLoctite 243™: Cone 35/2°ti at Shear Rate 129 S 350jpolancosNo ratings yet

- Loctite 243 Updated-EnDocument4 pagesLoctite 243 Updated-Enதமிழன் இராமசாமிNo ratings yet

- Aa 326-EnDocument3 pagesAa 326-EnmorashidNo ratings yet

- Loctite 242™: Product DescriptionDocument3 pagesLoctite 242™: Product DescriptionFabio ParceroNo ratings yet

- Loctite 243 New-EnDocument4 pagesLoctite 243 New-Enrazvan33No ratings yet

- Su-Dcwt HT - LT May 2022Document1 pageSu-Dcwt HT - LT May 2022Денис ГанинNo ratings yet

- Loctite 574™: Product DescriptionDocument3 pagesLoctite 574™: Product DescriptionmykedindealNo ratings yet

- Slider RH1Document1 pageSlider RH1Hector EstevezNo ratings yet

- Loctite 270™: Technical Data SheetDocument4 pagesLoctite 270™: Technical Data SheetM Jobayer AzadNo ratings yet

- Silicon DiodesDocument6 pagesSilicon DiodesbdmbudimanNo ratings yet

- Distributed By: Pt. Elang Mas IndoasiaDocument3 pagesDistributed By: Pt. Elang Mas IndoasiaMuizti RimadhonaNo ratings yet

- Pcis 5Document1 pagePcis 5usama2003113mNo ratings yet

- Te) ",:lel : E9 - 1 - Hewitt - Simulation - Edr E9 - 1 - Hewitt - Simulation - BJTDocument7 pagesTe) ",:lel : E9 - 1 - Hewitt - Simulation - Edr E9 - 1 - Hewitt - Simulation - BJTMOHSENNo ratings yet

- Daniel Edward 6/16/2017: Drawn Checked QA MFG Approved DWG No TitleDocument1 pageDaniel Edward 6/16/2017: Drawn Checked QA MFG Approved DWG No TitleDaniel Edward OmondiNo ratings yet

- Technical Data Sheet Product 243: Worldwide Version, October 1995Document2 pagesTechnical Data Sheet Product 243: Worldwide Version, October 1995Yacine MARICHENo ratings yet

- (En) AmberMill Brochure EnglishDocument4 pages(En) AmberMill Brochure EnglishMihai CucuNo ratings yet

- Loctite 641 enDocument3 pagesLoctite 641 engeorgeNo ratings yet

- LOCTITE 2422-tdsDocument4 pagesLOCTITE 2422-tdsIndo KalbarNo ratings yet

- The Museum of Piledrivers Ver010en01Document4 pagesThe Museum of Piledrivers Ver010en01Binh le ThanhNo ratings yet

- L Feet-Bracket-W45-AssyDocument1 pageL Feet-Bracket-W45-AssyThomas Dwi Putra SalimNo ratings yet

- Segment of 200mm: 2 X N X 2 X M4x0.7 6Document1 pageSegment of 200mm: 2 X N X 2 X M4x0.7 6Santi Diaz MonteroNo ratings yet

- 22f00200 Plans 4Document10 pages22f00200 Plans 4Serge Guevarra ParochaNo ratings yet

- Precision Diffraction Slits Manual OS 8453Document3 pagesPrecision Diffraction Slits Manual OS 8453Brenda CruzNo ratings yet

- Vessel Drum Sew DWGDocument2 pagesVessel Drum Sew DWGSANGEETHANo ratings yet

- Arkas PDFDocument24 pagesArkas PDFDaniel UrquizaNo ratings yet

- Sewage_BrochureDocument20 pagesSewage_BrochureMario TintaNo ratings yet

- Self-aligning clevis coupling assemblyDocument1 pageSelf-aligning clevis coupling assemblyGerges RamzyNo ratings yet

- AC-203 PLAN PARTER 02Document1 pageAC-203 PLAN PARTER 02lupumihaicosmin89No ratings yet

- Submersible Pumps For Industry and SewerageDocument20 pagesSubmersible Pumps For Industry and SewerageSunil MaharjanNo ratings yet

- LOCTITE 603 en - GLDocument4 pagesLOCTITE 603 en - GLAdrian SetyadharmaNo ratings yet

- Disc Holder CMT FCD 45Document1 pageDisc Holder CMT FCD 45ILHAMNo ratings yet

- Rey Vencedor-Saxo AltoDocument2 pagesRey Vencedor-Saxo AltoKaren CuellarNo ratings yet

- Rework: Drn. by Date Date CHKD - by Date Aprd - by Rev. Sheet Size MaterialDocument2 pagesRework: Drn. by Date Date CHKD - by Date Aprd - by Rev. Sheet Size MaterialQUARK AUTOMATIONNo ratings yet

- Lay Out NewDocument1 pageLay Out NewIcha DavisaNo ratings yet

- A8Document1 pageA8Prabhat GautamNo ratings yet

- Montaj ve etiket yönleri için resimDocument1 pageMontaj ve etiket yönleri için resimLaura Sofía VélezNo ratings yet

- RelyX UltimateDocument2 pagesRelyX UltimateOral CareNo ratings yet

- 2/2 SOLENOID VALVES PRODUCT INDEXDocument62 pages2/2 SOLENOID VALVES PRODUCT INDEXĐặng Trung AnhNo ratings yet

- Standard Solid BATIN Scaffold CastersDocument1 pageStandard Solid BATIN Scaffold CastersFo MuNo ratings yet

- Bacteria-Bass SaxophoneDocument2 pagesBacteria-Bass SaxophoneOakbeanNo ratings yet

- DEORE XT Mega-9 Rapidfire LeverDocument1 pageDEORE XT Mega-9 Rapidfire LeverCirilNo ratings yet

- 2013 Your Way To Portugal: A Guide For Erasmus Mundus StudentsDocument20 pages2013 Your Way To Portugal: A Guide For Erasmus Mundus StudentsquilmesportNo ratings yet

- Telecurso 2000 - Inglês 17Document4 pagesTelecurso 2000 - Inglês 17Ingles TCNo ratings yet

- Magna Carta GutenbergDocument10 pagesMagna Carta Gutenbergrroxana_popaNo ratings yet

- Adverse and Averse: Business WritingDocument4 pagesAdverse and Averse: Business Writingrroxana_popaNo ratings yet

- Email:, Web:: Wordland International Language and Business Training CenterDocument3 pagesEmail:, Web:: Wordland International Language and Business Training Centerrroxana_popaNo ratings yet

- Examples of Expository and Narrative TextsDocument1 pageExamples of Expository and Narrative Textsrroxana_popaNo ratings yet

- Examples of Expository and Narrative TextsDocument1 pageExamples of Expository and Narrative Textsrroxana_popaNo ratings yet

- Romanian Language Quick FactsDocument1 pageRomanian Language Quick Factsrroxana_popaNo ratings yet

- The Many Faces of EuropeDocument8 pagesThe Many Faces of Europerroxana_popaNo ratings yet

- Mare Sat Pat: Big/sea Village BedDocument7 pagesMare Sat Pat: Big/sea Village Bedrroxana_popaNo ratings yet

- (En) Questions - DrillsDocument7 pages(En) Questions - Drillsrroxana_popaNo ratings yet

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- W 30 EdmundsDocument44 pagesW 30 Edmundsrroxana_popaNo ratings yet

- TD102 Conductor - Standard ConductorsDocument2 pagesTD102 Conductor - Standard ConductorsHFandino1No ratings yet

- Partial Full Volume of TankDocument8 pagesPartial Full Volume of TankBabita GuptaNo ratings yet

- Sap AbapDocument7 pagesSap Abapidrees aliNo ratings yet

- Numerical Investigation of The Effect of Nappe Non Aeration On Caisson Sliding Force During Tsunami Breakwater Over Topping Using OpenFOAM Akshay PatilDocument73 pagesNumerical Investigation of The Effect of Nappe Non Aeration On Caisson Sliding Force During Tsunami Breakwater Over Topping Using OpenFOAM Akshay PatilSamir BelghoulaNo ratings yet

- Due Diligence InvestmentsDocument6 pagesDue Diligence InvestmentselinzolaNo ratings yet

- Preface: What Is Financial Intelligence?Document4 pagesPreface: What Is Financial Intelligence?Iuliana GondosNo ratings yet

- BS 3892-1 1997 - Pulverized-Fuel AshDocument22 pagesBS 3892-1 1997 - Pulverized-Fuel Ashmykel_dp100% (1)

- G.princy Xii - CommerceDocument21 pagesG.princy Xii - CommerceEvanglin .gNo ratings yet

- Equipment Sheet: Cable Laying VesselDocument2 pagesEquipment Sheet: Cable Laying Vesselsitu brestNo ratings yet

- As 2669-1983 Sulphuric Acid For Use in Lead-Acid BatteriesDocument7 pagesAs 2669-1983 Sulphuric Acid For Use in Lead-Acid BatteriesSAI Global - APACNo ratings yet

- PRACTICA (1) (1) - Páginas-2-4Document3 pagesPRACTICA (1) (1) - Páginas-2-4EDDY POLICARPIO BRAVO HUAMANINo ratings yet

- Fnce 220: Business Finance: Lecture 6: Capital Investment DecisionsDocument39 pagesFnce 220: Business Finance: Lecture 6: Capital Investment DecisionsVincent KamemiaNo ratings yet

- Parent DC Promo Ui LogDocument193 pagesParent DC Promo Ui LogRachell SmithNo ratings yet

- Case Study of Vietinbank Dao Hoang NamDocument14 pagesCase Study of Vietinbank Dao Hoang NamNam ĐàoNo ratings yet

- Electricity Began With Man's Curiosity On The Peculiar Ability of Amber and Lodestone To Attract Other Material.Document2 pagesElectricity Began With Man's Curiosity On The Peculiar Ability of Amber and Lodestone To Attract Other Material.Axle Rose CastroNo ratings yet

- Consideration PropDocument2 pagesConsideration PropQasim GorayaNo ratings yet

- Honeywell 393690 Inlet Outlet Flange Kits 69-0256Document2 pagesHoneywell 393690 Inlet Outlet Flange Kits 69-0256Alfredo Castro FernándezNo ratings yet

- Em8 1session2.2Document25 pagesEm8 1session2.2DreamCodmNo ratings yet

- SatconDocument18 pagesSatconBADRI VENKATESHNo ratings yet

- Production AnalysisDocument15 pagesProduction AnalysisAman -BCOMNo ratings yet

- The Stolen EaglesDocument12 pagesThe Stolen EaglesJavier Horacio FernandezNo ratings yet

- LCD PinoutsDocument1 pageLCD PinoutsPablo Daniel MagallanNo ratings yet

- Etextbook 978 0078025884 Accounting Information Systems 4th EditionDocument61 pagesEtextbook 978 0078025884 Accounting Information Systems 4th Editionmark.dame383100% (48)

- Tle 6 Ict Q4 M9Document16 pagesTle 6 Ict Q4 M9Christ Khayzee R. BacalsoNo ratings yet

- Chapter 6Document53 pagesChapter 6Sam KhanNo ratings yet