Professional Documents

Culture Documents

Mazda Diesel

Uploaded by

wilderOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mazda Diesel

Uploaded by

wilderCopyright:

Available Formats

ECD-V5 Injection Pump System

ECD-V5

Injection Pump System

NOTE: Some of the components of the ECD-V5 injection pump system are very similar in

design and operation to those of the NP-VE4 injection pump system. Therefore this

lesson only describes the components which are new or operate in a different way to

those in the NP-VE4 injection pump system.

Service Training 117

ECD-V5 Injection Pump System

Intake system

The construction and operation of the intake system is essentially carried over from that of

the NP-VE4 injection pump system except for the following:

Mass air flow sensor has been eliminated (only Euro 2 vehicles)

Turbocharger with variable geometry turbine has been adopted (only Euro 3

vehicles)

Variable swirl control valve has been adopted (only Euro 3 vehicles)

Parts location

1 Fresh-air duct 7 VBC vacuum actuator

2 Resonance chamber 8 VBC check valve

3 Air cleaner 9 VBC solenoid valve

4 Turbocharger 10 VBC vacuum chamber

5 Charge air cooler 11 VSC vacuum actuator

6 Intake manifold 12 VSC solenoid valve

118 Service Training

ECD-V5 Injection Pump System

Intake system (continued)

System overview

1 Fresh-air duct 8 VBC solenoid valve

2 Air cleaner 9 VBC check valve

3 Turbocharger 10 VSC vacuum actuator

4 Charge air cooler 11 VSC solenoid valve

5 Intake manifold 12 Vacuum pump

6 VBC vacuum actuator 13 To PCM

7 VBC vacuum chamber 14 Vacuum chamber

Service Training 119

ECD-V5 Injection Pump System

Turbocharger

Mazda vehicles with RF-T engine and Euro 3 emission standard feature a turbocharger with

VGT (Variable Geometry Turbine), which controls the boost pressure by adjusting guide

blades. The blades are located in the turbine housing and are driven by a vacuum actuator,

resulting in an increased power output and a reduced fuel consumption.

The guide blades vary the cross-section in front of the turbine and thus the passages that

duct the exhaust gas to the turbine. The position of the guide blades is controlled by the

PCM, which activates the VBC (Variable Boost Control) solenoid valve via a duty signal. As

a result, the boost pressure remains approximately the same over the entire engine speed

range.

1 Adjusting linkage 4 Guide blades

2 Vacuum actuator 5 Compressor housing

3 Turbine

120 Service Training

ECD-V5 Injection Pump System

Turbocharger (continued)

1 Turbocharger 6 Vacuum pump

2 VBC vacuum actuator 7 VBC check valve

3 VBC vacuum chamber 8 To PCM

4 VBC solenoid valve 9 Vacuum chamber

5 Charge air cooler

At low engine speeds the PCM controls the VBC solenoid valve with a large duty cycle, so

that vacuum is applied to the vacuum actuator. Due to this the guide blades move in the

closing direction and the passages that duct the exhaust gas to the turbine become narrow.

Thus the exhaust gas stream impinges with a high velocity and a small angle on the turbine,

resulting in a high boost pressure.

1 From PCM control relay 3 PCM

2 VBC solenoid valve

Service Training 121

ECD-V5 Injection Pump System

Turbocharger (continued)

1 High boost pressure 2 Low boost pressure

At high engine speeds the PCM controls the VBC solenoid valve with a small duty cycle, so

that atmosphere pressure is applied to the vacuum actuator. Due to this the guide blades

move in the opening direction and the passages that duct the exhaust gas to the turbine

become wide. Thus the exhaust gas stream impinges with a low velocity and a large angle

on the turbine, resulting in a low boost pressure.

NOTE: If the VBC system fails, the blades adopt in a parked position again in which only a

minimal boost pressure is produced.

The PCM controls the VBC solenoid valve by a duty signal between 0…12 V.

122 Service Training

ECD-V5 Injection Pump System

Turbocharger (continued)

Diagnostics

The turbocharger can be checked as following:

Monitoring the boost pressure via the PID MAP (Press/Volt)

Checking turbocharger (see NP-VE4 injection pump system)

Checking boost pressure (see NP-VE4 injection pump system)

Monitoring/Activating the blade adjustment via the PID VBCV# (Per)

Checking the voltage signal at the VBC solenoid valve

Checking blade adjustment

Checking blade adjustment

Connect a hand-operated vacuum pump to the VBC actuator and apply vacuum. Check,

whether the adjusting linkage moves easily, and returns to the parked position when the

system is vented.

NOTE: The blade adjustment system is a fixed part of a turbocharger. As turbochargers usually

cannot be repaired with the means available in workshops, they must be changed

complete.

Service Training 123

ECD-V5 Injection Pump System

Variable swirl control valve

Mazda vehicles with RF-T engine and Euro 3 emission standard are equipped with VSC

(Variable Swirl Control) valves in the intake manifold, reducing the exhaust emissions at low

engine speed. The VSC valves are driven by a vacuum actuator and vary the cross-section

of the manifold. Therefore the intake manifold features two inlet ports per each cylinder. The

swirl port induces the intake air tangentially into the combustion chamber, while the charge

port induces it vertically.

The shutter valves close or open the charge ports, influencing the passages that duct the

intake air into the cylinder. The position of the shutter valves is controlled by the PCM,

which activates the VSC solenoid valve by an ON/OFF signal.

1 VSC solenoid valve 3 VSC vacuum actuator

2 VSC valve

124 Service Training

ECD-V5 Injection Pump System

Variable swirl control valve (continued)

1 VSC vacuum actuator 4 Vacuum pump

2 VSC solenoid valve 5 Vacuum chamber

3 Intake manifold 6 To PCM

At an engine speed below 2300 min-1 the PCM energizes the VSC solenoid valve, so that

vacuum is applied to the vacuum actuator. Due to this the shutter valves close the charge

ports, decreasing the cross-section of the intake manifold. Thus the intake air enters the

cylinder only via the swirl port, creating a high air flow speed and a strong swirl. This

improves the mixture of the injected fuel with the air and hence the combustion.

1 From PCM control relay 3 PCM

2 VSC solenoid valve

Service Training 125

ECD-V5 Injection Pump System

Variable swirl control valve (continued)

1 VSC valve closed 5 Piston

2 VSC valve open 6 VSC valve

3 Charge port 7 Swirl port

4 Exhaust ports

At an engine speed above 2300 min-1 the PCM de-energizes the VSC solenoid valve, so

that atmosphere pressure is applied to the vacuum actuator. Due to this the shutter valves

open the charge port, making the complete cross-section of the intake manifold available.

Thus the intake air stream enters the cylinder via the swirl port and the charge port,

resulting in high air throughput and a good cylinder charging. This ensures, that the engine

delivers the required high power.

NOTE: If the VSC system fails, the shutter valves adopt in a parked position again in which no

swirl is produced.

Diagnostics

The VSC system can be checked as following:

Monitoring/Activating the shutter valve adjustment via the PID IMRC# (Mode)

Checking the voltage at the VSC solenoid valve

Checking shutter valve adjustment

Checking shutter valve adjustment

Connect a hand-operated vacuum pump to the VSC actuator and apply vacuum. Check,

whether the adjusting linkage moves easily, and returns to the parked position when the

system is vented.

126 Service Training

ECD-V5 Injection Pump System

Fuel system

The construction and operation of the fuel system is essentially carried over from that of the

NP-VE4 injection pump system except for the following:

High-pressure system has been modified

Injection amount control has been modified

Injection timing control has been modified

Parts location

1 Fuel filter 3 Injector

2 Injection pump

Service Training 127

ECD-V5 Injection Pump System

Fuel system (continued)

System overview

1 Fuel tank 3 Injection pump

2 Fuel filter 4 Injector

128 Service Training

ECD-V5 Injection Pump System

Fuel system (continued)

Injection pump

The ECD-V5 injection pump system features an axial-piston distributor pump manufactured

by Denso.

1 Spill valve 6 Roller ring

2 FLT sensor 7 Toothed rotor

3 TCV 8 Cam plate

4 Pump speed sensor 9 Distributor plunger

5 Overflow restrictor

Service Training 129

ECD-V5 Injection Pump System

High-pressure system

The design and operation of the high-pressure system is essentially carried over from the

NP-VE 4 injection pump system except for the following:

Axial-piston distributor pump with spill valve has been adopted

Two-spring injectors have been adopted

Axial-piston distributor pump

On the ECD-V5 injection pump system the axial-piston distributor pump features a spill

valve instead of transverse cut-off bore and control sleeve. The valve is located in an

additional passage, which bypasses the FSOV and connects the high-pressure chamber to

the pump chamber. According to the signals from the PCM the spill valve opens or closes

this additional passage.

1 Cam plate 5 High-pressure chamber

2 Distributor plunger 6 To injector

3 Roller ring 7 Spill valve

4 From pump chamber

130 Service Training

ECD-V5 Injection Pump System

High-pressure system (continued)

Axial-piston distributor pump (continued)

As the distributor plunger moves from TDC to BDC, the spill valve opens the additional

passage. Now fuel flows through the open inlet passage into the high-pressure chamber

(filling phase).

1 Pump chamber 6 High-pressure chamber

2 Roller ring 7 Injector

3 Cam plate 8 Intake port

4 Distributor plunger 9 Spill valve open

5 Distribution slot

At BDC the plungers rotating movement then closes the inlet passage and opens the

distributor slot for a certain outlet port. When the plunger moves from BDC to TDC (working

stroke), the spill valve closes the additional passage. Due to this, the fuel is compressed in

the high-pressure chamber (high-pressure phase). As the pressure rises in the high-

pressure chamber and in the outlet port passage, it suffices to open the delivery valve in

question and the fuel is forced through the high-pressure line to the injection nozzle.

1 Roller ring 3 Spill valve closed

2 Cam plate

Service Training 131

ECD-V5 Injection Pump System

High-pressure system (continued)

Axial-piston distributor pump (continued)

The working stroke is completed as soon as the spill valve opens the additional passage,

spilling the fuel into the pump interior (end of high-pressure phase). As the pressure in the

high-pressure chamber collapses, the delivery valve closes the high-pressure line and no

more fuel is delivered to the injector.

1 Roller ring 3 Spill valve open

2 Cam plate

132 Service Training

ECD-V5 Injection Pump System

High-pressure system (continued)

Injectors

On the ECD-V5 injection pump system two-spring injectors are used. The injectors consist

of nozzle body with nozzle needle, pressure pin, two springs and stop sleeve.

1 Nozzle body 8 Intermediate element

2 Adjustment shim 9 Stop sleeve

3 Spring No.1 10 Nozzle needle

4 Pressure pin 11 Nozzle retaining nut

5 Guide element 12 Nozzle

6 Spring No.2 13 Initial stroke

7 Spring seat 14 Main stroke

Service Training 133

ECD-V5 Injection Pump System

High-pressure system (continued)

Injectors (continued)

The two-spring injector injects the fuel in two stages into the combustion chamber. It

features two springs with different spring rates, which are located one behind the other.

During the injection process the needle is lifted against the force of spring No.1 (low spring

rate), until it reaches the stop sleeve. Due to this a small annular gap is opened, so that only

a small amount of fuel is injected with low-pressure (initial spray).

Since the injection pump delivers more fuel than can flow through the small gap, the

pressure in the injector rises. Due to this the needle and the stop sleeve are lifted further

against the force of spring No.2 (high spring rate). Now the spray orifice is widened, and the

major amount of fuel is injected with high-pressure (main spray). Since the pressure in the

combustion chamber rises less sharply, combustion in part-load range is smoother and

though quieter.

The injectors are equipped with a hole-type nozzle, which improves the atomization of the

fuel in the combustion chamber. The spray holes with 0.18 mm in diameter are located on

the circumference of the nozzle body. Depending on the emission level of the vehicle the

nozzle features 6 (Euro 3 vehicles) or 5 spray holes (Euro 2 vehicles).

1 Euro 3 vehicles 4 Five fuel jets

2 Euro 2 vehicles 5 Piston

3 Six fuel jets

For low HC emissions it’s highly important that the volume filled with fuel (residual volume)

between nozzle needle and nozzle body is kept to a minimum. Therefore the tip of the

nozzle needle is rounded off. Since the thin spray holes produce a good atomization at a

high pressure, power output as well as fuel consumption and exhaust emissions are

improved.

134 Service Training

ECD-V5 Injection Pump System

High-pressure system (continued)

Diagnostics

The high-pressure system can be checked as following:

Checking the start of fuel delivery

Checking the injectors

Checking the start of fuel delivery

Check whether the marks of the housing and the bracket of the injection pump are aligned.

If not as specified, slacken the high-pressure lines and the mounting nuts / bolts and adjust

the start of fuel delivery by turning the injection pump.

1 Injection pump 2 Injection pump bracket

Checking the injectors

The injectors can be checked as following:

1. Connect the injector to an injector tester and bleed the air by pumping the injector tester

handle several times.

2. To check the opening pressure of the injector’s first stage slowly lower the handle and

note the pressure when injection starts.

3. If not as specified, replace the injector.

4. To check the injector’s atomization lower the handle several times as quickly as

possible, so that a pulsating whistling noise is heard and inspect the atomization

pattern.

5. If not as specified, replace the injector.

6. To check the injector for leakage apply a certain pressure (see Workshop Manual) to the

injector and inspect for fuel leakage from the nozzle spray port.

7. If fuel leaks, replace the injector.

NOTE: As the pressure build-up of the injector tester is too slow, only the first stage of the two-

stage injector can be checked.

Service Training 135

ECD-V5 Injection Pump System

High-pressure system (continued)

Diagnostics (continued)

Checking the injectors (continued)

1 Normal spray 3 Poor misting

2 Spray angle incorrect

NOTE: If the diagnostic check reveals, that the concern indicates one or more faulty injectors,

this can be checked by releasing the high-pressure lines at the injectors while the engine

is running. When the high-pressure lines are released, check whether the engine running

changes and whether fuel escapes between the high-pressure line and the injector. If the

engine running is unchanged and fuel escapes, the injector concerned is faulty.

136 Service Training

ECD-V5 Injection Pump System

Injection amount control

The design and operation of the injection amount control is essentially is essentially carried

over from the NP-VE 4 injection pump system except for the following:

Spill valve has been adopted

Injector driver module has been adopted

Fuel shut-off valve has been modified

Spill valve

The ECD-V5 injection pump system features a SPV (Spill Valve) instead of an electronic

governor. The valve controls the high-pressure phase of the axial piston pump, so that the

fuel injection amount varies depending on the operating conditions. The SPV is located on

top of the distributor head and consists of a coil and a spring-loaded spool valve. The

position of the spool valve is controlled by the PCM, which drives the SPV via the injector

driver module.

1 Distributor plunger 4 Coil

2 To pump chamber 5 Spool valve

3 Spill ports

Service Training 137

ECD-V5 Injection Pump System

Injection amount control (continued)

Spill valve (continued)

When the SPV is energized by the IDM, the spool valve closes the additional passage

between high-pressure chamber and pump chamber. Due to this the high-pressure phase

starts, i.e. fuel is delivered to the injectors.

1 SPV closed 2 SPV open

3 To high-pressure chamber 4 To pump chamber

When the SPV is de-energized by the IDM, the spool valve opens the additional passage

and the fuel in the high-pressure chamber is spilled into the pump interior. Due to this the

high-pressure phase ends, i.e. no more fuel is delivered to the injectors. So the closing time

of the SPV determines the duration of the high-pressure phase, changing the injection

amount from zero to maximum.

NOTE: The SPV serves also to switch off the engine. When the ignition is switched off, the SPV

is de-energized by the IDM. The spring force causes the spool valve to adopt in a parked

position, setting the fuel injection amount to zero.

NOTE: When the SPV fails the spool valve adopts in a parked position and sets the fuel

injection amount to zero, i.e. the engine doesn’t run anymore.

138 Service Training

ECD-V5 Injection Pump System

Injection amount control (continued)

Injector driver module

The IDM (Injector Driver Module) drives the SPV at high speed and high accuracy. It has a

high-voltage generator inside, which amplifies the battery voltage input from the SPV relay

into a high voltage of approx. 150 V and stores it in a capacitor. A control circuit outputs the

high voltage to the SPV as a drive signal. The IDM is controlled by the PCM via a duty

signal. Besides the PCM switches the power supply to the IDM with the aid of the SPV

relay.

1 From SPV relay 5 Control circuit

2 Injection signal 6 SPV

3 Injection confirmation signal 7 Connector

4 High voltage generator

Service Training 139

ECD-V5 Injection Pump System

Injection amount control (continued)

Injector driver module (continued)

The IDM energizes the SPV in two stages. When the injection signal is input from the PCM

to the IDM, the IDM actuates the SPV with a high voltage of approx. 150 V. Due to the high

pull-down current (approx. 12 A) the valve closes rapidly. After a certain time the IDM

reduces the actuating voltage to 12 V, resulting in a lower holding current (approx. 6 A). Due

to this the power loss in the IDM and in the SPV is minimized, avoiding unnecessary heat in

these components. While the SPV is closed the IDM detects the drive current and outputs

an injection confirmation signal (SPV operating status) to the PCM.

1 Injection confirmation signal 5 Holding current

2 Injection signal 6 Pull-down current

3 SPV drive current 7 Fail signal (High side)

4 Holding current switching time 8 Fail signal (Low side)

140 Service Training

ECD-V5 Injection Pump System

Injection amount control (continued)

Injector driver module (continued)

Service Training 141

ECD-V5 Injection Pump System

Injection amount control (continued)

Injector driver module (continued)

When the required injection amount is small, the PCM controls the IDM with a small duty

cycle, so that the drive signal outputted to the SPV has also a small duty cycle. Due to this

the closing time of the SPV is short, resulting in a short high-pressure phase and though in

a small injection amount.

1 Cam lift 5 End of injection

2 SPV control 6 Cam angle

3 Injection amount 7 Small injection amount

4 Start of injection 8 Large injection amount

When the required injection amount is large, the PCM controls the IDM with a large duty

cycle, so that the drive signal outputted to the SPV has also a large duty cycle. Due to this

the closing time of the SPV is long, resulting in a long high-pressure phase and though in a

large injection amount.

142 Service Training

ECD-V5 Injection Pump System

Injection amount control (continued)

Fuel shut-off valve

On the ECD-V5 injection pump system the FSOV is controlled by the PCM via a relay.

1 FSOV 3 PCM

2 FSOV relay

When the engine is started, the PCM energizes the FSOV relay, switching the power supply

to the FSOV. Due to this the passage between the interior of the pump and the high-

pressure chamber is opened and fuel is supplied the high-pressure chamber, enabling the

engine to start.

When the ignition is switched off, the PCM de-energizes the FSOV relay, cutting off the

power supply from the FSOV. Due to this the passage between the interior of the pump and

the high-pressure chamber is closed and the fuel supply to the high-pressure chamber is

shut off, stopping the engine.

Service Training 143

ECD-V5 Injection Pump System

Injection amount control (continued)

Diagnostics

The components of the injection amount control can be checked as following:

Checking the voltage signal of the SPV

Checking the resistance of the SPV

Checking the voltage at the SPV relay

Checking the voltage signal to the IDM

Monitoring the FLT sensor via the PID FLT/FLT V (Temp/Volt)

Checking the voltage of the FLT sensor

Checking the resistance of the FLT sensor

Monitoring the FSOV relay via the PID FSOV (Mode)

Checking the voltage at the FSOV relay

Checking the voltage at the FSOV

Checking the resistance of the FSOV

144 Service Training

ECD-V5 Injection Pump System

Injection timing control

The design and operation of the injection timing control is essentially is essentially carried

over from the NP-VE 4 injection pump system except for the following:

Timer device has been modified

Timer position sensor has been eliminated

Pump speed sensor has been modified

Timer device

On the Mazda vehicles with RF-T engine the TCV is located in a passage between the

pump chamber and the low-pressure side of the timer piston, varying the pressure on the

low-pressure side of the timer piston. An additional orifice in the passage to the suction side

of the feed pump serves to maintain a high pressure on the low-pressure side of the timer

piston.

1 TCV 5 High-pressure side

2 To feed pump (suction side) 6 Low-pressure side

3 Roller ring 7 Timer piston

4 Pump chamber 8 Orifice

At low engine speeds the PCM controls the TCV with a large duty cycle, so that the

solenoid valve opens and the pressure on the low-pressure side increases. Due to this the

spring force and the pressure on the low-pressure side overcome the pressure on the high-

pressure side and the piston moves away from the return spring. Thus the roller ring rotates

into the turning direction of the cam plate, retarding the injection timing.

Service Training 145

ECD-V5 Injection Pump System

Injection timing control (continued)

Timer device (continued)

At high engine speeds the PCM controls the TCV with a small duty cycle, so that the

solenoid valve closes and the pressure on the low-pressure side decreases. Due to this the

pressure on the high-pressure side overcomes the spring force and the pressure on the

low-pressure side and the piston moves into the direction of the return spring. Thus the

roller ring rotates against the turning direction of the cam plate, advancing the fuel injection

timing.

NOTE: When the TCV fails the solenoid valve adopts in a parked position, setting the injection

timing to advance position. This can be recognized by the increased engine noise at idle

(Diesel knocking).

Pump speed sensor

On the Denso ECD-V5 injection pump system the pump speed sensor is mounted on the

roller ring of the axial piston pump and scans a rotor with 52 teeth. According to the number

of cylinders the rotor has 4 tooth gaps spread evenly around the circumference. Due to the

elimination of the TPS the signal of the pump speed sensor is used to detect the position of

the timer device, giving a feedback about the actual injection timing to the PCM.

X Time Y Output voltage

1 Pump speed sensor 4 Roller ring

2 Timer piston 5 Tooth gap

3 Toothed rotor 6 Output voltage characteristics

146 Service Training

ECD-V5 Injection Pump System

Injection timing control (continued)

Pump speed sensor (continued)

When the injection timing is altered by the timer device the roller ring and hence the sensor

is turned in the “advance” or “retard” direction, changing the position of the pump speed

sensor in relation to the rotor. Thus the position of the tooth gap on the rotor also changes in

relation to the TDC position of the engine. The PCM calculates the difference between the

signals from the pump speed sensor and the TDC sensor and compares it with a reference

value. As a result, the PCM determines an accurate position of the timer device.

Furthermore the PCM uses the pump speed sensor signal to detect the position of the

distributor plunger, determining the time at which the SPV is actuated. Actuation must take

place at precisely the correct angle so that both the closing and the opening of the SPV take

place in the appropriate position of the distributor plunger. This ensures that the start of fuel

injection and the fuel injection amount are correct.

NOTE: When the pump speed sensor fails, the engine doesn’t run anymore.

The pump speed sensor supplies the PCM with an alternating voltage of approx. 2…9 V

(peak to peak).

Service Training 147

ECD-V5 Injection Pump System

Emission system

The construction and operation of the emission system is essentially carried over from the

NP-VE4 injection pump system except for the following:

Warm-up oxidation catalyst has been adopted (only Euro 3 vehicles)

EGR control solenoid valve has been eliminated

EGR valve position sensor has been eliminated (only Euro 3 vehicles)

EGR water cooler has been eliminated

Intake shutter valve has been eliminated (only Euro 2 vehicles)

Parts location

1 EGR valve 5 ISV solenoid valve

2 EGR ventilation solenoid valve 6 Crankcase ventilation hose

3 EGR vacuum solenoid valve 7 Warm-up oxidation catalyst

4 ISV vacuum actuator 8 Oxidation catalyst

148 Service Training

ECD-V5 Injection Pump System

Emission system (continued)

System overview

1 EGR valve 6 Crankcase ventilation hose

2 EGR ventilation solenoid valve 7 Warm-up oxidation catalyst

3 EGR vacuum solenoid valve 8 Oxidation catalyst

4 ISV vacuum actuator 9 Vacuum pump

5 ISV solenoid valve 10 To PCM

Service Training 149

ECD-V5 Injection Pump System

Warm-up oxidation catalyst

In addition to the oxidation catalyst equipped Euro 3 vehicles feature a warm-up oxidation

catalyst, which improves the emission performance of the cold engine. The warm-up

catalyst is located just behind the exhaust manifold, so that it reaches its operating

temperature quickly after cold start. As a result the HC and CO emissions of the cold engine

are reduced, meeting the requirements of the emission control legislation.

1 Warm-up oxidation catalyst 2 Oxidation catalyst

NOTE: The warm-up oxidation catalyst can’t be cleaned or repaired. If necessary replace the

catalyst.

150 Service Training

ECD-V5 Injection Pump System

Control system

The construction and operation of the control system is essentially carried over from that of

the NP-VE4 injection pump system.

Parts location

1 PCM (incl. Barometric pressure sensor) 16 EGR ventilation solenoid valve

2 MAF sensor 17 EGR vacuum solenoid valve

3 IAT sensor 18 ISV solenoid valve

4 MAP sensor 19 IDM

5 Engine coolant temperature sensor 20 Glow plug relay

6 Crankshaft position sensor 21 SPV relay

7 Accelerator pedal position sensor 22 FSOV relay

8 Idle switch 23 PCM control relay

9 Clutch pedal position switch 24 A/C relay

10 FLT sensor 25 Condenser fan relay

11 Pump speed sensor 26 Cooling fan relay

12 Injection pump EPROM 27 Data link connector

13 TCV 28 Battery

14 VBC solenoid valve 29 Park / Neutral position switch

15 VSC solenoid valve

Service Training 151

ECD-V5 Injection Pump System

Control system (continued)

Block diagram

152 Service Training

ECD-V5 Injection Pump System

Control system (continued)

Block diagram (continued)

1 Injection amount control 24 Refrigerant pressure switch (with A/C)

2 Injection timing control 25 Immobilizer module

3 Idle speed control 26 Battery

4 Glow control 27 Data link connector

5 EGR control 28 Starter (starter signal)

6 VBC 29 Barometric pressure sensor (in PCM)

7 VSC 30 VBC solenoid valve

8 Electrical fan control 31 VSC solenoid valve

9 A/C control (if equipped) 32 TCV

10 Immobilizer system 33 EGR vacuum solenoid valve

11 MAF sensor 34 EGR ventilation solenoid valve

12 Engine coolant temperature sensor 35 SPV relay

13 Accelerator pedal position sensor 36 FSOV relay

14 Idle switch 37 Glow indicator light

15 IAT sensor 38 Glow plug relay

16 Pump speed sensor 39 A/C relay (with A/C)

17 FLT sensor 40 Cooling fan relay

18 Injection pump EPROM 41 Condenser fan relay (with A/C)

19 Crankshaft position sensor 42 IDM

20 MAP sensor 43 SPV

21 Park / Neutral position switch 44 PCM

22 Clutch pedal position switch 45 ISV

23 Vehicle speed sensor

Service Training 153

ECD-V5 Injection Pump System

Control system (continued)

Relationship chart

x: Applicable

Control item

Injection amount control

Injection timing control

Electrical fan control

Immobilizer system

Device

Idle speed control

Glow control

EGR control

A/C control

VBC

VSC

Engine coolant temperature sensor X X X X X X X X X

Accelerator pedal position sensor X X X X X X X

Idle switch X X X X X X

MAF/IAT sensor X X X

IAT sensor No.2 X

Pump speed sensor X X X X X X X X

FLT sensor X

Injection pump EPROM X X

Crankshaft position sensor X X

Input

MAP sensor X X X

Park / Neutral position switch X X X X X X

Clutch pedal position switch X X X X X X

Vehicle speed sensor X X X X X X

Barometric pressure sensor (integrated in PCM) X X X

Refrigerant pressure switch (with A/C) X X X

Immobilizer module X

Battery voltage X

DLC (TEN terminal) X

Starter signal X X X X X X

VBC solenoid valve X

VSC solenoid valve X

TCV X

EGR solenoid valve (vacuum, vent) X

Spill valve relay X X

FSOV relay X X

Output

Glow indicator light X

Glow plug relay X

A/C relay X X

Cooling fan relay X

Condenser fan relay (with A/C) X

ISV solenoid valve X

IDM X X X

154 Service Training

ECD-V5 Injection Pump System

Sensors

The design and operation of the sensors is essentially carried over from those of the NP-

VE4 injection pump system except for the following:

Crankshaft position sensor has been modified

Barometric pressure sensor has been eliminated (only Euro 2 vehicles)

Vehicle speed sensor has been eliminated

Crankshaft position sensor

Mazda vehicles with RF-T engine feature an inductive-type CKP sensor. The sensor

consists of a permanent magnet and a coil, which scan a rotor with one tooth.

1 Toothed rotor 3 Output voltage characteristics

2 CKP sensor

When the rotor passes the sensor, an alternating voltage is induced in the coil and input to

the PCM. The level of the alternating voltage depends on the distance between sensor and

rotor as well as on the speed of the crankshaft, i.e. the amplitude rises with decreasing

distance and increasing speed.

NOTE: When the CKP sensor fails, the TCV adopts in a parked position, setting the injection

timing to advance position. This can be recognized by the increased engine noise at idle

(Diesel knocking).

Service Training 155

ECD-V5 Injection Pump System

Sensors (continued)

Crankshaft position sensor (continued)

1 CKP sensor 2 PCM

The CKP sensor supplies the PCM with an alternating voltage between 6…18 V (peak to

peak).

Diagnostics

The CKP sensor can be checked as following:

Checking the voltage signal

Checking the resistance

156 Service Training

ECD-V5 Injection Pump System

Actuators

The design and operation of the actuators is essentially carried over from those of the NP-

VE4 injection pump system except for the following:

Electrical fan has been adopted

Immobilizer system has been modified

Electrical fan

On Mazda vehicles with RF-T engine the PCM controls the cooling fan and the condenser

fan (if equipped) via relays. When the engine coolant temperature reaches a given value

(approx. 100 °C), the PCM energizes the cooling fan relay, switching the power supply to

the cooling fan motor. In addition the PCM activates the condenser fan relay, when the A/C

is switched on or when the coolant temperature reaches a given value (approx. 105 °C),

supplying the condenser fan motor with power.

1 Cooling fan 4 Condenser fan relay

2 Condenser fan 5 PCM

3 Cooling fan relay 6 With A/C

NOTE: In order to prevent the engine from overheating when the ECT sensor is faulty, the PCM

activates the cooling and the condenser fan permanently. Furthermore both fans are

switched on, when the terminal TEN in the 17-pin data link connector is grounded and

the accelerator pedal is depressed.

Diagnostics

The function of the electrical fan can be checked as following:

Monitoring the engine coolant temperature via the PID ECT (Temp/Volt)

Monitoring / Activating the cooling and the condenser fan relay via the PID

FAN2# / FAN3# (Mode)

Checking the voltage at the cooling and the condenser fan relay

Checking the voltage at the cooling and the condenser fan

Service Training 157

ECD-V5 Injection Pump System

Actuators (continued)

Immobilizer System

On Mazda vehicles with RF-T engine the PCM deactivates the FSOV (via the FSOV relay)

and the IDM, when the vehicle is started with an invalid key. If the vehicle is equipped with a

starter relay, the immobilizer module disables the starter as well. As a result the engine

doesn’t even crank.

When a vehicle without starter relay is started with an invalid key, the PCM allows the

engine to start but cuts off the fuel supply after approx. 2 s, stopping the engine. After three

attempts to start the engine with an invalid key the PCM permanently cuts off the fuel

supply. As a result the engine doesn’t start at all.

NOTE: If a vehicle without starter relay starts and stalls after a short time or cranks and doesn’t

start, verify that this concern isn’t related to the immobilizer system by observing the

immobilizer warning light.

1 Immobilizer module 5 SPV

2 SPV relay 6 FSOV

3 FSOV relay 7 PCM

4 IDM

NOTE: For diagnosis on the immobilizer system refer to the workshop manual (section T –

Immobilizer System).

158 Service Training

You might also like

- VP44 Service ManualDocument39 pagesVP44 Service Manualhelder100% (5)

- Bosch Vp37 PumpsDocument32 pagesBosch Vp37 PumpsLuís Fidalgo92% (13)

- 2011 Jeep Liberty Limited 2011 Jeep Liberty Limited: Fig. 73: Transmission Control Output Wiring DiagramDocument7 pages2011 Jeep Liberty Limited 2011 Jeep Liberty Limited: Fig. 73: Transmission Control Output Wiring DiagramcarlosNo ratings yet

- Electrical Wiring Diagram: TOYOTA: Hilux Sport RiderDocument60 pagesElectrical Wiring Diagram: TOYOTA: Hilux Sport RiderThiri HlaingNo ratings yet

- Diesel Injection Pump Test BenchDocument15 pagesDiesel Injection Pump Test BenchedgarjayaNo ratings yet

- CAN Bus Interface Description CANbus Pin Out, and Signal Names. Controller ADocument8 pagesCAN Bus Interface Description CANbus Pin Out, and Signal Names. Controller AVincentius Nikim100% (1)

- 1996 Toyota Land Cruiser Prado, RJ Modification - All Pics, Specs, Parts andDocument4 pages1996 Toyota Land Cruiser Prado, RJ Modification - All Pics, Specs, Parts andVincentius NikimNo ratings yet

- Kart Basic Chassis SetupDocument6 pagesKart Basic Chassis SetupVincentius NikimNo ratings yet

- Simple Car DynamicsDocument16 pagesSimple Car DynamicsVincentius NikimNo ratings yet

- Welcome Common Rail Diesel Fuel Systems: To A Technical Overview ofDocument61 pagesWelcome Common Rail Diesel Fuel Systems: To A Technical Overview ofMuhammad DinataNo ratings yet

- Launch x431 Heavy Duty For Trucks Vehicle ListDocument85 pagesLaunch x431 Heavy Duty For Trucks Vehicle ListARYNo ratings yet

- Fuel SystemDocument98 pagesFuel SystemLei Yii Villanes100% (1)

- TCM InjectorSID05 7Document7 pagesTCM InjectorSID05 7leather_nunNo ratings yet

- Daewoo Matiz 2000-2013 Wheel AlignmentDocument6 pagesDaewoo Matiz 2000-2013 Wheel AlignmentOMARNo ratings yet

- Electric EGR ValveDocument2 pagesElectric EGR ValveLóránd Barta100% (1)

- VVT GeelyDocument6 pagesVVT GeelydokarusNo ratings yet

- Common Rail Injectors Repairing Table: MM Bar M M M NM NM NM NMDocument1 pageCommon Rail Injectors Repairing Table: MM Bar M M M NM NM NM NMakhmedNo ratings yet

- All Passenger Car Dealers/TascsDocument9 pagesAll Passenger Car Dealers/TascssouravNo ratings yet

- Index Catalogue Supplement Vehicle Equipment For Passenger CarsDocument137 pagesIndex Catalogue Supplement Vehicle Equipment For Passenger CarsdavideNo ratings yet

- Service Manual: Common Rail System (CRS) For Isuzu 6de1 EngineDocument33 pagesService Manual: Common Rail System (CRS) For Isuzu 6de1 EngineDagar GRNo ratings yet

- Ref. No.: EG 4010 Date: Page: Jul., 2004Document80 pagesRef. No.: EG 4010 Date: Page: Jul., 2004mpecha67% (3)

- Service Manual: Common Rail System For NISSAN YD1-K2 Type EngineDocument40 pagesService Manual: Common Rail System For NISSAN YD1-K2 Type EngineBryan Edu Curay ZavalaNo ratings yet

- Powertrain Control: CY324 - System Basis IC For Powertrain Control UnitsDocument2 pagesPowertrain Control: CY324 - System Basis IC For Powertrain Control Unitsfreddys merchanNo ratings yet

- Lesson 5: Denso-Common Rail System: ObjectivesDocument27 pagesLesson 5: Denso-Common Rail System: ObjectivesSenghakPhally100% (1)

- 001Document2 pages001Nacer Mezghiche50% (4)

- Meter / Gauge System: PrecautionDocument76 pagesMeter / Gauge System: PrecautionlogammicNo ratings yet

- AirbagDocument430 pagesAirbagSoujiro Vhs100% (1)

- Trago-10EM ETMDocument237 pagesTrago-10EM ETMHoàng VũNo ratings yet

- CRS (ECD-U2P) For Land CruiserDocument45 pagesCRS (ECD-U2P) For Land CruiserВячеслав ГлушакNo ratings yet

- Maxximo: Diagnostic Manual MAN-00129Document1 pageMaxximo: Diagnostic Manual MAN-00129LeelaNo ratings yet

- Nissan Almera P1251 Engine Trouble Code - Nissan Almera P1251 OBD-II Diagnostic Powertrain (P) Trouble Code For Nissan Almera PDFDocument2 pagesNissan Almera P1251 Engine Trouble Code - Nissan Almera P1251 OBD-II Diagnostic Powertrain (P) Trouble Code For Nissan Almera PDFJoaquin Enrique Rivas HungNo ratings yet

- Navara Owner Manual en 2017Document336 pagesNavara Owner Manual en 2017Mary Ann UsaragaNo ratings yet

- ECD-V4 OutlineDocument4 pagesECD-V4 OutlineВячеслав ГлушакNo ratings yet

- Glow Plug ControllerDocument2 pagesGlow Plug ControllerVijay Mirje100% (1)

- MS 6.3 ECU - 2.8L Engine - v02Document15 pagesMS 6.3 ECU - 2.8L Engine - v02pankituna5487No ratings yet

- En 063 Diagnostics Parts and Services For Vans and TrucksDocument32 pagesEn 063 Diagnostics Parts and Services For Vans and TrucksmugavanaNo ratings yet

- Bosch ECI Injection - ECIDocument17 pagesBosch ECI Injection - ECIBeTONo ratings yet

- Operation Manual - 74714763 - Injection - Power - Stage - HPI - 5Document20 pagesOperation Manual - 74714763 - Injection - Power - Stage - HPI - 5Aussi SidNo ratings yet

- Opel Airbag Reset Manual PDFDocument7 pagesOpel Airbag Reset Manual PDFSergio Gardeazabal100% (1)

- Toyota Avensis DPFDocument22 pagesToyota Avensis DPFCarl Anthony Chamberlain100% (3)

- Relay Loc LCR 200Document40 pagesRelay Loc LCR 200Yannick de WalqueNo ratings yet

- 3s FuelDocument310 pages3s FuelPrecisionetica100% (3)

- Volvo 850 ODB A1 Automatic Transmission DiagnosticDocument9 pagesVolvo 850 ODB A1 Automatic Transmission DiagnosticBartłomiej KilianNo ratings yet

- Fit For The Future:: Everything For Diesel ServiceDocument68 pagesFit For The Future:: Everything For Diesel Servicemihai37100% (2)

- Pe Ecu 1 Manual ViDocument45 pagesPe Ecu 1 Manual ViBruno PelletierNo ratings yet

- Bk2q-9k546-Ag 20190701 143833Document2 pagesBk2q-9k546-Ag 20190701 143833คุณชายธวัชชัย เจริญสุขNo ratings yet

- Back Leak TestDocument13 pagesBack Leak Testcartronix20100% (1)

- NP300Document8 pagesNP300sfsman1100% (1)

- Ak TrainingDocument40 pagesAk TrainingBatuhanÇetinGüven100% (1)

- LCV Crde ManualDocument55 pagesLCV Crde ManualVicky100% (2)

- 8d22de PDFDocument299 pages8d22de PDFA-t HectorNo ratings yet

- Body Wiring System: Section: 9ADocument12 pagesBody Wiring System: Section: 9AsvedexNo ratings yet

- Pinout-Schematic DiagramsDocument14 pagesPinout-Schematic DiagramsIvan RdzNo ratings yet

- Electronic Engine Controls TDV6 2.7Document10 pagesElectronic Engine Controls TDV6 2.7elisei sorinNo ratings yet

- CR InjectorDocument15 pagesCR InjectorbhupeshNo ratings yet

- HMC Accident Repair Getz BodyDocument6 pagesHMC Accident Repair Getz BodyAnon BoletusNo ratings yet

- Operation Manual XMQ6128Document132 pagesOperation Manual XMQ6128Bobby AldNo ratings yet

- Denso Common Rail SystemDocument68 pagesDenso Common Rail SystemAngeliNo ratings yet

- Eee 1Document3 pagesEee 1Gordo FragosoNo ratings yet

- ECD V5 Injection Pump SystemDocument42 pagesECD V5 Injection Pump SystemArtur Bujdoso78% (9)

- Denso CR - Hp2 NissanDocument31 pagesDenso CR - Hp2 NissanMarcelo Diesel86% (7)

- Covec FDocument22 pagesCovec FVictor Montesdeoca100% (1)

- DarshanDocument21 pagesDarshanMandar Ambi100% (1)

- Cam Less EngineDocument18 pagesCam Less EnginePushkar VermaNo ratings yet

- Variable Valve TimingDocument3 pagesVariable Valve Timingsandesh ganigaNo ratings yet

- CAN Bus TutorialDocument8 pagesCAN Bus TutorialVincentius Nikim100% (1)

- EML2322L Wheel Hub DesignDocument5 pagesEML2322L Wheel Hub DesignVincentius NikimNo ratings yet

- AUTT 1050 Automotive Suspension and Steering Systems: Master Course SyllabusDocument5 pagesAUTT 1050 Automotive Suspension and Steering Systems: Master Course SyllabusVincentius NikimNo ratings yet

- Ironman 4X4: GQ, GU Series With Coil Springs 5 Degree Caster Plates For 130mm - 170mm LiftsDocument1 pageIronman 4X4: GQ, GU Series With Coil Springs 5 Degree Caster Plates For 130mm - 170mm LiftsVincentius NikimNo ratings yet

- Mechanisms With Lower PairsDocument43 pagesMechanisms With Lower PairsVincentius NikimNo ratings yet

- Suspension 001Document26 pagesSuspension 001Vincentius NikimNo ratings yet

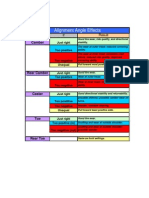

- Alignment Angle EffectsDocument5 pagesAlignment Angle EffectsVincentius NikimNo ratings yet

- Chapter 67 AlignmentDocument25 pagesChapter 67 AlignmentVincentius NikimNo ratings yet

- Engine Cdi PDFDocument78 pagesEngine Cdi PDFSergio Sanchez Rocha94% (16)

- Steering and Turning Vehicles 1Document24 pagesSteering and Turning Vehicles 1Vincentius NikimNo ratings yet

- Ervice AND Arts Anual: Elmhults Konstruktions AbDocument57 pagesErvice AND Arts Anual: Elmhults Konstruktions AbRicardo VieiraNo ratings yet

- The Pressure Test of The DBB ValveDocument3 pagesThe Pressure Test of The DBB ValvevaliullahNo ratings yet

- Detect and Indentity The Cause of Machinery Ma-1Document64 pagesDetect and Indentity The Cause of Machinery Ma-1sukarlem marsiahNo ratings yet

- Rack & Pinion (03062015)Document16 pagesRack & Pinion (03062015)Agustina De WinneNo ratings yet

- Allegheny Bradford Corporation: Craftsmen in StainlessDocument11 pagesAllegheny Bradford Corporation: Craftsmen in Stainlessアルビン ベネNo ratings yet

- MN 206 Market Survey CopperDocument210 pagesMN 206 Market Survey CopperArjun MishraNo ratings yet

- Kenr5623kenr5623-06 SisDocument2 pagesKenr5623kenr5623-06 SisFrank Agurto Luciano100% (3)

- ManualsOperator 3007Document146 pagesManualsOperator 3007Enver Santos VelasquezNo ratings yet

- ODME ExplainationDocument36 pagesODME ExplainationRachit Srivastava100% (2)

- thermCA en Stand 2013 03 18Document56 pagesthermCA en Stand 2013 03 18mohamed ghareebNo ratings yet

- Ball Valves Floating OmbDocument24 pagesBall Valves Floating OmbMASOUDNo ratings yet

- Service Manual Rev0Document11 pagesService Manual Rev0Александр ДлинныйNo ratings yet

- Engine of Richard Trevithick of 1806 Model of The High Pressure Dredger Assemblies Bill of Materials, Parts andDocument1 pageEngine of Richard Trevithick of 1806 Model of The High Pressure Dredger Assemblies Bill of Materials, Parts andNetflix JednaNo ratings yet

- Truma Camping World Int GBDocument91 pagesTruma Camping World Int GBIngrid LewisNo ratings yet

- Bray Series 35 36 Weights DimensionsDocument1 pageBray Series 35 36 Weights Dimensionsjacquesstrappe06No ratings yet

- 515-LUB-01 Vogel Pump Unit PDFDocument94 pages515-LUB-01 Vogel Pump Unit PDFalexNo ratings yet

- Data Sheet For Cooling Tower:, Cti CertifiedDocument2 pagesData Sheet For Cooling Tower:, Cti CertifiedHemanti SharmaNo ratings yet

- ODME - What Is It - (Part 2) - General Technical KnowledgeDocument4 pagesODME - What Is It - (Part 2) - General Technical KnowledgeanNo ratings yet

- Manual de Mantenimiento COMPRESOR DE TORNILLODocument16 pagesManual de Mantenimiento COMPRESOR DE TORNILLOWilder Fernando Vilca Ore100% (1)

- MTO For Manual Valve and Specialty ItemsDocument4 pagesMTO For Manual Valve and Specialty ItemsNguyen VHNo ratings yet

- Fire Pump Compliance MatrixDocument5 pagesFire Pump Compliance Matrixshakil612No ratings yet

- Amsco Evolution L Medium Steam Sterilizers Technical Data SheetDocument12 pagesAmsco Evolution L Medium Steam Sterilizers Technical Data Sheettranle2283No ratings yet

- Fan Coil UnitDocument1 pageFan Coil UnitkaamNo ratings yet

- VIO55-5B Parts Catalog (Engine) PDFDocument27 pagesVIO55-5B Parts Catalog (Engine) PDFsuriantoNo ratings yet

- Final Exam Mea 322Document89 pagesFinal Exam Mea 322Faris Abd HalimNo ratings yet

- Is - 14846 - 2000Document23 pagesIs - 14846 - 2000Sangita GhaisasNo ratings yet

- Flow Measurement Design CriteriaDocument21 pagesFlow Measurement Design Criteriakathiresan nadarNo ratings yet

- Wheatly XDocument2 pagesWheatly XElinton SarmientoNo ratings yet

- IsoTherm Mixing Module Installation ManualDocument1 pageIsoTherm Mixing Module Installation Manuale-ComfortUSANo ratings yet

- Manual - Performa CV Twin AltDocument20 pagesManual - Performa CV Twin AltGreg ReynekeNo ratings yet