Professional Documents

Culture Documents

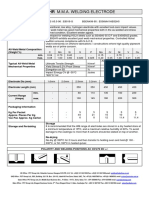

Aws A5.22 E316lt1-1/4

Uploaded by

jaime huertas0 ratings0% found this document useful (0 votes)

56 views1 pageAWS A5.22 E316LT1-1/4

Original Title

AWS A5.22 E316LT1-1/4

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAWS A5.22 E316LT1-1/4

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

56 views1 pageAws A5.22 E316lt1-1/4

Uploaded by

jaime huertasAWS A5.22 E316LT1-1/4

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Weldcote Metals 842 Oak Road Kings Mountain, NC 28086 704-739-4115 www.weldcotemetals.

com

E316LT1-1/4

DESCRIPTION: E316LT1-1/4 is suitable for welding of 18%Cr-12%Ni-2%Mo steel(SUS 316)

and extra-low carbon 18%Cr-12%Mo steel(SUS 316L). E316LT1-1/4 is a flux cored wire for Flat,

H-Fillet and V-up position welding for CO2 or 75%Ar-25%CO2 shielding gas. It provides

excellent usability with stable arc, less spattering, good bead appearance. For mechanized welding

of H-Fillet this wire is an excellent choice, as it meets the requirement of superior wire feeding

properties combined with high deposition efficiency.

APPROVAL: CWB(A5.22 E316LT1-1/4) & AWS A5.22 E316LT1-1/4

CHEMICAL COMPOSITION MECHANICAL PROPERTIES

CARBON .028 Tensile Strength

SILICON .60 85,000 PSI 590 MPA

MANGANESE 1.61 Yield Strength

PHOSPHORUS .012 76,000 PSI 527 MPA

SULFUR .010 Elongation 42%

NICKEL 10.10

CHROMIUM 19.42

DEPOSITION WELDING BUTT WELDING

*WELDING PROCEDURE* *WELDING PROCEDURE*

Wire diameter: 1.2mm Wire diameter: 1.2mm

Amperage: 180~220A Amperage: 180~220A

Voltage: 30~32V Voltage: 30~32V

Current & polarity: DCEP Current & polarity: DCEP

Shielding gas: CO2100%, 20ℓ/min Shielding gas: CO2100%, 20ℓ/min

Wire Stick-out: 20~ 25mm Wire Stick-out: 20 ~ 25mm

Interpass temp: 150°C max. Interpass temp.: 150°C max.

Welding position: Flat Welding position: Flat

Welding speed: 300~400mm/min Welding speed: 300~ 400mm/min

Preheat temp: N/A Preheat temp: N/A

Root treatment: No Root Treatment: No

Weldcote Metals believes this data to be accurate and to reflect qualified expert opinion regarding current research. However, Weldcote Metals can

not make any expressed or implied warranty as to this information.

You might also like

- Physical Electronics: Handbook of Vacuum PhysicsFrom EverandPhysical Electronics: Handbook of Vacuum PhysicsA. H. BeckNo ratings yet

- Pinnacle Alloys E11018 MDocument2 pagesPinnacle Alloys E11018 MMoch_adiganjarNo ratings yet

- SOW 7018A11 8 SpecSheetDocument2 pagesSOW 7018A11 8 SpecSheetKmi GutierrezNo ratings yet

- Pinnacle Alloys E8018 C3Document2 pagesPinnacle Alloys E8018 C3Sajeev SivanandanNo ratings yet

- Pinnacle Alloys E9018-M Code and Specification DataDocument2 pagesPinnacle Alloys E9018-M Code and Specification DataPutra Panca WardhanaNo ratings yet

- Pinnacle Alloys E7018 E7018 1Document2 pagesPinnacle Alloys E7018 E7018 1BerniIrleNo ratings yet

- Pinnacle Alloys E8018-B6 Code and Specification DataDocument2 pagesPinnacle Alloys E8018-B6 Code and Specification DataMurad AlmoudiNo ratings yet

- Datasheet Sandvik 2212htDocument2 pagesDatasheet Sandvik 2212htDarryl007No ratings yet

- Datasheet Sanicro 72hpDocument2 pagesDatasheet Sanicro 72hpphillipskincaidNo ratings yet

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Document1 pageAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNo ratings yet

- Wb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2Document1 pageWb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2lathasri78No ratings yet

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- Bronze c54400 SpecificationsDocument3 pagesBronze c54400 SpecificationsRam Parimalam100% (1)

- Technical Report (CSF-81TM)Document5 pagesTechnical Report (CSF-81TM)matiasg.sanchezv95No ratings yet

- Automig FC 71 T1Document1 pageAutomig FC 71 T1Sushil BhansaliNo ratings yet

- 3M Datasheet HV Push On Portfolio For GISDocument2 pages3M Datasheet HV Push On Portfolio For GISTuấn Khoa VõNo ratings yet

- Wires - Technical & Application DataDocument5 pagesWires - Technical & Application DatagersomNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Instruction Manual Elite Acdc225 PDFDocument13 pagesInstruction Manual Elite Acdc225 PDFEdwin ParraNo ratings yet

- Wb35S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb35S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- IP Code Operating Torque Number of Contacts Capacity of Contacts Operating Angle Cable Size Mechanical Life Electrical Life Working Temp. Working Humidity Material N.WDocument2 pagesIP Code Operating Torque Number of Contacts Capacity of Contacts Operating Angle Cable Size Mechanical Life Electrical Life Working Temp. Working Humidity Material N.WArnold StevenNo ratings yet

- Wb56S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb56S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- 316L-SS-annealed Bar and Cold DrawnDocument2 pages316L-SS-annealed Bar and Cold DrawnARUNKANNANNo ratings yet

- 304 Stainless SteelDocument3 pages304 Stainless Steelnum fistismNo ratings yet

- Datasheet Sanicro 60Document2 pagesDatasheet Sanicro 60Ismail JamaluddinNo ratings yet

- Singleturn Potentiometers PD200/210 20.0mm 100,000 Cycles WirewoundDocument6 pagesSingleturn Potentiometers PD200/210 20.0mm 100,000 Cycles WirewoundRafael CocãoNo ratings yet

- Arsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!Document2 pagesArsenical Admiralty Copper, Uns C44300, Oso25 Temper Tubing: Advertise With Matweb!David LluguinNo ratings yet

- ASM Material Data Sheet 304Document2 pagesASM Material Data Sheet 304.xNo ratings yet

- T Work9000Document2 pagesT Work9000Maike SongNo ratings yet

- CWC-BookletF1 10Document1 pageCWC-BookletF1 10satnamNo ratings yet

- GBTDocument1 pageGBTRaviTeja BhamidiNo ratings yet

- Sandvik 22.15.3.L: (Welding Wire)Document2 pagesSandvik 22.15.3.L: (Welding Wire)marcos2509mpNo ratings yet

- Sandvik 25.22.2.Lmn: (Welding Wire)Document3 pagesSandvik 25.22.2.Lmn: (Welding Wire)Anonymous w6TIxI0G8lNo ratings yet

- Merit S-6: Lincoln Electric China Gmaw Solid WireDocument2 pagesMerit S-6: Lincoln Electric China Gmaw Solid Wirelovaldes62No ratings yet

- Welding Process Techniques: KG - Pandithan, Iwe Technical Advisor, RiboDocument51 pagesWelding Process Techniques: KG - Pandithan, Iwe Technical Advisor, RibojswldeepNo ratings yet

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- Pinnacle Alloys E6013Document2 pagesPinnacle Alloys E6013rahulNo ratings yet

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngNo ratings yet

- ABB - Filament Wound ComponentDocument4 pagesABB - Filament Wound ComponentAbu Haydar Amin MustanginNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- 316L-SS-annealed BarDocument2 pages316L-SS-annealed BarARUNKANNANNo ratings yet

- 316 Stainless Steel, Annealed SheetDocument2 pages316 Stainless Steel, Annealed SheetZASSNo ratings yet

- Item 19 Esk107m050ag3aaDocument1 pageItem 19 Esk107m050ag3aadifa20061168No ratings yet

- Top Gun Acdc 315dDocument13 pagesTop Gun Acdc 315dTom PleysierNo ratings yet

- Weldclad WLDC 3Document1 pageWeldclad WLDC 3furiousgaulNo ratings yet

- Bohler Fox N CM 2 KBDocument1 pageBohler Fox N CM 2 KBkamals55No ratings yet

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanNo ratings yet

- Robust Pressure Transmitters T.3: 1.4404 / AISI 316LDocument4 pagesRobust Pressure Transmitters T.3: 1.4404 / AISI 316LRodica PuscauNo ratings yet

- выключатель массы ДАФ 105 S250 - FT04ENDocument4 pagesвыключатель массы ДАФ 105 S250 - FT04ENВячеслав ШапочкаNo ratings yet

- Borealis Supercopo™ Lh4201R Polyethylene Insulation Compound, CrosslinkableDocument2 pagesBorealis Supercopo™ Lh4201R Polyethylene Insulation Compound, CrosslinkableAnonymous 1AAjd0No ratings yet

- Wb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Item 18 Esk107m035ae3aaDocument1 pageItem 18 Esk107m035ae3aadifa20061168No ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- CuNiSi AlloyDocument6 pagesCuNiSi AlloyJdjoNo ratings yet

- MaterialData - 56973 2Document2 pagesMaterialData - 56973 2red_beastNo ratings yet

- Technical Data Sheet: Description Values Technical ParticularsDocument2 pagesTechnical Data Sheet: Description Values Technical ParticularsAli ShahzadNo ratings yet

- WB56S E7016-1Document1 pageWB56S E7016-1cwiksjNo ratings yet

- Structural Inspection Report HMSDocument38 pagesStructural Inspection Report HMSjaime huertasNo ratings yet

- Sds Transcopy Liquid GB en m0001Document9 pagesSds Transcopy Liquid GB en m0001jaime huertasNo ratings yet

- Nital EtchDocument2 pagesNital Etchjaime huertasNo ratings yet

- Members Data 8Document2 pagesMembers Data 8jaime huertasNo ratings yet

- Nital EtchDocument2 pagesNital Etchjaime huertasNo ratings yet

- Procedimiento de Reparación TurbinaDocument4 pagesProcedimiento de Reparación Turbinajaime huertasNo ratings yet

- SCTR Marzo 2019Document2 pagesSCTR Marzo 2019jaime huertasNo ratings yet

- Structural Inspection Report HMSDocument38 pagesStructural Inspection Report HMSjaime huertasNo ratings yet

- Caja de VacioDocument1 pageCaja de Vaciojaime huertasNo ratings yet

- Procedimiento de Reparación TurbinaDocument4 pagesProcedimiento de Reparación Turbinajaime huertasNo ratings yet

- Wps Gtaw PDFDocument4 pagesWps Gtaw PDFjaime huertasNo ratings yet

- Iso 4386-1 1992Document13 pagesIso 4386-1 1992german2639931100% (1)

- ASME V Art 27 LT PDFDocument12 pagesASME V Art 27 LT PDFAgniva DuttaNo ratings yet

- ASNT Level 3Document8 pagesASNT Level 3Indigo Wave0% (2)

- Ul 142Document4 pagesUl 142jaime huertasNo ratings yet

- Structural Inspection Report HMSDocument38 pagesStructural Inspection Report HMSjaime huertasNo ratings yet

- Perkins 45 KVADocument4 pagesPerkins 45 KVASadiman SadimanNo ratings yet

- Noc18 Ce23 Assignment2 PDFDocument4 pagesNoc18 Ce23 Assignment2 PDFrichard kwofieNo ratings yet

- Csa Rotordryer PDFDocument8 pagesCsa Rotordryer PDFpeterpunk75No ratings yet

- Generator For Wind Turbine: Installation and Maintenance ManualDocument18 pagesGenerator For Wind Turbine: Installation and Maintenance ManualimatafernandezNo ratings yet

- Whirlpool Awt 5067-3Document14 pagesWhirlpool Awt 5067-3Denes LazarNo ratings yet

- Robushi Robox BlowerDocument2 pagesRobushi Robox Bloweranguyen22153319No ratings yet

- Fan Drive-EATON PDFDocument10 pagesFan Drive-EATON PDFFrank Cusi YucraNo ratings yet

- Chapter-2 (Steel Design)Document22 pagesChapter-2 (Steel Design)danica ledesmaNo ratings yet

- Trajan 712 Owners ManualDocument21 pagesTrajan 712 Owners ManualGIVAN93No ratings yet

- Refluxing Condensation Systems (Dephlegmators)Document21 pagesRefluxing Condensation Systems (Dephlegmators)jdgh1986100% (1)

- Diesel Cycle: P-V Diagram T-S DiagramDocument3 pagesDiesel Cycle: P-V Diagram T-S DiagramJJ100% (1)

- Flywheel ExperimentDocument4 pagesFlywheel ExperimentNasim Mammadov67% (3)

- List of Vessel Equipment To Be Handed Over: Engine Machineries Bridge, ECR, EtcDocument18 pagesList of Vessel Equipment To Be Handed Over: Engine Machineries Bridge, ECR, EtcOMS BROMONo ratings yet

- An Experimental Study On The Effect of MIG Welding Parameters On The Weld-Bead Shape CharacteristicsDocument5 pagesAn Experimental Study On The Effect of MIG Welding Parameters On The Weld-Bead Shape Characteristicstejap314No ratings yet

- VAQ Station For Climate Control: Application NotesDocument11 pagesVAQ Station For Climate Control: Application NotesAnkit JainNo ratings yet

- 422FDocument24 pages422FVictor Raul Osnayo Mamani100% (2)

- Vicat Test: Report1Document5 pagesVicat Test: Report1Khalid MohammadNo ratings yet

- Ufgs 41 22 13.15Document60 pagesUfgs 41 22 13.15Abdul wahid ButtNo ratings yet

- T Bolt Specs PDFDocument2 pagesT Bolt Specs PDFrefaeNo ratings yet

- Paper gt2016-56548 - Support Vibration Diagnostics and Limits in GT - 16jan2016 PDFDocument11 pagesPaper gt2016-56548 - Support Vibration Diagnostics and Limits in GT - 16jan2016 PDFbigsteve9088No ratings yet

- Water Contamination in Hydraulic and Lube SystemsDocument11 pagesWater Contamination in Hydraulic and Lube SystemsBrayan MejiaNo ratings yet

- Lagrangian Particle TrackingDocument35 pagesLagrangian Particle TrackingLiviuNo ratings yet

- CEPSA Lubricants WindpowerDocument5 pagesCEPSA Lubricants WindpowerVaida Man KanNo ratings yet

- TM 55 1905 223 24 2 PDFDocument127 pagesTM 55 1905 223 24 2 PDFMohamed HmayenNo ratings yet

- Electric Motor EE ST and L - EEA Comment Attended 22 July 2015Document193 pagesElectric Motor EE ST and L - EEA Comment Attended 22 July 2015gomeraNo ratings yet

- Corolla 1.8 - 1Document4 pagesCorolla 1.8 - 1Diego496No ratings yet

- MarutiDocument286 pagesMarutiMarcelo DominguezNo ratings yet

- Trifilar Experiment: Submitted by Prakhar Gupta 2008UME139 M2Document11 pagesTrifilar Experiment: Submitted by Prakhar Gupta 2008UME139 M2HLMOPTUW0% (1)

- Sar Nba Etc partIIDocument231 pagesSar Nba Etc partIISantosh WagajNo ratings yet

- Perma STAR VARIO / Perma Star Control Perma NOVA Perma FLEX Perma FUTURADocument4 pagesPerma STAR VARIO / Perma Star Control Perma NOVA Perma FLEX Perma FUTURAGeorge ZiovasNo ratings yet

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceFrom EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceRating: 4 out of 5 stars4/5 (19)

- Analog Design and Simulation Using OrCAD Capture and PSpiceFrom EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNo ratings yet

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (52)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsFrom EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo ratings yet

- Laws of UX: Using Psychology to Design Better Products & ServicesFrom EverandLaws of UX: Using Psychology to Design Better Products & ServicesRating: 5 out of 5 stars5/5 (9)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Lean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsFrom EverandLean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsRating: 4 out of 5 stars4/5 (2)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsFrom EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsRating: 5 out of 5 stars5/5 (1)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersFrom EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersRating: 4 out of 5 stars4/5 (13)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)