Professional Documents

Culture Documents

Technical Associates of Charlotte, Inc. Table Ii. Criteria For Overall Condition Rating (Rms Overall Velocity, MM/S) Rms

Technical Associates of Charlotte, Inc. Table Ii. Criteria For Overall Condition Rating (Rms Overall Velocity, MM/S) Rms

Uploaded by

Sarawuru Lohan0 ratings0% found this document useful (0 votes)

4 views1 pageWTP-148

Original Title

WTP-148

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWTP-148

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageTechnical Associates of Charlotte, Inc. Table Ii. Criteria For Overall Condition Rating (Rms Overall Velocity, MM/S) Rms

Technical Associates of Charlotte, Inc. Table Ii. Criteria For Overall Condition Rating (Rms Overall Velocity, MM/S) Rms

Uploaded by

Sarawuru LohanWTP-148

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

TECHNICAL ASSOCIATES OF CHARLOTTE, INC.

TABLE II. CRITERIA FOR OVERALL CONDITION RATING (RMS OVERALL VELOCITY, mm/s)rms

1. Assuming Machine Speed = 600 to 60,000 RPM.

2. Assuming Measurements by Accelerometer or Velocity Pickup securely mounted as Close as Possible to

Bearing Housing.

3. Assuming Machine is Not Mounted on the Vibration Isolated Machinery – Set Alarm 30% - 50% Higher).

4. Set Motor Alarms the Same as that for the Particular Machine Type unless Otherwise Noted.

5. Set Alarms on Individual External Gearbox Position about 25% Higher than of a particular Machine Type.

MACHINE TYPE GOOD OK ALERT CRITICAL

COOLING TOWER DRIVES

Long, Hollow Drive Shaft 0 – 6.7 6.7 – 10.8 10.8 16.2

Close Coupled Belt Drive 0 – 4.9 4.9 – 7.6 7.6 11.7

Close Coupled Direct Drive 0 – 3.6 3.6 – 5.4 5.4 8.1

COMPRESSORS

Reciprocating 0 – 5.8 5.8 – 9.0 9.0 13.5

Rotary Screw 0 – 5.4 5.4 – 8.1 8.1 11.7

Centrifugal With or W/O External Gearbox 0 – 3.6 3.6 – 5.4 5.4 8.1

Centrifugal – Integral Gear (Axial Meas.) 0 – 3.6 3.6 – 5.4 5.4 8.1

Centrifugal – Integral Gear (Radial Meas.) 0 – 2.7 2.7 – 4.5 4.5 6.7

BLOWERS (FANS)

Lobe-Type Rotary 0 – 5.4 5.4 – 8.1 8.1 12.1

Belt-Driven Blowers 0 – 4.9 4.9 – 7.6 7.6 11.7

General Direct Drive Fans (with Coupling) 0 – 4.5 4.5 – 6.7 6.7 9.9

Primary Air Fans 0 – 4.5 4.5 – 6.7 6.7 9.9

Large Forced Draft Fans 0 – 3.6 3.6 – 5.4 5.4 8.1

Large Induced Draft Fans 0 – 3.1 3.1 – 4.9 4.9 7.2

Shaft-Mounted Integral Fan (Extended Motor Shaft) 0 – 3.1 3.1 – 4.9 4.9 7.2

Vane-Axial Fans 0 – 2.7 2.7 – 4.5 4.5 6.7

MOTOR/GENERATOR SETS

Belt-Driven 0 – 4.9 4.9 – 7.6 7.6 12.1

Direct Coupled 0 – 3.6 3.6 – 5.4 5.4 8.1

CHILLERS

Reciprocating 0 – 4.5 4.5 – 7.2 7.2 10.8

Centrifugal (Open-Air) – Motor & Comp. Separate 0 – 3.6 3.6 – 5.4 5.4 8.1

Centrifugal (Hermetic) – Motor & Impellers Inside 0 – 2.7 2.7 – 4.0 4.0 6.3

LARGE TURBINE/GENERATOR

3600 RPM Turbine/Generators 0 – 3.1 3.1 – 4.9 4.9 7.2

1800 RPM Turbine/Generators 0 – 2.7 2.7 – 4.0 4.0 6.3

CENTRIFUGAL PUMPS

Vertical Pumps ( 12’ – 20’ Height) Height from Grade to Top Motor 0 – 5.8 5.8 – 9.0 9.0 13.5

Bearing. May be necessary to

Vertical Pumps ( 8’ – 12’ Height) Spec. Lower Alarm for Lower 0 – 4.9 4.9 – 7.6 7.6 11.7

Vertical Pumps ( 5’ – 8’ Height) Motor Bearing & for Upper Pump 0 – 4.0 4.0 – 6.3 6.3 9.4

Vertical Pumps ( 0’ – 5’ Height) Bearing (depending on height). 0 – 3.6 3.6 – 5.4 5.4 8.1

General Purpose Horizontal Pump – Direct Coupled 0 – 3.6 3.6 – 5.4 5.4 8.1

Boiler Feed Pumps – Horizontal Orientation 0 – 3.6 3.6 – 5.4 5.4 8.1

Hydraulic Pumps – Horizontal Orientation 0 – 2.2 2.2 – 3.6 3.6 5.4

MACHINE TOOLS

Motor 0 – 1.8 1.8 – 3.1 3.1 4.5

Gearbox Input 0 – 2.7 2.7 – 4.0 4.0 6.3

Gearbox Output 0 – 1.6 1.6 – 2.7 2.7 4.0

Spindles:

a. Roughing Operations 0 – 1.2 1.2 – 1.8 1.8 2.7

b. Machine Finishing 0 – 0.7 0.7 – 1.1 1.1 1.6

c. Critical Finishing 0 – 0.4 0.4 – 0.7 0.7 1.1

*NOTE: The “ALERT” and “CRITICAL” overall levels given above apply only to in-service machinery which has been

operating for some time after initial installation and/or overhaul. They do not apply (and are not meant to serve as )

Acceptance Criteria for either new or rebuilt machinery.

COPYRIGHT© 1993 – TECHNICAL ASSOCIATES OF CHARLOTTE, INC. R-0993-4PK

© Copyright 1993 Technical Associates Of Charlotte, inc. 7-22

Entek IRD International

You might also like

- Vibration Analyst Cat II Review Questions PDFDocument66 pagesVibration Analyst Cat II Review Questions PDFMohanMano54% (13)

- Vibration Cat II Practise ExamDocument3 pagesVibration Cat II Practise Examalxmaas91% (11)

- Vibration Analysis Level 1Document3 pagesVibration Analysis Level 1mohanmani0267% (3)

- ISO 18436 Category II Vibration Analyst TrainingDocument4 pagesISO 18436 Category II Vibration Analyst TrainingDean Lofall50% (2)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- JPS Reliability Bearing FailuresDocument14 pagesJPS Reliability Bearing FailuresAnonymous Bdt0OGh100% (1)

- RBMWizardDocument286 pagesRBMWizardJesus EspinozaNo ratings yet

- Proven Method For Specifying Both Six Spectral Alarm Bands As Well As Narrowband Alarm EnvelopesDocument4 pagesProven Method For Specifying Both Six Spectral Alarm Bands As Well As Narrowband Alarm EnvelopesVILLANUEVA_DANIEL2064No ratings yet

- Sperry Drill MotorsDocument4 pagesSperry Drill Motorsjoseahilarrazam100% (1)

- PeakvueDocument68 pagesPeakvueLe Thanh Hai100% (1)

- Creating PeakVue Measurement PointsDocument2 pagesCreating PeakVue Measurement PointsNewman RiosNo ratings yet

- Balancing Letter PDFDocument307 pagesBalancing Letter PDFCamilo Andres Quintero100% (6)

- Vibration Analysis Certification Exam Certified Analyst Category I Principles of Vibration Test Sample Question PDFDocument1 pageVibration Analysis Certification Exam Certified Analyst Category I Principles of Vibration Test Sample Question PDFMohammed Kamel Tony100% (1)

- Advanced Vibration Analysis On Gear Box TrainDocument25 pagesAdvanced Vibration Analysis On Gear Box TrainmitrachintuNo ratings yet

- Vibration Sample Template PDFDocument1 pageVibration Sample Template PDFnumanfawzal67% (3)

- Training Course IIIDocument188 pagesTraining Course IIIHosam Abd Elkhalek100% (2)

- Vibration Analysis Level - 1 Updated (Compatibility Mode)Document230 pagesVibration Analysis Level - 1 Updated (Compatibility Mode)jawadhussain189% (9)

- Forsthoffer’s Component Condition MonitoringFrom EverandForsthoffer’s Component Condition MonitoringRating: 4 out of 5 stars4/5 (2)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- 120H Caf Caterpillar TestDocument4 pages120H Caf Caterpillar TestMiguel Angel Garrido Cardenas100% (2)

- Introduction To PeakvueDocument55 pagesIntroduction To PeakvueAhmed Nazeem100% (4)

- Introduction To PeakvueDocument55 pagesIntroduction To PeakvuesebastianNo ratings yet

- CAT II Activity Book v4.0 - Letter - Answer KeyDocument7 pagesCAT II Activity Book v4.0 - Letter - Answer Keyazay_saja100% (2)

- PeakvueDocument68 pagesPeakvueChe Khairuddin100% (1)

- ISO Vibration Analysis Certification Exam Cat I Part 3 Signal Processing Ali M Al-ShurafaDocument1 pageISO Vibration Analysis Certification Exam Cat I Part 3 Signal Processing Ali M Al-ShurafaMohammed Kamel Tony100% (1)

- Predict-Mobius Training BrochureDocument7 pagesPredict-Mobius Training BrochurefaisalNo ratings yet

- Balancing Without Phase ReadingDocument2 pagesBalancing Without Phase Readingvirtual_56No ratings yet

- Vibration Analysis Level 2 Manual PDFDocument2 pagesVibration Analysis Level 2 Manual PDFAsad KhanNo ratings yet

- CHAPTER 6 Resonance and Critical Speed TestingDocument31 pagesCHAPTER 6 Resonance and Critical Speed TestingHosam Abd Elkhalek67% (3)

- Vibration Training Mobius1Document26 pagesVibration Training Mobius1azhar.simebest88% (8)

- AMPLITUDE MODULATION Versus BEATSDocument5 pagesAMPLITUDE MODULATION Versus BEATSHaitham YoussefNo ratings yet

- Vibration Dignostic ChartDocument5 pagesVibration Dignostic ChartIbrahim Sammour92% (12)

- VIBS Modal Overview 021703 MACLDocument55 pagesVIBS Modal Overview 021703 MACLBakkiya RajNo ratings yet

- Time Waveform AnalysisDocument26 pagesTime Waveform AnalysisSurika Martalina100% (1)

- Vibration Diagonistic ChartDocument1 pageVibration Diagonistic ChartsamiNo ratings yet

- 11 PeakVue OverviewDocument38 pages11 PeakVue OverviewAhmad Syahroni100% (1)

- Vibration Analysis Cat I II Exam Q&A Rotating EquipmentDocument4 pagesVibration Analysis Cat I II Exam Q&A Rotating EquipmentChandra PratamaNo ratings yet

- Autocorrelation: 131 CAT IV Part 1 - Signal Processing SlidebookDocument8 pagesAutocorrelation: 131 CAT IV Part 1 - Signal Processing SlidebookLe Thanh Hai100% (2)

- Examen Vibraciones Nivel IIDocument41 pagesExamen Vibraciones Nivel IIJim Morrison67% (3)

- Chapter 10Document63 pagesChapter 10Hosam Abd Elkhalek100% (1)

- Cat II Cover A4 250912Document4 pagesCat II Cover A4 250912Shahbaz KhanNo ratings yet

- AMS Machinery Manager Test DriveDocument39 pagesAMS Machinery Manager Test DriverharaksiNo ratings yet

- 303mills PDFDocument32 pages303mills PDFfaisalNo ratings yet

- Vibration Analysis Reports of RM ChemicalsDocument25 pagesVibration Analysis Reports of RM ChemicalsAnant Jain100% (1)

- Cuaderno Curso - CAT I Activity Book Spanish With CoverDocument34 pagesCuaderno Curso - CAT I Activity Book Spanish With CoverJose Raul Reyes Dominguez100% (1)

- Advanced Vibration Analysis TechniquesDocument324 pagesAdvanced Vibration Analysis Techniquesharikrishnanpd3327100% (1)

- Shock Pulse MethodDocument10 pagesShock Pulse MethodjavedNo ratings yet

- Detection of Ski Slopes in Vibration SpectrumsDocument7 pagesDetection of Ski Slopes in Vibration SpectrumsjeyaselvanmNo ratings yet

- Detect Machinery Faults by Using Peak VueDocument13 pagesDetect Machinery Faults by Using Peak VueHarold Alconz100% (2)

- ISO 18436 Category IV Vibration Analyst Training TopicsDocument1 pageISO 18436 Category IV Vibration Analyst Training TopicsDean LofallNo ratings yet

- Dynamic Absorber DesignDocument14 pagesDynamic Absorber DesignLarry Deem0% (1)

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionFrom EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNo ratings yet

- Testing Methods For Rebuild UnitsDocument8 pagesTesting Methods For Rebuild UnitsBhone ThantNo ratings yet

- E Mopi TM001 E2Document39 pagesE Mopi TM001 E2Konjo KradicaNo ratings yet

- Stepper Motors CatalogDocument35 pagesStepper Motors Catalogapi-3700604100% (1)

- Quick Installation Guide 01Document17 pagesQuick Installation Guide 01Harish SivakumarNo ratings yet

- CNC - MechatronicsDocument93 pagesCNC - Mechatronicskr_abhijeet7235658767% (3)

- FT Alarms and Events System Configuration GuideDocument288 pagesFT Alarms and Events System Configuration GuidenamhtsNo ratings yet

- C9 Marine Engine Employs ...Document3 pagesC9 Marine Engine Employs ...namhtsNo ratings yet

- TR 210 - Im L541 - 2 0eDocument7 pagesTR 210 - Im L541 - 2 0enamhtsNo ratings yet

- Manual 820-Pp AsDocument12 pagesManual 820-Pp AsjabalpuramitNo ratings yet

- Formal LettersDocument10 pagesFormal LettersCarlos Mario Mera SerpaNo ratings yet

- TL105 Data Sheet PDFDocument1 pageTL105 Data Sheet PDFnamhtsNo ratings yet

- 5 - The Iec En62305 Standard - BouquegneauDocument76 pages5 - The Iec En62305 Standard - BouquegneauQaed MahmoodNo ratings yet

- Basic Principles of Electrical SafetyDocument39 pagesBasic Principles of Electrical SafetynamhtsNo ratings yet

- SCADA Portal 2 0 OverviewDocument9 pagesSCADA Portal 2 0 OverviewnamhtsNo ratings yet

- WAF / ModSec + OWASP CRSDocument61 pagesWAF / ModSec + OWASP CRSAdzmely MansorNo ratings yet

- Gbillah Mark Terseer Resume Rev 2Document7 pagesGbillah Mark Terseer Resume Rev 2Mark GbillahNo ratings yet

- Bar Bending Schedule SummaryDocument78 pagesBar Bending Schedule SummarySaurabh KumarNo ratings yet

- Woodworking: Ancient EgyptDocument4 pagesWoodworking: Ancient EgyptsableannNo ratings yet

- Intellectual Property Rights: Legal and Economic Challenges For DevelopmentDocument4 pagesIntellectual Property Rights: Legal and Economic Challenges For DevelopmentLAW MANTRANo ratings yet

- Mahindra and Mahindra - Swaraj Tractor Division - Project Semester PresentationDocument43 pagesMahindra and Mahindra - Swaraj Tractor Division - Project Semester PresentationHarpreet Randhawa100% (2)

- How To Setup DICOM Send: Created On September 19, 2008Document6 pagesHow To Setup DICOM Send: Created On September 19, 2008frankxxxNo ratings yet

- Oracle 10g Installation On OEL-4 With ExplanationDocument29 pagesOracle 10g Installation On OEL-4 With ExplanationG.R.THIYAGU ; Oracle DBANo ratings yet

- Uniform Circular Motion LabDocument4 pagesUniform Circular Motion Labapi-249849134No ratings yet

- Mold Design CalculationsDocument23 pagesMold Design CalculationsARUN KUMAR Koterimadathil100% (2)

- Amplis Total PackDocument6 pagesAmplis Total PackGabriel MeirelesNo ratings yet

- 2014-2015 TT PDFDocument5 pages2014-2015 TT PDFQuỳnh Như PhạmNo ratings yet

- 3.data Summarizing and Presentation PDFDocument34 pages3.data Summarizing and Presentation PDFIoana CroitoriuNo ratings yet

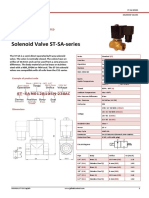

- Solenoid Valve ST-SA-series: 2/2-WAY Semi-Direct Operated Normally ClosedDocument5 pagesSolenoid Valve ST-SA-series: 2/2-WAY Semi-Direct Operated Normally ClosedVicente Moll ZamoranoNo ratings yet

- Computer Integrated Manufacturing 15ME62TDocument15 pagesComputer Integrated Manufacturing 15ME62TRaghuraj DanadamNo ratings yet

- DC-to-DC Converter in Maximum Power Point Tracking (THE PHOTOVOLTAIC POWER SYSTEM)Document14 pagesDC-to-DC Converter in Maximum Power Point Tracking (THE PHOTOVOLTAIC POWER SYSTEM)Andrei - Cristian SIMIONNo ratings yet

- Business Model CanvasDocument2 pagesBusiness Model CanvasMuhamad Arif RohmanNo ratings yet

- Section 26 Codeguard SecurityDocument52 pagesSection 26 Codeguard SecurityG30nyNo ratings yet

- 200892619594143687Document44 pages200892619594143687ArunNo ratings yet

- 9.2.2.6 Packet Tracer - Configuring Multiarea OSPFv2 InstructionsDocument3 pages9.2.2.6 Packet Tracer - Configuring Multiarea OSPFv2 InstructionsJessica GregoryNo ratings yet

- Improving The Transient Stability of Nigerian 330 KV Network Using SVCDocument13 pagesImproving The Transient Stability of Nigerian 330 KV Network Using SVCDavor JunušićNo ratings yet

- IoT and Machine Learning Approaches For AutomationDocument8 pagesIoT and Machine Learning Approaches For AutomationAbdul AzeezNo ratings yet

- Sensor de Flujo 9500ADocument40 pagesSensor de Flujo 9500AJuan Francisco Mora ZeladaNo ratings yet

- Distributed System 25 QuestionsDocument19 pagesDistributed System 25 QuestionsparassinghalNo ratings yet

- Installation & Operation ManualDocument25 pagesInstallation & Operation ManualDiego Mauricio Zapata GarciaNo ratings yet

- MOC Brochure EPC EngineeringDocument2 pagesMOC Brochure EPC EngineeringDragosNeaguNo ratings yet

- SAPM Term Project (Summer'12) - MIS 6308 (Group 8)Document45 pagesSAPM Term Project (Summer'12) - MIS 6308 (Group 8)Prashant RaiNo ratings yet

- History: Kota Tinggi Is A Town and Capital ofDocument7 pagesHistory: Kota Tinggi Is A Town and Capital ofChan Poh QuanNo ratings yet

- Joseph HenryDocument6 pagesJoseph HenryJhunnel MaganesNo ratings yet

- Data Science Brochure - JanDocument14 pagesData Science Brochure - Janakshaymit0No ratings yet