Professional Documents

Culture Documents

Chapter-1-5-Major-Revised-Final Naaaaa

Uploaded by

Kristian Mark RedondoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter-1-5-Major-Revised-Final Naaaaa

Uploaded by

Kristian Mark RedondoCopyright:

Available Formats

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

CHAPTER 1

INTRODUCTION

Over the years, ironing of clothes, particularly wearing well-ironed clothes have

played a part in our daily lives, for it contributes in the way we present ourselves through

our outward appearance. Ironing is done wherever garments are present, for instance, in a

single household, in a clothing industry, and the likes. An iron, particularly a clothes iron,

also known as flat iron or smoothing iron, was first known to be a household appliance

that was discovered and invented by Henry W. Seely in 1882 (History and Development

of Clothes Iron, 2017).

There are different types of clothes iron that has been developed over time, and is

continuing on progressing even up to this day. Some irons have steamers while some just

plainly use heat. In using a manual clothes iron, hands are the ones that does the job,

which requires a lot of repetitions in motion, in order to remove creases and wrinkles in a

garment. Not only that, upon ironing, folding would also then be required to ensure that

the ironed garment would remain as neat as it was ironed. Thus, ironing and folding at

most times come together when doing this certain chore. The said activity can affect

muscles, tendons, and joints that can be used thousands of times. According to Gallagher

and Heberger (2012), the risk of injury is even greater when repetitious jobs involve

awkward posture (e.g. bent or flexed wrists). One best example of this is the possible

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

1

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

development of Musculoskeletal disorders (MSDs). MSDs, particularly, work-related

Musculoskeletal Disorders (wMSDs), was found as a major problem, this is caused by

performing a physical work in a long period of time having done in a repetitive motion

and other factors such as force and awkward or incorrect position/posture. Moreover,

MSDs are injuries or dysfunctions that affect one’s muscles, bones, nerves, tendons,

ligaments, joints, cartilages, and spinal discs, and are among the leading cause of lost

workdays and are associated with a large economic burden According to American

Academy of Orthopedic Surgeons (2008). In United States, it has been accounted for the

one-third of all workplace injuries and injuries (Bureau of Labor Statistics, 2015).

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

2

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Background of the Study

Automation in ironing system tries to aid the problem of the society to decrease

the involvement of human activity and intervention that leads to fasten the production of

ironing clothes. The ironing technology has evolved from time to time, adding some

additional features for improving its safeness that will help its user to avoid some hazards

or disease. (Al-Zahrini, 2016). There are some innovation on the ironing technology with

a handheld features that still leads on the manual process of ironing. In manual process of

ironing, time and effort are needed for it to be done. It usually takes a person a day or so

in ironing a bulk number of clothes, thus, taking much of a person’s time in a day, thus

compensating time that could have been spent in some other activities. Manual ironing

requires repetitive movements in order to remove creases in a garment. Doing such

repetitive movements in a long period of time may lead to the development of MSDs.

Conducting household chores require much of a person’s time and effort. One of

these chores would be ironing of clothes. Although ironing technology have evolved as

time progressed, manual ironing, particularly in single household or even in some

businesses, are the ones still being observed even in our present time. The risk in

developing MSDs then can still then be possibly present and developed, given that

manual ironing has a handheld feature that consumes a lot of time and as stated earlier, is

done in a repetitive motion. Such issue contributed to the development and advancement

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

3

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

of technology in ironing, which involved the goal of eliminating judgmental aspects of

each factor, and replacing them with automated decision-making, wherein the machine

does all the work. An extensive effort on doing household chores can be categorized as a

work. Work-related musculoskeletal disorder needs to be considered. According to the

Occupational Health Safety Associations (OSHA), work-related musculoskeletal

disorders can be defined as a disorder that affects the muscles, skeleton, and related

tissue. This disorder has been suspected of causing a worker on a clothing industry or a

person on doing extensive work in ironing (Vasanth D, Ramesh N, Fathima FN,

Fernandez R, Jennifer S, Joseph B 2015).

With all these, given our fast-paced growing environment and the advancement of

technology, the proponents were inspired by how modern irons can possibly lead to

reduce the possibility on having a work-related musculoskeletal disorder and to

improvement of minimalized time consumption spent on ironing clothes and to Thus,

leading us to a study of developing a machine that automatically irons and folds fabrics,

therefore eliminating human effort in ironing and folding clothes.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

4

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Objective of the Study

The study entitled “Design and Development of Automated Steam Iron Machine

with Folding Mechanism” aims to reduce the time consumed on manual ironing and

folding process of clothes and the possibility of having a musculoskeletal disorder.

Specifically, the study aims:

To design a steam ironing machine and to assemble each components such as

linear guide and linear actuators.

To create a design for the control and the sensing unit of the machine using

microcontroller and light sensor.

To develop a program for the whole automation process of the machine using

Arduino IDE.

To determine the production capacity of the machine using time and motion

study.

To test the validity of the design and development of steam ironing machine with

folding mechanism in terms of:

a. Efficiency

b. Functionality

c. User-friendliness

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

5

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Conceptual Framework

INPUT PROCESS OUTPUT

Parameters: Software

Short-sleeve Development:

shirts (cotton) Programming

Hardware Hardware

Components: Development: Automated

Microprocessor Fabricating Steam Iron

Linear Guide Circuit Machine with

Light Sensor Designing Folding

Electric Steamer Mechanism

Linear Actuator Time and Motion

DC Motors Study

Wiper Motors

Stepper Motors Testing, Evaluation

Gripper Clamp and Validation

Software Components:

Arduino IDE

Figure 1. Conceptual Framework

In figure 1, it shows the conceptual framework of the study. The input parameter

of the machine is a short-sleeve shirt with a fabric type of cotton. By integrating the

hardware and software requirements and process it through programming, fabricating,

and circuit designing, and also conducting a test in order to validate the functionality of

the machine, it will come up with the automated steam iron machine with folding

mechanism.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

6

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Significance of the Study

The study aims to provide aid to the musculoskeletal disorder that occurs in

ironing and folding and to help its users to decrease the involvement of human activity

and to maximizing their time. Specifically, this study will benefit the following:

Laundry Shop Owners

This will benefit the laundry shop owners by adding an additional manpower and

business services for ironing and folding a clothes.

Ironing Workers

This will benefit the ironing workers to eliminate the risk of having a wMSD.

Moreover, it can also be more convenient for the elderly and even those who find it hard

to iron their clothes.

Future Researchers

Since this will be a reference and basis for the innovation and improvement that

will be used for conducting a study of the future researchers, as well as to the

advancement of the research regarding this study.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

7

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Scope and Limitations

The machine will be programmed to de-wrinkle and remove creases in a clothes

and fold it accordingly. It will be operated in an automated process wherein the user will

only have to put the clothes on the feeder of the machine, press the button, and the

machine will then take the clothes in for ironing and folding.

The machine can take up to 6 items in the first setting and it is in a continuous

loop. It will perform properly on a particular type of clothing, short-sleeved shirts. Such

type of clothing are the only ones the machine could execute the ironing and folding

properly, given that the machine has a single folding pattern that is systemized to work

for short-sleeved shirts only. The range of sizes of the short-sleeve shirt allowable in the

machine is from unisex short sleeve shirts from extra-small (XS) with a height of 60-

64cm, shoulder width of 33-35cm, and waist width of 26-29cm up to extra-large (XL)

with a height of 70-76cm, shoulder width of 43-46cm, and waist width of 38-42cm.

Other types of clothes such as shorts, pants, long-sleeve shirts, skirts, would still

be accepted by the automated steam iron machine, although, desired results would not be

met. The said types of clothes can undergo ironing process, but it cannot be folded

properly on the folding process because the automated steam iron machine has a single

folding pattern that is only for short sleeve shirts. Moreover, the machine is also

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

8

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

particular to the kind of fabric it would take in, since there are types of fabric that may be

damaged due to the presence of a steamer. Other types of fabrics such as acrylic, acetate,

nylon, polyamide, polyester, silk, and wool will be damaged because the temperature and

the pressure of the steamer is designed to work smoothly for cotton fabrics only.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

9

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Definition of Terms

Arduino Mega

Microcontroller that is developed from Arduino is able to control the sensors and

motors. This can be used as the control unit of the machine.

Electric Iron

Portable appliance, which has an electrically heated sole-plate and is used for

ironing textile materials (International Electrotechnical Commission, 2002).

Electric Motor

An electrical components that has a capability to converts electric energy into

mechanical energy.

Electric Steam Boiler

A closed tank where the water is stored and the water is boiled by means of

electricity which become the source of steam for ironing.

Efficiency

Measurement of the machine in terms of being efficient to accomplish its given

desired process.

Linear Guide

Mechanical components that assists the movement of a motor in a straight path.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

10

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Production Capacity Test

Type of testing in which the machine will be evaluated according to its capacity to

produce the right amount of output.

Steam Ironing

An iron having means to produce and supply steam to textile materials while

ironing. It can be provided with means to supply a shot of steam (International

Electrotechnical Commission, 2002).

Therbligs Analysis

A method used to count the number of motions, then eliminate the inefficient and

unproductive movements.

User-friendliness

Measurement of the machine in terms of its safety to its user and its difficulty to

the user.

Water Tank

This will serve as the water storage of the machine. The steam ironing process

will not work without water to steam.

Work-Related Musculoskeletal Disorders (wMSDs)

These are injuries or dysfunctions that affect one’s muscles, bones, nerves, tendons,

ligaments, joints, cartilages, and spinal discs. They include sprains, strains, carpal tunnel

syndrome (CTS), hernias, and connective tissue injuries of these structures. (American

Academy of Orthopedic Surgeons, 2008).

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

11

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

CHAPTER II

REVIEW OF RELATED LITERATURE

An article by Al-Zahrani (2016) showed what method and apparatus are needed to

come up with an automatic ironing machine that removes creases and wrinkles of an

article or clothes, which can be done using steam, without any part of the apparatus

touching the article or clothes. The water present needs time to undergo process before it

turns into steam. The system comprises a volumetric enclosure for receiving the article or

clothes to be steamed. Base for the support, power, enclosed volume for steamed water,

rotary engine, steam nozzle, receptacle for receiving the condensed steam, and electronic

control unit, are the ones that control all the stages of ironing operation. Without the

control unit, the whole automation process cannot be done on the machine. The machine

is automatically operated and the user only needs to hang the clothes on the automatic

steam iron machine and to remove the clothes after the ironing process (Al-Zahrani,

2016).

The inconsistencies of previous studies regarding the construction of steam boiler

of the steam ironing machine has a huge effect on the studies related on building steam

iron machine. Such studies helped on the development that caused a big innovation on

the steam boiler of the steam iron machine, which is nowadays used by the researchers to

come up with a safety structured steam iron machine. This study became a standard on

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

12

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

researches that needs to construct a safe electric boiler in different applications.

According to HF Chen (2002), the malfunctioning of the design of previous steam

ironing machine led to create a design of a safety structure that gives prevention on

exploding in the water tank, due to boiling process that causes the destruction of the

machine. Explosion occurs when the water tank is emptied and the boiling process

continues on the steam ironing machine. The safety structure of the steam ironing

machine improved the capability in controlling the operation of the steam ironing

machine through the basis of the water level on the water tank.

Every type of garments has a designated temperature to remove its creases and

wrinkles without causing any damage. According to Cheriaa et al. (2016), in achieving

the safety measurements of garment in the ironing process, the temperature depends on

the thermal properties and the construction of fabric or garment. In ironing specific

garments, the temperature that will soften and remove creases and wrinkles needs to be

determined. In this study, the first group of garments include acetate, acrylic, and

polyamide. The temperature range that is needed for it to be ironed without damages is

from 108 to 112 degree Celsius. For the second group of garments, polyester, silk, wool,

and viscose, the temperature range is from 148-152 degree Celsius. Lastly, for the third

group of garments, which are linen and cotton, the temperature range allowed is from 198

to 202 degree Celsius. 14 trials were needed to test the quality of the cloth after ironing

process using an industrial iron and a steam iron.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

13

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Relating to the study stated above, a type of fabric that needs a high temperature

to remove wrinkles and creases must use a steam iron machine for fast response. In the

article by Ridgeway (2018), entitled "Commercial Steam Iron" it stated that a commercial

steam iron machine is a tool to use for handling a large volume of clothes on ironing

process with fast time response on removing the creases and wrinkles. For constructing a

high-quality commercial steam iron machine, the design of the water reservoir must be

large enough so that one may not need to refill water on the reservoir as often as used.

And needed to use a durable materials for long and efficient operating life. The means of

removing the creases and wrinkles is steam. The steam pressure is often measured on a

bar or in PSI. A professional or commercial steam iron machine the pressure of steam

must be 3.0 bar or approximately 44psi for the maximum penetration of steam to remove

the wrinkles and creases on clothes.

Considering that ironing workers are known for doing a repetitive work done in a

repetitive motion, which is ironing and folding specifically, the study on Musculoskeletal

Disorders (MSDs) paved its way into studying the interaction between repetition and

force, and its relationship with MSDs. This is evident in the study by Gallagher and

Heberger (2013), wherein they examined the interaction amongst the three. In the course

of their study, 12 studies that allowed force-repetition interaction in relation with MSD

risk were identified, and results showed that only 10 showed a significant evidence of

interaction between the two factors. The totality of their research and their results

suggested that interdependence may be considered to be present in explaining the

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

14

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

relationship between force and repetition in relation with MSD risk. It was also

concluded by Gallagher and Heberger (2013) that, repetition seems to result in modest

increases in risk for low force tasks but rapid increases in risk for high force tasks, thus,

such interaction may be a representative of a fatigue failure process in affecting tissues.

Studies showed that there are risk factors on health from ironing, and some of

which, are the work-related Musculoskeletal Disorders (wMSDs). wMSDs as defined by

Occupational Safety Health Association (n.d.) are disorders of muscles, skeleton, and

related tissue, which was concluded to have been caused by one’s occupation or one’s

line of work. It is also known to be one of the leading causes of lost workdays in industry,

as it is proved and shown to be more severe as compared to average nonfatal workplace

illness, which requires longer recovery period, thus affecting lost workdays as well as

economic costs (American Academy of Orthopaedic Surgeons, 2008). The said disorders

was thoroughly discussed in a study conducted by KCK and Ratri (2018), entitled “Study

on prevalence of MSDs among Ironing Workers in Occupational Laundry Shops.” Their

study included 300 participants, particularly, ironing workers, with the objective of

estimating the prevalence of MSDs to their study population, and at the same time,

identifying associations between key selected factors and MSDs among their study

population. Results showed high prevalence of MSDs on ironing workers, which

garnered a percentage of 88%, as pain symptoms in shoulders (76.66%), low back pain

(54.76%), and knee pain (51.90%) were also observed among them. Furthermore,

statistical significant associations have been proved between height and weight of the

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

15

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

person, working hours per day, weight of the iron box, and shoulder pain (P<0.05). The

same is true with height and weight of the person, quantity of clothes per day, and knee

pain (P<0.05).

Related Studies

According to Al-Zahrani (2016), there are two examples of automatic ironing

system that has its advantages and disadvantages depending on its use. The first example

is an automatic ironing system that contains two large presses, which possess heat and

steam. The two presses have a large surface area and is therefore much faster to use than

the manual iron. However, this large press automatic ironing system is limited to some

flat articles, such as linens. The other of automatic ironing system mentioned in his study,

comprise an upright enclosure that irons an article by means of steam. This system is for

non-flat articles or clothes. However, this type of system needs to consider that largest

article as the input. Therefore, the said system would not be energy and time efficient

when ironing a small article having small amount of load.

According to Kaushik et. al. (2014), automated ironing machine is designed as an

innovation in technology of ironing with motorized mechanism for improving the

effectiveness of ironing various clothes in terms of time and the difficulties in the task of

ironing. The assembled gear used for transferring motion to move the irons within the

chains. The two direction of movements of irons (X and Y) are based on the chain and

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

16

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

sprocket mechanism. The design of the study also helps the needs of requiring a

minimum power or energy source for operation by using two stepper motors as actuators

and two manual irons. Since it is a low powered device, the automatic ironing machine

can be used in a single household.

According to Gomesh et al. (2013), a folding machine that is totally automated

and uses solar panel as its main source along with servo motor that acts as the actuator of

the machine, can fold a cloth faster than the manual process. A person can roughly fold a

single cloth with an average time of 4 seconds compared to the automated folding

machine that can do it within 2 seconds. By folding a number of 1000 clothes, a person

can get the job done in 67 minutes, while the machine only needs 33 minutes to finish it.

Therefore, the machine reduces the process on folding a cloth by half. Building an

automated folding machine that consists of microcontroller, servo motors, and relay

switches is way cheaper than a folding machine that uses computer numerical control

(CNC). Thus, it can eventually become a trend in some several industries such as clothing

lines, laundry services, hospitals, and the likes, because of its cost.

Moreover, a folding machine that consists servo motor for exerting force to the

machine, a sensor that detects the position of the cloth, and a microcontroller as the

control unit of the operation, can be used in the industry of clothing for processing a cloth

in a much lessen time of production. The automated folding machine can be a new trend

on conventional way of household chorus in terms of folding clothes because it reduces

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

17

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

time on a cloth to be fold. In the clothing industry, it is cheaper to invest rather than

investing a folding machine that operates using computer numerical control (CNC)

because both can perform the same operation and principle. (Zahri and Somantri, 2018)

Synthesis

With the related literature mentioned above, previous studies and development of

automatic ironing machine by means of steam by Al-Zahrani (2016) and Kaushik et. al.

(2014) both clearly reduced the time and difficulty compared to manual ironing. Though,

their machines differ in terms of size, the mechanisms used, and types of article or

clothes their machines can accommodate. Furthermore, a recent study of a fully

automated folding machine made by Gomesh et al. (2013) proves that the use of folding

machine reduces the process of folding of clothes by half. Both ironing and folding

machine focused on saving energy and time as well as avoiding the risks of having work-

related musculoskeletal disorders (wMSDs) in doing the particular household chores.

Based from the related materials found, no study has been made as to combine

these two areas. This study was undertaken to develop an ergonomically designed

machine that will combine the concepts of the said machines into one, in which will

eliminate human labor in ironing and folding and eventually might become a trend in

industries in the near future.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

18

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

CHAPTER 3

METHODOLOGY

This chapter presents the type of the research design, system model, flowchart,

block diagram, and the specification of the machine. It will also elaborate on the

procedure and methods of the researchers, as well as the different tests and evaluations

that will be conducted to assess the study.

Research Design

The concept of this research is to create a steam iron machine with a folding

mechanism that operates automatically. To determine if the research can achieve its

objective, the researchers use Experimental Approach wherein the machine will be

compared to the manual ironing process in terms of benefits, effectiveness, speed and

risks. The researchers will also determine the availability of the machine if it can be used

for individual ironing workers, in laundry services, or clothing manufacturing industry in

terms of its size and availability. The machine will be tested based on its efficiency,

functionality, and user-friendliness. The machine will also undergo production capacity

test, in order to determine the number of output capacity of the machine. Afterwards, the

machine will be compared to the manual process of ironing and folding of clothes.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

19

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Research Instrument

The proponents will conduct time and motion study on the manual ironing and

folding process and in the machine. In this study, the time consumption on manual

ironing and folding process and the machine will be observed. This method will be used

to determine the production capacity of the manual process of ironing and folding, and

also the machine.

Figure 2 Motion and Time Observation Sheet

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

20

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Rapid Upper Limb Assessment (RULA) - RULA is a survey method developed

for use in ergonomic investigations of workplaces where work related upper limb

disorders are reported. RULA is a screening tool that assesses biomechanical and postural

loading overall body with particular attention to the neck, trunk and upper limbs.

Figure 3 RULA Employee Assesment Worksheet

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

21

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Project Development

Project Design and Determination of Process

Selection of Hardware and Software Components

Procurement of Components

Examination of the Components

Construction of the Machine Design and System

Testing and Evaluation of the Machine

Adjustment and Finalization of the Machine

Fabrication of Hardware and Software

Figure 4 Project Development

Figure 4 shows the proponents project development starting from project

designing and determination of process up to the fabrication of hardware and software of

the machine. Below is the detailed discussion of the project development of the machine.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

22

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

1. Project Design and Determination of Process

In this procedure, the proponents will gather ideas and plan to determine the final

design structure of the machine, its whole process, and automation.

2. Selection of Hardware and Software Components

The proponents will determine the needs of the machine in terms of proper

hardware and software components that will be used in creating the machine.

3. Procurement of Components

The proponents will check the availability of the components in the Philippine

market and gather the needed components for the construction of the machine.

4. Examination of the Components

The proponents will check the functionality of the components, whether it is

working properly and if it will meet its desired use in the machine.

5. Construction of the Machine Design and System

This procedure includes building the whole structure of the machine, integrating

the components, and creating a program that will be suited on the proper function

and process of the machine.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

23

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

6. Testing and Evaluation of the Machine

In this procedure, the machine will undergo on testing and evaluation to

determine if the constructed design and system of the machine is working

properly.

7. Adjustment and Finalization of the Machine

After conducting some tests and evaluations, changes and adjustment will be

made if there are malfunctions and technicalities. After some adjustments, the

machine needs to be finalize.

8. Fabrication of Hardware and Software

As the machine was totally finalized, it needs to undergo on the process of

fabrication. The machine, its components and program will be verified by some

professionals.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

24

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

System Model

Figure 5 Waterfall Model

Figure 5 shows the system model of the proponents will implement in this project

is the Waterfall Model. In this model, phases are processed and completed one at a time

and do not overlap. This makes the waterfall model the most viable model for the project

since the project follows a sequence to work. Each phase or sequence can be tested and

developed separately for its functionality and when done, theses phases are cascaded or

integrated together in which progress is seen steadily downwards through the phases.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

25

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

System Flowchart

Switch off

circuit

breaker

End

Press

Reset

All process stop

and goes back to

initial position

Start

Figure 6 System Flowchart

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

26

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Block Diagram

Figure 7 Block Diagram

Figure 7 shows the simplified block diagram that shows the flow of process and

the system of the machine. The microcontroller plays a big role in the machine,

accountable on the automation of the buttons, linear actuator, light dependent resistor,

temperature sensor, wiper motors, servo motors, stepper motors and limit switch. Light

dependent resistor will alert the microcontroller if there is a cloth entered in the machine.

It controls the actuator for lifting up and pressing down the steam press to the clothes.

Also, it will dictate the movement and control of the three different types of motors.

Limit switches will alert the microcontroller, if the movement of specific part hit its limit.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

27

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Project Plan Specification

A. Machine Design

Figure 8 Isometric Side View of the Machine Design

Figure 9 Front View of the Machine Design

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

28

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Figure 10 Right Side View of the Machine Design

Figure 11 Left Side View of the Machine Design

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

29

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

B. Machine Specification

Control Unit

For the control unit of the machine, the microcontroller that will be used is Arduino Mega

2560 R3. The microcontroller is accountable for the whole automation and controls of the

machine.

Figure 12 Actual Photo of Arduino (Mega 2560 R3)

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

30

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Sensing Unit

For the sensing unit of the machine, the sensor that will be used is light dependent

resistor. Light dependent resistor is a variable resistor that changes the resistance

depending on the intensity of light it detects. It will be used for sensing if there are

clothes that will be fed up before the start of the process.

Figure 13 Actual Photo of Light Dependent Resistor Module

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

31

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

DC Motor

DC Motor will be used for the horizontal movement of the gripper. The operating voltage

is 12V DC, with a speed of 150rpm.

Figure 14 Actual Photo of DC motor

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

32

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Relay Module

Relay will act as a switch for the motors in the machine. Relay is a component that

operates like a switch. Most of the relay has electromagnets which will able to

mechanically operate a switching mechanism. In the machine, relay will act as a switch

for the DC Motors. The type of relay that will be used in this machine is a low trigger

relay. Two relay module will be used in this machine, a 4-channel and 8-channel relay

module.

Figure 15 Actual Photo of Relay

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

33

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Wiper Motor

Wiper Motor will be used for the folding pattern of the machine. This motor

operates at 12V DC, a stall current of 10A and a motor power of 120W.

Figure 16 Actual Photo of Wiper Motor

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

34

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Servo Motor with Gripper Clamp

This motor is accountable for the clipping of the clothes from the feeder and put it

on the platform of the machine. It operates at 5V DC, with a speed of 0.20 seconds,

output torque of 3.3 kg.

Figure 17 Actual Photo of Gripper Clamp with Servo Motor

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

35

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Stepper Motor

Stepper Motor is accountable for the vertical movement of the feeder and the horizontal

movement of the gripper. The operating voltage of this motor is 24V and a current of

30A. The step angle of this motor is 1.8 degree per step. This motor can be drive only by

a stepper motor driver.

Figure 18 Actual Photo of Stepper Motor

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

36

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Linear Guide

Linear guide is a mechanical component that supports the linear motion of the motor. In

this machine, it will be used as guide for the vertical movement of the gripper clamp and

the feeder.

Figure 19 Actual Photo of Linear Guide

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

37

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Folding Pattern

The folding motion of the machine will be lifted up by using gears that is powered by a

Wiper Motors. The folding pattern will be made out of wood.

Figure 20 Folding Pattern

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

38

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Project Testing Evaluation and Validation

The automatic steam ironing machine with folding mechanism will undergo on

different testing and evaluation procedures that the proponents will use in order to see its

functionality and if it is feasible to use in our daily life.

Production Capacity Test

This testing defines the number of ironed clothes that will produced by the

machine whole cycle including the folding mechanisms to identifying the desired time for

steaming the clothes and time needed for folding. In this testing, the proponents will

conduct a test on the number of ironed clothes that will be produced in a certain period of

time.

Efficiency Test

The machine reduces the number of hand motions compared to the manual

process. To test the efficiency of the machine, the researchers will compare the number

of hand motions in manual process and in the machine. The researchers checked also

quality of the clothes that will be processed by the machine. The researchers used the

given formula in order to test the efficiency of the machine.

Manual – Automated x 100

Manual

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

39

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

User-Friendliness Test

The purpose of this test is to identify if the machine are easily to use and is not

harmful from the user. In line with this, the proponents will validate the user-friendliness

of the machine by conducting a survey to the laundry shop workers and ironing workers

of Brgy. Biclatan, General Trias, Cavite, the questions under the survey comprises on

comparing the automated machine and the manual process of ironing in terms of

hazardous and harmful effects and if it is easy to use.

Functionality Test

The purpose of this test is to provide the detail of the whole functionality of the

machine. The proponents will inspect the overall desired function of the machine. The

functions will be listed and will be checked if it meet its desired operation.

Validation

For the validation, the proponents will conduct a survey within the deployment of

the prototype. The survey indicates questions that will evaluate the performance, features

and the user-friendliness on the machine. The proponents will use expert sampling in

having the number of respondents of the survey. The respondents of the survey falls

under to the laundry shop workers and ironing workers. The respondents tested and

evaluated the machine with a scale of 1 to 5 rating scale depending on their point of view.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

40

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

CHAPTER 4

RESULTS AND DISCUSSION

This chapter contains the presentation of the machine design, discussion of its

work flow operation. The different testing procedures, evaluation and validation and the

interpretation of the gathered data and results. And the business model of the machine.

Presentation of Machine Design

Figure 21 Left Side View of the Machine

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

41

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Figure 22 Top View of the Machine

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

42

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Figure 23 Front View of the Machine

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

43

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Figure 24 Right Side View of the Machine

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

44

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Figure 25 Back View of the Machine

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

45

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Figure 26 Actual Photo of Linear Actuator

Linear actuator is a mechanical component that creates a motion within a straight

path. This components is accountable for lifting up and pressing down the steam press of

the machine.

Figure 27 Actual Photo of Electric Garment Steamer

Electric Garment Steamer is a device that can remove wrinkles and creases due to

steam. This is used as a heating element to heat up the metal coil attached to the metal

plate that serves as the steam iron of the machine.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

46

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

The prototype was built for ironing and folding of clothes automatically, pressing

the start button to start the operation, reset button to reset the operation, and button for

iron only process. The prototype comprises an electronic components such as

microcontroller, wiper motors, stepper motors and its driver, servo motors, limit switches,

light dependent resistor, linear actuator, temperature and humidity sensor, and steamer.

The whole operation of the prototype was based on the actual design and the flow chapter

discussed in the previous chapter. The integration of components leads to the following

operation with the intended function of the prototype:

1. The boiling process of the steamer is manually operated. As the machine is

plugged, the machine will move to its original position. The user must switch the

steamer “ON” first in “HIGH” mode. A temperature sensor will sense the

temperature of the metal plate. If the metal plate is ready, the buzzer will activate,

indicating that the start button can be pressed.

2. The machine has three buttons, a start button, a reset button, and a button for

ironing process only. The operation of the machine will start after pressing the

start button. The start button and button for iron process is disabled until the

temperature sensor senses the desired temperature in the metal plate. The button

for ironing process will alarm the microcontroller to iron the cloth in the flat form.

3. The microcontroller powers up the DC Motor to control the vertical movement of

the gripper in the prototype. Then the stepper motor is powered up, giving a

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

47

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

horizontal movement to gather clothe. The microcontroller will power up the

servo motor to grip the cloth in the feeder.

4. The gripper then moves backward a little bit, placing the cloth under a light

dependent resistor. The light dependent resistor from the gripper will sense if the

gripper gathered a cloth. If the sensor does not sense a cloth from the gripper, the

feeder will move downward and gather the next cloth.

5. As a cloth is laid in the platform, the gripper returns to its starting position. Then,

microcontroller powers up the linear actuator and commands it to press down the

metal plate to the cloth. Ironing process takes up 20 seconds to iron the cloth then

the steam press will go back to its original position.

6. After the ironing process, then proceeds to folding process. Every movement of

the pattern has a wiper motor to give a driving force. In every position in folding

process, limit switch will indicate the microcontroller that it folds the cloth, then

proceeds to next position. The last part of the folding process is to throw the cloth

in the tray. When the cloth is place in the tray, tray moves downward.

7. In every movement, there are limit switches, it will indicate the microcontroller

that it reached its limit, proceeds to the next step.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

48

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Results of Testing Evaluation and Validation

The proponents conducted some tests to evaluate the machine. The two objectives

of the test are to measure the production capacity and efficiency of the machine. The

results gathered in those tests were recorded and interpreted.

Production Capacity Test

The proponents conducted time and motion study on the manual process of

ironing and folding. In this study, the time consumption of the three different operators

was observed, measuring the time intervals in every procedure. The standard time of the

machine will determine the production capacity output of the manual process.

The researchers conducted motion and time observation of the manual process of

ironing and folding of clothes. The study comprises of five different trials with three

different operators, one piece of cloth in each trial, and with seven procedures in order to

finish the whole process. The total selected and standard time given in the figure is the

average time being consumed for the whole manual process. The Allowances considered

for getting the standard time are the personal allowances 5%, Basic Fatigue 4%, Standing

allowance 2%, Lighting Allowance 2% (well below) and Abnormal Position Allowance

2% in total of 15% Allowance.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

49

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Given the formula of standard time:

Standard Time = Observe Time (Percentage allowance + 1)

Output per minute = 1 / standard time

Output per hour = Output per minute x 60

Output per day = Output per hour x 8

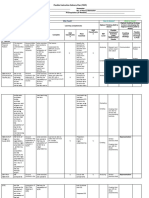

Table 1 Average Data for Time and Motion Study for Manual Process

In table 1, based on the time and motion study, the average standard time for the

three operators is 3.1191 minutes. The manual process of ironing and folding can produce

a total output of 19 piece per hour, and 154 pieces per day. The output capacity per day of

the manual process were determined based on 8 working hours.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

50

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

The proponents conducted also a time and motion study on the machine to

determine its production capacity. Then the proponents compared the production capacity

of the manual process and the machine.

Based on the results of time and motion study of the machine, the time interval for

every procedure of the machine was recorded. From getting the cloth from the feeder

until it was fully processed on the machine. The standard time of the machine is 3.1137

minutes. It means that it consumes an average time of 3 minutes and 7 seconds to process

a cloth through the machine.

Table 2 Time and Motion Study of Machine

STANDARD OUTPUT PER OUTPUT PER OUTPUT PER

TIME MINUTE HOUR DAY

3.1130 0.3212 19.27 154.19

In Table 2 shows the production capacity of the machine based on the standard

time gathered on the time and motion study of the machine. The capacity of the machine

to produce an output is 19 pieces per hour and 154 pieces per day. If the machine will

operate above 8 hours, it exceeds the production capacity on manual process of ironing

and folding.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

51

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Efficiency Test

The efficiency testing of the machine was divided into two parts. The first part is

for the quality checking of output in the machine. The second part is comparing the

number of hand motions upon using the machine to the manual process.

To test the efficiency of the machine based on the number of hand motions, the

researchers conducted therbligs analysis to gather the total number of hand motions in

manual process and in the machine. Then, the results will the used to calculate the

efficiency of the machine.

This testing discussed the quality output of the machine. The proponents checked

and determined if the clothes were processed with a good result. Thus, giving a good

quality output of the machine. Different types of clothes was used in this testing.

Note: ✓ - Good Output x – Bad Output

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

52

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Table 3.1 Output Quality Checking for Extra Small Size

TRIAL NO. CONDITION REMARKS

1 ✓ OK

2 ✓ OK

3 x Machine did not fold properly

4 ✓ OK

5 x Machine did not fold properly

6 ✓ OK

7 ✓ OK

8 ✓ OK

9 ✓ OK

10 ✓ OK

11 x Did not grip the cloth properly

12 ✓ OK

13 ✓ OK

14 ✓ OK

Table 3.1 shows the results of the output of the machine for short sleeve shirt in

extra-small sizes. Three out of five trials gives a good quality output of ironing and

folding of clothes. The researchers found out that error occurs on the gripping function

and folding function since the cloth is too small for the folding pattern of the machine.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

53

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Table 3.2 Output Quality Checking for Small Size

TRIAL NO. CONDITION REMARKS

1 ✓ OK

2 ✓ OK

3 ✓ OK

4 ✓ OK

5 ✓ OK

6 ✓ OK

7 ✓ OK

8 ✓ OK

9 ✓ OK

10 ✓ OK

11 ✓ OK

12 ✓ OK

13 ✓ OK

14 ✓ OK

Table 3.2 shows the results of the output of the machine for short sleeve shirt in

small sizes. The machine gives a good quality of ironing and folding output for short

sleeve shirt in small size.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

54

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Table 3.3 Output Quality Checking for Medium Size

TRIAL NO. CONDITION REMARKS

1 ✓ OK

2 ✓ OK

3 ✓ OK

4 ✓ OK

5 ✓ OK

6 ✓ OK

7 ✓ OK

8 ✓ OK

9 ✓ OK

10 ✓ OK

11 ✓ OK

12 ✓ OK

13 ✓ OK

14 ✓ OK

Table 3.3 shows the results of the output of the machine for short sleeve shirt in

medium size. The machine gives a good quality of ironing and folding output for short

sleeve shirt in medium size.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

55

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Table 3.4 Output Quality Checking for Large Size

TRIAL NO. CONDITION REMARKS

1 ✓ OK

2 ✓ OK

3 ✓ OK

4 ✓ OK

5 ✓ OK

6 ✓ OK

7 ✓ OK

8 ✓ OK

9 ✓ OK

10 ✓ OK

11 ✓ OK

12 ✓ OK

13 ✓ OK

14 ✓ OK

Table 3.4 shows the results of the output of the machine for short sleeve shirt in

large size. The machine gives a good quality of ironing and folding output for short

sleeve shirt in large size.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

56

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Table 3.5 Output Quality Checking for Extra Large Size

TRIAL NO. CONDITION REMARKS

1 ✓ OK

2 ✓ OK

3 ✓ OK

4 ✓ OK

5 ✓ OK

6 ✓ OK

7 ✓ OK

8 ✓ OK

9 ✓ OK

10 ✓ OK

11 ✓ OK

12 ✓ OK

13 ✓ OK

14 ✓ OK

Table 3.5 shows the results of the output of the machine for short sleeve shirt in

extra-large size. The machine gives a good quality of ironing and folding output for short

sleeve shirt in extra-large size.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

57

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Table 4 Therbligs Analysis in Manual Process of Ironing and Folding

Motion No. Motion Element Item Explanations

1 Reach Shirt Reaches for the shirt

2 Grasp Shirt Grabs the shirt

Holds the cloth to place in the ironing flat

Hold Shirt

3 form

Transports the cloth to place in the ironing

Transport Load Shirt

4 flat form

5 Release Load Shirt Release the shirt to the ironing flat form

6 Position Shirt Position the shirt neatly

7 Reach Spray bottle Reaches for the water spray bottle

8 Grasp Spray bottle Grabs the water spray bottle

9 Hold Spray bottle Holds the water spray bottle

10 Use Spray bottle Uses the water spray bottle

Transports the water spray bottle to the

Transport Load Spray bottle

11 table

12 Release Load Spray bottle Release the water spray bottle to the table

13 Reach Flat iron Reaches for the flat iron

14 Grasp Flat iron Grabs the flat iron

15 Hold Flat iron Holds the flat iron

Transport the flat iron to the ironing

Transport Load Flat iron

16 platform

17 Use Flat iron Uses the flat iron

Transport the flat iron to its original

Transport Load Flat iron

18 position

19 Position Flat iron Positions the flat iron

Release the flat iron to its original

Release Load Flat iron

20 position

21 Inspect Shirt Inspects for the shirt after ironing process

22 Reach Shirt Reaches for the shirt

23 Grasp Shirt Grabs for the shirt

24 Hold Shirt Holds for the shirt to fold

25 Position Shirt Positions for the shirt

26 Release Load Shirt Release the shirt

27 Grasp Shirt Grabs for the shirt

28 Hold Shirt Holds for the shirt to fold

29 Position Shirt Positions for the shirt

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

58

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Transport the flat iron to the ironing

Transport Load Flat iron

30 flatform

31 Use Flat iron Uses the flat iron on the left side of shirt

Transport the flat iron to its original

Transport Load Flat iron

32 position

33 Position Flat iron Positions the flat iron

Release the flat iron to its original

Release Load Flat iron

34 posistion

35 Inspect Shirt Inspects for the shirt after ironing process

36 Grasp Shirt Grabs for the shirt

37 Hold Shirt Holds for the shirt

38 Position Shirt Position the shirt, folding the right side

39 Release Load Shirt Release the shirt to the table

40 Grasp Shirt Grabs for the shirt

41 Hold Shirt Holds for the shirt

42 Position Shirt Position the shirt, folding the left side

43 Release Load Shirt Release the shirt to the table

44 Reach Shirt Reaches for the shirt

45 Grasp Shirt Grasbs for the shirt

46 Hold Shirt Holds for the shirt to fold

47 Transport Load Shirt Finishes the folding process

48 Position Shirt Positions the shirt to the table

Release the shirt to the table, ready for the

Release Load Shirt

49 next shirt

Table 4 shows the therbligs analysis in manual process of ironing and folding of

cloth to get the number of hand motions to iron and fold a single cloth. The manual

process takes a total of 49 hand motions to finish the process.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

59

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Table 5 Therbligs Analysis in the Machine for Full Automation Process

Motion No. Motion Elements Item Explanation

1 Reach Acrylic Sheet Reaches for the acrylic sheet

2 Grasp Acrylic Sheet Grab for Acrylic Sheet, ready to pull

Pulls the acrylic sheet, prepares to add

3 Position Acrylic Sheet shirt

4 Hold Acrylic Sheet Hold the acrylic sheet

5 Reach Shirt reaches for the shirt

6 Grasp Shirt Grabs the shirt

7 Hold Shirt Holds the Shirt

8 Transport Load Shirt Transport the shirt to the acrylic sheet

9 Released load Shirt Release the shirt to the acrylic sheet

10 Position Shirt Position the shirt neatly

Position the acrylic sheet to its original

Position Acrylic

11 position

Shirt and

Inspect

12 Acrylic Sheet Inspects the shirt and the acrylic sheet

13 Reach Button Reaches for button

14 Hold Button Press the button

Release the button, the machine starts

Released load Button

15 the operation

Table 5 shows the therbligs analysis in the machine using the full automation

process to get the number of hand motions to iron and fold a single cloth. The full

automation process only needs a total of 15.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

60

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Table 6 Therbligs Analysis for Semi-Automated Process

Motion No. Motion Element Item Explanation

1 Reach Shirt Reach for the shirt

2 Grasp Shirt Grabs the shirt

3 Hold Shirt Holds the shirt

4 Transport Load Shirt Transport the shirt to the platform

5 Release load Shirt Release the shirt

6 Position Shirt Position the shirt neatly

7 Reach Button Reach for the button

8 Hold Button Press the button

Release the button and the machine

9 Release load Button

will operate

Table 6 shows the therbligs analysis in the machine using the semi-automated

process to get the number of hand motions to iron and fold a single cloth. The semi-

automated process only needs a total of 9 hand motions.

Table 7 Efficiency of the Machine

Number of Hand Motions Efficiency

Machine Manual (%)

Fully Automated 15 49 69.39

Semi-Automated 9 49 81.63

Table 7 shows the efficiency in terms of number of hand motions. The number of

hand motions in manual process and in the machine was gathered based on the therbligs

analysis. Using the formula stated, the percent of number of hand motions reduce was

gotten. Based on the results given, the machine is considered efficient.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

61

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Functionality Test

Table 8 Functionality of the Machine

Note: ✓ - Successful x – Not Successful

TRIAL

FUNCTION

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Start button ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Reset button ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Iron Process Button ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Temperature Sensor ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Buzzer Indicator ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Sensor for Cloth Detection ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Upward Movement of ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Motor in Feeder ✓ ✓ ✓ ✓ ✓

Downward Movement of ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Motor in Feeder ✓ ✓ ✓ ✓ ✓

Upward Movement of ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Motor in Gripper ✓ ✓ ✓ ✓ ✓

Downward Movement of ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Motor in Gripper ✓ ✓ ✓ ✓ ✓

Forward Movement of ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Motor in Gripper ✓ ✓ ✓ ✓ ✓

Backward Movement of ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Motor in Gripper ✓ ✓ ✓ ✓ ✓

Gripping Operation of ✓ ✓ ✓ ✓ ✓ ✓ ✓

Motor in Gripper ✓ ✓ ✓ x ✓ x x

Downward movement of ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Linear Actuator ✓ ✓ ✓ ✓ ✓

Upward movement of ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Linear Actuator ✓ ✓ ✓ ✓ ✓

Motor in Bottom part of ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Folding ✓ ✓ ✓ ✓ ✓

Motor in Middle part of ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Folding ✓ ✓ ✓ ✓ ✓

Motor in Left part of ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Folding ✓ ✓ ✓ ✓ ✓

Motor in Right part of ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Folding ✓ ✓ ✓ ✓ ✓

Motor in Upper part of ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

Folding ✓ ✓ ✓ ✓ ✓

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

62

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Table 8 shows the testing of the functionality of the machine. The functions listed

in the table above are the whole activities of the machine that needs to be tested. As can

be seen in the table, the proponents found out that error occurs on the gripping function

of the machine.

Respondents of the Study

Twenty respondents were identified using convenient sampling technique for the

validation, evaluation and user-friendliness test. Convenient sampling technique were

employed because of the availability and willingness of the respondents to be involved

when the survey was conducted. Those respondents are people who works for the laundry

shop and ironing workers. These respondents had a range age between 19 to 26 years old

with an average of 22.10 years old and standard deviation of 2.198 years old.

Preliminary Information

Table 9 Response of the Respondents if the Designed and Developed Iron Machine is

Easy to Use

Response Frequency Percent

Yes 18 90

No 2 10

Total 20 100

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

63

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Table 10 Response of the Respondents if the Designed and Developed Iron Machine is

Harmful to Use

Response Frequency Percent

Yes 13 65.00

No 7 35.00

Total 20 100.00

Table 11 Response of the Respondents if they are willing to use the Designed and

Developed Iron Machine

Response Frequency Percent

Yes 15 75.0

No 5 25.0

Total 20 100.0

Table 12 Mean Comparison of the Respondents’ RULA Results in Using the Regular and

Designed and Developed Iron Machine using Wilcoxon Signed Ranks Test

Mean

Std. Difference

Group Mean Z p-Value Interpretation

Deviation (Regular-

Developed)

Regular 7.35 0.587 The pain

4.35 -4.093 0.000** difference is

Machine 3.00 0.000

significant

Note:

For Mean: 7 Investigate and Implement Change

6–5 Further Investigation, Change Soon

4–3 Further Investigation, Change may be needed

2–1 Acceptable Posture

For p-Value: * * - With Significant Difference at 0.05 level of confidence.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

64

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Table 13 Mean Validation on the Efficiency and User-Friendliness of the Designed and

Developed Iron Machine

Std.

Characteristics of Quality Steam Iron Mean Interpretation

Deviation

1. Produce right amount of steam with power

4.30 1.081 Very Good

temperature to iron the clothes properly.

2. Neatly iron the whole surface of clothes 4.10 0.788 Good

3. The iron surface of the machine is non-stick 4.60 0.503 Very Good

Steam Assist 4.33 0.552 Very Good

4. Response time of the machine. 3.15 0.671 Fair

5. Quickly removes the creases and wrinkles in

3.40 0.503 Good

clothes.

Time 3.28 0.444 Fair

Efficiency 3.80 0.370 Very Good

6. Ability to iron the entire clothes inserted. 3.15 0.671 Fair

7. Suitability of the machine’s size to place in

4.15 0.745 Good

your house.

Size 3.65 0.587 Good

8. Cooling down time required for the machine

4.20 0.894 Very Good

upon usage.

9. Possibility to touch the iron surface that can

1.50 0.607 Very Poor

cause injury.

10. Safeness from the possibility for fire

3.55 0.510 Good

incident to occur through this machine.

Safety 3.08 0.373 Fair

User-Friendliness 3.37 0.320 Fair

Note: 5. 00 – 4.20 Very Good 4.19 – 3.40 Good 3.39 – 2.60 Fair

2.59 – 1.80 Poor 1.79 – 1.00 Very Poor

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

65

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Statistically, when RULA scores in using the regular iron is compared to the

RULA in using the designed and developed iron machine, the difference of the two (2)

means is very significant with a p-Value of 0.000 which is less than 0.05 level of

confidence. This means that the decrease of 4.35 from mean score of 7.35 using regular

iron machine to mean score of 3.00 in RULA in using the designed and developed iron

machine is really significant. That using the designed and developed iron machine, it will

lessen the pain of the users.

To validate the efficiency, steam assist and time were evaluated by the

respondents. In terms of steam assist, respondents agreed that the designed and developed

iron machine is very good in it with a mean score of 4.33 and standard deviation of 0.552.

However, time was rated by the respondents as fair with a mean score of 3.28 and

standard deviation of 0.444. This yields to a very good efficiency with a mean score of

3.80 and standard deviation of 0.370.

In the validation of user-friendliness, size and safety were used. For size of the

designed and developed steam iron machine, respondents rated it as good with a mean

score of 3.65 and standard deviation of 0.587. Meanwhile, safety was rated as fair with

mean score of 3.08 and standard deviation of 0.320. This yields the user-friendliness to

be fair with mean score of 3.37 and standard deviation of 0.320.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

66

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

RULA Assessment

The proponents conducted a Rapid Upper Limb Assessment or RULA. This is a tool used

to measure the degree of strain on the affected body parts of the ironing workers while

manually iron and fold clothes and using the machine.

Figure 28 RULA Assessment on Manual Process of Ironing and Folding

Figure 28 shows the result of RULA Assessment on manual process of ironing

and folding. Part A focuses on arm and wrist analysis having a score of 6. Part B focuses

on neck, trunk and leg analysis having a score of 1. The score in table C added to the

Activity score of 1 gives the final RULA score of 7. This is interpreted into Very High

Risk that needs to implement for immediate changes.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

67

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Figure 29 RULA Assessment Using the Machine

Figure 29 shows the result of RULA Assessment on the users while using the

machine. Upon using the machine, the result of RULA Assessment on part A is 2 and on

part B is 1. The score gives the final RULA score of 3. This which is interpreted into

Negligible Risk and no action is required.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

68

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Analysis and Interpretation of Data

Data were gathered from different testing procedures; the production capacity

test, functionality test, efficiency test, and user-friendliness test and validation. The first

one revolves around the production capacity of the machine. The production capacity test

evaluates the number of output that the machine can produce. On manual process, it takes

3 minutes and 7.146 seconds to iron and fold a single cloth. In a span of 1 hour, it can

produce 19 pieces of clothes. The output capacity per day were determined based on 8

working hours, producing 154 pieces of clothes. Using the machine, it takes 3 minutes

and 6.822 seconds to iron and fold a single cloth. The machine produces the same amount

compared to the manual process. But the health of the ones who does the manual process

is at risk. Having a RULA score of 7 which falls under a very high risk of having a

musculoskeletal disorder. Using the machine has a RULA score of 3 which is a negligible

risk of having a musculoskeletal disorder.

Functionality test indicates if the machine can perform its function without

failures. The functionality of the machine was tested with seven repeated trials and the

proponents found out that there is a minimal error occurs on the gripping function of the

machine. This indicates that the machine is functionally working.

The efficiency of the machine was determined in terms of number of hand

motions from manual process to the machine. The number of hand motions were gathered

using the Therbligs Analysis. Therbligs Analysis was designed to find unnecessary

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

69

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

movements or inefficient motions. The machine has a significantly lower number of hand

motions compared to the manual process of ironing and folding. In full automation

process is 69.39% efficient and in semi-automated process, wherein the user wants to use

the iron function is 81.63% efficient.

The last part was the user-friendliness test and validation of the machine which

divides into two parts. The first part is for validation of the efficiency, steam assist, and

time. The steam assist and efficiency were rated with a “Very Good”, while the time was

rated with a “Fair”. The second part is to validate the user-friendliness, size and safety of

the machine. The size of the machine was rated with a “Good”, for the safety and user-

friendliness, it was rated with a “Fair” from the total mean response computed from 20

respondents. Based on statistics, the machine was found out a really significant to use to

avoid the occurrence of having a musculoskeletal disorder and to lessen the pain of the

users when ironing and folding the clothes with a p-Value of 0.000 which is less than

0.05 level of confidence.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

70

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Business Model

Table 14 Business Model

Key Key Activities Value Customer Customers

Partners Proposition Relationship Segments

Promoting a user

Laundry Friendly steam New Personal Institutional and

shops ironing machine Technology private investors

Laundry shops

Individual Key Resources Channels Municipalities

Ironing People Website Residential

Workers Materials

Financial

Cost Structures Revenue Streams

Materials and Components

Sales

Monitoring and service fee

Shipping fee

Key Partners

Laundry shops

Institutional and private investors like Laundry shop with a large demand of

clothes being ironed and fold.

Ironing Workers

Individual ironing workers who decided to use the machine instead of using the

manual method for their ironing business.

Key activities

Promoting a user-Friendly steam ironing machine that will be used for their

businesses.

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

71

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Key Resources

People

To make this project into business, it is needed to have people who are

professional to design and develop the project.

Materials

The project materials that are available locally and suitable to make the project

Financial

Also, to have financial capability to fund the project and business.

Value Proposition

New Technology

The organization will partner with Laundry shops and some residences.

Channels

Website

The way to purchase the project is to contact the founders through website.

Customer Relationship

Personal

As a key to any good customer relationship, communicating is essential way to

build customer relationship. Rather than telling customers about your business,

have conversation with them and find what customers need

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

72

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Customers Segments

Institutional and private investors

Laundry shops

Ironing Workers

Cost Summary

Table 15 Cost Summary

Quality Name of Materials Price Total Price

2 Gripper Clamp With Servo Motor 1,500.00 3,000.00

7 Wiper Motor 1,200.00 8,400.00

1 Stepper Motor 2,500.00 2,500.00

1 Circuit Breaker 220 220.00

5 Linear Guide 2,500.00 12,500.00

3 Bolt Screw 3,000.00 9,000.00

1 Linear Actuator 5,500.00 5,500.00

1 Stepper Driver 2,000.00 2,000.00

1 Power Supply 12v-10a 800 800.00

1 Power Supply 24v-16a 1,600.00 1,600.00

2 8channel Relay 500 1,000.00

1 4channel Relay 300 300.00

2 Stepdown Regulator 189 378.00

1 Solid State Relay 60a 889 889.00

20 Limit Switch 35 700.00

1 Steamer 1,500.00 1,500.00

2 Button 18 36.00

1 Stainless Casing 12,500.00 12,500.00

12 1meter Stranded Wire 7 84.00

1 100pieces Banana wire 90 90.00

7 24inch x 30inch Acrylic Sheet 850 5950.00

TOTAL 68,947.00

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

73

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

Revenue Streams

Sales

Monitoring and service fee

Shipping fee

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

74

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

CHAPTER V

SUMMARY, CONCLUSION, AND RECOMMENDATION

Summary

This study entitled “Design and Development of Automated Steam Iron Machine

with Folding Mechanism” was established because of the inspiration comes from the

advancement of technology in ironing industry that tries to aid the problem of the society

to decrease the involvement of human activity and intervention that leads to fasten the

production of ironing clothes. The study conducted with the main objective of reducing

the time consumed on manual ironing and folding process of clothes and to eliminate the

possibility of having a musculoskeletal disorder. The prototype comprises a

microcontroller, wiper motors, stepper motors and its driver, servo motors, limit switches,

light dependent resistor, linear actuator, and steamer. The proponents conducted several

types of test to measure the production capacity and efficiency of the machine. As

progress lead to completion of the machine, several tests and evaluation were done to

measure the production capacity and efficiency of the machine.

As part of the test, three operators were asked to perform the manual process of

ironing and folding and compared the data gathered to the process time of the automated

machine. The proponents observed the Time and Motion Study of the manual ironing

process versus the Time and Motion Study of the automated process. Based on the

results, the production capacity of the machine is almost equal to the manual process. The

COLLEGE OF ENGINEERING, COMPUTER STUDIES AND ARCHITECTURE

75

LYCEUM OF THE PHILIPPINES UNIVERSITY - CAVITE

proponents also took the functionality test by observing each activity the machine can

perform and found out that there was a slight error in the gripping functionality of the

machine. For Efficiency tests, the proponents used Therbligs analysis in which the

number of hand motions for manual process versus the automated process was observed.

And based on the results, the machine was considered efficient. Output quality check was

done on three (5) different sizes of shirts in which we gathered different kinds of results.

The proponents also asked twenty people with age that ranges from 19-26 years old as for

validation, evaluation, and user-friendliness of the machine. The respondents are people

who works for the laundry shop and ironing workers.

Conclusion

The developed system was able to satisfy the main objectives of the study which

was to reduce the time consumed on manual ironing and folding process of clothes and

remove the possibility of having a musculoskeletal disorder. The specific objectives that

were aimed at the start of the study were also established in accordance to the whole

functionality of the system.