Professional Documents

Culture Documents

Blockage or Ball Test: NPS To NPS 3

Uploaded by

ra1nofkha0sOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blockage or Ball Test: NPS To NPS 3

Uploaded by

ra1nofkha0sCopyright:

Available Formats

Blockage or ball test[edit]

When a pipe is welded or bent the most common method to inspect blockages, misalignment,

ovality, and weld bead dimensional conformity is to pass a round ball through the pipe coil or

circuit. If the inner pipe dimension is to be measured then the weld bead should be subtracted, if

welding is applicable. Typically, the clearance tolerance for the ball must not exceed 1 millimetre

(0.039 in). Allowable ovality of any pipe is measured on the inside dimension of the pipe,

normally 5% to 10% ovality can be accepted. If no other test is conducted to verify ovality, or

blockages, this test must be seen as a standard requirement. A flow test can not be used in lieu

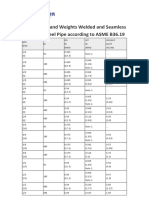

of a blockage or ball test. See pipe dimensional table, Specification ASME B36.10M or B36.19M

for pipe dimensions per schedule.

Stainless steel pipe is most often available in standard weight sizes (noted by the S designation;

for example, NPS Sch 10S). However stainless steel pipe can also be available in other

schedules.

Both polyvinyl chloride pipe (PVC) and chlorinated polyvinyl chloride pipe (CPVC) are made in

NPS sizes.

NPS tables for selected sizes[edit]

NPS ⅛ to NPS 3½[edit]

DN does not exactly correspond to a size in millimeters, because ISO 6708 defines it as being a

dimensionless specification only indirectly related to a diameter. The ISO 6708 sizes provide a

metric name for existing inch sizes, resulting in a 1:1 correlation between NPS and DN sizes.

ISO 6708 does not include values for "DN 6" or "DN 8", however ASME B36.10M list the "DN 6"

and "DN 8" . Also, the European Standard EN 12 516-1 (Industrial valves - Shell design strength

- Part 1: Tabulation method for steel valve shells) specifies the dimensions "DN 6" and "DN 8",

respectively their equivalents NPS 1/8 "and NPS 1/4".

Wall thickness [in (mm)]

DN OD

NP Sch. Sch.

[in Sch.

S[7] Sch. Sch. 40s/ 80s/ Sch. Sch.

(dimensionl (mm)] 10s/ XXS

5s 30 40 80 120 160

ess) 20

/STD /XS

0.03 0.04 0.05 0.06 0.09

0.405

5 9 7 8 5

⅛ 3 (10.29 — — —

(0.88 (1.24 (1.44 (1.72 (2.41

)[8]

9) 5) 8) 7) 3)

0.04 0.06 0.07 0.08 0.11

0.540

9 5 3 8 9

¼ 6 (13.72 — — —

(1.24 (1.65 (1.85 (2.23 (3.02

)

5) 1) 4) 5) 3)

0.04 0.06 0.07 0.09 0.12

0.675

9 5 3 1 6

⅜ 10 (17.15 — — — —

(1.24 (1.65 (1.85 (2.31 (3.20

)

5) 1) 4) 1) 0)

0.06 0.08 0.09 0.10 0.14

0.840 0.188 0.294

5 3 5 9 7

½ 15 (21.34 — (4.775 (7.468

(1.65 (2.10 (2.41 (2.76 (3.73

) ) )

1) 8) 3) 9) 4)

0.06 0.08 0.09 0.11 0.15

1.050 0.219 0.308

5 3 5 3 4

¾ 20 (26.67 — (5.563 (7.823

(1.65 (2.10 (2.41 (2.87 (3.91

) ) )

1) 8) 3) 0) 2)

0.06 0.10 0.11 0.13 0.17

1.315 0.250 0.358

5 9 4 3 9

1 25 (33.40 — (6.350 (9.093

(1.65 (2.76 (2.89 (3.37 (4.54

) ) )

1) 9) 6) 8) 7)

0.06 0.10 0.11 0.14 0.19

1.660 0.250 0.382

5 9 7 0 1

1¼ 32 (42.16 — (6.350 (9.703

(1.65 (2.76 (2.97 (3.55 (4.85

) ) )

1) 9) 2) 6) 1)

0.06 0.10 0.12 0.14 0.20

1.900 0.281 0.400

5 9 5 5 0

1½ 40 (48.26 — (7.137 (10.16

(1.65 (2.76 (3.17 (3.68 (5.08

) ) 0)

1) 9) 5) 3) 0)

0.06 0.10 0.12 0.15 0.21 0.25

2.375 0.344 0.436

5 9 5 4 8 0

2 50 (60.33 (8.738 (11.07

(1.65 (2.76 (3.17 (3.91 (5.53 (6.35

) ) 4)

1) 9) 5) 2) 7) 0)

0.08 0.12 0.18 0.20 0.27 0.30

2.875 0.375 0.552

3 0 8 3 6 0

2½ 65 (73.03 (9.525 (14.02

(2.10 (3.04 (4.77 (5.15 (7.01 (7.62

) ) 1)

8) 8) 5) 6) 0) 0)

0.08 0.12 0.18 0.21 0.30 0.35

3.500 0.438 0.600

3 0 8 6 0 0

3 80 (88.90 (11.12 (15.24

(2.10 (3.04 (4.77 (5.48 (7.62 (8.89

) 5) 0)

8) 8) 5) 6) 0) 0)

0.08 0.12 0.18 0.22 0.31

4.000 0.636

3 0 8 6 8

3½ 90 (101.6 — — (16.15

(2.10 (3.04 (4.77 (5.74 (8.07

0) 4)

8) 8) 5) 0) 7)

Tolerance: The tolerance on pipe OD is +1/64 (.0156) inch (0.40 mm), -1/32 (.0312)inch

(0.79 mm).[9]

As per ASME B36.10M -2018 Pipe wall thickness are rounded to nearest 0.01 mm (0.00039 in),

while converting Wall Thickness from inch to mm.

You might also like

- Tabel Ukuran Dan Berat Pipa Schedule Stainless SteelDocument11 pagesTabel Ukuran Dan Berat Pipa Schedule Stainless SteelExschel Putra SinexNo ratings yet

- Nps Tables For Selected Sizes NPS To NPS 3Document4 pagesNps Tables For Selected Sizes NPS To NPS 3POWERNo ratings yet

- Nominal Pipe Size - WikipediaDocument23 pagesNominal Pipe Size - WikipediaPrakashNo ratings yet

- Tabel Ukuran PipaDocument8 pagesTabel Ukuran PipaAhmad SofandiNo ratings yet

- Table 1 Dimensions of Welded and Seamless Stainless Steel Pipe and Nominal Weights of Steel Pipe, Plain EndDocument3 pagesTable 1 Dimensions of Welded and Seamless Stainless Steel Pipe and Nominal Weights of Steel Pipe, Plain EndSandesh SadvilkarNo ratings yet

- Dimensions & Weights Welded and Seamless Wrought Steel Pipe ASME B36.10Document6 pagesDimensions & Weights Welded and Seamless Wrought Steel Pipe ASME B36.10MaysaraNo ratings yet

- Clase AmbientalDocument4 pagesClase AmbientalLuisa Fernanda Hoyos LorduyNo ratings yet

- Tabel Ukuran NPS - DN All Pipe SizeDocument2 pagesTabel Ukuran NPS - DN All Pipe SizeVirgus Wira YJ Umbai100% (1)

- Dimensions & Weights Welded and Seamless Wrought Steel Pipe ASME B36.10Document6 pagesDimensions & Weights Welded and Seamless Wrought Steel Pipe ASME B36.10MaysaraNo ratings yet

- PETR 3134 Codes and Specifications in The Petroleum IndustryDocument18 pagesPETR 3134 Codes and Specifications in The Petroleum IndustrynuvanNo ratings yet

- Boru Caplari DN Nps SCHDocument1 pageBoru Caplari DN Nps SCHKoray BAYAZITNo ratings yet

- LBKP RismaDocument20 pagesLBKP RismaRisma Yunita DarwinNo ratings yet

- Dimensions and Weights Welded and Seamless Stainless Steel Pipe According To ASME B36.19Document11 pagesDimensions and Weights Welded and Seamless Stainless Steel Pipe According To ASME B36.19MaysaraNo ratings yet

- Tabla de Tuberia Asme B 36 10 PDFDocument32 pagesTabla de Tuberia Asme B 36 10 PDFGustavo XochihuaNo ratings yet

- Dimensions & Weights of Pipes ASTM A53Document4 pagesDimensions & Weights of Pipes ASTM A53MaysaraNo ratings yet

- Stainless Steel Pipes - Dimensions and Weights ANSI - ASME 36Document3 pagesStainless Steel Pipes - Dimensions and Weights ANSI - ASME 36mecamb100% (1)

- Lineas de Influencia para Viga Hiperestatica: Metodos Aproximados para Diseños PreliminaresDocument7 pagesLineas de Influencia para Viga Hiperestatica: Metodos Aproximados para Diseños PreliminaresKevin Gabriel More MorónNo ratings yet

- Valoare Maxima Numar Intervale Oi: (Frecventa Obs.)Document3 pagesValoare Maxima Numar Intervale Oi: (Frecventa Obs.)SebastianCosminAlecuNo ratings yet

- Dimensions and Weights Welded and Seamless Stainless Steel Pipe According To ASME B36.19Document11 pagesDimensions and Weights Welded and Seamless Stainless Steel Pipe According To ASME B36.19MaysaraNo ratings yet

- Tabel Ukuran Dan Berat Pipa Schedule Stainless Steel & Duplex. Standart 6000 MMDocument6 pagesTabel Ukuran Dan Berat Pipa Schedule Stainless Steel & Duplex. Standart 6000 MMRiki Depano MembumiNo ratings yet

- NPS - Pipe & TubeDocument5 pagesNPS - Pipe & TubeHà MemoNo ratings yet

- Chart Title: 4 0 10 21.6 20 49.5 40 102.6 60 89.1 100 95.6 200 60.4 Bandeja 31.2Document6 pagesChart Title: 4 0 10 21.6 20 49.5 40 102.6 60 89.1 100 95.6 200 60.4 Bandeja 31.2Mario Andres BarreraNo ratings yet

- Tubos RedondosDocument6 pagesTubos RedondoshebermarcussiNo ratings yet

- Espesores X DiametrosDocument1 pageEspesores X DiametroschinexxxNo ratings yet

- Libro 1Document6 pagesLibro 1Adrian DosalNo ratings yet

- B36 10 PDFDocument16 pagesB36 10 PDFLuis BarraganNo ratings yet

- Table 1 Dimensions and Weights of Welded and Seamless Wrought Steel PipeDocument16 pagesTable 1 Dimensions and Weights of Welded and Seamless Wrought Steel PipeLuis BarraganNo ratings yet

- Tablas de Diámetro NominalDocument1 pageTablas de Diámetro NominalhectorNo ratings yet

- Jl. Pendidikan, 27 Malaingkedi, Kota Sorong, Telp (0951) 328775 Faks (0951) 326162Document13 pagesJl. Pendidikan, 27 Malaingkedi, Kota Sorong, Telp (0951) 328775 Faks (0951) 326162era watiNo ratings yet

- Opration Management TAMDocument5 pagesOpration Management TAMHK 'sNo ratings yet

- Convirtiendo Fracciones A Decimales 03-13Document2 pagesConvirtiendo Fracciones A Decimales 03-13Susana ElisaNo ratings yet

- Excel Caudales Hidra 2018Document2 pagesExcel Caudales Hidra 2018isaias charaja montañoNo ratings yet

- Theis CurveDocument8 pagesTheis CurveumairNo ratings yet

- Experiment Name:: Soil Mechanics LaboratoryDocument12 pagesExperiment Name:: Soil Mechanics LaboratoryAhmad F AwwadNo ratings yet

- Stainless Steel Pipe SCHDocument5 pagesStainless Steel Pipe SCHmahaveenNo ratings yet

- Table 1 Dimensions and Weights of Welded and Seamless Wrought Steel PipeDocument1 pageTable 1 Dimensions and Weights of Welded and Seamless Wrought Steel PipeBernardo EscorciaNo ratings yet

- Design Mix of Filter Media: Base Material Soil (BA No 4) Filter Material (70% Stone Dust +30% 10mm Aggregate)Document2 pagesDesign Mix of Filter Media: Base Material Soil (BA No 4) Filter Material (70% Stone Dust +30% 10mm Aggregate)Biplab dattaNo ratings yet

- Proyek Lokasi Material: Dynamic Cone Penetrometer Test (DCPT)Document4 pagesProyek Lokasi Material: Dynamic Cone Penetrometer Test (DCPT)Ikhromul Khoirul AqshomNo ratings yet

- Galvanized Pipe Friction LossDocument5 pagesGalvanized Pipe Friction Lossdaud heruNo ratings yet

- Chart Title: Diagrama de Patron de TormenaDocument3 pagesChart Title: Diagrama de Patron de TormenaDeivid ToribioNo ratings yet

- 고압파이프규격Document1 page고압파이프규격YOO SHINNo ratings yet

- PLATE BEARING TEST (Acc. DIN 18134) - Part - 1 (Field Data)Document2 pagesPLATE BEARING TEST (Acc. DIN 18134) - Part - 1 (Field Data)EMANUELINo ratings yet

- Uniformly Accelerated Motion: Activity No. 3Document3 pagesUniformly Accelerated Motion: Activity No. 3Bharath CricketNo ratings yet

- Asme b36.10 M 2004 10Document14 pagesAsme b36.10 M 2004 10SICKERESANo ratings yet

- 74 en US FactSheet Main 01Document3 pages74 en US FactSheet Main 01Raron1No ratings yet

- Pipe Schedule Table PDFDocument16 pagesPipe Schedule Table PDFAlaa edine SmaaliNo ratings yet

- Pipe Schedule Table PDFDocument16 pagesPipe Schedule Table PDFJuanPérezNo ratings yet

- Table-1-ASME-B36.10M-2015-pip ScheduleDocument18 pagesTable-1-ASME-B36.10M-2015-pip SchedulebaladiroyaNo ratings yet

- Wcass0003 en AqDocument4 pagesWcass0003 en AqzoogleNo ratings yet

- Head & Piping Calculation Ref. Section WFU Flow Pipe Diam. Material Velocity Press - Loss Length Eq - Leng. Res.P.Loss Fric - Loss Tot.P.LossDocument4 pagesHead & Piping Calculation Ref. Section WFU Flow Pipe Diam. Material Velocity Press - Loss Length Eq - Leng. Res.P.Loss Fric - Loss Tot.P.LossNghiaNo ratings yet

- Fadoua Ait Youssef + HoumaDocument41 pagesFadoua Ait Youssef + Houmasig-hanaNo ratings yet

- Examen Unidad 2Document5 pagesExamen Unidad 2AndreaNo ratings yet

- Business Statistics 3rd Edition Sharpe Solutions ManualDocument34 pagesBusiness Statistics 3rd Edition Sharpe Solutions ManualPatriciaStonebwyrq100% (71)

- UntitledDocument2 pagesUntitledFrank RendinaNo ratings yet

- LBP (M) 25 B Mold (M) 5.3 D Mold (M) 2.4 D Mold (M) 2.1Document16 pagesLBP (M) 25 B Mold (M) 5.3 D Mold (M) 2.4 D Mold (M) 2.1UUSungNo ratings yet

- Dias (NOV - DIC) P (MM) Orden Pa X P (MM) Tiempo de Retorno: Pluviometro - Nueva EsperanzaDocument8 pagesDias (NOV - DIC) P (MM) Orden Pa X P (MM) Tiempo de Retorno: Pluviometro - Nueva EsperanzaIan Alejos CastilloNo ratings yet

- Quality Engineering Report IIIDocument3 pagesQuality Engineering Report IIIKurtNo ratings yet

- Cumulative Time (Min) Burette Reading (ML) Initial Final No of Obs. Volume of Sample Taken (ML)Document4 pagesCumulative Time (Min) Burette Reading (ML) Initial Final No of Obs. Volume of Sample Taken (ML)Snigdha AuroraNo ratings yet

- Dimensions and Weights Asme B36.19 Pipes NPS1 8-NPS30Document10 pagesDimensions and Weights Asme B36.19 Pipes NPS1 8-NPS30Chrina MalolotNo ratings yet

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- Item Analysis Report On Pilot Testing 1ST QuarterDocument512 pagesItem Analysis Report On Pilot Testing 1ST QuarterRA CastroNo ratings yet

- Vdocuments - MX - SR HD 60364 6 PDF Wordpresscom A Cenelec HD 60364 1 D InformativeDocument2 pagesVdocuments - MX - SR HD 60364 6 PDF Wordpresscom A Cenelec HD 60364 1 D InformativeLucian BarboiNo ratings yet

- Microsoft Word - Measures - English, Metric, and EquivalentsDocument1 pageMicrosoft Word - Measures - English, Metric, and EquivalentsLen HebronNo ratings yet

- Rts-001 Rts-002 Rts-003 Rts-004 Rts-005: 1 ReenixDocument12 pagesRts-001 Rts-002 Rts-003 Rts-004 Rts-005: 1 Reenixjaison403No ratings yet

- IEC 60034-18-1 Function Evaluation of Insulation Systems-General GuidelinesDocument20 pagesIEC 60034-18-1 Function Evaluation of Insulation Systems-General GuidelinesWei YaoNo ratings yet

- IGNOU OPENMAT 2019 Question PaperDocument87 pagesIGNOU OPENMAT 2019 Question PaperMufaddal DaginawalaNo ratings yet

- E-02-Final A3Document1 pageE-02-Final A3kitnaNo ratings yet

- PCert - BA GIMPA PDFDocument2 pagesPCert - BA GIMPA PDFZACHARIAH MANKIRNo ratings yet

- BS en Iso 17892-2 (2014)Document26 pagesBS en Iso 17892-2 (2014)zaid darwishNo ratings yet

- 10 Steps To PMP CertificationDocument8 pages10 Steps To PMP CertificationRASHEED YUSUFNo ratings yet

- CISCO 1 BlendedDocument9 pagesCISCO 1 BlendedXiao Yei ChenNo ratings yet

- Guide To General Tolerance - ISO 2768 1&2 StandardDocument6 pagesGuide To General Tolerance - ISO 2768 1&2 StandardQuality controller100% (1)

- Sist en 60874 1 2012 1 9Document9 pagesSist en 60874 1 2012 1 9sabuhiNo ratings yet

- PRBT Call FlowDocument4 pagesPRBT Call FlowbsaptohNo ratings yet

- 01.4-Input 4 BilDocument39 pages01.4-Input 4 Bilzainal arifinNo ratings yet

- TCC-80/80I Series: Port-Powered RS-232 To RS-422/485 Converters With Optional 2.5 KV IsolationDocument5 pagesTCC-80/80I Series: Port-Powered RS-232 To RS-422/485 Converters With Optional 2.5 KV IsolationSudharsan KingNo ratings yet

- As 4635-2004 Non-Destructive Testing - Qualification of Personnel For Limited Applications of Non-DestructiveDocument8 pagesAs 4635-2004 Non-Destructive Testing - Qualification of Personnel For Limited Applications of Non-DestructiveSAI Global - APACNo ratings yet

- 7 Layer OSI Model Open System Interconnection ModelDocument44 pages7 Layer OSI Model Open System Interconnection ModelÑätÎnk EtNo ratings yet

- Wyco, A Division of Racine Federated IncDocument1 pageWyco, A Division of Racine Federated IncdalexehNo ratings yet

- Nom Pal.2 Guerin B204Document17 pagesNom Pal.2 Guerin B204bennai yougourtaNo ratings yet

- SOLiD - GENESIS - Generic Rack Deployment Layout - Sub3 & n78Document1 pageSOLiD - GENESIS - Generic Rack Deployment Layout - Sub3 & n78Danny MunetsiNo ratings yet

- Baxter P.reese Calibration in Regulated Industries Federal Agency Use ISO-17025 ANSI Z540.3 28Document131 pagesBaxter P.reese Calibration in Regulated Industries Federal Agency Use ISO-17025 ANSI Z540.3 28Volca CmmNo ratings yet

- HND Admission 2nd List 2017 2018 Uploaded 1 1Document26 pagesHND Admission 2nd List 2017 2018 Uploaded 1 1Adeniji OlusegunNo ratings yet

- Hawk-M Uhd 6K: Board SchematicDocument53 pagesHawk-M Uhd 6K: Board SchematicJosé Edilson da PazNo ratings yet

- SNI 7336 2008 Pertukaran Data Lokasi GeografisDocument16 pagesSNI 7336 2008 Pertukaran Data Lokasi Geografisbk cahyonoNo ratings yet

- Egypt Isced Mapping 0Document2 pagesEgypt Isced Mapping 0ahmadfares1500No ratings yet

- BS en 00957-5 1997 (En)Document18 pagesBS en 00957-5 1997 (En)Emanuele MastrangeloNo ratings yet

- 2.8" TOUCH: Andriod SeriesDocument18 pages2.8" TOUCH: Andriod Seriesmohitsinghal22No ratings yet

- Tpj050b Pt. Trirara Purnama Jaya Ems ZqualcertDocument1 pageTpj050b Pt. Trirara Purnama Jaya Ems ZqualcertBali Besar InternasionalNo ratings yet

- G C e (O L) 2018Document15 pagesG C e (O L) 2018Möhâmêd ÑâvêędNo ratings yet