Professional Documents

Culture Documents

Rock Socket 111

Rock Socket 111

Uploaded by

teh0 ratings0% found this document useful (0 votes)

5 views1 pageThe document presents test results from 79 pile sockets installed in granitic rock. The piles' lengths, diameters, socket lengths, excavation methods, rock types, unconfined compressive strengths, maximum side resistances, and displacement indexes are presented in a table. Charts show the relationship between side resistance and displacement for piles with different displacement indexes in granitic rock. The results show variability in the shape of the resistance-displacement curves and displacement at which ultimate resistance occurs. The document discusses factors that influence the shape of the curves but notes it is difficult to determine relationships based on the limited information provided.

Original Description:

rock socket111

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document presents test results from 79 pile sockets installed in granitic rock. The piles' lengths, diameters, socket lengths, excavation methods, rock types, unconfined compressive strengths, maximum side resistances, and displacement indexes are presented in a table. Charts show the relationship between side resistance and displacement for piles with different displacement indexes in granitic rock. The results show variability in the shape of the resistance-displacement curves and displacement at which ultimate resistance occurs. The document discusses factors that influence the shape of the curves but notes it is difficult to determine relationships based on the limited information provided.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views1 pageRock Socket 111

Rock Socket 111

Uploaded by

tehThe document presents test results from 79 pile sockets installed in granitic rock. The piles' lengths, diameters, socket lengths, excavation methods, rock types, unconfined compressive strengths, maximum side resistances, and displacement indexes are presented in a table. Charts show the relationship between side resistance and displacement for piles with different displacement indexes in granitic rock. The results show variability in the shape of the resistance-displacement curves and displacement at which ultimate resistance occurs. The document discusses factors that influence the shape of the curves but notes it is difficult to determine relationships based on the limited information provided.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

TABLE 4.

(Continued )

Pile Socket Socket Average

Pile length diameter length UCS q̄max

number Reference (m) (mm) (m) Method of excavation Rock type (MPa) (kPa) DI

65 Leung (1996) ? ? ? ? Granite (granitic) 2⌿ 600 ⌿ C

66 Leung (1996) ? ? ? ? Granite (granitic) 2⌿ 400 ⌿ C

67 Leung (1996) ? ? ? ? Granite (granitic) 2⌿ 125 ⌿ C

68 Leung (1996) ? ? ? ? Granite (granitic) 2.3 ⌿ 375 ⌿ C

69 Leung (1996) ? ? ? ? Granite (granitic) 2.8 ⌿ 210 ⌿ C

70 Leung (1996) ? ? ? ? Granite (granitic) 4⌿ 60 ⌿ C

71 Leung (1996) ? ? ? ? Granite (granitic) 4.1 ⌿ 310 ⌿ C

72 Leung (1996) ? ? ? ? Granite (granitic) 4⌿ 250 ⌿ C

73 Leung (1996) ? ? ? ? Granite (granitic) 5⌿ 1,250 ⌿ C

74 Leung (1996) ? ? ? ? Granite (granitic) 13 ⌿ 300 ⌿ C

75 Leung (1996) ? ? ? ? Granite (granitic) 14 ⌿ 525 ⌿ C

76 Leung (1996) ? ? ? ? Granite (granitic) 20 ⌿ 725 ⌿ C

77 Leung (1996) ? ? ? ? Granite (granitic) 40 ⌿ 500 ⌿ C

78 Leung (1996) ? ? ? ? Granite (granitic) 45 ⌿ 900 ⌿ C

79 Leung (1996) ? ? ? ? Granite (granitic) 50 ⌿ 625 ⌿ C

Note: ⌿ = scaled-off figure in publication.

a

Socket was artificially roughened.

database, as it was installed in volcanic breccia, which was

too decomposed to allow UCS tests to be carried out. This

explains it achieving the lowest side resistance of all the tests

in Fig. 3(a). The breccia was characterized by corestones of

sound rock interlayered by seams of Grade V and IV material

and with voids caused by the dissolution of marble.

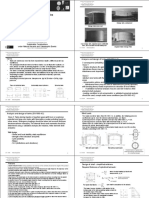

In Fig. 3(b) the results with a DI of B are shown. Note that

the scale of the horizontal axis of Fig. 3(b) is only half that

of Fig. 3(a). Similar to Fig. 3(a), the shapes of the curves are

scattered and significant yielding appears to occur at varying

displacements. The piles in granitic rocks display noticeable

yielding at displacements <8 mm, whereas the tests in sedi-

mentary rocks in some cases do not display noticeable yielding

at displacements up to 14 mm. In most cases, side resistance

is still increasing at the termination of the test, indicating work

hardening behavior. This is most obvious in the curve for Pile

FIG. 2. Proposed Criteria for Displacement Index (DI) 3, which displays a continuing increase in resistance at a dis-

placement of 25 mm. The results in Fig. 3(c) are difficult to

interpret due to the general lack of mobilization of resistance.

(Piles 7, 12, and 40) display peak behavior with a drop in side The stiff responses of the sockets are likely to be related to

resistance after the peak is reached. Pile 5 shows only a slight the rocks having high UCS values (refer to Table 3).

drop in resistance after the peak, which occurs at a displace- Generally, in Figs. 3(a)–(c) there is scatter in the rate of

ment of 45 mm, whereas the remaining piles do not show a mobilization and in the shape of the resistance-displacement

drop in resistance or do not reach a peak value before a dis- relationship. The ultimate side resistance is reached at different

placement of 20 mm. The results of Pile 26 and 27 are almost displacements in different sockets. There is insufficient evi-

bilinear in shape and it is unclear at what displacement ulti-

dence to suggest that the ultimate resistance is mobilized at a

mate side resistance will be reached. A large number of factors

single common displacement, such as the displacement of 6

are likely to contribute to the differences between the curves

mm observed by Horvath and Kenney (1979), Horvath et al.

in Fig. 3(a), and with reference to Tables 3 and 4, it is difficult

(1983), and Williams et al. (1980a). In the case of Horvath et

to relate the results with the available information on the tests.

al. (1983), the apparent difference is the part due to varying

In particular, no strong correlation can be drawn between the

shapes of the relationships and the socket length and diameter, methods used to define ‘‘ultimate side resistance.’’ In fact,

which theoretically have been shown to be important in con- Horvath et al. (1983) more precisely used the phrase ‘‘essen-

trolling the shape of the resistance-displacement relationship tially mobilized’’ and implemented a graphical double-tangent

as reported by Rowe and Pells (1980). method to define this point. The writers have used the maxi-

A clear distinction can be observed between the results in mum achieved side resistance for all tests, which in some cases

Fig. 3(a) of the piles tested in granitic and volcanic rocks with is significantly higher than the resistance interpreted using the

the piles tested in sedimentary rocks. The piles in sedimentary double tangent method. However, in the case of the load-dis-

rocks achieve higher side resistance in all cases. The behavior placement relationship published by Williams et al. (1980a),

is difficult to relate to rock strength due to the rocks tested all clearly peak side resistance occurred at a displacement of 6

having similar UCS values (refer to Tables 3 and 4) with the mm (0.9% of the pile diameter). The pile in question is re-

exception of Pile 12. Possibly the behavior is related to other ferred to as Pile 40 in this paper (Table 4).

rock properties or was caused by the differences in the drilling For design purposes, if the intention is to maintain an elastic

methods. The piles in sedimentary rocks were drilled with au- socket response at working load, it is unclear as to what value

gers and with artificial roughening in one case, whereas the the displacement should be confined. From the results in gra-

piles in granitic rocks were drilled by RCD, which may result nitic rock, a displacement of approximately 4 mm or 0.4% of

in a smoother socket. Pile 12 is nontypical of the tests in the the pile diameter (for piles constructed by RCD) may be ac-

JOURNAL OF GEOTECHNICAL AND GEOENVIRONMENTAL ENGINEERING / AUGUST 2001 / 649

You might also like

- Quotation For Soil TestDocument1 pageQuotation For Soil TestBikas Jha100% (1)

- Building With Reclaimed Components and Materials A Design Handbook For Reuse and Recycling PDFDocument225 pagesBuilding With Reclaimed Components and Materials A Design Handbook For Reuse and Recycling PDFKris CrystalNo ratings yet

- Highway Structures: Design (Substructures and Special Structures), Materials Section 1 SubstructuresDocument26 pagesHighway Structures: Design (Substructures and Special Structures), Materials Section 1 SubstructurestehNo ratings yet

- Python BookDocument194 pagesPython Bookteh100% (1)

- BFC21303 - Sem 1 Session 1516Document6 pagesBFC21303 - Sem 1 Session 1516Lukman HakimNo ratings yet

- Bfc21303-Engineering - Geology Sem 2 Sessi 2021 2022Document9 pagesBfc21303-Engineering - Geology Sem 2 Sessi 2021 2022Omar BayouNo ratings yet

- Building Material Odisha JE AEE Previous Year Papers With SolutionDocument6 pagesBuilding Material Odisha JE AEE Previous Year Papers With SolutionaebsdNo ratings yet

- KPSC PDFDocument12 pagesKPSC PDFthemathloverNo ratings yet

- 5bquestion 5dfinalexamsem1sesi20202021 Encrypted UnlockedDocument10 pages5bquestion 5dfinalexamsem1sesi20202021 Encrypted UnlockedEizln HqmNo ratings yet

- Civl 3202Document3 pagesCivl 3202Nivesh NamanNo ratings yet

- LIBRO3Document43 pagesLIBRO3Camilo LacoutureNo ratings yet

- Errata Sheet For Gate Questions (1. WSM and LSM Questions)Document9 pagesErrata Sheet For Gate Questions (1. WSM and LSM Questions)Sanket AgrawalNo ratings yet

- Geotechnical Solutions For Unstable Rock Mass at Sg. Buloh AreaDocument8 pagesGeotechnical Solutions For Unstable Rock Mass at Sg. Buloh Areajinwook75No ratings yet

- Metal Forming ME GATE 2020 Previous Year With Ans KeyDocument9 pagesMetal Forming ME GATE 2020 Previous Year With Ans Keyhyper meshNo ratings yet

- SET-4 (CHANDAN's Guidance)Document15 pagesSET-4 (CHANDAN's Guidance)Debashis RouthNo ratings yet

- Gradien HidrolikDocument14 pagesGradien HidrolikmarsinNo ratings yet

- Final GEOLOGI 1 Sem I Sesi 2017 2018 - Final All - JKIG VetDocument8 pagesFinal GEOLOGI 1 Sem I Sesi 2017 2018 - Final All - JKIG VetOmar BayouNo ratings yet

- Uganda Technical College - Lira: IMPORTANT SAMPLE QUESTIONS (Design of Concrete Structures To Eurocode 2)Document38 pagesUganda Technical College - Lira: IMPORTANT SAMPLE QUESTIONS (Design of Concrete Structures To Eurocode 2)Mugara Waitega PeterNo ratings yet

- School of Engineering & Physical Sciences Mechanical EngineeringDocument7 pagesSchool of Engineering & Physical Sciences Mechanical EngineeringRashid AzadliNo ratings yet

- Final Examination BFC 21303 SEM21516Document7 pagesFinal Examination BFC 21303 SEM21516Mohammad AsnizamNo ratings yet

- CSEC Geography June 2009 P2Document15 pagesCSEC Geography June 2009 P2aubrey wallisNo ratings yet

- Solved Per Junio R Instructor (Surveyor) : J Ronm" Industrial TrainingDocument1 pageSolved Per Junio R Instructor (Surveyor) : J Ronm" Industrial TrainingharithaNo ratings yet

- PDF ReaderDocument7 pagesPDF ReaderPankaj BadiwalNo ratings yet

- To An The: (A) An The of (B) Instrument Measure Magnitude ofDocument2 pagesTo An The: (A) An The of (B) Instrument Measure Magnitude ofjhalakduttaNo ratings yet

- MN 0212-Ue 2020-SolutionDocument11 pagesMN 0212-Ue 2020-SolutionAlfredtungu PiusNo ratings yet

- Concrete RatioDocument1 pageConcrete RatioKiel BuenconsejoNo ratings yet

- 3 ASSIGN Sem I 2017-18 (QU & ANSWER)Document5 pages3 ASSIGN Sem I 2017-18 (QU & ANSWER)Malik AbedNo ratings yet

- Raiseboring in Difficult Rock ConditionsDocument14 pagesRaiseboring in Difficult Rock Conditionswww.di_stefano70No ratings yet

- Universiti Tun Hussein Onn Malaysia Final Examination Semester I SESSION 2019/2020Document11 pagesUniversiti Tun Hussein Onn Malaysia Final Examination Semester I SESSION 2019/2020Eizln HqmNo ratings yet

- 26 To 125 QuestionsDocument17 pages26 To 125 QuestionsS MNo ratings yet

- Ert 03 02Document14 pagesErt 03 02S A KaleNo ratings yet

- Sheet Metal FormingDocument37 pagesSheet Metal FormingCh Talha100% (1)

- Me1022 4 Sem PDFDocument2 pagesMe1022 4 Sem PDFRajiv KumarNo ratings yet

- 2010 EDITION Standard Code For Granite and Marble Stonework (MG C1)Document13 pages2010 EDITION Standard Code For Granite and Marble Stonework (MG C1)Abhay ShrivastavaNo ratings yet

- Standard Specifications For Construction of RoadsDocument238 pagesStandard Specifications For Construction of RoadsGenesis Castro (Engr. Pianista)No ratings yet

- Mie211 2019 11Document9 pagesMie211 2019 11Leonel MadzNo ratings yet

- Final Examination - BFC 21303 - Sem 2 Session 1617aDocument9 pagesFinal Examination - BFC 21303 - Sem 2 Session 1617aCarlsten KarlzNo ratings yet

- Lead PDocument7 pagesLead PsaNo ratings yet

- Chapter 9 - Rock MassDocument116 pagesChapter 9 - Rock MassZulaikha Kamal50% (2)

- Das Seely (1985) Uplift Capacity of Pipe Piles in Saturated ClayDocument4 pagesDas Seely (1985) Uplift Capacity of Pipe Piles in Saturated ClaySafak BooksNo ratings yet

- ML7301Document3 pagesML7301PoojaNo ratings yet

- Wear Prediction and Maintenance Frequencies of Slurry Pipes For TBM TunnelingDocument5 pagesWear Prediction and Maintenance Frequencies of Slurry Pipes For TBM TunnelingMacarena Arriagada AguilarNo ratings yet

- Los Angeles Abrasion Test PDFDocument6 pagesLos Angeles Abrasion Test PDFAshishJamadar100% (1)

- Itm University, Raipur Itm University, Raipur: School of Architecture & Planning School of Architecture & PlanningDocument1 pageItm University, Raipur Itm University, Raipur: School of Architecture & Planning School of Architecture & PlanningM Pradeep KumarNo ratings yet

- Proposed Village Milk Centre Meat Stalls and Slaughter Slabs - Salaxley...... 2Document36 pagesProposed Village Milk Centre Meat Stalls and Slaughter Slabs - Salaxley...... 2guuleedNo ratings yet

- Casting E BookDocument46 pagesCasting E BookunitybeginsathomeNo ratings yet

- Toppling FailureDocument7 pagesToppling FailureBayu AslanNo ratings yet

- ISRM2019 BB QslopeFaultedRocksAndFaultZonesDocument9 pagesISRM2019 BB QslopeFaultedRocksAndFaultZonesJuan Fernando Joya NuñezNo ratings yet

- Mix DesignDocument30 pagesMix DesignyogiforyouNo ratings yet

- Geography Paper 1 November 2003Document7 pagesGeography Paper 1 November 2003Lastwell NdebvuNo ratings yet

- Ies Master SSC Je Mains 18-19 Test 05Document30 pagesIes Master SSC Je Mains 18-19 Test 05Navya PrajapatNo ratings yet

- QUESTIONS FinalDocument15 pagesQUESTIONS FinalkevalNo ratings yet

- Gateforall (Coching Institute of Gate Agriculture Engineering, Bankafo, Ars & Icar)Document4 pagesGateforall (Coching Institute of Gate Agriculture Engineering, Bankafo, Ars & Icar)gaganpreet singhNo ratings yet

- Puea Set-3Document11 pagesPuea Set-3NISHIKANTA MONDALNo ratings yet

- Han 2013Document10 pagesHan 2013Benjamin GonzalezNo ratings yet

- z183 2003 micropilesFoundedRockDocument6 pagesz183 2003 micropilesFoundedRockPercy CasaniNo ratings yet

- CE 5414 - Rock Mechanics 2022Document6 pagesCE 5414 - Rock Mechanics 2022Thamindu JayaweeraNo ratings yet

- Design Assumpttions: Geometry y & LayoutDocument15 pagesDesign Assumpttions: Geometry y & LayoutMichael ProtopapasNo ratings yet

- Assignment QUESTIONDocument6 pagesAssignment QUESTIONTaran Tatleender Kaur A/P Salinder SinghNo ratings yet

- PI-Metrology CRPQ PDFDocument57 pagesPI-Metrology CRPQ PDFRishav VermaNo ratings yet

- (1993) High Slit Wear of Hydroturbine RunnersDocument5 pages(1993) High Slit Wear of Hydroturbine RunnersthiagoturraNo ratings yet

- CP1 Quantity Calc Drainage 20221027Document2 pagesCP1 Quantity Calc Drainage 20221027captaincharizma07No ratings yet

- Installation of Offshore Driven Piles - Regional Experience: View Publication Stats View Publication StatsDocument1 pageInstallation of Offshore Driven Piles - Regional Experience: View Publication Stats View Publication StatstehNo ratings yet

- Gabion Retaining Wall Analysis and Design (Bs8002:1994) : Project Job NoDocument3 pagesGabion Retaining Wall Analysis and Design (Bs8002:1994) : Project Job NotehNo ratings yet

- Pile-Driving Analysis by One-Dimensional Wave Theory: State of The ArtDocument22 pagesPile-Driving Analysis by One-Dimensional Wave Theory: State of The ArttehNo ratings yet

- Lecture No. 4: Dr. Warakorn Mairaing Associate ProfessorDocument72 pagesLecture No. 4: Dr. Warakorn Mairaing Associate ProfessortehNo ratings yet

- Soil-Cement Mixture Properties and Design Considerations For Reinforced ExcavationDocument8 pagesSoil-Cement Mixture Properties and Design Considerations For Reinforced ExcavationtehNo ratings yet

- Soil Nailing With Flexible Structural Facing - Design and ExpDocument6 pagesSoil Nailing With Flexible Structural Facing - Design and ExptehNo ratings yet

- Since 1997, Your Complete Online Resource For Information Geotecnical Engineering and Deep FoundationsDocument71 pagesSince 1997, Your Complete Online Resource For Information Geotecnical Engineering and Deep FoundationstehNo ratings yet

- 287B - PB - 4out - Same - 50835 - ASCE - Vol - 01 - Final - Job - Process Cyan - 08/07/2012 - 05:31:52Document11 pages287B - PB - 4out - Same - 50835 - ASCE - Vol - 01 - Final - Job - Process Cyan - 08/07/2012 - 05:31:52tehNo ratings yet

- Applicability of Molding Procedures in Laboratory Mix Tests For Quality Control and Assurance of The Deep Mixing MethodDocument17 pagesApplicability of Molding Procedures in Laboratory Mix Tests For Quality Control and Assurance of The Deep Mixing MethodtehNo ratings yet

- Large Deformation Finite-Element Modelling of Progressive Failure Leading To Spread in Sensitive Clay SlopesDocument12 pagesLarge Deformation Finite-Element Modelling of Progressive Failure Leading To Spread in Sensitive Clay SlopestehNo ratings yet

- British Soil Classification System For Engineering PurposesDocument4 pagesBritish Soil Classification System For Engineering PurposestehNo ratings yet

- Appendix A: Field Piling & PDA Driving Monitoring Records of Test PilesDocument16 pagesAppendix A: Field Piling & PDA Driving Monitoring Records of Test PilestehNo ratings yet

- International Forum Cum Conference Thailand 2000 v1Document155 pagesInternational Forum Cum Conference Thailand 2000 v1tehNo ratings yet

- Foundation of StructuresDocument748 pagesFoundation of Structuresteh100% (2)

- The Failure of Carsington Dam: G&technique 43, No. 1, 151-173Document23 pagesThe Failure of Carsington Dam: G&technique 43, No. 1, 151-173tehNo ratings yet

- Geotechnical EngineeringDocument27 pagesGeotechnical EngineeringtehNo ratings yet

- Overcoating of Lead-Based Paint On Steel StructuresDocument51 pagesOvercoating of Lead-Based Paint On Steel Structuresspahicdanilo100% (1)

- Norma ASTM C156Document5 pagesNorma ASTM C156Jony GutiérrezNo ratings yet

- DNV CG 0667Document23 pagesDNV CG 0667sony2anggaraNo ratings yet

- Phase EquilibriaDocument14 pagesPhase EquilibriaPaden TranNo ratings yet

- Front Side Silver Paste 653G SDS - GENERAL - TEXANOL (English Version) V2.7 (PB)Document6 pagesFront Side Silver Paste 653G SDS - GENERAL - TEXANOL (English Version) V2.7 (PB)Desheng ChewNo ratings yet

- Processing Guides Isbmbottlepresentation PDF 1Document25 pagesProcessing Guides Isbmbottlepresentation PDF 1Jay MehtaNo ratings yet

- Experience MinebackfillDocument5 pagesExperience MinebackfillCarlos Gutierrez0% (1)

- Exp No-5Document15 pagesExp No-5shiamNo ratings yet

- Liftonin Xpress Pres en Pa ModDocument24 pagesLiftonin Xpress Pres en Pa ModAlma PustaNo ratings yet

- Lubricant Coding Comparison - Din, Iso 6743 & GM Ls-2Document1 pageLubricant Coding Comparison - Din, Iso 6743 & GM Ls-2MOHAMED GamalNo ratings yet

- 5070 w14 QP 12Document16 pages5070 w14 QP 12hakimonlyNo ratings yet

- VCCTDocument35 pagesVCCTAshutosh SinglaNo ratings yet

- Technical Data Sheet Masterflow 810Document3 pagesTechnical Data Sheet Masterflow 810Marvin BaquialNo ratings yet

- Introduction To PlasmonicsDocument256 pagesIntroduction To Plasmonicsms853732No ratings yet

- Coatings and Construction Components (EU)Document20 pagesCoatings and Construction Components (EU)Shahid MirzaNo ratings yet

- SS2 HQ 5 PDFDocument11 pagesSS2 HQ 5 PDFRocka TranNo ratings yet

- Cement and Concrete Research: Ulla Hjorth Jakobsen, Klaartje de Weerdt, Mette R. GeikerDocument16 pagesCement and Concrete Research: Ulla Hjorth Jakobsen, Klaartje de Weerdt, Mette R. GeikerYollanda LorenzaNo ratings yet

- Petol Ps 460-5G: Technical SheetDocument2 pagesPetol Ps 460-5G: Technical SheetA MahmoodNo ratings yet

- Master's Research ProposalDocument7 pagesMaster's Research ProposalPeter OkitoiNo ratings yet

- Mechanics of Micro Electromechanical Systems (MEMS) : (A Brief Overview.)Document53 pagesMechanics of Micro Electromechanical Systems (MEMS) : (A Brief Overview.)Pulkit ChaudhariNo ratings yet

- Unit 1 Part 2 Element, Compound and MixtureDocument38 pagesUnit 1 Part 2 Element, Compound and MixtureI LOVE JAKENo ratings yet

- Untitled 3Document13 pagesUntitled 3SreeNo ratings yet

- QC RT AA TC35bDocument1 pageQC RT AA TC35bAizuddin RosliNo ratings yet

- Segregation of WasteDocument6 pagesSegregation of WasteMelem SaraNo ratings yet

- JyotiDocument67 pagesJyotigulatisrishti15No ratings yet

- Hsslive Xi Chemistry Simplified Notes - 221018 - 200627Document35 pagesHsslive Xi Chemistry Simplified Notes - 221018 - 200627Aadil NujumNo ratings yet

- Rumeca IdlerDocument20 pagesRumeca IdlerTriết Lãm NgôNo ratings yet

- PE CoatingDocument8 pagesPE CoatingHotnCrispy CrispyNo ratings yet