Professional Documents

Culture Documents

PP BPMLT Template

Uploaded by

raaghu0 ratings0% found this document useful (0 votes)

81 views3 pagesThis document outlines the key steps in the production planning process, including:

1) Creating planned orders to meet stock/requirements

2) Generating production orders from planned orders and assigning batch numbers

3) Releasing production orders, recording goods movements, and confirming production

4) Technically completing production orders and updating stock levels

It provides details on the transaction codes used to perform each step in SAP.

Original Description:

';oihgfx

Original Title

Pp Bpmlt Template

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the key steps in the production planning process, including:

1) Creating planned orders to meet stock/requirements

2) Generating production orders from planned orders and assigning batch numbers

3) Releasing production orders, recording goods movements, and confirming production

4) Technically completing production orders and updating stock levels

It provides details on the transaction codes used to perform each step in SAP.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

81 views3 pagesPP BPMLT Template

Uploaded by

raaghuThis document outlines the key steps in the production planning process, including:

1) Creating planned orders to meet stock/requirements

2) Generating production orders from planned orders and assigning batch numbers

3) Releasing production orders, recording goods movements, and confirming production

4) Technically completing production orders and updating stock levels

It provides details on the transaction codes used to perform each step in SAP.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 3

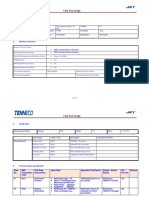

Production Planning

S.NO Business Process T. Code

1 Master Data

1000144 Material Master - MRP Views MM01

Material Master - Work Scheduling View MM01

Material Master - Basic Data View - Additional Data - Alternate U MM01

Bill of Material CS01

Resource COR1

Master Recipe C201

Production Version C223

Change Master CC01

2 Planning ( Make to Stock )

Create Planned Independent Requirements MD61

Stock / Requirements List (Check for PIR's) MD04

Run MRP MD02/MD01N

Check for Generated Planned Orders MD04

3 Production Process

Create Process Order or convert from planned order to process MDO4

Assign Batch Number to Finished / Semifinished Materials COR2

Batch Determination for Raw / Semi Finished Materials COR2

Release Process Order COR2

Store Requisition slip ZMCIL

Goods Issue to Process Order MIGO

Check List ZMCIL

Production Confirmation (Operation / Phase) for Yield and actual COR6N

q

Post Goods Receipt for Process Order MIGO

Display Stock Over view MMBE

Technically Complete the Process Order COR2

4 BMR/BPR

BMR/BPR print ZPP02

Production Planning & Controlling - BPMLT

Results Planed order Process Order Batch

Ok

Ok

Ok

Ok

Ok

Ok

Ok

Ok

Entered the Stock for the month

Planning

Noted the stocks and Requirement

Noted the statistics for the number of

Planned orders generated

Checked the planned orders generated

by MRP 5151

Check the Planned order and select

planned order 11000026

Batch number craeted 0002000002

Batches are determined according to

the FIFO and FEFO

Order has beeb released

SRS printed

Goods issue has done

Check list printed

Goods reciept doen

Stock displayed in urestricted

Order status change to TECO

Material Doc. No. Accounting Doc. No.

4900000150 49000000

5000000031 50000003

You might also like

- Schaum's Outline of Principles of Accounting I, Fifth EditionFrom EverandSchaum's Outline of Principles of Accounting I, Fifth EditionRating: 5 out of 5 stars5/5 (3)

- Truefire Guitar Chord Cookbook PDFDocument101 pagesTruefire Guitar Chord Cookbook PDFeuripides7794% (17)

- SAP MM Tables + Tcode + MM ReportDocument7 pagesSAP MM Tables + Tcode + MM ReportNguyen Ngoc Minh100% (1)

- A1D - Rework Production Order WIP in Process - BBPDocument17 pagesA1D - Rework Production Order WIP in Process - BBPGRMUDIMELA REDDYNo ratings yet

- Operational Profitability: Systematic Approaches for Continuous ImprovementFrom EverandOperational Profitability: Systematic Approaches for Continuous ImprovementNo ratings yet

- CA-Clipper For DOS Version 5.3 Programming and Utilities GuideDocument718 pagesCA-Clipper For DOS Version 5.3 Programming and Utilities GuideChris Harker91% (11)

- Raghunath Reddy KaminiDocument2 pagesRaghunath Reddy KaminiraaghuNo ratings yet

- Mto BPMLT TemplateDocument16 pagesMto BPMLT TemplateraaghuNo ratings yet

- Mto ScenarioDocument45 pagesMto ScenarioVi KraNo ratings yet

- MM Transaction CodesDocument17 pagesMM Transaction Codesvaibhavsam0766No ratings yet

- Materials Requirements PlanningDocument73 pagesMaterials Requirements PlanningParth Shah100% (1)

- Sap User DocumentationDocument37 pagesSap User DocumentationkkNo ratings yet

- Business Processes Master List Financial Accounting & ControllingDocument21 pagesBusiness Processes Master List Financial Accounting & ControllingPrathamesh ParkerNo ratings yet

- List of IEC StandardsDocument12 pagesList of IEC Standardsaravindeee08100% (1)

- PM Tcode List For UserDocument4 pagesPM Tcode List For Userritesh shrivastavNo ratings yet

- Equity Valuation: Models from Leading Investment BanksFrom EverandEquity Valuation: Models from Leading Investment BanksJan ViebigNo ratings yet

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Ericsson Command LineDocument39 pagesEricsson Command LinejulescarrelNo ratings yet

- 50TPD Soybean Oil Batch Type Solvent Extraction PlantDocument4 pages50TPD Soybean Oil Batch Type Solvent Extraction PlantKenan KardasNo ratings yet

- Rapid Manufacturing: An Industrial Revolution for the Digital AgeFrom EverandRapid Manufacturing: An Industrial Revolution for the Digital AgeNo ratings yet

- Simplification of MRP Functionality Is DoneDocument6 pagesSimplification of MRP Functionality Is DoneraaghuNo ratings yet

- SAP PP PI For Beginners PDFDocument23 pagesSAP PP PI For Beginners PDFNikhilesh KalavacharlaNo ratings yet

- Soda Ash PDFDocument45 pagesSoda Ash PDFM TNo ratings yet

- PP Changes in HANADocument3 pagesPP Changes in HANAraaghu100% (1)

- Raghu PPQM CVDocument4 pagesRaghu PPQM CVraaghuNo ratings yet

- Material Staging For Process OrderDocument17 pagesMaterial Staging For Process Orderraaghu100% (1)

- 7814 - 6 - Material Requirement PlanningDocument36 pages7814 - 6 - Material Requirement PlanningorbansaNo ratings yet

- Material Requirement Planning: Master Schedule FORDocument22 pagesMaterial Requirement Planning: Master Schedule FORBhanu Pratap Singh ShekhawatNo ratings yet

- Material Requirements PlanningDocument10 pagesMaterial Requirements Planningjubin654No ratings yet

- Steps For REM & DiscreteDocument7 pagesSteps For REM & DiscreteganeshNo ratings yet

- Business Process Steps & Transactions: SL - No Transaction T.codeDocument6 pagesBusiness Process Steps & Transactions: SL - No Transaction T.codeK Raghunatha ReddyNo ratings yet

- Production Planning and Execution (PP) : Master DataDocument1 pageProduction Planning and Execution (PP) : Master DataDanielAlamoNo ratings yet

- Client DiscusssionDocument18 pagesClient DiscusssionANIL SINGHNo ratings yet

- PP Trans CodeDocument5 pagesPP Trans CodeRajaRamNo ratings yet

- Chapter - Iii Materials Requirement PlanningDocument7 pagesChapter - Iii Materials Requirement PlanningSindhu ApoorvaNo ratings yet

- Chapter 13 PPSJ Lecture 1Document26 pagesChapter 13 PPSJ Lecture 1ali aknarNo ratings yet

- Department Transaction T - CodesDocument5 pagesDepartment Transaction T - Codesravi nNo ratings yet

- MRPDocument43 pagesMRPTariku AbateNo ratings yet

- Batch03 DemoDocument713 pagesBatch03 DemoSAP PMNo ratings yet

- CH4.4.2 Inventory Control MRPDocument27 pagesCH4.4.2 Inventory Control MRPseadamoh80No ratings yet

- T CodesDocument7 pagesT CodesjihanemkaNo ratings yet

- PP Master Data Version 002Document34 pagesPP Master Data Version 002pranitNo ratings yet

- Material Requirement PlanningDocument89 pagesMaterial Requirement PlanningPrem AnandNo ratings yet

- Transactioncodes SAP PPDocument2 pagesTransactioncodes SAP PPDana BolocaNo ratings yet

- Production Planning SAP TcodesDocument3 pagesProduction Planning SAP TcodesSifati MituNo ratings yet

- Manufacturing All AppsDocument3 pagesManufacturing All Appswai waiNo ratings yet

- Chapter 13 PPSJ Lecture 2Document14 pagesChapter 13 PPSJ Lecture 2ali aknarNo ratings yet

- Submitted To: Submitted By:: Sachin Kumar Vishal Kumar & RajdeepDocument33 pagesSubmitted To: Submitted By:: Sachin Kumar Vishal Kumar & Rajdeepvishakh kumar srivastavaNo ratings yet

- 6 - Material Requirement PlanningDocument37 pages6 - Material Requirement PlanningEza R LANo ratings yet

- List of SAP MM Transaction CodesDocument20 pagesList of SAP MM Transaction CodesPILLINAGARAJUNo ratings yet

- MM Tcode and TableDocument25 pagesMM Tcode and TableankitaNo ratings yet

- Installation and Dismantling List (Multi-Level) Equipment List StructureDocument19 pagesInstallation and Dismantling List (Multi-Level) Equipment List StructureHarish DesaiNo ratings yet

- Supply of Concrete or Block To Own Company Projects MRPDocument14 pagesSupply of Concrete or Block To Own Company Projects MRPTushar KohinkarNo ratings yet

- 10 Annexure I - Workflow-Reqirements - All ModulesDocument5 pages10 Annexure I - Workflow-Reqirements - All ModulessowjanyaNo ratings yet

- 09 MO Materials Requirement PlanningDocument35 pages09 MO Materials Requirement PlanningYogikantana. BNo ratings yet

- Lecture 7 Dependent Demand InventoryDocument20 pagesLecture 7 Dependent Demand InventoryWilliam DC RiveraNo ratings yet

- Sap MM Flow Chart CMDocument4 pagesSap MM Flow Chart CMgrc.coo.123No ratings yet

- BJK S4hana2023 BPD en deDocument19 pagesBJK S4hana2023 BPD en deabdeltifNo ratings yet

- Chapter 11 (MRP) 1Document39 pagesChapter 11 (MRP) 1VeilNo ratings yet

- Material Requirement PlanningDocument41 pagesMaterial Requirement PlanningLkmdfNo ratings yet

- Material Requirements Planning (MRP)Document19 pagesMaterial Requirements Planning (MRP)Jayanatha BandaraNo ratings yet

- SAP S:4HANA Simplification ListDocument3 pagesSAP S:4HANA Simplification Listprady.sapficoNo ratings yet

- Operation Management Case MRP at A Cat Corp PDFDocument44 pagesOperation Management Case MRP at A Cat Corp PDFSanju Durgapal100% (2)

- Unit Testing Test ScriptDocument21 pagesUnit Testing Test ScriptErBikasKumarPathakNo ratings yet

- SAP Transaction Wise Flow - Job Work - OEDocument2 pagesSAP Transaction Wise Flow - Job Work - OEKoustubha KhareNo ratings yet

- Sap PP: Production PlanningDocument10 pagesSap PP: Production PlanningNARESH SINGARAMNo ratings yet

- SAP T-Code2Document2 pagesSAP T-Code2Gaurav MatetwarNo ratings yet

- Engineering Service Revenues World Summary: Market Values & Financials by CountryFrom EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNo ratings yet

- The Cell Control ReportFrom EverandThe Cell Control ReportNo ratings yet

- Pradeep Kumar Bobbili - Dec'17 - PayslipDocument1 pagePradeep Kumar Bobbili - Dec'17 - PayslipraaghuNo ratings yet

- Z Tcodes of PuniskaDocument5 pagesZ Tcodes of PuniskaraaghuNo ratings yet

- Health Id Card, KJHDocument2 pagesHealth Id Card, KJHraaghuNo ratings yet

- Creat Material Cost Estimate With Quantity StructureDocument4 pagesCreat Material Cost Estimate With Quantity StructureraaghuNo ratings yet

- Rmmg1-Matnr Storage Location RMMG1-Mbrsh RMMG1 - Mtart RMMG1 - WerksDocument6 pagesRmmg1-Matnr Storage Location RMMG1-Mbrsh RMMG1 - Mtart RMMG1 - WerksraaghuNo ratings yet

- Master Inspection Characteristics DEMODocument1 pageMaster Inspection Characteristics DEMOraaghuNo ratings yet

- Production Planning PaySlip636934334806973847 AprailDocument1 pageProduction Planning PaySlip636934334806973847 AprailraaghuNo ratings yet

- Notifications QM11 List of NotificationsDocument2 pagesNotifications QM11 List of NotificationsraaghuNo ratings yet

- Zcqp01 ProgrameDocument8 pagesZcqp01 ProgrameraaghuNo ratings yet

- PQ PP PuniskaDocument3 pagesPQ PP PuniskaraaghuNo ratings yet

- OQ/P/10/SAP/PP: Protocol No: Operation Qualification Annexure - 1 - Scripts Sap/Erp Department Page 1 of 3Document3 pagesOQ/P/10/SAP/PP: Protocol No: Operation Qualification Annexure - 1 - Scripts Sap/Erp Department Page 1 of 3raaghuNo ratings yet

- Test Document of FG01 Storage Location AuthorisationDocument5 pagesTest Document of FG01 Storage Location AuthorisationraaghuNo ratings yet

- TCODES List Related To KUSUMDocument8 pagesTCODES List Related To KUSUMraaghuNo ratings yet

- BPMLT TemplateDocument4 pagesBPMLT TemplateraaghuNo ratings yet

- Staircase Preliminary Design Based On NBC and IS CodeDocument10 pagesStaircase Preliminary Design Based On NBC and IS CodeEducation. HubNo ratings yet

- Electrical Submersible Pump HandbookDocument67 pagesElectrical Submersible Pump HandbookAnonymous Xy309m9Sm9No ratings yet

- Hard Disk Drive Specification HGST Travelstar Z7K500Document173 pagesHard Disk Drive Specification HGST Travelstar Z7K500OmegalexNo ratings yet

- Relayoperationprinciples 141126065914 Conversion Gate01Document43 pagesRelayoperationprinciples 141126065914 Conversion Gate01kenlavie2No ratings yet

- Three-Dimensional Lithium-Ion Battery ModelDocument35 pagesThree-Dimensional Lithium-Ion Battery ModelmortezagashtiNo ratings yet

- Parola A Do ZDocument8 pagesParola A Do ZjovicaradNo ratings yet

- Genetic Variability and Correlation Studies in Okra (Abelmuschus Esculentus (L) Moench)Document67 pagesGenetic Variability and Correlation Studies in Okra (Abelmuschus Esculentus (L) Moench)rajsign5100% (3)

- Calculation of Altitude CorrectionDocument3 pagesCalculation of Altitude CorrectionMikami TeruNo ratings yet

- Estimation of Microbial GrowthDocument25 pagesEstimation of Microbial GrowthziaiitdNo ratings yet

- His To GramsDocument15 pagesHis To GramsMaryam HasanNo ratings yet

- Upflow Anaerobic Sludge Blanket-Hollow Centered Packed Bed (UASB-HCPB) Reactor For Thermophilic Palm Oil Mill Effluent (POME) TreatmentDocument12 pagesUpflow Anaerobic Sludge Blanket-Hollow Centered Packed Bed (UASB-HCPB) Reactor For Thermophilic Palm Oil Mill Effluent (POME) TreatmentAgung Ariefat LubisNo ratings yet

- Manual AvicadDocument676 pagesManual AvicadOlivia BlanaruNo ratings yet

- Methods of Test For Rheometer - ODR: 1. ScopeDocument1 pageMethods of Test For Rheometer - ODR: 1. ScopeArun GuptaNo ratings yet

- UntitledDocument33 pagesUntitledapi-235198167No ratings yet

- PLCC-28: FeaturesDocument5 pagesPLCC-28: Features肖磊No ratings yet

- Article On Online ShoppingDocument23 pagesArticle On Online ShoppingsaravmbaNo ratings yet

- Sap Basis Transaction CodesDocument2 pagesSap Basis Transaction CodeskatrinbreaksNo ratings yet

- Module 4. Heat TransferDocument28 pagesModule 4. Heat TransferBry RamosNo ratings yet

- Cell Biology: Science Explorer - Cells and HeredityDocument242 pagesCell Biology: Science Explorer - Cells and HeredityZeinab ElkholyNo ratings yet

- Stars and Galaxies 9th Edition Seeds Test BankDocument20 pagesStars and Galaxies 9th Edition Seeds Test Bankngocalmai0236h100% (32)

- Catalogue Solid Core PDFDocument16 pagesCatalogue Solid Core PDFdangodNo ratings yet

- Concept Note For The Conversion of 75 TPHDocument2 pagesConcept Note For The Conversion of 75 TPHMeera MishraNo ratings yet

- Chapter6b-Combinational Logic Design PracticesDocument38 pagesChapter6b-Combinational Logic Design PracticesZulkarnineNo ratings yet

- Field Report of Attock-Cherat Range PDFDocument6 pagesField Report of Attock-Cherat Range PDFAslam KhanNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)