Professional Documents

Culture Documents

Optimize PRD Inspection Intervals Using RBI < 40

Uploaded by

mukeshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimize PRD Inspection Intervals Using RBI < 40

Uploaded by

mukeshCopyright:

Available Formats

RBI: CASE STUDY

OPTIMIZE PRD INSPECTION INTERVALS USING PRD RBI

The traditional inspection planning method for setting intervals for PRDs in the API 510 inspection code only considers

the probability of failure of the valve. It does not consider the consequence and risk of a potential failure.

RBI is a more rigorous inspection planning method that sets intervals based on both the Probability and Consequence of

Failure. RBI is a beneficial inspection method because in most facilities a large percent of the total risk is concentrated

in a relatively small percent of the equipment items. RBI allows a facility to focus on the high-risk equipment and not on

equipment with little to no risk.

PROBLEM

A facility asked E2G to determine acceptable PRD inspection intervals using an RBI planning method as opposed to the

traditional inspection planning method they had been implementing.

CALCULATION BACKGROUND

• The RBI inspection intervals were determined using the API 581 PRD RBI technology.

• An acceptable risk level based on industry standards was used to determine the maximum interval a PRD could be in

service without needing inspection.

BENEFITS TO THE CLIENT

• By shortening the high risk valves’ inspection interval, the RBI assessment also decreased the overall risk of the

valves by 60%.

• The RBI assessment increased the average PRD inspection interval from 4.3 years to 7.3 years (70% increase).

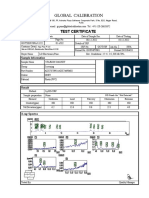

INSPECTION INTERVAL COMPARISON RISK COMPARISON

Total Current Risk Total RBI Risk

Average Current Interval Average RBI Interval Reduction

Acceptable Risk Acceptable Risk

4.3 years 7.3 years 233% 94% 60%

Corporate Headquarters For More Information:

20600 Chagrin Boulevard, Suite 1200 Valerie Magyari

Shaker Heights, OH 44122 P. 216.658.4744

www.EquityEng.com E. VMagyari@EquityEng.com

RBI: CASE STUDY (CONTINUED)

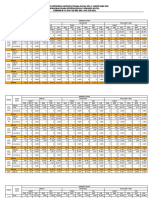

EXAMPLE OF INSPECTION PLAN COMPARISON (EXCERPT TAKEN FROM ANALYSIS)

LAST CURRENT TOTAL CURRENT RISK RBI TOTAL RBI RISK NEXT RBI

PRD TAG PROTECTED SERVICE

INSPECTION INTERVAL INTERVAL INSPECTION

NUMBER COMPONENT FLUID ACCEPTABLE RISK ACCEPTABLE RISK

DATE (YRS) (YRS) DATE

Naphtha

PRD-0007 C-3805 Feb-2013 4.0 79% 4.7 100% Oct-2017

H2S 0.5

C3 (H2S

PRD-0032 D-1605 Nov-2012 4.0 118% 3.6 100% Jun-2016

2000PPM)

PRD-0044 C-41100 C1-C3 Feb-2013 4.0 126% 3.4 100% Aug-2016

PRD-0045 C-1608 Air + Caustic Nov-2012 4.0 67% 5.0 100% Nov-2017

PRD-0053 D-4183 Mercaptan Mar-2013 4.0 32% 8.2 100% May-2021

PRD-0062 D-1655 LVGO Mar-2013 4.0 31% 9.0 100% Mar-2022

PRD-0064 D-1656 LVGO Mar-2013 4.0 37% 8.0 100% Feb-2021

C3-C4,

PRD-0078 C-1909 Amine, Feb-2013 4.0 58% 5.5 100% Aug-2018

Water

PRD-0086 D-1645 Fuel Gas Feb-2013 4.0 96% 4.1 100% Apr-2017

PRD-0305 D-1001 Steam Dec-2012 4.0 22% 9.7 100% Sep-2022

PRD-0354 G-1043A Ammonia Jan-2014 5.0 395% 2.0 100% Apr-2016

Corporate Headquarters For More Information:

20600 Chagrin Boulevard, Suite 1200 Valerie Magyari

Shaker Heights, OH 44122 P. 216.658.4744

www.EquityEng.com E. VMagyari@EquityEng.com

You might also like

- 41 41 Comprehensive Project Report FormatDocument46 pages41 41 Comprehensive Project Report FormatNirali ShahNo ratings yet

- Central Plant Optimization For Waste Energy Reduction (CPOWER)Document58 pagesCentral Plant Optimization For Waste Energy Reduction (CPOWER)Chhaya ThakorNo ratings yet

- Report OQPV GC NGADocument12 pagesReport OQPV GC NGAyogiNo ratings yet

- Result Presentation (Result)Document14 pagesResult Presentation (Result)Shyam SunderNo ratings yet

- PEE Practices in The Philippines - V2Document44 pagesPEE Practices in The Philippines - V2MAKANNo ratings yet

- Periode 2022 - 2023: Karung PT Yana Prima Hasta PersadaDocument21 pagesPeriode 2022 - 2023: Karung PT Yana Prima Hasta PersadaSyahril CalliNo ratings yet

- QUOTATION - Uni Farm - Sampling&Analysis - SerdangBedDocument4 pagesQUOTATION - Uni Farm - Sampling&Analysis - SerdangBedbudi irawanNo ratings yet

- Hydraulic Calculation Report R0Document36 pagesHydraulic Calculation Report R0Pawan Sparrow100% (1)

- Benchmark Report For India AIFs 2022Document7 pagesBenchmark Report For India AIFs 2022Apurva ChamariaNo ratings yet

- Case Week 2 - Kelompok 2Document10 pagesCase Week 2 - Kelompok 2Felix FelixNo ratings yet

- XYZ Insurance Company Incurred Loss Development and Reserving AnalysisDocument6 pagesXYZ Insurance Company Incurred Loss Development and Reserving AnalysisSetyo Tyas JarwantoNo ratings yet

- MS For Leak Test in ManholesDocument7 pagesMS For Leak Test in ManholesMadhavMitruNo ratings yet

- A Study On Financial Performance of Hindustan Copper LimitedDocument4 pagesA Study On Financial Performance of Hindustan Copper LimitedIJRASETPublicationsNo ratings yet

- Projects Development CompanyDocument135 pagesProjects Development CompanySn AhsanNo ratings yet

- MRF 1Q Fy2013Document12 pagesMRF 1Q Fy2013Angel BrokingNo ratings yet

- Descriptive FindingsDocument8 pagesDescriptive FindingsValdi NadhifNo ratings yet

- Chile Utilities - 2014.10.13 - Better Outlook For 2014-15 Ice-Melting SeasonDocument15 pagesChile Utilities - 2014.10.13 - Better Outlook For 2014-15 Ice-Melting SeasonPaola NajeraNo ratings yet

- Financial ReseachDocument14 pagesFinancial ReseachAman RenaNo ratings yet

- Champions Trophy: Industry 4.0Document13 pagesChampions Trophy: Industry 4.0Uday SharmaNo ratings yet

- Return Summary 3Document6 pagesReturn Summary 3mai quynhNo ratings yet

- Fq-Tec-904 - Ultrasonic A-Scan ReportDocument2 pagesFq-Tec-904 - Ultrasonic A-Scan ReportMajdi JerbiNo ratings yet

- MRF 2Q Sy 2013Document12 pagesMRF 2Q Sy 2013Angel BrokingNo ratings yet

- Project Reference - List - EurotechDocument12 pagesProject Reference - List - EurotechEurotech Tra TranNo ratings yet

- Project Proposal for Poultry Feed UnitDocument45 pagesProject Proposal for Poultry Feed UnitSoundararajan Seerangan73% (33)

- Financial Analysis of Hoa Phat Joint Stock Company (HPGDocument22 pagesFinancial Analysis of Hoa Phat Joint Stock Company (HPGMinh NguyệtNo ratings yet

- Financial AnalysisDocument8 pagesFinancial AnalysisAnh TramNo ratings yet

- AA13N-5. Estándar Cromo. 18-05-2026Document2 pagesAA13N-5. Estándar Cromo. 18-05-2026calidadlaboratoriocgrNo ratings yet

- NDE NDT Procedures Piping ADM 35313M-01 Q 153 01-1-150Document150 pagesNDE NDT Procedures Piping ADM 35313M-01 Q 153 01-1-150QC ManagerNo ratings yet

- NDE NDT Procedures Piping ADM 35313M-01 Q 153 01Document392 pagesNDE NDT Procedures Piping ADM 35313M-01 Q 153 01Neil JavierNo ratings yet

- APM Case Study (RegionFlyDocument14 pagesAPM Case Study (RegionFlyVignesh Balachandar100% (3)

- Regionfly: Cutting Costs in The Airline IndustryDocument17 pagesRegionfly: Cutting Costs in The Airline IndustrySandy ZhengNo ratings yet

- Bonos AfueraDocument9 pagesBonos AfueraMatias VargasNo ratings yet

- Manchester University student contact listDocument22 pagesManchester University student contact listdaniel angusNo ratings yet

- Laporan Monitoring Angkutan Udara Natal 2019Document11 pagesLaporan Monitoring Angkutan Udara Natal 2019Andika Chandra PermataNo ratings yet

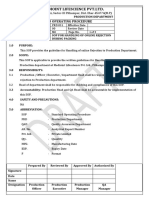

- Medioint Lifescience PVT - LTD.: Standard Operating ProcedureDocument3 pagesMedioint Lifescience PVT - LTD.: Standard Operating ProcedureChoudhary DhirajNo ratings yet

- Meeting PointsDocument2 pagesMeeting PointshellosaadyNo ratings yet

- Price Comparison Shows Impact of Localization on Auto Parts SalesDocument2 pagesPrice Comparison Shows Impact of Localization on Auto Parts SaleshellosaadyNo ratings yet

- TMB Presentation 1Q20Document22 pagesTMB Presentation 1Q20ysgoutham_304757100No ratings yet

- yriearningsforecastDocument7 pagesyriearningsforecastjhllninmNo ratings yet

- Rubber Sponge Test ReportDocument5 pagesRubber Sponge Test ReportDesi Anisa Amini PurnagaraNo ratings yet

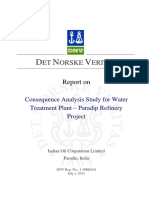

- Consequence Analysis Report For WTPDocument28 pagesConsequence Analysis Report For WTPSanjeev Kumar DasNo ratings yet

- S&P 500 Earnings Scorecard: Proprietary ResearchDocument11 pagesS&P 500 Earnings Scorecard: Proprietary ResearchWill AdefehintiNo ratings yet

- 191. Agro-Chemical Sprayer FinalDocument25 pages191. Agro-Chemical Sprayer FinalRobel KefelewNo ratings yet

- Nucor Corporation (NUE) : Key MetricsDocument3 pagesNucor Corporation (NUE) : Key MetricsepbeaverNo ratings yet

- TEMPLATE DCF Made Simple by Kefas EvanderDocument32 pagesTEMPLATE DCF Made Simple by Kefas EvanderMuhammad RizaldiNo ratings yet

- Toxicity test criteria for railcarsDocument81 pagesToxicity test criteria for railcarsphoebe chanNo ratings yet

- Equipment CostingDocument67 pagesEquipment CostingNazario Emil LintagNo ratings yet

- Rejection Analysis of Casting Defect Using Statical Quality ToolsDocument5 pagesRejection Analysis of Casting Defect Using Statical Quality ToolsIJRASETPublicationsNo ratings yet

- Total StationDocument2 pagesTotal StationjoshuaNo ratings yet

- 26071-203-V66A-MTFR-20013 - Rev002 - NDE Procedure (PAUT, RT, PT, MT, UT)Document189 pages26071-203-V66A-MTFR-20013 - Rev002 - NDE Procedure (PAUT, RT, PT, MT, UT)randi martaNo ratings yet

- Reporte de Indicador Safety ProcessDocument107 pagesReporte de Indicador Safety ProcessjoseNo ratings yet

- GC TXRF 589a 11 22Document2 pagesGC TXRF 589a 11 22Kunal PadamwarNo ratings yet

- C.banner 2014AR Eng FinalDocument24 pagesC.banner 2014AR Eng FinalKhishigbayar PurevdavgaNo ratings yet

- Mahatma Phule Krishi Vidyapeeth Rahuri: College of Agriculture, Babhulgaon Course - Wise Result SheetDocument2 pagesMahatma Phule Krishi Vidyapeeth Rahuri: College of Agriculture, Babhulgaon Course - Wise Result SheetTushar JadhavNo ratings yet

- Avionics Shop Manual: Uncontrolled DocumentDocument53 pagesAvionics Shop Manual: Uncontrolled DocumentWallyNo ratings yet

- SNGPLDocument20 pagesSNGPLMuhammad Ali TahirNo ratings yet

- Calibrating a Silica AnalyzerDocument5 pagesCalibrating a Silica AnalyzerVINOTHINI R B.EdNo ratings yet

- Security Assessment: XYZ FacilityDocument20 pagesSecurity Assessment: XYZ FacilityThuongNo ratings yet

- Economic Indicators for South and Central Asia: Input–Output TablesFrom EverandEconomic Indicators for South and Central Asia: Input–Output TablesNo ratings yet

- Economic Indicators for Southeastern Asia and the Pacific: Input–Output TablesFrom EverandEconomic Indicators for Southeastern Asia and the Pacific: Input–Output TablesNo ratings yet

- Mining Gate2021Document7 pagesMining Gate2021level threeNo ratings yet

- Slides 06 PDFDocument71 pagesSlides 06 PDFLoai MohamedNo ratings yet

- Tooling Standard (Die Casting)Document39 pagesTooling Standard (Die Casting)Kmilo GiraldoNo ratings yet

- Courts CP, XO CP, Circumvention - DDI 2015 SWSDocument311 pagesCourts CP, XO CP, Circumvention - DDI 2015 SWSdavidsi325No ratings yet

- 809kW Marine Propulsion Engine SpecificationsDocument2 pages809kW Marine Propulsion Engine SpecificationsRoberto StepankowskyNo ratings yet

- EXPRESS Report: Express KIO008R Export ReceivalDocument4 pagesEXPRESS Report: Express KIO008R Export ReceivalYasir HabibNo ratings yet

- Digitech's s100 ManualDocument24 pagesDigitech's s100 ManualRudy Pizzuti50% (2)

- LogProcessing-TEICH v2Document23 pagesLogProcessing-TEICH v2slides courseNo ratings yet

- NEPAL OBTE Curriculum Grade 6 8 Page 0 23 1 ENDocument19 pagesNEPAL OBTE Curriculum Grade 6 8 Page 0 23 1 ENSonam Lama0% (1)

- How To Add Message Queuing Feature - Dell IndiaDocument2 pagesHow To Add Message Queuing Feature - Dell Indiayuva razNo ratings yet

- Sachin Vinod Nahar: SVKM's Usha Pravin Gandhi College of ManagementDocument3 pagesSachin Vinod Nahar: SVKM's Usha Pravin Gandhi College of ManagementSachin NaharNo ratings yet

- Level 3 Repair: 8-1. Components LayoutDocument50 pagesLevel 3 Repair: 8-1. Components LayoutManuel BonillaNo ratings yet

- DB858DG90ESYDocument3 pagesDB858DG90ESYОлександр ЧугайNo ratings yet

- SEZOnline SOFTEX Form XML Upload Interface V1 2Document19 pagesSEZOnline SOFTEX Form XML Upload Interface V1 2శ్రీనివాసకిరణ్కుమార్చతుర్వేదులNo ratings yet

- The Tamil Nadu Municipal General Service Rules, 1970Document13 pagesThe Tamil Nadu Municipal General Service Rules, 1970urbangovernance99100% (1)

- Scf-Capital Structure Questions (Tybfm)Document2 pagesScf-Capital Structure Questions (Tybfm)TFM069 -SHIVAM VARMANo ratings yet

- Production Part Approval Process: Fourth EditionDocument5 pagesProduction Part Approval Process: Fourth Editiontanya67% (3)

- Evacuation Process of HVAC SystemDocument23 pagesEvacuation Process of HVAC SystemDinesh SinghNo ratings yet

- Swelab User ManualDocument2 pagesSwelab User Manualhayder FadelNo ratings yet

- Tech Elevator School Catalog, 2020 PDFDocument29 pagesTech Elevator School Catalog, 2020 PDFjohanmulyadi007No ratings yet

- DF4 5 6 MedidasDocument2 pagesDF4 5 6 MedidasMiguel Ruivo AlmeidaNo ratings yet

- International Auditing Overview: Principles of Auditing: An Introduction To International Standards On Auditing - Ch. 1Document36 pagesInternational Auditing Overview: Principles of Auditing: An Introduction To International Standards On Auditing - Ch. 1Almi HafizNo ratings yet

- Acramin Prefix KDocument3 pagesAcramin Prefix KB.M. RasheduzzamanNo ratings yet

- Understanding the Doctrine of Volenti Non Fit InjuriaDocument14 pagesUnderstanding the Doctrine of Volenti Non Fit InjuriaRishabh BhandariNo ratings yet

- GEC 6 Lesson 12Document19 pagesGEC 6 Lesson 12Annie CabugNo ratings yet

- Carbon Cycle SEDocument7 pagesCarbon Cycle SEAlex0% (3)

- Alabama Tenants HandbookDocument26 pagesAlabama Tenants HandbookzorthogNo ratings yet

- Sumo Safari SpicerDocument3 pagesSumo Safari SpicerAbishek MongaNo ratings yet

- Paf-Karachi Institute of Economics & Technology Spring - 2021Document3 pagesPaf-Karachi Institute of Economics & Technology Spring - 2021Basic Knowledge Basic KnowledgeNo ratings yet

- Complainant Vs Vs Respondent: Third DivisionDocument7 pagesComplainant Vs Vs Respondent: Third DivisionervingabralagbonNo ratings yet