Professional Documents

Culture Documents

Anti Fouling

Uploaded by

Tun Naing WinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anti Fouling

Uploaded by

Tun Naing WinCopyright:

Available Formats

CUPRION®

MARINE ANTI-FOULING SYSTEM

OFFSHORE PLATFORMS

Biofouling of water intake pumps and pipework on offshore platforms can be a major problem, causing expensive

equipment damage and pipework blockages, leading to shut down of vital seawater supplies.

In the case of fire water systems crew safety and structure integrity must be

considered. In addition, repairs to damaged pumps and pipe work are both

costly and time consuming.

Maintenance Managers would consider any remedial actions involving pipe

section removal, repair, cleaning and re-installation as major refurbishment

work on any operating offshore facility.

CUPRION® - THE SOLUTION

Cathodic Protection Co. Limited (CPCL) has developed a range of CUPRION® anti-fouling systems to protect

submerged pumps, seawater intakes and associated pipework against marine growth. Originally the CUPRION®

system was developed and utilised for North Sea applications during the early 1970’s. Today the system is specified

for use on offshore platforms worldwide by many of the major oil & gas offshore operators.

The CUPRION® system is listed on Article 95 of the EU Biocides Regulation (528/2012) which came into effect on

1st September 2015, ensuring CPCL is legally entitled to place the CUPRION® system on to the European market.

CUPRION® operates on electrolytic principles, employing a small d.c. current flow (generally less than 1 kW). This

current flow energises copper and aluminium anodes to produce a fully effective, anti-foulant dosing solution.

Selected dosing levels vary slightly to suit location and application, however maximum dosing limits utilised for design

purposes are 24 μg/litre and 4 μg/litre for copper and aluminium respectively.

Copper is a natural biocide and provides

complete protection from hard marine growth

with no adverse environmental impact.

Aluminium anodes produce aluminium hydroxide,

which combines with the copper ions holding

them in solution, keeping pipe work blockage free.

Aluminium hydroxide also helps arrest corrosion

on internal pipe surfaces.

The CUPRION® system has been successfully applied on all types of seawater intakes from submerged pumps to

open intake sea chests. The design of the electrode units can be adapted to suit all application requirements, but are

usually mounted on submerged pumps or bolted to the wall of a sea chest.

T: +44 (0)1476 590666

E: sales@cuprion.co.uk www.cuprion.co.uk

CUPRION®

MARINE ANTI-FOULING SYSTEM

OFFSHORE PLATFORMS

Where space or weight restrictions are design

considerations, CPCL has developed a deck mounted

system that utilises an electrolysis tank with required

seawater supply connections.

The CUPRION® anodes are simply mounted in the tank

and energised to produce anti-foulant solution, which is

delivered to the intake area via suitably rated pipes or

hoses.

The reaction chamber is generally mounted on a steel

plinth adjacent to the d.c. power unit, making the complete

system integral, ideal for maintenance operations. Anti-

Fouling electrodes take around 30 minutes to replace.

CUPRION® - IN THE OFFSHORE INDUSTRY

CUPRION® systems have been installed on all types of offshore structures worldwide, indicative list below.

Field / Platform Country Client System Description

Valhall West

Norway Eureka Pump CUPRION® system for sea water lift pump

Flank

Umm Lulu & CUPRION® system installed with removable inlet

UAE Various

NASR strainer

ANOA & AGX Indonesia Premier Oil CUPRION® Deck system for sea water lift pumps

Ravenspurn UK Perenco CUPRION® system for sea water lift pump

Forties CUPRION® fitted to sea water lift and fire water

UK Apache

A/B/C/D/E pumps

CUPRION® fitted to cooling water, sea water lift

Rough Field UK Centrica

and fire water pumps to replace EC system

T: +44 (0)1476 590666

E: sales@cuprion.co.uk www.cuprion.co.uk

You might also like

- Underwater Technology: Offshore PetroleumFrom EverandUnderwater Technology: Offshore PetroleumL. AtteraasNo ratings yet

- Cuprion Anti Fouling Section - New1Document9 pagesCuprion Anti Fouling Section - New1taroxfumaNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Cuprion PDFDocument30 pagesCuprion PDFduong hoang tin100% (1)

- Maintain and Improve Your Powerboat: 100 Ways to Make Your Boat BetterFrom EverandMaintain and Improve Your Powerboat: 100 Ways to Make Your Boat BetterNo ratings yet

- Cup 03 BB3 Uk WebDocument7 pagesCup 03 BB3 Uk Webschumiizz2bestNo ratings yet

- Pci Africa - WatefDocument4 pagesPci Africa - WatefEmelia JugdavNo ratings yet

- OUTDATED-AQUARIUS EC Case Study 082012 Hi ResDocument2 pagesOUTDATED-AQUARIUS EC Case Study 082012 Hi ResÇağlayan TopNo ratings yet

- 7807 Rev - (Village Marine Product Brochure)Document32 pages7807 Rev - (Village Marine Product Brochure)Jonathan Marcelo Lara CraveroNo ratings yet

- KSB butterfly valves help increase efficiency at Drax Power StationDocument2 pagesKSB butterfly valves help increase efficiency at Drax Power Stationseetharaman k sNo ratings yet

- Cathelco ElectrochlorinationDocument8 pagesCathelco ElectrochlorinationmohammadazraiNo ratings yet

- KYsearo Profile PDFDocument24 pagesKYsearo Profile PDFRacil EzzedineNo ratings yet

- INS DS 0274 Mariner OmnipureDocument4 pagesINS DS 0274 Mariner OmnipureJuan LlempiNo ratings yet

- District Energy PlantDocument11 pagesDistrict Energy Plantyara2011No ratings yet

- PDF-Reavell Marine Offshore BrochureDocument8 pagesPDF-Reavell Marine Offshore BrochureDaniel ArbeláezNo ratings yet

- Hypochlorite GenerationDocument2 pagesHypochlorite GenerationsidatsenaNo ratings yet

- Cathodic Protection OffshoreDocument8 pagesCathodic Protection OffshoreSubramanian Saravanan100% (1)

- Cuprion Anti Fouling: Cathodic Protection For The Oil, Gas, Water & Power IndustriesDocument4 pagesCuprion Anti Fouling: Cathodic Protection For The Oil, Gas, Water & Power IndustriesLâm ThanhNo ratings yet

- Seacure Gen W DT Dynagas PDocument46 pagesSeacure Gen W DT Dynagas PAlex KuvoricNo ratings yet

- Ebara - Cryogenic Pump and ExpandersDocument20 pagesEbara - Cryogenic Pump and ExpandersXue Feng Du0% (1)

- INEC 2022 Paper - Vaporise After Reading - Pyrolysis and Waste Management On Queen Elizabeth Class Carriers - Post Comments - 27.09.22Document11 pagesINEC 2022 Paper - Vaporise After Reading - Pyrolysis and Waste Management On Queen Elizabeth Class Carriers - Post Comments - 27.09.22Hayden C100% (1)

- 10 - 0201 Aqua-Nova Lo - Res PDFDocument4 pages10 - 0201 Aqua-Nova Lo - Res PDFjl181No ratings yet

- Simply Safer - . .: Wahlco U2A® Urea To Ammonia SystemDocument6 pagesSimply Safer - . .: Wahlco U2A® Urea To Ammonia SystemkangsungjinNo ratings yet

- Gefico General 2012Document35 pagesGefico General 2012rsalvasanNo ratings yet

- Aqua CellDocument23 pagesAqua CellPeterMulcahy2000No ratings yet

- Ec Chloropac BR 0209Document8 pagesEc Chloropac BR 0209dubaisrinivasuluNo ratings yet

- Calm Boy Leaflet - Vopak - ENOC PDFDocument2 pagesCalm Boy Leaflet - Vopak - ENOC PDFdndudcNo ratings yet

- Epcon - Tech (CFU)Document5 pagesEpcon - Tech (CFU)achmadh_2010No ratings yet

- Cathelco Seawater Pipework Anti-FoulingDocument7 pagesCathelco Seawater Pipework Anti-FoulingMichael CorderoNo ratings yet

- Pump BrochureDocument10 pagesPump Brochuresen_subhasis_58No ratings yet

- Seawater Pipe Anti-Fouling SystemsDocument7 pagesSeawater Pipe Anti-Fouling Systemsm_metco2240No ratings yet

- 28990-Turbinebypass Prds PDFDocument12 pages28990-Turbinebypass Prds PDFbuddhivasu100% (2)

- Sistema para Trabjar en Lagunas, Agua, Mar, Construcción de DockingDocument2 pagesSistema para Trabjar en Lagunas, Agua, Mar, Construcción de DockingMarcelo CañaverasNo ratings yet

- Paragon's methanol recovery system makes Williams Canyon deepwater gas project viableDocument4 pagesParagon's methanol recovery system makes Williams Canyon deepwater gas project viableFelipe Di Napoli GarciaNo ratings yet

- MTR Brochure Polyvinyl Chloride 2Document2 pagesMTR Brochure Polyvinyl Chloride 2Lê LợiNo ratings yet

- Brochure o Pumps Fire Fighting PackagesDocument4 pagesBrochure o Pumps Fire Fighting PackagesporkovanNo ratings yet

- Retrofitting Coanda Screens Improves Hydro Plant PerformanceDocument7 pagesRetrofitting Coanda Screens Improves Hydro Plant PerformancebarabatinaNo ratings yet

- Modern Water - AquaPak-B - BrochureDocument4 pagesModern Water - AquaPak-B - BrochureYoo BoyyooNo ratings yet

- Kaplan TurbineDocument8 pagesKaplan Turbinedave chaudhuryNo ratings yet

- Multi-Unit Shutdown Due To Boiler Feedwater Chemical ExcursionDocument22 pagesMulti-Unit Shutdown Due To Boiler Feedwater Chemical ExcursionPatrick ramotlopiNo ratings yet

- Case Study Jul - Aug-ChangiDocument2 pagesCase Study Jul - Aug-ChangiJeffrey TooNo ratings yet

- Siphonic and Gravity Rainwater Drainage SystemsDocument4 pagesSiphonic and Gravity Rainwater Drainage SystemsGreen Action Sustainable Technology GroupNo ratings yet

- Cathelco Seawater Pipework Anti-Fouling SystemsDocument12 pagesCathelco Seawater Pipework Anti-Fouling SystemsAtanasio PerezNo ratings yet

- Fresh Water For Life: Desalination Solutions For Every NeedDocument8 pagesFresh Water For Life: Desalination Solutions For Every Needjpsingh75No ratings yet

- Voith Eco Friendly Turbine DesignDocument8 pagesVoith Eco Friendly Turbine DesignBehailu FelekeNo ratings yet

- CTM Softener A1Document2 pagesCTM Softener A1Angelo Mar MallariNo ratings yet

- Industrial Specifications Booklet Dec 2013Document9 pagesIndustrial Specifications Booklet Dec 2013rizqi amirullah daudNo ratings yet

- BRO Kompetenz Eng Final 180408Document40 pagesBRO Kompetenz Eng Final 180408Paul DanielNo ratings yet

- Canyonv Hydro Brochure PDFDocument8 pagesCanyonv Hydro Brochure PDFbagastcNo ratings yet

- Climax Marine 2020 CatalogueDocument13 pagesClimax Marine 2020 CataloguePERABNo ratings yet

- A Guide To Fire Pumps On ShipDocument16 pagesA Guide To Fire Pumps On ShipNyan ThutaNo ratings yet

- Oil Field Terms PDFDocument79 pagesOil Field Terms PDFPatrick Bolen100% (1)

- Addcap, UAEDocument2 pagesAddcap, UAEcanonscanmenaNo ratings yet

- Kanon Loading Arms.Document24 pagesKanon Loading Arms.manjunath8685100% (1)

- International Process Plants: 1,100 Metric Tons/Day U PLT Urea PlantDocument17 pagesInternational Process Plants: 1,100 Metric Tons/Day U PLT Urea PlantRawagNo ratings yet

- Buoyed Up: Proven in The Past, Prepared For The FutureDocument10 pagesBuoyed Up: Proven in The Past, Prepared For The FutureantidemosNo ratings yet

- Offshore Mag9 v2Document51 pagesOffshore Mag9 v2ParaZzzitNo ratings yet

- 0106 SV Follow-Up ReportDocument6 pages0106 SV Follow-Up ReportGabriel Eduardo Contreras PerozoNo ratings yet

- Pub000 018 00 - 0905Document16 pagesPub000 018 00 - 0905Julio C. SalinasNo ratings yet

- Fire Fighting Sprinkler TanksDocument32 pagesFire Fighting Sprinkler TanksPetar TopicNo ratings yet

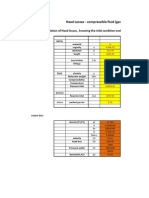

- Hypochlorite Dosage CheckDocument4 pagesHypochlorite Dosage CheckTun Naing WinNo ratings yet

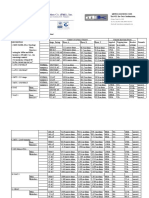

- Copper-Based Mgps Retrofitting Works On Seawater Pumps & Firewater Pumps (MOC-195)Document14 pagesCopper-Based Mgps Retrofitting Works On Seawater Pumps & Firewater Pumps (MOC-195)Tun Naing WinNo ratings yet

- Recent Changes To API 521 PDFDocument23 pagesRecent Changes To API 521 PDFPablo R. Jimenez SalcesNo ratings yet

- Compressor Monitering SheetDocument1 pageCompressor Monitering SheetTun Naing WinNo ratings yet

- Reporte IOGP 456 - 2018Document88 pagesReporte IOGP 456 - 2018AndreaNo ratings yet

- PSV Blocked Fire Relief Valve CasesDocument21 pagesPSV Blocked Fire Relief Valve CasesTun Naing WinNo ratings yet

- IPTC13765Document9 pagesIPTC13765Tun Naing WinNo ratings yet

- PSV Blocked Fire Relief Valve CasesDocument21 pagesPSV Blocked Fire Relief Valve CasesTun Naing WinNo ratings yet

- Reporte IOGP 456 - 2018Document88 pagesReporte IOGP 456 - 2018AndreaNo ratings yet

- IPTC13765Document9 pagesIPTC13765Tun Naing WinNo ratings yet

- The Six - Fundamental Control Strategies PDFDocument48 pagesThe Six - Fundamental Control Strategies PDFAnonymous AsIbqUNo ratings yet

- Total Process Engineering ManualDocument260 pagesTotal Process Engineering Manualmusabammadkhan86% (7)

- Gas Control Valve Sizing: (Masoneilan)Document1 pageGas Control Valve Sizing: (Masoneilan)Tun Naing WinNo ratings yet

- Screening Questionaire Myanmar Wastewater v1Document12 pagesScreening Questionaire Myanmar Wastewater v1Tun Naing WinNo ratings yet

- Flare Noise PredictionDocument3 pagesFlare Noise PredictionTun Naing WinNo ratings yet

- Norsok ST 2001Document131 pagesNorsok ST 2001mamounsdNo ratings yet

- CZC-6500013665-055-A14-0003Rev01 Code FDocument1 pageCZC-6500013665-055-A14-0003Rev01 Code FTun Naing WinNo ratings yet

- Corrosion BasicsDocument56 pagesCorrosion BasicsTun Naing WinNo ratings yet

- G2000 234 Aldo 55 Espirit 38 Air Ticket 169 Zalora 83 579Document1 pageG2000 234 Aldo 55 Espirit 38 Air Ticket 169 Zalora 83 579Tun Naing WinNo ratings yet

- Oily Water Separator Calculation ParametersDocument2 pagesOily Water Separator Calculation ParametersTun Naing WinNo ratings yet

- P 100Document9 pagesP 100Tun Naing WinNo ratings yet

- Insulation Thickness Heat Transfer Pipe CalculationsDocument2 pagesInsulation Thickness Heat Transfer Pipe Calculationsrajpal14667% (6)

- Pressure Safety Valve-Preliminary Sizing: Input DataDocument5 pagesPressure Safety Valve-Preliminary Sizing: Input DataTun Naing WinNo ratings yet

- CZC-6500013665-055-C07-0003 Rev05 Code FDocument3 pagesCZC-6500013665-055-C07-0003 Rev05 Code FTun Naing WinNo ratings yet

- FunmilayoDocument14 pagesFunmilayoTun Naing WinNo ratings yet

- Armstrong HeatersDocument16 pagesArmstrong Heatersirshaad_sNo ratings yet

- Tun PSV SizingDocument70 pagesTun PSV SizingTun Naing WinNo ratings yet

- PD - LG-STL JmaDocument9 pagesPD - LG-STL JmaTun Naing WinNo ratings yet

- Gas Line SizingDocument7 pagesGas Line SizingTun Naing WinNo ratings yet

- Updated Port Master Plan PDFDocument12 pagesUpdated Port Master Plan PDFRedi SefaNo ratings yet

- Oil & Gas Accounting 1Document78 pagesOil & Gas Accounting 1jm100% (2)

- Sub-Zero Refrigerator Use & CareDocument44 pagesSub-Zero Refrigerator Use & CarephilaskNo ratings yet

- Green Building Rating Systems: Sustainability How-To Guide SeriesDocument53 pagesGreen Building Rating Systems: Sustainability How-To Guide SeriesAyanNo ratings yet

- cs830 A4rdDocument10 pagescs830 A4rdprimero marnezNo ratings yet

- Installation, Operation, and Maintenance: Packaged Fresh Air UnitDocument84 pagesInstallation, Operation, and Maintenance: Packaged Fresh Air UnitAdrian ReyesNo ratings yet

- Success Story CJPP BatangDocument2 pagesSuccess Story CJPP BatangQurratA.AbuAyubNo ratings yet

- Qa/Qc Department Welding Inspection ReportDocument3 pagesQa/Qc Department Welding Inspection Reportabdulgafoor54No ratings yet

- D 4762 - 04 Rdq3njiDocument16 pagesD 4762 - 04 Rdq3njicristina ramosNo ratings yet

- Free and Forced Vortex Experiment AnalysisDocument27 pagesFree and Forced Vortex Experiment AnalysisAuzaNo ratings yet

- Chapter 8 Internal Forced ConvectionDocument26 pagesChapter 8 Internal Forced ConvectionDazuky UkyNo ratings yet

- OpelDocument21 pagesOpelAndreia FlorescuNo ratings yet

- 220kv GSSDocument46 pages220kv GSSAnkit KumarNo ratings yet

- Anixter Energy Efficiency and Environmental Considerations For The Data Center White Paper en UsDocument8 pagesAnixter Energy Efficiency and Environmental Considerations For The Data Center White Paper en Ussaba0707No ratings yet

- Particle Size EnlargementDocument8 pagesParticle Size EnlargementZaid Bin GhaziNo ratings yet

- SPC-0804.02-20.04 Rev D2 General Welding and NDE Requirements For Pressure VesselDocument15 pagesSPC-0804.02-20.04 Rev D2 General Welding and NDE Requirements For Pressure VesselPadmanabhan VenkateshNo ratings yet

- Communicative English Solutions for Class IXDocument56 pagesCommunicative English Solutions for Class IXSahilNo ratings yet

- Droop CalculationDocument3 pagesDroop CalculationAnonymous CO7aaHrNo ratings yet

- Unit 420, One Oasis Condominium,: Ortigas, Pasig City 1608 Tel. No. (02) 941-1408, 0995-7561767Document6 pagesUnit 420, One Oasis Condominium,: Ortigas, Pasig City 1608 Tel. No. (02) 941-1408, 0995-7561767Jasper AlcantaraNo ratings yet

- Solution Combustion Synthesis, Energy and Environment: Best Parameters For Better MaterialDocument39 pagesSolution Combustion Synthesis, Energy and Environment: Best Parameters For Better MaterialBFCNo ratings yet

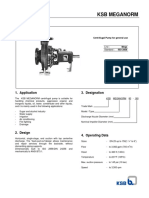

- Ms Meganorm A2742 8e 3 PDFDocument19 pagesMs Meganorm A2742 8e 3 PDFiamsam869No ratings yet

- QQ MeterDocument10 pagesQQ MeterHasiburNo ratings yet

- BHA PROPOSAL FOR SERD-N2 ST WELLDocument1 pageBHA PROPOSAL FOR SERD-N2 ST WELLPinggir KaliNo ratings yet

- GIS 8DQ1 DS eDocument18 pagesGIS 8DQ1 DS esachinkudachiNo ratings yet

- Apodosi Fotovoltaikon GagliaDocument40 pagesApodosi Fotovoltaikon GagliathaneroNo ratings yet

- Research Paper A Novel Method For Near State Pulse Width Modulation (NSPWM) Based Chopper DrivesDocument4 pagesResearch Paper A Novel Method For Near State Pulse Width Modulation (NSPWM) Based Chopper Drivesdivyamanikandan007No ratings yet

- B&J Fuel InjectionDocument24 pagesB&J Fuel InjectionZeeshan Ahmad100% (1)