Professional Documents

Culture Documents

6520 Defects Overview Final3

Uploaded by

Scott Trainor0 ratings0% found this document useful (0 votes)

12 views1 pageVisual Inspection of Welds

Original Title

6520 Defects Overview Final3 (1)

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentVisual Inspection of Welds

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views1 page6520 Defects Overview Final3

Uploaded by

Scott TrainorVisual Inspection of Welds

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

Northern

Engineering Limited DOC.No 12

VISUAL INSPECTION OF WELDS

ISSUE:- 01

DATE:- 04/07/2019

GENERAL

1. Before Welding The Welder Shall Ensure Welding Preparation And Conditions

Comply With Applicable Weld Procedure Specification.

2. Selected Welds For Inspection Shall Be 100% Examined.

3. Examine Weld And Heat Affected Zones For Below Characteristics.

4. Arc Strikes Adjacent to The HAZ Are NOT Permitted

MEASURED CHARACTERISTIC ACCEPTANCE CRITERIA

CRACKS NOT PERMITTED

LACK OF SIDEWALL FUSION NOT PERMITTED

SURFACE POROSITY NOT PERMITTED

COLDLAP NOT PERMITTED

OVERLAP NOT PERMITTED

UNDERCUT INTERMITTENT NOT EXCEEDING 1.0mm DEPTH

OR 5% OF THE MATERIAL THICKNESS

(WHICHEVER IS LESS)

SLAG / SCALE ALL LOOSE TO BE REMOVED.

SPATTER ALL SPATTER TO BE REMOVED

(ANTI-SPATTER SPRAY SHALL BE USED)

WELD SIZE (LEG LENGTH) SHALL NOT BE LESS THAN REQUIRED AND NO

MORE THAN 1.5mm GREATER.

WELD SURFACE 1. WELDS SHALL BE STRAIGHT AND REGULAR

IN PROFILE.

2. THE TOES OF WELDS SHALL BLEND

SMOOTHLY WITH THE PARENT METAL.

3. SURFACE SHALL BE FLAT OR SLIGHTLY

CONVEX.

REPAIR

THE WELDER SHALL REMOVE WELDS CONTAINING REJECTABLE DEFECTS

BY GRINDING BACK TO THE ORIGINAL PREPARATION AND RE-WELD IN

ACCORDANCE WITH THE APPLICABLE WELD PROCEDURE SPECIFICATION.

REVIEWED BY: APPROVED BY:

NAME: Mr Joseph Quinn NAME:

POSITION: Responsible Welding Engineer POSITION: General Manager Date: 04/07/19

Date: 04/07/19

Doc 12

You might also like

- JC Seal Leakage CausesDocument1 pageJC Seal Leakage CausesasrikalyanNo ratings yet

- Factory Production Control System - Welding Quality Manual 23-01-17 - Issue 1Document29 pagesFactory Production Control System - Welding Quality Manual 23-01-17 - Issue 1Scott Trainor100% (2)

- Factory Production Control System - Welding Quality Manual 23-01-17 - Issue 1Document29 pagesFactory Production Control System - Welding Quality Manual 23-01-17 - Issue 1Scott Trainor100% (2)

- Colmonoy 5-S Data SheetDocument2 pagesColmonoy 5-S Data SheetLuis Hernandez0% (1)

- Troubleshooting of Mechanical Seals PDFDocument5 pagesTroubleshooting of Mechanical Seals PDFNasser KhattabNo ratings yet

- Moulding TroubleshootingDocument22 pagesMoulding TroubleshootingPiousPatialaNo ratings yet

- Job Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechDocument3 pagesJob Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechMohamedSaidNo ratings yet

- Welders Visual Inspection Handbook-2013 WEB PDFDocument77 pagesWelders Visual Inspection Handbook-2013 WEB PDFketanNo ratings yet

- ACFMDocument10 pagesACFMAnson MartinNo ratings yet

- Weld Test Checklist: Welder (S) DetailsDocument2 pagesWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- Mechanical Seal PresentationDocument48 pagesMechanical Seal Presentationsathesh100% (6)

- Fabrication Weld ManualDocument12 pagesFabrication Weld ManualChaidir Transmission100% (2)

- Method Statement - Pipe WorksDocument14 pagesMethod Statement - Pipe WorksDarl Anthony Veloso100% (4)

- Tle - Ia - Smaw: Quarter 4 - Module 1 Marking/Locating Weld DefectsDocument12 pagesTle - Ia - Smaw: Quarter 4 - Module 1 Marking/Locating Weld DefectsJessel Mejia OnzaNo ratings yet

- Fundamentals of Gas Welding and CuttingDocument85 pagesFundamentals of Gas Welding and CuttingScott TrainorNo ratings yet

- Astm F-1136Document2 pagesAstm F-1136tai100% (3)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- Visual SL APEXDocument3 pagesVisual SL APEXOscar Gomez Gonzalez100% (1)

- Comparison Between Aluminium & Galvalume As Roofing MaterialDocument4 pagesComparison Between Aluminium & Galvalume As Roofing MaterialKedar BhideNo ratings yet

- Who Needs To Comply With BS EN 1090Document2 pagesWho Needs To Comply With BS EN 1090Scott TrainorNo ratings yet

- Visual Inspection of WeldsDocument1 pageVisual Inspection of WeldsScott TrainorNo ratings yet

- RCA - Mechanical - Seal - 1684971197 2Document20 pagesRCA - Mechanical - Seal - 1684971197 2HungphamphiNo ratings yet

- General Notes For Slab & StairDocument1 pageGeneral Notes For Slab & StairBibek BasnetNo ratings yet

- Visual Inspection Procedure: Annexure-II (Top Closure of 750 KG Batch Reduction Retort)Document6 pagesVisual Inspection Procedure: Annexure-II (Top Closure of 750 KG Batch Reduction Retort)Yasser Hammad MohamedNo ratings yet

- Sample Chapter Campbell-SpaldingDocument22 pagesSample Chapter Campbell-SpaldingAli RazuNo ratings yet

- Cornell-Engineers-Sample-Drawings PAGE1Document1 pageCornell-Engineers-Sample-Drawings PAGE1mohanumaNo ratings yet

- Fibre RollsDocument1 pageFibre RollsWing MacNo ratings yet

- 2750 514-23 en Rev BDocument4 pages2750 514-23 en Rev BGuitART TVNo ratings yet

- J1273-S001-General NotesDocument1 pageJ1273-S001-General Notesroy jackNo ratings yet

- Illustration and Analysis of Seal Face Damage PatternsDocument12 pagesIllustration and Analysis of Seal Face Damage PatternsЭдуардс КеистерсNo ratings yet

- E. Reinforcement A. General B. Foundation: NotesDocument12 pagesE. Reinforcement A. General B. Foundation: NotesIsrael AdegboyegaNo ratings yet

- Drilling Defects ProcessArticleDocument5 pagesDrilling Defects ProcessArticleAnkit VishwakarmaNo ratings yet

- Seal-Lock Apex Ancillary Specifications: SubjectDocument4 pagesSeal-Lock Apex Ancillary Specifications: SubjectBoy SpinNo ratings yet

- Seal Parts Description: A B C D E FDocument6 pagesSeal Parts Description: A B C D E FAli YarahmadiNo ratings yet

- OchureDocument13 pagesOchureFabian CampañaNo ratings yet

- General: 5. Construction Notes: WarehouseDocument1 pageGeneral: 5. Construction Notes: WarehouseJayson EscobarNo ratings yet

- Constrution Exit Vibration Grid 2Document1 pageConstrution Exit Vibration Grid 2Wing MacNo ratings yet

- CSS 5124Document24 pagesCSS 5124Shankar PediredlaNo ratings yet

- Fujifilm FinePix S9000 S9500 Service Manual PDFDocument147 pagesFujifilm FinePix S9000 S9500 Service Manual PDFadamNo ratings yet

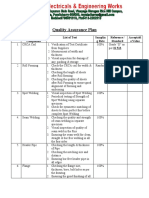

- Quality Assurance Plan SL - No Item / Component List of Test Sampling Rate Reference / Standard Acceptable ValueDocument2 pagesQuality Assurance Plan SL - No Item / Component List of Test Sampling Rate Reference / Standard Acceptable ValueAdhavan ThamizhanNo ratings yet

- 03-SOP No. ENG-GEN-003 - 01 Welding, Cutting and GrindingDocument5 pages03-SOP No. ENG-GEN-003 - 01 Welding, Cutting and GrindingAjlan KhanNo ratings yet

- VTI-Seal Lock HC-003Document3 pagesVTI-Seal Lock HC-003Cong BuiNo ratings yet

- Construction Notes-AaDocument2 pagesConstruction Notes-AaRieo VillaNo ratings yet

- Structural SoilsDocument1 pageStructural SoilsWing MacNo ratings yet

- Bearings FailDocument15 pagesBearings FailHamza BounezraNo ratings yet

- Corrosion Resistant Coated Dowel Bars: Standard Specification ForDocument2 pagesCorrosion Resistant Coated Dowel Bars: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Welding Guidelines For Section ADocument6 pagesWelding Guidelines For Section AemadabdelsattarNo ratings yet

- SAN Radiators-Manufacturing Process PDFDocument6 pagesSAN Radiators-Manufacturing Process PDFAdhavan ThamizhanNo ratings yet

- SAN Radiators-Manufacturing ProcessDocument6 pagesSAN Radiators-Manufacturing ProcessAdhavan ThamizhanNo ratings yet

- ZavarivacDocument19 pagesZavarivacnokojNo ratings yet

- SAN-Quality Assurance PlanDocument3 pagesSAN-Quality Assurance PlanAdhavan ThamizhanNo ratings yet

- GM 7111Document2 pagesGM 7111Felipe De la cruzNo ratings yet

- Repsol Oil Operations: Nc-115 Field DevelopmentDocument11 pagesRepsol Oil Operations: Nc-115 Field DevelopmentYangui AliNo ratings yet

- 334213Document4 pages334213Nani CherryNo ratings yet

- Final SOP For WeldingDocument10 pagesFinal SOP For WeldingBhaskar KolichelimaNo ratings yet

- Prefabricated Asphalt Reservoir, Pond, Canal, and Ditch Liner (Exposed Type)Document3 pagesPrefabricated Asphalt Reservoir, Pond, Canal, and Ditch Liner (Exposed Type)Edmundo Jaita CuellarNo ratings yet

- Section 20 WorkmanshipDocument2 pagesSection 20 WorkmanshipJ T Mendonça SantosNo ratings yet

- AA0850126 Rev 02Document10 pagesAA0850126 Rev 02Manish KumarNo ratings yet

- Cswip 3 (1) .1 Bridge Examination QuestionDocument3 pagesCswip 3 (1) .1 Bridge Examination QuestionbassamNo ratings yet

- AMIR KABIR SSDU IWS Report Rev01Document6 pagesAMIR KABIR SSDU IWS Report Rev01saeed ghafoori0% (1)

- Soldering Guidelines and SMD Footprint DesignDocument13 pagesSoldering Guidelines and SMD Footprint DesignIgor PNo ratings yet

- The Dow Chemical Company Engineering Specification Materials G8S-4001-50 Global 14-MAR-2002 Page 1 of 4Document4 pagesThe Dow Chemical Company Engineering Specification Materials G8S-4001-50 Global 14-MAR-2002 Page 1 of 4maheshNo ratings yet

- M.I.G-M.A.G. Welding - M2 - U10Document61 pagesM.I.G-M.A.G. Welding - M2 - U10Scott TrainorNo ratings yet

- 04 Modern Welding ProcessesDocument38 pages04 Modern Welding ProcessesScott TrainorNo ratings yet

- Rutile Electrodes: Basic (Low Hydrogen - Lime Coated) ElectrodesDocument3 pagesRutile Electrodes: Basic (Low Hydrogen - Lime Coated) ElectrodesScott TrainorNo ratings yet

- What Is The Difference Between FerriticDocument4 pagesWhat Is The Difference Between FerriticScott TrainorNo ratings yet

- 1522-IA-13 - Science and Calculations For Fabrication and Welding Work BookDocument26 pages1522-IA-13 - Science and Calculations For Fabrication and Welding Work BookScott TrainorNo ratings yet

- 36 - Declaration of PerformanceDocument1 page36 - Declaration of PerformanceScott TrainorNo ratings yet

- Stormtec Services Limited Non-Conformance Register: X XNCRDocument1 pageStormtec Services Limited Non-Conformance Register: X XNCRScott TrainorNo ratings yet

- Welding and Cutting Issue 5 2014Document75 pagesWelding and Cutting Issue 5 2014Scott TrainorNo ratings yet

- Finally MThesisDocument165 pagesFinally MThesisScott Trainor100% (1)

- PEO/2.05 Unit No 05: Producing Components Using Hand Fitting TechniquesDocument3 pagesPEO/2.05 Unit No 05: Producing Components Using Hand Fitting TechniquesScott TrainorNo ratings yet

- PEO/2.05 Unit No 05: Producing Components Using Hand Fitting TechniquesDocument3 pagesPEO/2.05 Unit No 05: Producing Components Using Hand Fitting TechniquesScott TrainorNo ratings yet

- PEO/2.29 Unit No 29: Preparing and Using Manual MIG, MAG and Other Continuous Wire Welding EquipmentDocument3 pagesPEO/2.29 Unit No 29: Preparing and Using Manual MIG, MAG and Other Continuous Wire Welding EquipmentScott TrainorNo ratings yet

- Welding and Cutting Issue 5 2014Document75 pagesWelding and Cutting Issue 5 2014Scott TrainorNo ratings yet

- 2.05 Bench Fitting To Support 206 BMDocument61 pages2.05 Bench Fitting To Support 206 BMScott TrainorNo ratings yet

- Welding and Cutting Issue 4 2014 LowresDocument68 pagesWelding and Cutting Issue 4 2014 LowresScott TrainorNo ratings yet

- Welding and Cutting Issue 2 2014 LowresDocument64 pagesWelding and Cutting Issue 2 2014 LowresScott TrainorNo ratings yet

- Welding and Cutting Issue 3 2014 LowresDocument80 pagesWelding and Cutting Issue 3 2014 LowresScott TrainorNo ratings yet

- Welding and CuttingDocument64 pagesWelding and CuttingScott TrainorNo ratings yet

- Inostar: Wolfram INOSTAR - Nothing Makes More From LessDocument64 pagesInostar: Wolfram INOSTAR - Nothing Makes More From LessScott TrainorNo ratings yet

- WWW - Welding-And-Cutting - Info Technical Journal For Welding and Allied ProcessesDocument60 pagesWWW - Welding-And-Cutting - Info Technical Journal For Welding and Allied ProcessesScott TrainorNo ratings yet