Professional Documents

Culture Documents

V005t14a001 86 GT 204 PDF

Uploaded by

Kamal BuddyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

V005t14a001 86 GT 204 PDF

Uploaded by

Kamal BuddyCopyright:

Available Formats

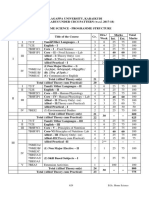

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS 86-GT-204

345 E. 47 St., New York, N.Y. 10017

The Society shall not be responsible for statements or opinions advanced in papers or in dis-

cussion at meetings of the Society or of its Divisions or Sections, or printed in its publications.

Discussion is printed only if the paper is published In an ASME Journal. Papers are available

from ASME for fifteen months after the meeting.

Printed In USA.

Copyright © 1986 by ASME

More Effective Control for Centrifugal Gas Compressors

Operating in Parallel

DR. NAUM STAROSELSKY with LAWRENCE LADIN

Compressor Controls Corporation

Des Moines, Iowa

ABSTRACT Rr compressor ratio, dimensionless

RPM revolutions per minute

Parallel Operating centrifugal gas compressors S relative distance from surge control line,

are major elements in the chemical industry, in oil dimensionless

production and in natural gas gathering, injection, SCMM flow rate, standard cubic meters/minute

separation, transmission and LNG production. Large SCMMma , maximum flow, standard cubic meters/minute

energy savings, reduced repairs and improved automation T transmitter

are possible with more effective solutions for O i normalizing coefficents for scaling Criteria S,

compressor station control. dimensionless

The authors suggest an improved definition Ap pressure differential across compressor, bar

c

of compressor energy efficiency. They analyze several °Po,s pressure differential across flow measuring

common approaches to control of parallel compressors device in compressor suction, mm H 2 O

and evaluate them in terms of energy efficiency,

stability of control, equipment protection and level of INTRODUCTION

automation. An improved system developed by one of the

authors will be described theoretically and with an Centrifugal gas compressors operating in parallel

example from field operation. are a major component of the chemical industry, oil

production industry, and all phases of the natural gas

NOMENCLATURE industry. They are expensive to buy, expensive to

repair and expensive to operate. Improving the

b distance between surge limit line and surge efficiency and reliability of these compressors is

control line, dimensionless therefore worthy of serious attention.

e deviation of operating point from surge control The efficiency and reliability of these

line, dimensionless compressors can be severely limited by the control

specific power consumption system. Less-than-effective controls, rather than

ha specific power consumption, absolute units mechanical design, is often the cause of lost

hr specific power consumption, relative units efficiency, shutdowns and damage. This paper will

I/P current-to-pneumatic transducer analyze several common methods of control, describe

K slope of surge control line, dimensionless improved methods developed by one of the authors, and

KW power, kilowatts conclude with an example taken from field operation.

KWmax maximum power, kilowatts Strategies for load sharing will be examined in

ml output of Antisurge Controller particular detail with comparisons, where possible, of

m2 proportional plus integral output of Antisurge energy efficiency, stability and precision-of-control,

Controller machine protection and level of automation. An

m3 open loop output of Antisurge Controller algorithm for an improved load-sharing strategy will be

m4 output of Performance Controller described, and records will be analyzed from a field

m5 output of Load-Sharing Controller installations.

m6 proportional plus integral plus derivative In many installations load changes are anticipated

output of Load-Sharing Controller for parallel compressor operation. Load changes on a

PI proportional plus integral control algorithm 24 hour, weekly or seasonal cycle. However, in many

PID proportional plus integral plus derivative installations examined by the authors,

control algorithm less-than-adequate provisions have been made in the

Ps pressure in compressor suction, bar control system for these load changes. Often load

',user flow to user, standard cubic meters/minute control is manual and very costly in terms of wasted

maximum flow, standard cubic meters/minute energy and lessened reliability. Whether the load

gmax

Presented at the International Gas Turbine Conference and Exhibit

Dusseldorf, West Germany—June 8-12, 1986

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 06/27/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

control is now manual or automatic, it can, in the AN IMPROVED DEFINITION OF COMPRESSOR EFFICIENCY

authors' opinions, be improved significantly. The user

will be well rewarded for any improvements. First, let us carefully review the definition of

In some installations, load changes are not compression energy efficiency. The measurement

anticipated, steady load being predicted. But only in commonly used, polytropic efficiency of the compressor,

a perfect world would load demand never change. Only has major limitations we believe. Polytropic

in a perfect world would a station always operate in efficiency defines the energy efficiency required to

steady state at the design point of each compressor. In compress the gas between the inlet port and

the real world in which we live, many operations that the discharge port of the compressor. However, this is

have been designed for steady state at full load have not the energy efficiency of gas delivered to the user,

been forced, as experience shows, into load changes. a point of great importance. In normal compressor

Economic cycles or other events beyond our control may operation there can be substantial energy losses

have reduced user demand. Changes in the feedstock or between the discharge port of the compressor and the

improvements in process design may have changed the discharge header, where the gas is delivered to the

compressor load. Moreover, mechanical or control user, process, or pipeline. In a compressor system

failures in any part of the process may any time major energy losses can occur through the antisurge

forcibly change the load. valve or through the cooling or quenching, all as a

A more realistic approach is to design the control part of normal operation.

system of a compressor station to cope safely and

efficiently with substantial load changes. We will SPECIFIC POWER CONSUMPTION

show that this approach leads also to more-precise and

more-stable pressure control, better machine protection Instead, we shall propose a wider definition of

and improved automation. energy efficiency, which we term the Specific Power

Many different strategies have been employed to Consumption "h". It can be defined as follows:

unload and load a compressor station. One common

method is to set the speed control manually and run Specific Power Consumption "h" is

each compressor continuously at full load. Swings in the energy input to a compressor

station load are met by recirculation of gas around the system required to maintain the

compressors. This system is obviously wasteful of controlled gas parameter and

energy. divided by the number of flow units

Biasing flow is another common station control of gas delivered to the discharge

method. This method employs a primary or station header. "h" may be defined in

pressure controller plus separate flow controllers on absolute units h a , or in relative

each compressor. Flow controllers are adjusted to units h r .

divide the flow between the station compressors in some

ratios according to their performance characterstics, For example, if it takes 500 kw of power to

e.g. 50 percent, 35 percent and 15 percent. As will be deliver 1,000 standard cubic meters/minute of gas at a

described at a later point, this system requires compression ratio of 2, then in absolute values

constant readjustment as operating conditions change kw Units are power divided by flow rate.

h a = .5

and has other shortcomings. A similiar problem will be SCMM

found with station control strategies that bias In order to compare efficiencies of compressors of

compressor speeds. different capacities and power consumptions, it is

Another very common method calls for base loading convenient to use a dimensionless measurement for

the most efficient compressors either at their maximum Specific Power Consumption. Units are power divided by

flow or at their point of maximum polytropic maximum power and flow rate divided by maximum flow for

efficiency. The swings in demand load are then met by a specific compressor.

modulated control of the less-efficient compressors or

by on-off control of these compressors. This system is KW SCMM

h r (1) SCMMmax

not energy efficient or sufficiently reliable in our KWmax

opinion.

We believe that all the above methods can be Since h increases with energy consumption, note

improved on. In our analysis we shall attempt to show: that an increase in h is a decrease in system energy

a. Simultaneous loading and unloading of the efficiency and vice versa.

compressors is the most-effective station Specific Power Consumption, therefore, includes

strategy. Properly controlled, it gives the energy costs that must be paid for, but are not

most energy efficiency, the most precise measured by polytropic efficiency. The authors believe

control, better machine protection and that Specific Power Consumption gives a more realistic

improved automation. measure of the economic costs of a compression system.

b. Reducing recycle is the most-important

component of station energy efficiency. Put UNLOADING AND LOADING STRATEGIES FOR THE COMPRESSOR

another way, station control strategy requires STATION

an effective antisurge system for energy

efficiency, as well as for machine protection. Compressors may be loaded and unloaded by speed

c. Regardless of variations in compressor changes, changes in guide vane position, throttling or

polytropic efficiency, the station should recirculation. We shall use for our examples

unload so that all the compressors reach their centrifugal gas compressors with variable speed gas

surge control lines simultaneously. We shall turbine drives and recirculation, controlled for

propose a loading and unloading algorithm for compression ratio.

this strategy which we call the "S Criteria".

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 06/27/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Analogous results would follow if the controlled

parameter was inlet pressure, discharge pressure or

flow rate. The reasoning and results would be

analagous, too, if the compressors were controlled by

adjustable guide vanes or throttles. 0. 3.5

The strategy selected for sequencing compressors

loading and unloading and the algorithm controlling

loading and unloading, significantly influences the

station efficiency, as we shall show. Three strategies

cc

will be analyzed for specific power consumption under 2 3.0

different loading and unloading strategies. We shall

compare these loading and unloading strategies for

their energy efficiency, machine protection and

automation.

Minimum Safe Flow LLJ

A centrifugal compressor may be unloaded only to CC 2.0

its surge limit line. At that limit, dangerous flow and O. '

pressure oscillations begin which can damage or destroy 0

the compressor. To protect the compressor from surge

damage, gas is recycled through the antisurge valve 1.5

(also known as the reycle or bypass valve), before the 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

surge limit is reached. The control line where recycle m 0.9 A

begins is the surge control line. We may consider this 105% RPM

0.8

to be the line of minimum safe flow. The calculation

Re..2.76

of the minimum safe flow is complex. There is a • 0.7

different minimum safe flow for each compressor inlet 100% RPM

pressure, head, speed, inlet temperature, gas • 0.6

composition and position of guide vanes. The minimum CC

• 0.5

safe flow will also varies substantially, depending on

the effectiveness of the surge control system. The 90%RPM

O 0.4

more effective the surge control, the closer the surge 0.

control line will be to the surge limit line, and the LL! 0.3

less the recycle needed. IT; 0.2

Calculating Specific Power Consumption 0.1

LL.I

the unloading of compressors within the station CC 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 0„ e,./Oma,

may be simultaneous, successive, or mixed. The most RELATIVE FLOW

efficient strategy can be found by comparatively simple

calculations based on an analysis of the performance FIG. I. PERFORMANCE MAP OF A CENTRIFUGAL GAS

map of each compressor in the station. COMPRESSOR

Suppose a station of two identical compressors

operating in parallel. Fig. 1 gives the performance

curves for two identical gas compressors built by a

leading European manufacturer. Assume that a user or .c 1 . 5

process requires that the station maintain a constant

compression ratio R c = 2.75. Note that the reasoning 0

which follows would apply equally well if the a.

controlled parameter were discharge pressure, or 2

suction pressure or flow.

Z 1.0

Specific Power Consumption in Single-Compressor 0

Operation. The Specific Power Consumption "h r " plotted

as a function of the gas flow rate is shown for single cc

compressor operation in Fig. 2. Points A, B, and C lie LU

on a line of constant compression ratio but varying 0

flow rates. Point A belongs to the maximum performance a.

curve corresponding to the maximum speed and flow. At

point B, the design point (the expected operating point EL- 0.5

of the compressor), the speed and flow rate is somewhat

lower. The specific power consumption at B has 1.1.1

C.

decreased slightly, which indicates an increase of cn

efficiency. Point C lies on the compressor's surge

control line. Between points B and C the specific

power consumption has increased slightly and the 0.0 0.5 1.0

efficiency decreased slightly. RELATIVE FLOW Quser/Qmax

FIG. 2. SPECIFIC POWER CONSUMPTION IN

SINGLE-COMPRESSOR OPERATION

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 06/27/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

At point C, however, efficiency is still higher than at

the initial point A.

Point C is the minimum safe flow for this

compressor at this speed, with these inlet conditions

and with some specific surge control system. From

.c

point C, a further decrease of the station flow cannot

Z 1.20

be safely effected by a further decrease of flow 0

through the compressor. To prevent surge damage, the H 1.10

difference between the station demand flow and the o.

2 1.00

minimum safe flow through the compressor must be

recirculated to the suction network. Under such (,) 0.90

3 i

circumstances, the flow to the user decreases. But, Z

0 0.80

the flow through the compressor is constant at C and C.)

the compressor power is constant. As a result of this 0.70

cc

recirculation, the specific power consumption sharply ill 0.50

increases to the left of point C. Put in alternate

terms: g

CI.

0 0.40

The system efficiency of any compressor

ion begins,

Fops sharply once recirculat E.) 0.30

and the cost of compressing a flow unit UJ 0.20

of gas rises sharply.

0.10

The effectiveness of the surge control system now

becomes critical. The more effective the surge control 0.10 0.20 0.30 0.4' 0.50 0.60 0.70 0.80 0.90 1.00

system is, the narrower the recirculation zone can be. RELATIVE FLOW O user /O. max

A less effective surge control system will require that

the safety margin between the surge control and surge FIG. 3. SPECIFIC POWER CONSUMPTION

limit lines be increased. An increase of safety margin OF FOUR MAKES OF COMPRESSORS

by only 5 percent will decrease the efficiency at the

point C by about 10 percent. Effective surge control

systems have been described by the authors in "Improved There are three major alternatives to changing

Surge Control for Centrifugal Compressors". We refer station flow:

the reader to this article for more details.' a. To unload and load compressors

In contrast, the change in polytropic efficiency simultaneously

before recirculation begins is not significant at all. b. To unload and load compressors in sequence,

The authors have analyzed more than 200 centrifugal and first decreasing the flow of the least

axial compressors controlled by speed, or adjustable efficient compressor and keeping the others

guide vanes or throttles. This analysis indicates that at maximum load

the specific power consumption either stays steady as c. To combine the simultaneous and sequential

the compressor flow decreases to the surge control line unloading strategies.

or, in some cases, it increases slightly and then

decreases slightly. However, the specific power Specific Power Consumption for Simultaneous

consumption increases dramatically as soon as Unloading/Loading. Fig. 4 shows the specific power

recirculation begins. consumption of a simultaneous approach to the surge

As further examples, Fig. 3 shows the specific control lines versus sequential loading/unloading for

power consumption as a function of flow rate for these two identical compressors in parallel operation.

compressors of four other leading American and European The performance characterstics of these compressors

compressor manufacturers. This illustrates our first have already been discussed (See Fig. 1). The

conclusion for improving the efficiency of compressor compression ratio of the station will be maintained

operation: during unloading. Again, note that analogous results

obtained if the controlled parameter was suction

Increasing the safe operating range without pressure, discharge pressure or flow.

recirculation is more Curve I of Fig. 4 (A, B, C, D, E) shows in

efficiency than maintaining the relative units the change of specific power consumption

compressors p o pi on tr t :trit the point of

im using simultaneous unloading of the station. Exactly

highest polytropic iciency. as with the single compressor, the station efficiency

first increases slightly and then decreases slightly

Specific Power Consumption in Multi-Compressor between the maximum station capacity (point A) and the

Operation. We will now examine the parallel operation minimum safe flow (point B). Both compressors approach

of two or more compressors. Suppose the sample station their surge control lines at B simultaneously. Between

has two identical compressors. A constant compression points B and C the station output is adjusted to the

ratio must be maintained for this sample station, and lower gas demand by partial recirculation around the

the station flow must be adjusted to meet the demand. compressors.

Note, again, that suction pressure control or discharge At point C, compressor No. 1 is shut down. The

pressure control give analagous results. control system compensates for this flow loss by

loading compressor No. 2 to its maximum speed (point

D). Then, the station is further unloaded by reducing

the speed of compressor No. 2 down to its surge control

line (point E). Further decrease in flow to the user

1 Chemical Engineering, May 21, 1979 is compensated once more by recirculation.

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 06/27/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

the surge control lines is the first condition for

higher station energy efficiency at all gas demand

levels.

Some reflection will show that this conclusion

1.5

applies to compressors operating in series, as well as

in parallel.

G

.c

Precise Pressure Control

0 I Besides improving energy efficiency, the

1 \ simultaneous approach to the surge control lines has

1 \ SEQUENTIAL UNLOADING dynamic control advantages, too. It can give faster

I

U) 1.0

and more precise control of station pressure. When the

I flow demand by the user changes, the pressure

1 differential across the station changes, too. This

0 C changes, in turn, the flow through each compressor. If

cc \ F the control system changes the performance of only one

compressor at the time, then the overall response time

of the system increases. In control terminology, the

0

a. 05 SIMULTANEOUS APPROACH TO gain decreases. In order to compensate for the loss of

SURGE CONTROL LINES the system gain and to make system response time

C)

faster, it is necessary to increase the speed of

response of each controller. However, this is

w difficult to do in some cases because system components

cL.

such as the valves and transmitters become the limiting

0 . 0 0 . 5 1 .0 factors.

RELATIVE FLOW Q user/O max In general the system response can be

significantly faster and more precise with simultaneous

FIG. 4. SPECIFIC POWER CONSUMPTION OF loading/unloading.

TWO IDENTICAL COMPRESSORS

Machine Protection

Comparing the two strategies with regards to

Between points B and C, the efficiency of the machine protection, the simultaneous approach to the

station drops but, after the shutdown of compressor No. surge control line again has the advantage. With

1, it increases at D to the efficiency observed at the simultaneous unloading, the compressors spend a minimum

initial point A. Efficiency changes insignificantly time on their surge control lines as compared to

from D to point E, after which it drastically sequential unloading. This is an important feature for

decreases. Between points A and E, there is no damage control, because operation on the surge control

significant change of the station efficiency. line always carries some risk of surge and surge

damage.

Specific Power Consumption for Sequential The compressors also spend less time at their load

Unloading/Unloading. The dotted curve II of Fig. 4 limit or speed limit, another advantage for machine

corresponds to sequential unloading/loading. Between protection.

points A and F, compressor No. 1 base loaded and kept There are fewer starts and stops, which is a third

at its maximum speed. Compressor No. 2 is unloaded advantage.

down to its surge control line (point F). The

efficiency with sequential unloading is less in this Automation

segment of curve II than the efficiency under Automation is easier with the station having

simultaneous unloading. simultaneous loading and unloading. Shutting down a

At point F it is not possible to shut down compressor is not indicated until the station flow has

compressor No. 2 because it it would be impossible to dropped to 30 percent. With sequential unloading,

deliver the flow demand. Should compressor No. 2 be shutting down a compressor is indicated at 50 percent

shut down at this time, then the flow, the compression of station flow. Therefore, there is less need for

ratio and the pressure at the discharge of the station operator intervention with simultaneous unloading. The

will drop below their required levels. To shut down same reasoning applies to loading the station. There

one compressor without disturbing the required pressure will be fewer startups with simultaneous loading.

is possible only at point G, where the station There are other automation advantages possible which

efficiency is extremely low. Shutting compressor No. 2 will appear in our analysis of advanced station control

down at G increases the station efficiency to point D. later in this article.

From point D to point E and beyond there is no

difference between the curves I and II in efficiency. Unloading/Loading Compressors of Different Sizes

Curve II of sequential unloading is nearly always Selecting the unloading/loading sequence for

higher in specific energy consumption than curve I of parallel-operated centrifugal compressors may become

simultaneous unloading between points A and D. This more complicated when the size, power and efficiency of

proves, in our opinion, that simultaneous unloading is compressors are different.

far more efficient, but only if all compressors reach Suppose, for example, that one of two parallel

their sure control 71Ties simultaneously. working compressors is slightly more efficient (curve

or t e737FF7tFel n TiTig majority of compressor

- - 2, Fig. 3) than the other compressor (curve 1, Fig. 3).

stations equipped with two or more centrifugal The more-efficient compressor also has the higher

compressors, an unloading by simultaneous approach to maximum flow and a wider range of operation without

recirculation.

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 06/27/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

The Fig. 5 compares the simultaneous approach to patented by one of the authors. We believe this

the surge control line (curve II) and sequential approach to loading/unloading is of value for:

unloading (dotted curve I). In the sequential a. controlling a simultaneous approach to the surge

unloading, the less-efficient machine is first unloaded limit by all the station compressors,

to its surge control line. Between points A (maximum b. increasing station energy efficiency,

station capacity) and B (the surge control line of the c. improving precision and speed of pressure control,

less efficient machine) the station efficiency under d. improving machine protection, and

the sequential or simultaneous unloading does not show e. improving automation.

any significant difference for these compressors of

slightly different efficiency. The Equation Of The Surge Control Line

At Point B, efficiency drops drastically under To calculate S, the relative distance from the

sequential unloading. In contrast under the surge control line of any compressor at any given

simultaneous approach to the surge limits, the moment, we must begin with the equation of its surge

efficiency remains high until Point C. At C, both control line.

compressors must begin recirculating. Many equations have been offered for thy surge

Supposing a difference in capacity or efficiency control line. In the article by the authors we

of not more than 7 percent, a simultaneous approach to defined one useful equation as:

the surge control lines is the most efficient strategy.

With compressors of significantly different K AP c + b = ap o, s (2)

efficiencies (more than 10 percent) mixed unloading or

sequential unloading may be more efficient, in our where:

opinion. However, such stations are few in number. K is a constant defining the slope of the surge

limit line

Ap c is the pressure differential across the

compressor

po,s is the pressure differential across a flow

measuring device in the compressor suction,

k SIMULTANEOUS APPROACH TO b is a constant defining the distance in some flow

SURGE CONTROL LINES

unit between the surge limit and the surge

II control line.

1.0 N,e-SEQUENTIAL UNLOADING

This equation is valid for compressors with

0.9

constant geometry, stable gas composition and a surge

as limit that is linear in the above coordinates. This

0.7

equation is self compensating for inlet temperature

changes. Refer to the article for a detailed analysis

as of this equation.

0.5 Another equation widely used to calculate the

surge control line is:

0.4

0.3 A P A p

c 0

+ b = -n-- (3)

0.2 S

0.1 where:

p s is compressor suction pressure.

0.1 0.2 0.3 0.4 0.5 05 0702 0.9 1.0

More-complex equations are recommended for

compressors with variable guide vanes, for gases with

RELATIVE FLOW Quser/Qmax variable composition, or for compressors with irregular

surge limit lines. However these simple but widely

FIG. 5. SPECIFIC POWER CONSUMPTION useful surge control line equations will suffice for

OF TWO DIFFERENT COMPRESSORS this example.

THE "S CRITERIA" FOR MORE-EFFECTIVE STATION CONTROL The Equation of the S Criteria

Based on these surge control equations we shall

There are many possible algorithms for define S as follows:

simultaneous approach to the surge control lines.

Obviously, each algorithm depends on measuring the Pc

distance from the operating point to the surge control f +b

K A P c + b

line. Since compressors may differ in capacity and

S = or S - (4)

characterstics, the absolute distance of the operating °Po AP

o/ P s

point from the surge control line is not useful. We

recommend using a dimensionless number expressing the If S is less than 1, the operating point is in the

relative distance from the surge control line. This safe zone. The lower the value of S, the greater the

measurement technique will now be incorporated into a safe distance from the surge control line.

control algorithm. An S which is equal to 1 corresponds to a

The algorithm that will be described here we shall compressor operating point located just on the surge

call the "S Criteria". It is one possible method of control line.

improved control. The S Criteria was developed and

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 06/27/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

An S higher than 1 corresponds to the operating (S=1) simultaneously. If B2 are unequal, the

point having crossed the surge control line and moved compressors will reach their surge control lines

toward surge. sequentially. This permits any sequencing desired.

There are two alternatives to calculate the This value goes to the PID part of the

deviation "e" of a compressor's operating point from load-sharing controller as its control variable. One

Surge Control Line. single set point for all load-sharing controllers is

The first is: developed by the primary station controller, which

maintains constant station inlet pressure.

el = S - 1 The control shown in Fig. 6 is a typical cascade

control. The primary controller develops the set

The second is: points for all the secondary controllers. As is well

known from control theory, the stability of cascade

AP o

°Pc control can be achieved only if the secondary

e2 = f + b1 - controllers are much faster than the primary

Ps controller. However, under this controller tuning,

AP c when the flow demand changes then the load-sharing

—P-- + b 1

f controllers would first change the speed of a

°Po compressor in a direction opposite to that required to

e2 =

Ps °Poes adjust station output to the gas demand. This would

increase deviation of suction pressure from its

or required level and would make the time of the transient

A Po process longer. There are two alternatives to avoid

e2 = -F-s- (S 1), this decrease of dynamic precision while using this

cascade control scheme.

or The first alternative is to install a dynamic

AP

o filter between the antisurge controller computing S'

e2 = ps e1. (9) and the load-sharing controller using S' as its process

variable. Such a filter presents a rough model of the

Using e l in the control algorithm, it is possible to controlled object. It permits the primary controller

ensure stable operation over the whole range of to rapidly change the set point of the load-sharing

operating conditions even with a high controller gain. controllers and correctly change the speed of the

This provides faster, better quality, more precise compressors to immediately restore pressure to the

control. required level.

The second alternative, patented by one of the

Controlling a Station by the S Criteria authors, is to send feed-forward adaptive signals from

Fig. 6 shows a station controlled by S Criteria the primary controller directly to the control members,

for suction pressure, having two centrifugal gas temporarily bypassing cascade control. The principal

compressors with gas turbine drives. schematic of the author's solution is given on Fig. 7.

The primary or station controller maintains The output of the primary station controller not

suction pressure. Each compressor has a load-sharing only enters the load sharing controller as its set

controller that divides the station load, plus an point, but it also enters the multiplication modules of

antisurge controller. both the antisurge controller and load-sharing

The antisurge controllers of compressors No. 1 and controller. Then, the outputs of these controllers can

No. 2 calculate the criteria S for their respective be defined as:

machines. Each antisurge controller sends its

calcuated S value to the calculating module of its (11)

m l = m 2 m 3 f 2 (S ) x m4

companion load-sharing controller.

m 5 = m 6 f 1 (S) x m4 (12)

The calculating module of each load-sharing

controller computes the value The functions fl(S) and f2(S) are shown in Fig. 8.

Making fl(B) variable permits reducing the gain of

S' = al (S - 1) B2 (1 0) the primary or station controller via the load-sharing

controller as the operating point of compressor

This is a universal equation that can be used for any approaches the surge control line. To complete the

compressor sequencing. control system, the primary controller has a

By tuning 0 1 , it is possible to individually symmetrical connection where the gain to the output of

control the rate of change of flow for each compressor the antisurge controller is increased as the operating

between its maximum load and surge control line. This point approaches the surge control line. Thus, the

can further improve station efficiency. primary or station controller switches from controlling

If both B 2 are equal then, regardless of the the speed to controlling the position of the recycle

values of B 1 , under decreasing flow both compressors valve while approaching surge. The controllers in this

No. 1 and No. 2 will reach their surge control lines scheme should be set so that the primary controller

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 06/27/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

TURBINE TURBINE

COMPRESSOR

SPEED SPEED

GOVERNOR GOVERNOR

CO

PRIMARY Far I s ANTISURGE CONTROLLERI

1-17(717— --1 ANTISURGE CONTROLLER

CONTROL- SHARING

'CONTROLLER

1 COMPUTING b2

SHARING

'CONTROLLER

COMPUTING 4

I

LER MODULE MODULE

P ID COMPUTING COMPUTING

MODULE MODULE

4

I

r3 1(s - )+B 2 131(S-1)4-132

SET POINT SET POINT

ml

∎

Oi PID PI OPEN LOOP SURGE DETECTION PID SURGE DET

RESPONSE & REL

r

& RELOCATION

m2

OF S.C.L. OF S.C.L.

I

L_ ms

L_

FIG. 6. CONTROLLING COMPRESSORS IN PARALLEL BY S CRITERIA

(SUCTION-PRESSURE CONTROL, LOAD-SHARING CONTROL, ANTISURGE CONTROL)

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 06/27/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

PRIMARY

CONTROL-

LER

PID

m4

r LOAD SHARING CONTROLLER

COMPUTING

MODULE

NS-1)-02

■•■■

COMPUTING

MODULE

ANTISURGE CONTROLLER

V

m4 OPEN LOOP SURGE DETECTION

PID PI ADAPTIVE & RELOCATION OF

SET POINT SURGE CONTROL

RESPONSE

LINE

m3

X s) • -• f2(s) X

Im4

_J _

m4

TO THE TO THE

SPEED ANTISURGE

GOVERNOR VALVE

FIG. 7. LOAD SHARING CONTROL BY S CRITERIA

will be much faster than the load-sharing controllers. conditions change. That is to say, any change in

Then, during changes in gas flow, the station pressure suction pressure, suction flow, temperature, or

will be controlled first and the load sharing molecular weight.

controller will divide the total compressor station Therefore, a simultaneous approach to the surge

flow between the compressors the optimum way. control line will require retuning of the controllers

This scheme achieves energy economy with excellent for optimum load distribution. This is a nearly

steady-state precision and dynamic precision. Since impossible task for an operator and no easy task for a

the compressors spend a minimum time on their surge computer.

control lines or speed limit lines, it adds to machine A second defect of these commonly used systems is

protection, especially since the number of starts and the interaction of the independent surge control loops

stops are minimized too. with the pressure control. The surge controller

The use of advanced antisurge controllers adds attempts to decrease discharge pressure and increase

significantly to the the machine protection. This inlet pressure ? while the pressure control system

control is self-compensating and needs no adjustment attempts to maintain discharge pressure. These are

over a very wide range for changes in inlet pressure, incompatible goals and the quality of one or more of

inlet temperature, or flow demand. It, therefore, lends the control loops is seriously affected. Oscillation

itself to improved automation. or "hunting" is likely to occur from time to time.

Manual control will be called for to stabilize the

OTHER STATION CONTROL STRATEGIES system.

Suppose the controlled parameter is discharge F1(S)

pressure and the station consists of two centrifugal

gas compressors with gas turbine drives having speed

control.

Fig. 9 shows the station controlled by biasing f2(S)

flow. Fig. 10 shows the station controlled by biasing

speed. (Biasing the position of the guide vanes or

inlet throttle would be analagous control schemes).

In both cases, the settings for each load

controller, whether it be controlling through speed or

flow, is valid for only one set of inlet conditions.

A glance at the compressor performance map Fig. 1

confirms this. The intersection of the discharge

pressure control line and the surge control line for

each compressor will correspond to a different speed,

or flow rate, or guide vane position whenever inlet FIG. 8. FUNCTIONS f 1 AND f OF CRITERIA S

2

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 06/27/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Ps

PRIMARY

P ID

CONTROLLER

FLOW RATIO ANTISURGE FLOW RATIO ANTISURGE

CONTROLLER CONTROLLER CONTROLLER CONTROLLER

PI PI PI

TO THE TO THE TO THE TO ME

SPEED

OVERNOR I ANTISURGE

VALVE

SPEED

GOVERNOR

ANTISURGE

VALVE

G

f 6P. V 11,

FIG. 9. STATION CONTROL BY BIASING FLOW

1 Ps

PRIMARY

CONTROLLER

FROM K 1 K2

OPERATOR —1111" ANTISURGE ANTISURGE

Ki x + b1 K2x+b2

OR COMPUTERb l CONTROLLER CONTROLLER b2

TO THE

SPEED

GOVERNOR

TO THE

ANTISURGE

VALVE

TO THE

ANTISURGE

I TO THE

SPEED

VALVE GOVERNOR

FIG. 10. STATION CONTROL BY BIASING SPEED

10

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 06/27/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

A FIELD INSTALLATION

An example of these theories in operation is

taken from an off-shore gas compression station

equipped with two gas-turbine-driven compressors. The

gas supply to this station has both large and fast

changes in flow rate. The simultaneously loaded and

unloaded compressors use the S Criteria for load

100%

sharing to maintain stable suction pressure. The

controllers are of the advanced type designed by one of

the authors. The controls described here are in ANTISURGE VALVE

continuous operation today. UNIT #1

The station control system was shown in Fig. 6.

Fig. 11 shows a strip-chart record of inlet pressure, 0%

speed changes of the turbines, and response of the

antisurge valves.

50%

The gas supply to the station at the time tA is

low. At t A , both compressors are operating at low SPEED OF THE

speed (70 percent of the maximum speed of the power POWER TURBINE

turbine for unit No. 1 and 68 percent of the maximum UNIT #1

speed for unit No. 2). Both antisurge (recycle) valves

are partially open, and the gas supply is starting to 100%

increase. The control system simultaneously closes

both antisurge (recycle) valves in response. A sharp

1 00%

increase in gas supply momentarily causes inlet

pressure to increase at time tB. The control system

rapidly increases the speed of both compressors to ANTISURGE VALVE

restore inlet pressure to the required level. After a UNIT # 2

slight decrease, the gas supply increases again sharply

at time t c . Again, the control system maintains the

0%

inlet pressure by rapidly speeding up both compressors.

The control system maintains stable inlet pressure

under further sharp fluctuations of the gas supply 50%

during the time intervals t0 to t E and t F to t G .

In general, the deviation of the inlet pressure SPEED OF THE

from its required level never exceeded 2 percent. This POWER TURBINE

record shows the precise control, fast response and UNIT # 2

control stability possible with simultaneous approach

to the surge control lines using the S criteria. 100%

Note that the recycle is very low due to:

a. the simultaneous approach to the surge control

lines using the S criteria, plus 100%

b. the advanced antisurge control.

INLET PRESSURE

A comparision of before and after energy 9 0%

efficiency is not possible, in this case, because this

control system is an orginal installation, not a

retrofit. Machinery repairs have been minimal, and the 80%

tA tB t c

tp tE tG

need for operator intervention or manual control is

negligible.

User reports to the authors indicate that, if FIG. 11. OPERATION OF A COMPRESSOR STATION,

considerable load variation exists, an energy savings SIMULTANEOUSLY UNLOADING BY CRITERIA S

between 10 percent and 30 percent can be anticipated.

Even when the load is stable, significant benefits can

be expected from precise pressure control, improved

machine protection, and improved automation. efficient, automatic operation under all possible

operating conditions.

SOME CONCLUSIONS To improve control of parallel (or series)

operating centrifugals, there are two key points that

Though much attention has been paid to more are commonly neglected:

efficient compressor design, the control systems, which a. The loading/unloading strategy, and

strongly influence operating efficiency and b. the surge control strategy.

reliability, are often neglected.

Experience shows that we cannot commit the future; The extra cost of the best control system is very

that is, we cannot guarantee stable operating small compared to the compressor repair costs and lost

conditions, good machine maintenance or trained operating efficiences of a mediocre system.

operators. The authors believe, therefore, that the A serious approach to improved control of

control system should be designed to insure safe, centrifugal compressors will be well rewarded.

11

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 06/27/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

REFERENCES

1. Gregory K. McMillan, Centrifugal and Axial

Compressor Control, ISA, 1983

2. Francis G. Shinsky, Energy Conservation Through

Control, Academic Press, 1979

3. J.R. Gaston, "Centrifugal Compressor Operations

and Control", ISA, 31st Annual Conference,

Houston, 1978

4. N. Staroselsky, L. Ladin, "Improved Surge Control

for Centrifugal Compressors", Chemical Engineering,

May, 1979

5. N. Staroselsky, "Better Efficiency and Reliability

for Centrifugal Compressors Operating in Parallel",

Canadian Mining and Metallurgical Bulletin,

November, 1980

12

Downloaded From: https://proceedings.asmedigitalcollection.asme.org on 06/27/2019 Terms of Use: http://www.asme.org/about-asme/terms-of-use

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Caterpillar Cat 301.8 Mini Hydraulic Excavator (Prefix BFA) Service Repair Manual (BFA00001 and Up) PDFDocument22 pagesCaterpillar Cat 301.8 Mini Hydraulic Excavator (Prefix BFA) Service Repair Manual (BFA00001 and Up) PDFfkdmma0% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Student Exploration: Force and Fan CartsDocument6 pagesStudent Exploration: Force and Fan CartsJustin on YouTubeNo ratings yet

- Lecture 4-Mathematical Modeling of Electrical SystemsDocument58 pagesLecture 4-Mathematical Modeling of Electrical SystemsNoor Ahmed86% (7)

- Enzyme Technology by Martin F. ChaplinDocument149 pagesEnzyme Technology by Martin F. ChaplinAKSHAYNo ratings yet

- Control Box ST Installation and UpgradeDocument75 pagesControl Box ST Installation and UpgradeKamal Buddy100% (2)

- MIT22 081JF10 Lec10 PDFDocument43 pagesMIT22 081JF10 Lec10 PDFKamal BuddyNo ratings yet

- Gas Turbines & Combined CyclesDocument47 pagesGas Turbines & Combined CyclesKamal BuddyNo ratings yet

- Nuclear Energy: Fission & Fusion: P. M. BellanDocument52 pagesNuclear Energy: Fission & Fusion: P. M. BellanKamal BuddyNo ratings yet

- Industrial Terms PDFDocument31 pagesIndustrial Terms PDFKamal BuddyNo ratings yet

- Factsheet VariableFrequencyDrive US v01Document1 pageFactsheet VariableFrequencyDrive US v01Ishit DhadaNo ratings yet

- List of Worldwide AC Voltages and FrequenciesDocument3 pagesList of Worldwide AC Voltages and FrequencieskrishnandrkNo ratings yet

- GE Centrifugal and Axial CompressorsDocument28 pagesGE Centrifugal and Axial Compressorsewok2030No ratings yet

- 16 White PDFDocument12 pages16 White PDFPutut D. UtomoNo ratings yet

- V005t14a001 86 GT 204 PDFDocument12 pagesV005t14a001 86 GT 204 PDFKamal BuddyNo ratings yet

- Centrifugal Compressor SRL 454 - Ge Oil&gasDocument20 pagesCentrifugal Compressor SRL 454 - Ge Oil&gasKamal Buddy50% (2)

- Design Basis Memorandum - Regulatory Document IndexDocument123 pagesDesign Basis Memorandum - Regulatory Document Indexaugur8866124No ratings yet

- Paper FRT DigsilentDocument5 pagesPaper FRT DigsilentLeonardo JuanNo ratings yet

- Standards and Guidelines For Natural Gas Fuelled Ship Projects'Document133 pagesStandards and Guidelines For Natural Gas Fuelled Ship Projects'mohammad kassarNo ratings yet

- Standard Penetration Test (SPT) : Prepared by Paul W. MayneDocument41 pagesStandard Penetration Test (SPT) : Prepared by Paul W. MayneRubén A. Flores Rojas100% (1)

- International Journal of Hydrogen EnergyDocument24 pagesInternational Journal of Hydrogen EnergyMarioNo ratings yet

- TSIDocument55 pagesTSISamNo ratings yet

- 03.5 - FPFF - Fire Preventing and FightingDocument78 pages03.5 - FPFF - Fire Preventing and FightingkunaalNo ratings yet

- Ch-2 Demand Side Management ReviewDocument128 pagesCh-2 Demand Side Management Reviewmariam williamNo ratings yet

- Fluid / Air Cooling Systems: Flks-1HDocument74 pagesFluid / Air Cooling Systems: Flks-1HpeterNo ratings yet

- RBM Expenses - Truck 1411 (Additional) & JCDocument9 pagesRBM Expenses - Truck 1411 (Additional) & JCMark DerracoNo ratings yet

- (PPMS Evercool Brochure) PPMS EvercoolDocument2 pages(PPMS Evercool Brochure) PPMS EvercoolMylena Pinto NascimentoNo ratings yet

- Zero Net Energy Buildings: Deep Energy Retrofit, Gloucester, MADocument1 pageZero Net Energy Buildings: Deep Energy Retrofit, Gloucester, MAOffice of Energy and Environmental Affairs, MANo ratings yet

- Energy Fuel Report Avalara Tax Changes 2023Document15 pagesEnergy Fuel Report Avalara Tax Changes 2023aramsaranNo ratings yet

- 2-IoT Functional Block & ArchitectureDocument18 pages2-IoT Functional Block & Architecturesahale sheraNo ratings yet

- GB - SGI LPG - CNG Software Manual - Version 5.1.0Document46 pagesGB - SGI LPG - CNG Software Manual - Version 5.1.0Ricardo PintoNo ratings yet

- Acoustic Pipe SupportsDocument6 pagesAcoustic Pipe Supportsnamdq-1No ratings yet

- Manual de Utilizare Ventilator MUB - 100 - 710DV - SileoDocument24 pagesManual de Utilizare Ventilator MUB - 100 - 710DV - SileopintileirobertNo ratings yet

- Modelling and Simulation of CO Absorption in Alkaline Buffer Solutions in gPROMSDocument6 pagesModelling and Simulation of CO Absorption in Alkaline Buffer Solutions in gPROMSalinoriNo ratings yet

- Chapter 15 - HydrocarbonsDocument16 pagesChapter 15 - HydrocarbonsNabindra RuwaliNo ratings yet

- 15repeat Formation TesterDocument8 pages15repeat Formation TesterMark allenNo ratings yet

- MRP 4424 Sistema Contra Incendio 1Document56 pagesMRP 4424 Sistema Contra Incendio 1Salvador Barrera MaldonadoNo ratings yet

- HT1-2 - (Quantity of Heat) v2Document17 pagesHT1-2 - (Quantity of Heat) v2Alrence BajumNo ratings yet

- 25 - B - SC - , Home Sciene Syllabus (2017-18)Document28 pages25 - B - SC - , Home Sciene Syllabus (2017-18)quickdannyNo ratings yet

- J Jpowsour 2006 02 003Document4 pagesJ Jpowsour 2006 02 003Customer Tech Support / Product Development Sales/CCT Dept. AECPLNo ratings yet

- Technical Folder Filtercel Cfa-W: SpecificationsDocument1 pageTechnical Folder Filtercel Cfa-W: SpecificationsmehrezNo ratings yet

- Cot DLP Science 7Document14 pagesCot DLP Science 7Janry Nino CaisedoNo ratings yet