Professional Documents

Culture Documents

Trial Mix Designing: Silica Fume Design

Uploaded by

Shivam Aggarwal0 ratings0% found this document useful (0 votes)

12 views3 pagesThis document provides a trial mix design for concrete with an M40 grade and 0% silica fume. It specifies the ingredients, volumes, weights, and percentages needed to achieve a target mean strength of 49 MPa including 392.8 kg/m3 of cement, 180.507 L of water, 807.47 kg/m3 of 20mm aggregate, 362.78 kg/m3 of 10mm aggregate, and 717.25 kg/m3 of sand. The final mix design is presented with the quantity of each constituent.

Original Description:

Original Title

Silica 0.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a trial mix design for concrete with an M40 grade and 0% silica fume. It specifies the ingredients, volumes, weights, and percentages needed to achieve a target mean strength of 49 MPa including 392.8 kg/m3 of cement, 180.507 L of water, 807.47 kg/m3 of 20mm aggregate, 362.78 kg/m3 of 10mm aggregate, and 717.25 kg/m3 of sand. The final mix design is presented with the quantity of each constituent.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views3 pagesTrial Mix Designing: Silica Fume Design

Uploaded by

Shivam AggarwalThis document provides a trial mix design for concrete with an M40 grade and 0% silica fume. It specifies the ingredients, volumes, weights, and percentages needed to achieve a target mean strength of 49 MPa including 392.8 kg/m3 of cement, 180.507 L of water, 807.47 kg/m3 of 20mm aggregate, 362.78 kg/m3 of 10mm aggregate, and 717.25 kg/m3 of sand. The final mix design is presented with the quantity of each constituent.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

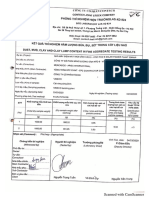

TRIAL MIX DESIGNING

SILICA FUME DESIGN

Design grade of concrete= M40 that confirms to IS 456 and IS 10262

According to the code, minimum cement content = 320 kg/m3

Maximum water cement ratio = 0.5

INGREDIENT SPECIFIC GRAVITY WATER ABSORPTION

Cement (OPC) 3.15 -

CA 20mm 2.72 0.59

CA 10mm 2.84 0.59

Fine Aggregate 2.5 1.2

Silica Fumes 2.2

Chemical Admixture 1.1

(Viscocrete)

Target Mean Strength = fck + 1.65s (where s= standard deviation = 5)

hence, ft = 40+ 1.65X5

= 48.25=49

Water cement ratio= 0.42

Let the free water =165L

weight of cementitious content= 165/0.42

=392.8 gm

Percentage of Silica fume used =0%

Weight of silica content = 0 kg

Vol of silica Fumes = 0 m3

Vol of cement = 392.8 / (3.15 X 1000)

=0.1247 m3

Vol of water = 165 / 1000

= 0.165m3

Let the chemical admixture be 1.2% of cementitious content

Hence, wt of admixture = 1.2 X 392.8 / 100

= 4.71 Kg/m3

Vol of admixture = 4.71 / (1.1 X 1000)

= 0.0043 m3

Remaining vol for aggregates = 1- (0 + 0.1247 + 0.165 + 0.0043)

= 0.706 m3

From the all in aggregate test,

CA = 62%, FA = 38%

Net specific gravity of the aggregate by weighted mean = ( 0.62 X 2.78 ) + ( 0.38 X 2.5)

= 2.6736

Hence, wt of aggregate = 2.6736 X 1000 X 0.706

= 1887.5 Kg/m3

Net weight of coarse aggregate = 1887.5 X .62 = 1170.25 kg/m3

Let 10mm aggregate be 31% and 20mm aggregate be 69% of net weight of coarse aggregate

weight of 20mm aggregate = 0.69 X 1170.25 = 807.47 Kg/m3

weight of 10mm aggregate = 0.31 X 1170.25 = 362.78 Kg/m3

Hence, weight of fine aggregate = 1887.5 - (1170.25)

= 717.25 Kg/m3

Now, water for absorption:

20mm = 0.59% X 807.47 = 4.76

10mm = 0.59% X 362.78 = 2.14

sand = 1.2% X 717.25 = 8.607

total water for absorption = 4.76+2.14+8.607 = 15.507

Hence, total water requirement = 165 + 15.507 = 180.507 L

Final MIX DESIGN

Constituent Quantity(kg/m3)

Cement(PPC) 392.8

Water 180.507

20 mm aggregate 807.47

10 mm aggregate 362.78

Sand 717.25

Admixture (Viscocrete) 4.71

Silica 0

You might also like

- Mix Design c40Document13 pagesMix Design c40Jaime Manalili LandinginNo ratings yet

- Concrete Mix DesignDocument7 pagesConcrete Mix DesignUma MaheshwaraNo ratings yet

- 3.3 Mix Design: 3.3.1 Mix Design ProcedureDocument4 pages3.3 Mix Design: 3.3.1 Mix Design Procedure14C151 SWATHI B.No ratings yet

- CALCULATION of Self Compacting ConcreteDocument16 pagesCALCULATION of Self Compacting ConcreteAntariksha NayakNo ratings yet

- Concrete Mix Design: Target Mean StrengthDocument12 pagesConcrete Mix Design: Target Mean StrengthAkash Kumar VermaNo ratings yet

- One Way Slab Design ExampleDocument14 pagesOne Way Slab Design ExampleUsman PervaizNo ratings yet

- Chapter Four: 4.0 Results and DiscussionsDocument10 pagesChapter Four: 4.0 Results and DiscussionsAyo OshoNo ratings yet

- Parameters For Mix Design M40Document3 pagesParameters For Mix Design M40Abhijit ErandeNo ratings yet

- Sp. Gravity: of Water Cement RatioDocument2 pagesSp. Gravity: of Water Cement RatioarjunNo ratings yet

- Mix Design Procedures and Test Results of Self-Compacting Concrete (SCC) 4.1. GeneralDocument35 pagesMix Design Procedures and Test Results of Self-Compacting Concrete (SCC) 4.1. GeneralWai Yann ZawNo ratings yet

- Mix Design Report M35Document6 pagesMix Design Report M35Zeeshan AbbasNo ratings yet

- Concrete Mix Design With GGBS M25Document13 pagesConcrete Mix Design With GGBS M25shamsuddin ShaikhNo ratings yet

- Mix Design As Per IS 10262-2019Document18 pagesMix Design As Per IS 10262-2019Suchitra PandaNo ratings yet

- Pervious Concrete Mix Design (M35) 1. Data For Mix ProportioningDocument5 pagesPervious Concrete Mix Design (M35) 1. Data For Mix ProportioningRashmi PleaseNo ratings yet

- CM36 Pattissery M20 Trial 1Document10 pagesCM36 Pattissery M20 Trial 1sudhakarthekingNo ratings yet

- Parameters For Mix Design M40Document6 pagesParameters For Mix Design M40Kumkum MukherjeeNo ratings yet

- Mix Design M30: Target Mean Strength (I.S - 10262-2009 Cl-3.2)Document4 pagesMix Design M30: Target Mean Strength (I.S - 10262-2009 Cl-3.2)aceNo ratings yet

- Mix Design M50 GradeDocument2 pagesMix Design M50 GradeLambu Sampath0% (1)

- M30 Normal - Mix Design With Trial SheetDocument4 pagesM30 Normal - Mix Design With Trial Sheetabir senguptaNo ratings yet

- Calculation of Concrete Mix Design: Cirebon - Jawa BaratDocument11 pagesCalculation of Concrete Mix Design: Cirebon - Jawa Baratelang ghifariNo ratings yet

- Calculation of Concrete Mix Design: Cirebon - Jawa BaratDocument11 pagesCalculation of Concrete Mix Design: Cirebon - Jawa Baratelang ghifariNo ratings yet

- RMC Mix Design PDFDocument19 pagesRMC Mix Design PDFluongiccNo ratings yet

- Trail No 198 - M50 BHARATHI + CHRYSO: Concrete Mix Proportioning Details A. Stipulations For ProportioningDocument4 pagesTrail No 198 - M50 BHARATHI + CHRYSO: Concrete Mix Proportioning Details A. Stipulations For ProportioningMohammad Arif RasheedNo ratings yet

- Development and Operation of Two Jetties 3 & 4 at Mongla Port Project Trough "PPP"Document5 pagesDevelopment and Operation of Two Jetties 3 & 4 at Mongla Port Project Trough "PPP"Engr.Estiaq AhmedNo ratings yet

- Bar Bending Schedule Kerala Overseer PSCDocument17 pagesBar Bending Schedule Kerala Overseer PSCsoorya KNo ratings yet

- Mix DesignDocument32 pagesMix DesignMinn LwinNo ratings yet

- Grade of Concrete:M 25/20Document9 pagesGrade of Concrete:M 25/20Niroj MaharjanNo ratings yet

- Trial Mix Design G25N Sual ProjectDocument1 pageTrial Mix Design G25N Sual ProjectZulaika LainiNo ratings yet

- Pervious Concrete Mix Design (M35) 1. Data For Mix ProportioningDocument4 pagesPervious Concrete Mix Design (M35) 1. Data For Mix ProportioningRashmi PleaseNo ratings yet

- Assigment 3-POCDocument4 pagesAssigment 3-POCHashir RanaNo ratings yet

- Concrete Mix Design m75Document2 pagesConcrete Mix Design m75nil sutar100% (1)

- Concrete Mix DesignDocument6 pagesConcrete Mix Designdilip01No ratings yet

- 14 - Appendix 1 PDFDocument7 pages14 - Appendix 1 PDFAnonymous qAPTE8REmnNo ratings yet

- Concrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)Document6 pagesConcrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)jishad_nalakath50% (2)

- M30 Design MixDocument10 pagesM30 Design Mixpendotavinay6No ratings yet

- Mix DesignDocument6 pagesMix DesignCharan Tej RudralaNo ratings yet

- Concrete Mix DesignDocument22 pagesConcrete Mix DesignkevalNo ratings yet

- C40 Concrete Mix DesignDocument2 pagesC40 Concrete Mix DesignIsaiahogeda50% (2)

- Major Project Review-2Document30 pagesMajor Project Review-2N Sandeep KumarNo ratings yet

- Concrete Mix Design Calculation: Group ADocument2 pagesConcrete Mix Design Calculation: Group AAyan GhoshNo ratings yet

- Concrete Mix Design Calculation: Group ADocument2 pagesConcrete Mix Design Calculation: Group AAyan GhoshNo ratings yet

- Mix Design Specification Requirements (A) Class of Concrete C-30Document5 pagesMix Design Specification Requirements (A) Class of Concrete C-30Atm Tjah Radix LoegoeNo ratings yet

- Lab Report On Concrete Mix DesignDocument5 pagesLab Report On Concrete Mix DesignAniruddha ChakrabortyNo ratings yet

- Mix Design M40Document3 pagesMix Design M40D21No ratings yet

- Mix Design For M35 Grade of ConcreteDocument4 pagesMix Design For M35 Grade of ConcretePaulos Wodajenehe TessemaNo ratings yet

- Concrete Design MixDocument15 pagesConcrete Design MixM HAFEEZ RAJANo ratings yet

- Stipulations For Mix Design Concrete M40Document5 pagesStipulations For Mix Design Concrete M40Md Sabbir HossainNo ratings yet

- Design of Mix ProportionsDocument2 pagesDesign of Mix ProportionsAbdul AzeemNo ratings yet

- 0.42 With Admixture BNDDocument130 pages0.42 With Admixture BNDHishmat Ezz AlarabNo ratings yet

- Class'C' Concrete-2Document9 pagesClass'C' Concrete-2Tewodros TadesseNo ratings yet

- Mix Design M-50 GradeDocument3 pagesMix Design M-50 GradeNM2104TE06 PRATHURI SUMANTHNo ratings yet

- Mix Design C-35.OD.03.10.23.Cement430Document4 pagesMix Design C-35.OD.03.10.23.Cement430sujanislam811No ratings yet

- 440 KG Cement ContentDocument1 page440 KG Cement ContentIsaiahogedaNo ratings yet

- Dhairya Chavda CE22M109Document3 pagesDhairya Chavda CE22M109Monika Gupta ce22m120No ratings yet

- Concrete Mix Design PDFDocument11 pagesConcrete Mix Design PDFLERIS PENOTELNo ratings yet

- Bhuvi MIX DESIGNDocument3 pagesBhuvi MIX DESIGNBhuvaneshwar ReddyNo ratings yet

- Ms Sidus Buildcon PVT .LTD Mix Design M 40 Opc+PfaDocument3 pagesMs Sidus Buildcon PVT .LTD Mix Design M 40 Opc+Pfaabhijit.paikNo ratings yet

- m60 Grade of Concrete Design Mix Procedure With Opc 53 Grade Cement and AlccofineDocument5 pagesm60 Grade of Concrete Design Mix Procedure With Opc 53 Grade Cement and AlccofineNitinLambaNo ratings yet

- AN5516 06 Optical Line Terminal PDFDocument168 pagesAN5516 06 Optical Line Terminal PDFDiego MattaNo ratings yet

- 2014-Db-Franck Pachot-Interpreting Awr Reports Straight To The Goal-ManuskriptDocument11 pages2014-Db-Franck Pachot-Interpreting Awr Reports Straight To The Goal-ManuskriptAnonymous OBPVTEuQLNo ratings yet

- Catalyst 2950 and Catalyst 2955 Switch Command ReferenceDocument460 pagesCatalyst 2950 and Catalyst 2955 Switch Command ReferenceVisitOn.T.witte.rNo ratings yet

- WFS BRDDocument23 pagesWFS BRDConrad RodricksNo ratings yet

- Data StageDocument76 pagesData StagegabrielmotocNo ratings yet

- RCC Isolated Footing DesignDocument3 pagesRCC Isolated Footing DesignK K Sumesh KumarNo ratings yet

- OptiX OSN 2500 Intelligent Optical TransmissionDocument1,589 pagesOptiX OSN 2500 Intelligent Optical TransmissionJuanNo ratings yet

- Open UIDocument16 pagesOpen UImohan999reddyNo ratings yet

- A PDFDocument10 pagesA PDFKimberly HerayNo ratings yet

- 1 Corba Vs RMI Vs DCOMDocument30 pages1 Corba Vs RMI Vs DCOMsgohb100% (1)

- Electrical Symbols: General Notes AbbreviationsDocument17 pagesElectrical Symbols: General Notes AbbreviationsMyPc ServicesNo ratings yet

- 4 Steps How To Measure For Curved Glass Manufacture & Installation - Blog - Coastal Curved GlassDocument4 pages4 Steps How To Measure For Curved Glass Manufacture & Installation - Blog - Coastal Curved GlassShivamNo ratings yet

- Creativity & Innovation: Individual Ideation MethodsDocument35 pagesCreativity & Innovation: Individual Ideation MethodsSandeep KautishNo ratings yet

- Abiy AlemuDocument139 pagesAbiy AlemuabadittadesseNo ratings yet

- 5319 - Iyumbu Tss DrawingsDocument19 pages5319 - Iyumbu Tss DrawingsGodfrey BaitanNo ratings yet

- Eurocode 5 1.2Document54 pagesEurocode 5 1.2Kulcsar Remus100% (1)

- How To Delete Failed DCs From Active Directory Using NtdsutilDocument6 pagesHow To Delete Failed DCs From Active Directory Using NtdsutilOke HariansyahNo ratings yet

- Theory of Architecture 2Document7 pagesTheory of Architecture 2Kent Acentada CapindoNo ratings yet

- Logistics & ITDocument19 pagesLogistics & ITTufail MallickNo ratings yet

- Chap 15Document21 pagesChap 15Ramz8899No ratings yet

- Monuments and Sites 16 What Is OUVDocument110 pagesMonuments and Sites 16 What Is OUVBernd PaulowitzNo ratings yet

- L Train TunnelDocument1 pageL Train TunnelNewsdayNo ratings yet

- CCNA CH7 Study GuideDocument2 pagesCCNA CH7 Study GuideJason HawthorneNo ratings yet

- Advanced-Car Parking SystemDocument23 pagesAdvanced-Car Parking SystemKamalesh RjNo ratings yet

- CW ATP Document V2.1Document4 pagesCW ATP Document V2.1HammadAlviNo ratings yet

- 07 Post Mauryan Religious Development Arts and ArchitectureDocument4 pages07 Post Mauryan Religious Development Arts and ArchitectureSourabha BhattNo ratings yet

- Info - The Sims 3.gold Edition.v 16.0.136 + StoreDocument39 pagesInfo - The Sims 3.gold Edition.v 16.0.136 + StoreCelsous D'oarteNo ratings yet

- Adv - Found.eng Lecture 6Document28 pagesAdv - Found.eng Lecture 6bini100% (1)

- Life and Career: Richard Streiter Georg Heuser Architectural RealismDocument7 pagesLife and Career: Richard Streiter Georg Heuser Architectural RealismRendyReynaldiNo ratings yet