Professional Documents

Culture Documents

Microscoop 100D Microscoop 100D Microscoop 100D Microscoop 100D

Uploaded by

Khalil LaouaneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Microscoop 100D Microscoop 100D Microscoop 100D Microscoop 100D

Uploaded by

Khalil LaouaneCopyright:

Available Formats

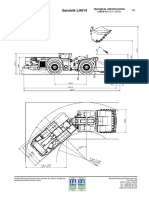

Technical Specification

9-900 S-A

2006-02-20

MICROSCOOP 100D

2045

1215

1030

220

1645 1525 1430 1055

4600

1050

36° 1840

3190

1890

APPLICATION BUCKET MOTION TIMES

The Microscoop 100D is a true compact and flexible full Raising time 2.6 sec.

Diesel loader for narrow vein mining. Lowering time 1.5 sec.

Tipping time 4.1 sec.

The highest possible rate of productivity is ensured by

fast and easy one pass loading.

The M100D layout is designed for good visibility and WEIGHTS

balance.

This and the powerful four-wheel-drive articulated Operating weight 3 650 kg (8 030 lb)

chassis ensure fast and safe manoeuvering in tight Total loaded weight 4 650 kg (10 230 lb)

spaces. Shipping weight

Axle weights without load

All the service points are well protected but easy to Front axle 1 300 kg (2 860 lb)

access. Rear axle 1 900 kg (4 180 lb)

Axle weights with load

Front axle 2 800 kg (6 160 lb)

CAPACITIES Rear axle 1 400 kg (3 080 lb)

Unit weight is dependent on the selected options.

Tramming capacity 1 000 kg (2 200 lb)

Breakout force, lftt 10.7 kN - 1 094 kg (2 407 lb)

Breakout force, tilt 36.9 kN - 3 766 kg (8 285 lb)

Tipping load 2 941 kg (6 470 lb) DRIVING SPEEDS FORWARD AND REVERSE

Bucket std. 0.54 m³ (0.7 yd³), 500 BNH lip Loaded, max 9 km/h (5.6 mph)

© 2006 Sandvik Mining and Construction 1/4

Technical Specification

9-900 S-A

2006-02-20

MICROSCOOP 100D

SERVICE CAPACITIES STEERING

Fuel tank 40 liters (10.5 gal.) Full hydraulic, centre-point articulation, power steering

Hydraulic oil tank 62 liters (16.4 gal.) with two double acting cylinders. Steering controlled by

Hydrostatic transmission oil tank 31 liters (8.2 gal.) stick, interlock protection.

Turning angle ± 36°

FRAME Turning radius inner 1840 mm (72”)

outer 3190 mm (125”)

Rear and front frame Welded steel construction

Material E 36.3 Main components in steering system:

Main valve HPI

Central hinge Spherical bearings

(large angle) Control valve Danfoss

Steering hydraulic cylinders 2 pcs, 60 mm (2.36”),

ENGINE Tamrock

Pressure settings:

Diesel engine Deutz F3L 912W Main relief valve 14.0 Mpa (170 bar)

Output 33 kW (45 hp) / 2 500 rpm Shock load valves 17.5 Mpa (175 bar))

Torque 170 Nm / 1 500 rpm

Number of cylinder In line 3 BUCKET HYDRAULICS

Displacement 2 827 cm³

Cooling system Air cooled Full hydraulic open center system with one gear pump.

Combustion principle 4-stroke, 2-stage combustion The oil flow from steering hydraulic pump is directed to

Electric system 12 V starter and accessories bucket hydraulics when steering is not used.

Air filtering Oil bath air cleaner Equipped with mechanical dual control lever.

Exhaust system Catalytic purifier Lift cylinder 1 pcs, ø100 mm (3.9”)

Tilt cylinder 1 pcs, ø120 mm (4.7”)

TRANSMISSION Pressure setting for:

Main relief valve 14.0 Mpa (140 bar)

Hydrostatic transmission Variable flow

Bucket tilt 6.0 Mpa (60 bar)

fully reversible

Bucket roll-back 18.0 Mpa (180 bar)

One pump Linde, variable displacement

Boom raise 18.0 Mpa (180 bar)

0 to 42 cm³/rev

Boom lower 6.0 Mpa (60 bar)

One motor Linde, fixed 35 cm³/rev

Main components:

Bucket hydraulic cylinders Tamrock

TRANSFER CASE

Control valve Commercial hydraulics

Type Gear Fittings JIC

Location Rear axle

ELECTRICAL EQUIPMENT

AXLES

Alternator 45 A, Bosch

Front and rear Tamrock, fixed Battery 1 x 12 V, 95 Ah

No-spin in front axle Starter 1.7 kW, 12 V

Central hinge oscillation ± 10° Driving and working lights font, 2 pcs (H1 55 W)

rear, 2 pcs (H1 55 W)

WHEELS

Tires 8.25 x 15

Air pressure, front and rear 3.5 bar (350 kPa) OPTIONAL EQUIPMENT

BRAKES *) Bucket size 0.5 m³ (0.7 yd³), width 950 mm (37”).

FOPS-ROPS safety canopy.

Dynamic service brake through the hydrostatic Reverse alarm.

transmission. Emergency steering system.

The parking and emergency brake is spring applied, Complete spare wheel.

hydraulically released multidisc oil immersed brakes *) EU, UL, CSA, AUS norms package.

inclosed on the rear axle.

*) replaces standard component

© 2006 Sandvik Mining and Construction 2/4

Technical Specification

9-900 S-A

2006-02-20

MICROSCOOP 100D

GRADEABILITY & SPEED

60

50

GRADE (%)

40

30

20

10

0

0 1 2 3 4 5 6 7 8 9

SPEED (kph)

PRODUCTIVITY CURVE

60

Basic data for calculations :

50 Payload 1 000 kg

Overall speed limit 8.5 km/h

Fixed cycle time 0.5 min.

Rolling resistance 3%

40 Fixed cycle time includes the time for filling,

dumping, turning and accelerating

Slope / Grade Hor./0 1:5/20

Loaded speed (kph) 8.5 7.1

30 Empty speed (kph) 8.5 8.5

TONNES

PER HOUR

20

10

0

0 50 100 150 200 250 300 350 400 450

ONE WAY DISTANCE IN METRES

0% 20 %

© 2006 Sandvik Mining and Construction 3/4

Technical Specification

9-900 S-A

2006-02-20

MICROSCOOP 100D

DUMP DATA

2320

1500

1745

42°

1290

600

835

CAGING DIMENSIONS

1215

3698 1055

Bucket and canopy removed ...........................................3 287 kg

1215

3463 1055

Bucket, canopy and lift arms removed ...........................3 107 kg

991

3453 1055

Bucket, canopy, lift arms, axles and tires removed.......2 372 kg

Sandvik Mining and Construction reserves the right to change this specification without further notice.

Sandvik Mining and Construction Lyon S.A.S. www.sandvik.com

B.P.46 - FR-69881 Meyzieu Cedex, France

Tel. +33 4 7245 2200, Telefax +33 4 7831 7980 4/4

You might also like

- Sandvick LH201 - 9900sbDocument4 pagesSandvick LH201 - 9900sbMario AlonsoNo ratings yet

- Micro Scoop France LoaderDocument6 pagesMicro Scoop France LoaderMax Bryan Rodriguez GarciaNo ratings yet

- LH410Document9 pagesLH410Anonymous XTsbOs4oUWNo ratings yet

- Technical Specification Sandvik TH320-03Document6 pagesTechnical Specification Sandvik TH320-03abadNo ratings yet

- Crawler Excavator: Features Specifi CationsDocument4 pagesCrawler Excavator: Features Specifi Cationsluismdmj100% (1)

- LH514 - OkokDocument6 pagesLH514 - OkokVictor Yañez Sepulveda100% (1)

- Terex - tc35Document4 pagesTerex - tc35AnaNo ratings yet

- TC_16_en(32a)Document4 pagesTC_16_en(32a)monsieur.anthonydecharnia37No ratings yet

- MTS ENERGY LIMITED Offers Skid Steer Loader and Wheel LoaderDocument22 pagesMTS ENERGY LIMITED Offers Skid Steer Loader and Wheel LoaderCarlos Jimenez Maqui-cardanNo ratings yet

- Technical Specification Sandvik LH203-08 PDFDocument3 pagesTechnical Specification Sandvik LH203-08 PDFacomisaminasNo ratings yet

- Sandvik LH203 Technical SpecificationDocument3 pagesSandvik LH203 Technical SpecificationEstyNo ratings yet

- Hitachi EX3600 Hydraulic Excavator PDFDocument11 pagesHitachi EX3600 Hydraulic Excavator PDFChaerul Umami100% (1)

- LH203 18 Eng Metric PDFDocument7 pagesLH203 18 Eng Metric PDFJohan CarpioNo ratings yet

- Sandvik LH201: Application Bucket Motion TimesDocument4 pagesSandvik LH201: Application Bucket Motion TimesChad WebbNo ratings yet

- Sandvic DD420 60C SpecDocument4 pagesSandvic DD420 60C SpecAlterSon Grafi KalayNo ratings yet

- Specifications: Ibratory OIL OmpactorDocument2 pagesSpecifications: Ibratory OIL OmpactorMohamad NuhNo ratings yet

- Sandvik TH430: Technical SpecificationDocument6 pagesSandvik TH430: Technical SpecificationRigo McFly Casanova Armijo0% (1)

- Lh410 18Document3 pagesLh410 18LudovicoPelucheNo ratings yet

- Mini Excavator: Features Technical DataDocument4 pagesMini Excavator: Features Technical DataluismdmjNo ratings yet

- Duralite 1000N Spec Sheet PDFDocument1 pageDuralite 1000N Spec Sheet PDFJhonattan GonzalezNo ratings yet

- A300/A300H All-Wheel Steer Loaders: DimensionsDocument10 pagesA300/A300H All-Wheel Steer Loaders: Dimensionsedwin quirozNo ratings yet

- Sandvik TH315 Technical SpecificationDocument6 pagesSandvik TH315 Technical SpecificationRigo McFly Casanova ArmijoNo ratings yet

- Terex Rigid Truck45Document4 pagesTerex Rigid Truck45Jamal HabbasNo ratings yet

- Libros PDFDocument571 pagesLibros PDFAnderson Lopez100% (2)

- Technical (Modified) Agreement For 750HP Truck Mounted Drilling RigDocument12 pagesTechnical (Modified) Agreement For 750HP Truck Mounted Drilling Rigchtoil2020100% (1)

- CAMION 80 T Supra0012h EspecDocument3 pagesCAMION 80 T Supra0012h EspecErich ThomasNo ratings yet

- 1m3 Diesel Escopo ParametrosDocument5 pages1m3 Diesel Escopo ParametrosnikolaimendozasNo ratings yet

- LH410 18Document3 pagesLH410 18JavierNo ratings yet

- Procedimiento 17FB173Document18 pagesProcedimiento 17FB173VictorNo ratings yet

- Lightweight portable diamond drill rigDocument2 pagesLightweight portable diamond drill rigSugeng Ciko DarmintoNo ratings yet

- ds511 Specification Sheet EnglishDocument4 pagesds511 Specification Sheet EnglishAntonio BocanegraNo ratings yet

- DR PB TD60M T3 6 11122023 ENG (M)Document6 pagesDR PB TD60M T3 6 11122023 ENG (M)ogi04No ratings yet

- Ficha Tecnica t800nDocument1 pageFicha Tecnica t800nAnyelo Diaz Romero100% (1)

- Sandvik DD210Document4 pagesSandvik DD210Lener Elvin Lopez LavadoNo ratings yet

- dd210 Specification Sheet English PDFDocument4 pagesdd210 Specification Sheet English PDFGerson Dario Rojas TorresNo ratings yet

- BH 50M PDFDocument4 pagesBH 50M PDFAnbarasanNo ratings yet

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler DozerJackson Phinni100% (2)

- 4WD Series Tractors: Tractor CompanyDocument6 pages4WD Series Tractors: Tractor CompanyParamesh Siva100% (1)

- EDM 95K SeriesDocument2 pagesEDM 95K SerieskingsfordathleeNo ratings yet

- Ucm03 177805Document4 pagesUcm03 177805luismdmjNo ratings yet

- Pala Hitachi Ex 5500Document13 pagesPala Hitachi Ex 5500RODOLFO ESTEBAN VARGAS TORONo ratings yet

- 320DRR 320DLRR PDFDocument9 pages320DRR 320DLRR PDFALEXANDRANo ratings yet

- B30 MKVI English - NewDocument6 pagesB30 MKVI English - Newnumero_212No ratings yet

- Ahv-Iv Articulated Hydrostatic VehiclesDocument3 pagesAhv-Iv Articulated Hydrostatic Vehiclesdewan pratomoNo ratings yet

- Lh621 Specification Sheet EnglishDocument9 pagesLh621 Specification Sheet EnglishDaniel SepulvedaNo ratings yet

- Sandvik Lh115L Low Profile Loader: Technical SpecificationDocument6 pagesSandvik Lh115L Low Profile Loader: Technical SpecificationDiego PauccaNo ratings yet

- PK 4100Document8 pagesPK 4100Ionut-CristianSalavatNo ratings yet

- Technical Specification Sandvik LH514-14yd3 PDFDocument3 pagesTechnical Specification Sandvik LH514-14yd3 PDFDagoberto Andres Ñancupil GonzalezNo ratings yet

- BR350 English Jan 2011Document6 pagesBR350 English Jan 2011ddionneNo ratings yet

- PMK T 8010Document4 pagesPMK T 8010pauloNo ratings yet

- Technical Specification Sandvik LH514-5Document3 pagesTechnical Specification Sandvik LH514-5Franklin Labbe100% (1)

- Sandvik DP1100: ApplicationDocument4 pagesSandvik DP1100: ApplicationAnbarasanNo ratings yet

- Specifications 20 TON DTDocument3 pagesSpecifications 20 TON DTCesar QuintanillaNo ratings yet

- 911 GT2 RS - CatalogueDocument49 pages911 GT2 RS - CatalogueAlexandru TerciuNo ratings yet

- Atm1122 Hydraulics Module 1Document20 pagesAtm1122 Hydraulics Module 1Masood AlamNo ratings yet

- Energy Efficient Motors: 60 Hertz Line Frequency - SF 1:15Document2 pagesEnergy Efficient Motors: 60 Hertz Line Frequency - SF 1:15adh3ckNo ratings yet

- SB CatalogDocument20 pagesSB CatalogCentral HydraulicsNo ratings yet

- Innovated Engine: Heavy-Duty Forklift TrucksDocument4 pagesInnovated Engine: Heavy-Duty Forklift TrucksCristian Manuel Daza MafiolisNo ratings yet

- Genesis 3.8L Section 7Document40 pagesGenesis 3.8L Section 7Nacho MowjiNo ratings yet

- Intro To AutomotiveDocument49 pagesIntro To AutomotiverezoltNo ratings yet

- Eaton Fuller RTX 14715Document43 pagesEaton Fuller RTX 14715Mauricio DuranNo ratings yet

- RX Screw CataloguesDocument2 pagesRX Screw CataloguesPuppala Laxmana PrasadNo ratings yet

- Old Room Thermostat en Up To Nov2017Document4 pagesOld Room Thermostat en Up To Nov2017BilalNo ratings yet

- Silent Generator TFN Type Specification Model YM6700T YM7700T YM9700T YM10000TDocument1 pageSilent Generator TFN Type Specification Model YM6700T YM7700T YM9700T YM10000TElvis Culma GallegoNo ratings yet

- 2010 Opel Vivaro 93852Document164 pages2010 Opel Vivaro 93852Alin DumiNo ratings yet

- BoardDocument8 pagesBoardJerald ManlangitNo ratings yet

- 4 - Sem Lab Manual: Spur Gear MillingDocument10 pages4 - Sem Lab Manual: Spur Gear MillingPRASSAN SHAHNo ratings yet

- Electrical Design Machine 1 Final - Asilo Justine Troy D.Document14 pagesElectrical Design Machine 1 Final - Asilo Justine Troy D.Hok HokNo ratings yet

- Equipment Upload FormatDocument80 pagesEquipment Upload FormatPankaj PandeyNo ratings yet

- Miniature Machining Tools - American EdelstaalDocument40 pagesMiniature Machining Tools - American EdelstaalPica MoixonencNo ratings yet

- 3512 MARINE ENGINE 50Y00001-00646 (SEBP1314 - 01) - DocumentationDocument5 pages3512 MARINE ENGINE 50Y00001-00646 (SEBP1314 - 01) - DocumentationChung ChungNo ratings yet

- Carillo Rod Bolts Tech InfoDocument1 pageCarillo Rod Bolts Tech Infoagrandi12No ratings yet

- SSP+27+Octavia+1 4+l+engine+and+gearbox+002 PDFDocument42 pagesSSP+27+Octavia+1 4+l+engine+and+gearbox+002 PDFAbhiboy Abhi SagarNo ratings yet

- Diesel Fuel Systems ComponentsDocument12 pagesDiesel Fuel Systems Componentsahmed jemalNo ratings yet

- Automobile L 5Document72 pagesAutomobile L 5MesipNo ratings yet

- JackhammerDocument3 pagesJackhammerMacharla KumaraswamyNo ratings yet

- Practical Training For WALTER M601 EngineDocument5 pagesPractical Training For WALTER M601 EngineMichelle Williams100% (1)

- Robotic Configurations 10.08 PDFDocument15 pagesRobotic Configurations 10.08 PDFVenkateshAthava50% (2)

- Automatic Transaxle PDFDocument50 pagesAutomatic Transaxle PDFdemos70100% (1)

- 936 Transmision Desarmado y ArmadoDocument51 pages936 Transmision Desarmado y ArmadoCalixto Leonardo Saenz AlejoNo ratings yet

- LUBI LES 40-160-2 Test CurveDocument1 pageLUBI LES 40-160-2 Test CurveRichard RajkumarNo ratings yet

- Catálogo HP675 A XP825Document2 pagesCatálogo HP675 A XP825Wender SilvaNo ratings yet

- Tur.3012.0919 Dyrhh Steam TurbineDocument2 pagesTur.3012.0919 Dyrhh Steam TurbineSerge RINAUDONo ratings yet