Professional Documents

Culture Documents

Nota Técnica

Nota Técnica

Uploaded by

Jose Arturo Alvarez BlandónOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nota Técnica

Nota Técnica

Uploaded by

Jose Arturo Alvarez BlandónCopyright:

Available Formats

Asset uptime for

the rest of us

Application Note

There’s the ideal predictive

maintenance program, and

there’s reality most of us

manage while we work toward it.

This is not an article about why you should

muscle-up and dedicate specific people, time,

and budget to predictive maintenance. This

article is about how to get excellent asset

uptime with the maintenance and reliability

resources at your disposal.

The ideal situation is a dedicated

predictive maintenance (PdM) or

reliability team at a large indus-

trial plant that has identified

the most important (expensive)

equipment in-plant; uses auto-

mated systems or a computerized

maintenance management

system (CMMS) to monitor equip-

ment and store and track data;

determines that sweet spot of

exactly when equipment needs That team knows its equip- Another basic principle is that

maintenance to optimize perfor- ment, does some amount of certain measurements can serve

mance and prevent damage or scheduled maintenance, has as warning signs of changes

failure; and has the people, time, strong troubleshooting skills, in equipment health. By taking

and budget to do proactive work. and has a team lead. However, those measurements regularly

Then there are the rest of us, the equipment knowledge and and comparing them to previous

with a small maintenance team skills are stored in individual records, technicians can detect

at a small or mid-sized industrial heads, so the information shar- changes before they become

facility with broad responsibili- ing part never really happens. problems.

ties but not the scope of work If we narrow down the list of

or budget to go full SCADA What the rest of us PdM must-haves to a “rest-of-us”

(supervisory control and data list, it looks like this:

acquisition) or to dedicate people can do

• Know your most important

to PdM work, applying the best Technology has advanced to pieces of equipment and

reactive maintenance prac- the point where maintenance their tell-tale measurements/

tices we can manage, including technicians often can use the inspection points that inform

gathering data manually as the same techniques and tools to you about their health.

job dictates to get the work done troubleshoot and inspect, log,

and solve problems as they arise. and share—the basics of proac-

tive maintenance.

From the Fluke Digital Library @ www.fluke.com/library

Some problems might occur, such

as team members won’t write

down measurements. Another

possible problem is that data

saved on the measurement tool

never leaves the measurement

tool—in other words, doesn’t get

shared with the team.

The solution is to use that

smartphone or tablet the team

members already are carrying or

that management has been look-

ing for more ways to use on the

job—in fact, work orders are the

number one application. Here’s

how:

• Convert from the hand-written

notebook to a smart device

and a cloud-based system

• Make it standard practice to 2. Check the data share on a such as Fluke Connect™.

check those tell-tales and semi-regular basis and look People like using their smart-

save the data points to a for changes that might indi- phones so much, they are

shared location whenever cate a problem (in general, more willing to enter data if

you’re working on that piece when measurements start to they can use their device to do

of equipment, organized by deviate by 5 or 10 percent, it’s it. It’s still a two-step process-

equipment type and marked time to investigate). process (take measurement,

by the date. – Management should be enter into cloud spreadsheet)

• Check the data-share first responsible for maintaining, but it’s better than the old

whenever you’re troubleshoot- checking, and assessing three-step involving hand-

ing. It might help you identify the data. written notes and data entry

the cause faster. – The team should be back at the office, and the

The next step involves manage- enabled and encouraged spreadsheet does double-duty

ment. The team lead can do to check the log on the job, as a checklist.

three things to help make this not just for data entry; also

to check the data history on • Use the Fluke Connect™

work: mobile apps now available for

1. Hold lunch-and-learns for the that system whenever they

enter a troubleshooting many test tools (see Figure 1)

team on the tell-tales and the to more automatically transfer

objective so everyone knows situation.

3. Set up incentives for the team data from the situation to the

what to look for and feels part log and from the individual to

of the mission. to:

– Speak up if they see some- the team.

– Provide some basic how-to

on using simple cloud- thing that might fall into a

based spreadsheets. tell-tale category.

This helps anyone who’s – Think of other ways to

uncomfortable using the use the cloud log and data

technology to learn what sharing to improve team

to do without feeling communication.

embarrassed.

– Share the data logs every

quarter and explain what

the measurements tell you.

This kind of “reason-why”

is more meaningful in the

context of your own equip-

ment than in the abstract.

Help people understand

their work makes a

difference.

Figure 1. With Fluke Connect ™, you can

transfer asset data from the plant asset or

field to the maintenance log and from the

individual to the team to help ensure knowl-

edge sharing.

2 Fluke Corporation Asset uptime for the rest of us

Figure 2. Proactive maintenance measurements aren’t that different from troubleshooting tests.

You’re looking for baseline data points related to failure modes. Note: These recommendations are

not a complete set of predictive maintenance (PdM) measurements or practices.

Baselines and tell-tales – Noncontact temperature: maintenance to their thinking,

scan the bearing hous- it’ll become clear that not every

for motor-drive systems large system in your facility

ings on motors, switches

Proactive maintenance measure- in circuit breaker panels, needs active monitoring all of

ments aren’t that different from and wiring connections at the time. The pinch point comes

troubleshooting tests. You’re important equipment. when a machine, or some of

looking for signs of potential fail- – Good/bad vibration read- its key components, starts to

ure, so you take measurements ings at each bearing degrade. At that point you need

related to failure modes, and location along the drive- to order in parts, schedule down-

record them. train while the machine is time as needed, and check the

1. Establish baseline data points running in a steady state system more often.

so you know what “good” and at normal operating Some teams have started to

looks like and so the team temperature. use small leave-behind mini-

lead has a point of comparison – Quick voltage and current meters that can be locked into

for later readings (see Figure checks, against the balance the panel and send data wire-

2). and loading thresholds. lessly to a master meter or

2. Make quick periodic inspec- computer. That way, you can

tions using carry-along tools Additional option: complete those more-frequent

such as multimeters, visual data checks more quickly. In

thermometers, and vibra-

incremental wireless

addition, you only need one

tion pens that are essentially Part of what makes a SCADA set of tools that you can rotate

stepped-down PdM tools system so attractive is the around to different systems as

designed for nonspecialist automatic data capture. As your needed.

technicians. Make the follow- team starts to add proactive

ing inspections:

Fluke. Keeping your world

up and running.®

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2014 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 8/2014 6003056A_EN

Modification of this document is not permitted

without written permission from Fluke Corporation.

3 Fluke Corporation Asset uptime for the rest of us

You might also like

- Telephone Billing SystemDocument43 pagesTelephone Billing Systemsouravroyonline79% (29)

- Payroll SystemDocument29 pagesPayroll SystemAliyu Aminu100% (2)

- Energy Storage Technologies and Applications PDFDocument328 pagesEnergy Storage Technologies and Applications PDF何家銘100% (1)

- Roundtracer Flash En-Us Final 2021-06-09Document106 pagesRoundtracer Flash En-Us Final 2021-06-09Kawee BoonsuwanNo ratings yet

- IPage Make Your Own Scalar Healing Device PDFDocument11 pagesIPage Make Your Own Scalar Healing Device PDFSadegh SimorghNo ratings yet

- NetOps 2.0 Transformation: The DIRE MethodologyFrom EverandNetOps 2.0 Transformation: The DIRE MethodologyRating: 5 out of 5 stars5/5 (1)

- Systems Analysis NotesDocument5 pagesSystems Analysis Notesbear bearNo ratings yet

- A Guide To Consolidating Your It Management ToolsDocument8 pagesA Guide To Consolidating Your It Management ToolsWilliam H. BoneyNo ratings yet

- Systems Approach in Administrative Office SystemDocument22 pagesSystems Approach in Administrative Office SystemAISYAH NABILAH ROSLANNo ratings yet

- Pizza Shope PPTDocument15 pagesPizza Shope PPTswapnil nanvareNo ratings yet

- Best Practices For Effective Defect TrackingDocument5 pagesBest Practices For Effective Defect Trackingitsme1978No ratings yet

- TermografiaDocument8 pagesTermografiadeyvis gonzles castilloNo ratings yet

- Management Information System: Prepared byDocument10 pagesManagement Information System: Prepared bysonalNo ratings yet

- Systems Administration and Maintenance: Learning ModuleDocument7 pagesSystems Administration and Maintenance: Learning ModuleAugustine Laureta50% (2)

- SRE Google NotesDocument8 pagesSRE Google Notesbalahari mahta100% (1)

- System ImplementationDocument7 pagesSystem ImplementationDivyaprathaprajuNo ratings yet

- AssignmentDocument15 pagesAssignmentkinzay batoolNo ratings yet

- Auditing, SoftwaresDocument26 pagesAuditing, SoftwaresOwen GarciaNo ratings yet

- Systems For ControlDocument20 pagesSystems For ControlCristian RodriguezNo ratings yet

- Instructions: Answer All Questions.: The MHC-PMSDocument9 pagesInstructions: Answer All Questions.: The MHC-PMSWambuiNo ratings yet

- To Prepare Software Requirements Specification Document For Employee Management ApplicationDocument9 pagesTo Prepare Software Requirements Specification Document For Employee Management ApplicationUTKARSH ARYANo ratings yet

- Electronic Data ProcessingDocument4 pagesElectronic Data Processingx 1No ratings yet

- Created by Roshan Nair Page 1 of 5: Performance Tuning in OracleDocument5 pagesCreated by Roshan Nair Page 1 of 5: Performance Tuning in Oraclegorthi.pavanNo ratings yet

- System Management: "There Is No Such Thing As A Single Problem All Problems Are Interrelated."Document23 pagesSystem Management: "There Is No Such Thing As A Single Problem All Problems Are Interrelated."Jerald AmabaNo ratings yet

- IB ComSci: 1.2 System Design BasicsDocument21 pagesIB ComSci: 1.2 System Design BasicsSheaNo ratings yet

- Computer Forensics Evidence and Capture: Data RecoveryDocument15 pagesComputer Forensics Evidence and Capture: Data Recoverygowrishankar nayanaNo ratings yet

- Group 5 Handouts - Docx743943420Document26 pagesGroup 5 Handouts - Docx743943420michaelanunag26No ratings yet

- Facility Management Preventive Maintenance Guide - by AkitaBoxDocument15 pagesFacility Management Preventive Maintenance Guide - by AkitaBoxBacchus HamidNo ratings yet

- Fundamentals of Information Systems 8th Edition Stair Solutions ManualDocument9 pagesFundamentals of Information Systems 8th Edition Stair Solutions Manualwarrenerambi70w35h100% (31)

- Auditing and Electronic Data Processing (EDP)Document6 pagesAuditing and Electronic Data Processing (EDP)Lizza Marie CasidsidNo ratings yet

- Data ProcessingDocument7 pagesData ProcessingOlapade BabatundeNo ratings yet

- INTRODUCTION: Techno Task Manager Is Where The Task Management Mainly ConcernsDocument88 pagesINTRODUCTION: Techno Task Manager Is Where The Task Management Mainly ConcernsLàsÿà ChowdàrÿNo ratings yet

- Mis 5Document23 pagesMis 5jerin johnNo ratings yet

- 1 Maintaining and Repairing Computer Systems and NetworksDocument18 pages1 Maintaining and Repairing Computer Systems and NetworksLeandro InciongNo ratings yet

- Workflow: A Foundational Element of Business ApplicationsDocument16 pagesWorkflow: A Foundational Element of Business ApplicationsEka NusaNo ratings yet

- Rev MidtermDocument17 pagesRev MidtermraqibappNo ratings yet

- Document VBDocument75 pagesDocument VBManoj Kumar SahuNo ratings yet

- SHES 2302 Sistem Maklumat 09 Bioinformatics Department Tutorial 11Document5 pagesSHES 2302 Sistem Maklumat 09 Bioinformatics Department Tutorial 11Koo Xue YingNo ratings yet

- Guide-TopOpps-Modern Mobile InspectionDocument16 pagesGuide-TopOpps-Modern Mobile InspectionYel BNo ratings yet

- Chapter One: Introduction To System and Network AdministrationDocument74 pagesChapter One: Introduction To System and Network AdministrationBilisuma chimdesaNo ratings yet

- Meaningful Ways To Interpret Building Data: FeatureDocument5 pagesMeaningful Ways To Interpret Building Data: Featurejdietz4No ratings yet

- Is - Chapter 1Document12 pagesIs - Chapter 1Lapa EtienneNo ratings yet

- Software Development Life CycleDocument5 pagesSoftware Development Life CycleTalha mansoorNo ratings yet

- Fullname: Mhlengi Ntsikeni Module: ITP Semester: 6 Lecturer:Mr Emmanuel HoweDocument15 pagesFullname: Mhlengi Ntsikeni Module: ITP Semester: 6 Lecturer:Mr Emmanuel HoweMhlengi Mlindi NtsikeniNo ratings yet

- Staff MGMTDocument117 pagesStaff MGMTKamia JainNo ratings yet

- Final ReportDocument33 pagesFinal ReportHelloo ByeeeNo ratings yet

- 001 - 003 Emplyee Management Information SystemDocument8 pages001 - 003 Emplyee Management Information SystemYUSUF ABDULMALIKNo ratings yet

- IB ComSci: 1.1 System in OrganizationsDocument18 pagesIB ComSci: 1.1 System in OrganizationsSheaNo ratings yet

- Migrate To New Technology LO2Document15 pagesMigrate To New Technology LO2Ayele TayeNo ratings yet

- Unit 23 Example AssignmentDocument19 pagesUnit 23 Example AssignmentWillNo ratings yet

- Note IsDocument6 pagesNote IsxxNo ratings yet

- Network Management SystemDocument10 pagesNetwork Management SystemMuhammad Moriandy GozaliNo ratings yet

- Overview of Information System Approach: Terminologies UsedDocument15 pagesOverview of Information System Approach: Terminologies Usedbambi2002No ratings yet

- Effect of Computers On Internal ControlDocument13 pagesEffect of Computers On Internal ControlAyessa Marie AngelesNo ratings yet

- A Report On Gym Management SystemDocument20 pagesA Report On Gym Management Systemdron upadhyayNo ratings yet

- System Administration and Maintenance Module 1Document31 pagesSystem Administration and Maintenance Module 1ABEGAIL CABIGTINGNo ratings yet

- A Smarter Way To Digitize Maintenance and ReliabilityDocument5 pagesA Smarter Way To Digitize Maintenance and ReliabilityRita HabchiNo ratings yet

- Maintenance Organization Control For Multi-Plant CorporutionsDocument1 pageMaintenance Organization Control For Multi-Plant Corporutionsكريم محمدNo ratings yet

- Desiemens0208rep HR tcm1023-57390 PDFDocument4 pagesDesiemens0208rep HR tcm1023-57390 PDFEduardo LuisNo ratings yet

- SL CS NotesDocument64 pagesSL CS NotesadamfathialsalehNo ratings yet

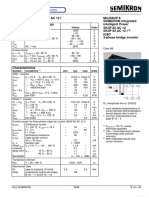

- SKIIP82AC12 SemikronDocument5 pagesSKIIP82AC12 SemikronMuhammad azeemNo ratings yet

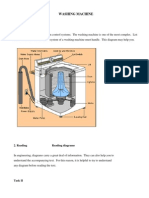

- Washing MachineDocument8 pagesWashing MachineHieu Nguyen TrungNo ratings yet

- A Proposal For Introduction of Geothermal Energy To The Energy Sector of BangladeshDocument6 pagesA Proposal For Introduction of Geothermal Energy To The Energy Sector of Bangladeshyajita12No ratings yet

- Dokumen - Tips Itacre311 Multiprog Exercises and Solutions Festo PLC Double SideDocument113 pagesDokumen - Tips Itacre311 Multiprog Exercises and Solutions Festo PLC Double SideTiyaniNo ratings yet

- LCD SPEC - XT1965 - 6.24-FHD-BOE-M6205G6F1-SD68C37284-LCD Spec-A0 - 20181009Document57 pagesLCD SPEC - XT1965 - 6.24-FHD-BOE-M6205G6F1-SD68C37284-LCD Spec-A0 - 20181009Axel VazquezNo ratings yet

- Device 3 Connection GuideDocument9 pagesDevice 3 Connection Guidemochammad aripinNo ratings yet

- Forced-Vibration Response: Forced - Vibration Harmonic Loading Periodic Loading Impulsive Loading General Dynamic LoadingDocument15 pagesForced-Vibration Response: Forced - Vibration Harmonic Loading Periodic Loading Impulsive Loading General Dynamic LoadingChí Khang ĐặngNo ratings yet

- Pdf 文件使用 "Pdffactory Pro" 试用版本创建: Www.Fineprint.CnDocument1 pagePdf 文件使用 "Pdffactory Pro" 试用版本创建: Www.Fineprint.CnJhon DoeNo ratings yet

- Experiment-3 - Mesh Analysis MethodDocument1 pageExperiment-3 - Mesh Analysis MethodMahomuda AkterNo ratings yet

- Ec8691 Unit Iv - PPTDocument49 pagesEc8691 Unit Iv - PPTVinothkumar UrumanNo ratings yet

- Norcon TTU-1 Installation ManualDocument2 pagesNorcon TTU-1 Installation ManualVlady SilvaNo ratings yet

- Pioneer s-rs3swDocument36 pagesPioneer s-rs3swloc nguyenNo ratings yet

- Ideal Filters: S X N S N yDocument26 pagesIdeal Filters: S X N S N yPreethiNo ratings yet

- Elex Module 2Document6 pagesElex Module 2Chemuel Mardie G. ObedencioNo ratings yet

- Adt FocusDocument244 pagesAdt Focusjustin tuckerNo ratings yet

- File Systems: Implementation: Bilkent University Department of Computer Engineering CS342 Operating SystemsDocument107 pagesFile Systems: Implementation: Bilkent University Department of Computer Engineering CS342 Operating SystemsSoundaryaNo ratings yet

- LA4422Document10 pagesLA4422HendraNo ratings yet

- P660 TubelistDocument79 pagesP660 TubelistJulian BunnNo ratings yet

- What Is VLANDocument4 pagesWhat Is VLANArvinte GiorgianaNo ratings yet

- Asth 5Document31 pagesAsth 5huidhyiuodghNo ratings yet

- Evolutionary Trends in Transmit-Receive Module For Active Phased Array RadarsDocument7 pagesEvolutionary Trends in Transmit-Receive Module For Active Phased Array RadarsPhan Xuân TuấnNo ratings yet

- Measuring ToolDocument70 pagesMeasuring ToolArif MalanaNo ratings yet

- Active Correction of Dynamic Mass Imbalance For A Precise RotorDocument6 pagesActive Correction of Dynamic Mass Imbalance For A Precise RotorJessica SandersNo ratings yet

- Catalogue Multi LayDocument1 pageCatalogue Multi Layessen999No ratings yet

- Stm32f4xx Tim HDocument22 pagesStm32f4xx Tim HonafetsNo ratings yet

- Reference UnbalancedDocument30 pagesReference UnbalancedVictor Luiz MerlinNo ratings yet

- AMCI - Stepper Motor Control - Stepper Motor Drivers - SD17060E Ethernet - IP Stepper Motor Indexer - DriveDocument5 pagesAMCI - Stepper Motor Control - Stepper Motor Drivers - SD17060E Ethernet - IP Stepper Motor Indexer - DrivePedro Cu AguirreNo ratings yet