Professional Documents

Culture Documents

Life Cycle Cost Analysis Applied to Reinforcement Corrosion Repair

Uploaded by

David IzquierdoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Life Cycle Cost Analysis Applied to Reinforcement Corrosion Repair

Uploaded by

David IzquierdoCopyright:

Available Formats

LIFE CYCLE COST ANALISYS APPLIED TO

REINFORCEMENT CORROSION REPAIR

D. Izquierdo1 Dr. Civil Engineer

ABSTRACT.

Reinforcement corrosion has been shown to be the most important cause of

structure disruption, and therefore the most extensive cause of repair in concrete

structures. Nowadays, the procedures for repairing reinforcement corrosion are

more or less well known and if certain types of recommendations are followed, the

repair procedures work properly. One of the procedures for selecting the most

appropriate repair method is the economical optimisation of the whole cost of the

repair procedure, or the Whole Life Cycle Cost (LCC). Present paper describes

several models and values for accounting the LCC of a structure and their

application to reinforcement corrosion repair

RESUME.

La corrosion des armatures est considérée comme la principale cause de

dégradation des structures en béton et, par conséquent, ce phénomème conduit á

un grand besoin de réparation. Actuellement, les processus de réparation de la

corrosion des armatures sont plus ou moins connus et, si queques

recommendations sont suivies alors les réparations seront durables. La plus

appropiée des méthodes de réparation est basée sur l´optimisation économique du

coût total. Elle est connue comme l´analyse du Cycle de Vie Totale (LCC). La

présente communication décrit quelques modèles mathématiques utilisés pour

réaliser un LCC en l´appliquant spécifiquement á la réparation des structures en

béton armé.

Keywords: Life Cycle Cost, Probabilistic Approach, Discount Rate,

Reinforcement Corrosion, Time Dependent Reliability

1. D. Izquierdo. Instituto Eduardo Torroja – CSIC, Serrano Galvache s/n,

28033 Madrid (Spain) izquierdo@ietcc.csic.es

Do not add page numbers to the final version

INTRODUCTION

Life Cycle Cost Analysis is not a new technique for optimisation civil

infrastructure 1, 2. Although there are new advances in research about optimisation

in the LCCA 3, 4 the main purpose of traditional procedures is the whole concept of

infrastructure design, which includes all phases of the infrastructure’s life:

Building, service life, repair and restoration, residual service life and disposal.

However, the repair stage can be considered as a new project phase and therefore

new alternatives are presented and an economical optimisation is suitable to be

employed. Of course the economical optimisation must comply with al the

requirements proposed by owners and other infrastructure agents.

LCCA is only a whole optimisation of the money used in the infrastructure. Of

course, the most easy expression for accounting this money can be obtained by

adding the building cost to the maintenance costs and the cost of a possible

infrastructure failure (equation 1):

CT = C I + CM + C f Equation 1

For accounting this equation it is essential to assess money in equivalent currency

by means an appropriate discount rate and Equation 2, where NPV is the Net

Present Value of a nominal cost Cn, r is the discount rate, and t is the actualisation

time of the cost.

1

NPV = Cn Equation 2

(1 + r )t

One of the most interesting new applications of LCCA is the selection of an

appropriate repair procedure in structures. Usually the selection of a repair

procedure or system is performed taking into account the actual investment in the

structure (the Direct Cost of the repair), thus the LCCA allows to evaluate not only

the effect of the repair cost, but also the expected service life of the repair and

therefore new possible costs of a failure in the repair.

Of course, it exists many types of LCCA depending of the amount of data and

information about the performance we have. The starting point should be a rational

classification of the typical LCCA used.

TYPES OF LIFE CICLE COST ANALISYS

A rational classification of LCCA can be established taking into account the

uncertainty of the input data, thus it can be possible to speak about:

- Deterministic Life Cycle Cost Analysis (DLCCA).

- Probabilistic Life Cycle Cost Analysis (PLCCA).

Within the PLCCA, the costs can be accounted by deterministic quantities or by

probabilistic quantities. Of course, the amount and quality of information is higher

Do not add page numbers to the final version

as higher is the level of the LCCA however the amount of input data should be

increased in an equivalent manner.

DETERMINISTIC LIFE CYCLE COST ANALYSIS

It is the simplest form of LCCA. It only considers deterministic costs and expected

service life and durability. It can be consider as a first step in the selection

procedure for repair strategies. Although their simplicity, usually practical

approaches of economical optimisation of a DLCCA.

The expression that can accounts for the total expected cost of the structure, taking

into account the maintenance and repair interventions is collected in Equation 3,

where each expected cost should be translated into actual currency by means the

discount rate r.

n

CM ,i n C f ,i

CT = CI + ∑ +∑ Equation 3

i =T 1 (1 + r ) i

i =T 1 (1 + r )i

The parameters in Eq. 3 are:

- CT total cost of structure.

- CM,i Maintenance cost at time i.

- Cf,i failure costs at time i.

- r discount rate

The distribution of cost, should be considered as localised – in – time costs,

because the service life in DLCCA is deterministic. An example is shown in

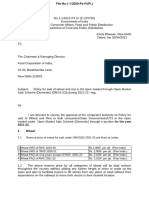

Figure 1.

Figure 1. Example of distribution of costs in DLCCA

Distribution of Costs in time

120

Maintenance

100 Repair

80 Strengthening

Cost

60

40

20

0

0

10

20

30

40

50

60

70

80

90

0

10

Time

PROBABILISTIC LIFE CYCLE ANALYSIS

It can be considered an evolution of DLCCA where all variables (except costs) are

considered as stochastic, therefore the costs of maintenance, repair and

strengthening are related to their probability of occurrence and their PDF. Thus,

Do not add page numbers to the final version

another type of costs should be considered. It is the cost of structure collapse,

whose probabilities are certainly low to be taken into account in the DLCCA.

A more general expression that takes into account the probabilistic approach in the

evaluation of LCC, can be rewritten in Equation 4, where it should be noticed that

in the case of costs due to Maintenance (CM), Repair / Strengthening (CR,S) or

Collapse (Cf) the sum is extended from the time t=1 because the probability of

repair/maintenance or structural failure is higher than 0.

n

CM ,i

CT = C I + ∑ PF ,M (ti ) +

i =1 (1 + r )i

Equation 4

n

C R ,S ,i n C f ,i

∑P (ti ) + PF (ti )

i =T 1

F ,R ,S

(1 + r )i ∑

i =1 (1 + r )i

Thus, the distribution costs throughout time, are not localised as in DLCCA if not

continuous because the cost is multiplied by the probability which usually has a

continuous distribution with time. In this sense, the product of probability by costs

is usually known as damage.

MODELS FOR REPAIR / MAINTENANCE COSTS

One of the most difficult points of using this type of approach (either

Deterministic or Probabilistic) is the determination of realistic models for taking

into account the costs due to repair / maintenance. The word model describe a

mathematical expression that relate expected costs due to Repair / Maintenance

and the geometrical, disposition or localisation characteristics of the structure.

Thus, a relatively short expression that can describe the costs due to a Repair /

Maintenance operation in a structure can be written as shown in Eq. 5.

C M / R = C D + C H + CU + C E Equation 5

In Eq. 5 the costs included are: Direct cost of repair (CD), Cost of loss of contents

or fatality and injury loses (CH), Cost of users (CU) and Socio – Economic loses

(CE). In each case the cost can be multiplied by their appropriate Probability

Density Function (PDF) and use PLCCA.

It can be considered that assess a realistic (more or less) appropriate value of

direct const can be carried out. Typical prices list and standardisation cost can be

directly used. However the evaluation of indirect costs is quite difficult and

depends on many factors. Some notes and examples will be shown in advance.

- Indirect costs models for buildings

Indirect cost models are quite different for building and for bridges. Typical

models for buildings include costs as shown in Eq. 65 where are included cost of

contents (CC), economic loss due to business interruption (CB), cost of injury in

repair processes (CIn) and costs of possible fatality in the repair process (CFa):

Do not add page numbers to the final version

C M / R = C D + CC + C B + C In + C Fa Equation 6

Cost of contents can be easily obtained form common price lists and cost of

business interruption can be computed by accounting past economical reports of

the factory or the cost of new rent if the building is dedicated to services, offices

or residential. It is usually presented in terms of initial construction cost of the

structure.

Cost of CIn and CFa are considerably difficult to analyse, because the special

influence of human life. Although in old reports and documents it was said that

trying to evaluate the economical value of a human life is rather inmoral, new

approaches suggest that the Life Quality Index may be assessed using LCCA6 .

- Indirect costs models for bridges and roads

In general roads and bridges costs consist of five major cost item: vehicle

operating costs, time delay costs, safety and accident costs, comfort and

convenience costs and environmental costs. It is usually considered that two first

are the most relevant although in order to evaluate them factors such as traffic

network, location of the infrastructure and information of rehabilitations must be

considered. A expression for accounting time delay costs can be written in Eq. 7.

J

N

CTD = ∑ nPj ·T j ·u1 j 1 − ∑ ri ∆t +

j =1 i =1

N J

Equation 7

∑ ·∑ r ·n

i =1 j =1

i Pj ·T j ·u1 j + rij ·nPij ·Tij ·u1ij ∆tij

where: j is an index representing the type of vehicle (business and non – business,

etc). nPj is the average number of passengers in vehicles type j, Tj is the Average

Daily Traffic Vehicle of type j, u1j is the unitary cost of unit of time for operator j,

ri is the rate of occurrence of route i and ∆t is the increment in time of route i.

Costs of vehicle operation can be computed using Eq. 8 where it is considered the

wages for each type of vehicle and the cost of fuel.

∑ (T 0 j ·u 2 j ) 1 −

J N

C TD =

j =1

∑ r ∆ t +

i =1

i

∑ r ·∑ (T ·u 2 j )∆ t i +

N J

i 0j Equation 8

i =1 j =1

ri ·∑ T 0 j ·(u 3 ij l di − u 4 ij l d 0 ) + T ij u 2 j ∆ t i

N J

∑ i =1 j =1

Where u2ij is the average operator wages for each type of vehicle, u3ij is the

average unit fuel cost pert unit of length on each detour route, uiij is the average

unit fuel cost per unit of length in the original route, li and l0 are the length of the

detour and original route, respectively.

Do not add page numbers to the final version

For other costs such as socio – economic costs, it is necessary to evaluate the Input

– output table for the productivity of the country.

IMPLICATIONS FOR TIME – VARIANT PLCCA

From a direct examination of Eq. 3, where the Probabilistic Life Cycle Cost

Analysis is described, it can be seen that each cost must be actualised in time. This

actualisation, as was explained above should be done continuously because the

implication of probabilities in the computation. To compute directly expressions

such as Eq. 3 is considerably difficult due to the calculation of probabilities with

time. One of the simplification proposed by authors7 is to compute Eq. 3 in a

similar manner as Eq. 2 at the end of the expected service life of the repair. One

possibility for simplification is to compute costs at a deterministic point in time

and actualise currency values in the same manner.

n

C M ,i tL

C M ,i CM ,i

∑ PF ,M (ti )

i =1 (1 + r ) i

= ∑ PF ,M (ti )

i =0 (1 + r ) t act

=

(1 + r )t act

PF ,M (t L ) Equation 9

The time – factor tact takes into account the effect of increasing evolution of

degradation with time. Of course tact depends essentially of two factors: PDF of

service life and discount rate. Figures 1 and 2 show the net value of the damage

cost as a function of the mean service life for a Log – normal distribution and

100% of variation.

Figure 2 and 3. Example of Damage costs and tact

0.6 180

160

0.5

140

0.4 120

100

Damage

T_act

0.3

80

0.2 60

40

0.1 20

0

0

0 50 100 150 200 250 300

0 50 100 150 200 250 300

Mean Service Life

Mean Service Life

r=2% r=4% r=8% r=12% r=2% r=4% r=8% r=12%

REALISTIC VALUES FOR DISCOUNT RATE

It can be easily seen that the results are quite different depending of the discount

rate (r) we chose for analysis. This aspect is one of the principal inconveniences

of LCCA. Of course it is known by politicians as a way to force or delay future

inversions in infrastructure or whatever type of business. Thus, it is commonly

accepted that national administrations force the technicians to use specific r values

depending on the type of inversion, these values are varying from 12% to 6%1. An

economical definition of r can be obtained as the difference between rate of

Do not add page numbers to the final version

interest and inflation, as shown in Eq. 10. Application of Eq. 10 to statistical

economical data of several countries has shown that it is unrealistic to adopt

values of discount rate above 2 – 5%. Figure 4 shows the values obtained for

several countries, taking into account time life windows of 50 and 10 years.

1+ i

r = −1 Equation 10

1+ a

Figure 4 . Realistic Discount Rate in Europe

7 6.43

6

5.1

Actualisation rate [%]

4 3.51 3.59

2.91

3

2.02 2.01 2.07

1.81

2 1.5

1.25

1

2

in

in

ax

ax

0

ax

50

0

en

M

M

-5

M

-5

M

M

n-

ed

m

0

SA

0

0

ai

-2

-2

10

0

er

0

-1

-1

Sw

-1

-1

U

Sp

EU

EU

G

n-

m

SA

m

SA

er

ai

er

U

Sp

G

U

CONCLUSIONS

Life Cycle Cost Analysis has been developed many years ago, and their

application to building projects is being increased in last twenty years. One of

their possible applications is the selection of adequate repair / strengthening

methods to be employed in infrastructure. The models for analysing each cost are

presented and identified, one of the problems is to adopt numerical values for each

variable.

In addition, repair / strengthening activities are linked to a degradation process

that involves the time effect. The time adds an additional difficult in the

computation process and more uncertainties. One possibility is to translate

calculations to DLCCA by means the actualisation time as was presented, making

considerably easy the results.

Finally, all results obtained in LCCA, are strongly dependent of discount rate

adopted in the calculations. A specific study is presented showing that realistic

values are located in the range of 2 – 5%.

REFERENCES

1. Tilly, G. P. , Principles of Whole Life Costing Safety of Bridges, 1997, Ed. By Parag C.

Das, Pag 138 – 144.

2. Ferry, D.J.O. Flanagan, R. Life Cycle Costing – a radical approach. CIRIA report, nº 122

3. Cho, H.N. Life Cycle Cost Effectiveness for Design and rehabilitation of Civil

Infrastructures Proceedings of SEWC’02.

4. Cho, H.N. Development of Bridge Life – Cycle Cost Analysis Model Final report to

Korea Infrastructure Safety and Technology corporation 2002.

5. Ang A, De Leon D. Determination of optimal target reliabilities for design and upgrading

of structures. Structural Safety,(1997) 19(1).Pag. 91 – 103.

6. Rackwitz R. Optimisation – The Basis of code making and Reliability Verification.

(2000) Structural Safety , 22 Pag 27 – 60.

7. Siemes. A. J. M. Vrouwenvelder A. C. Van del Beukel A. (1985) Durability of buildings:

a reliability analysis. HERON (1985) Vol. 30 nº 3 Delft University of Technology.

Do not add page numbers to the final version

You might also like

- Lecture 5 Cost PDFDocument39 pagesLecture 5 Cost PDFAmir Kan67% (3)

- A Feedback Model of Control PDFDocument9 pagesA Feedback Model of Control PDFsnickoo1No ratings yet

- Transportation Costs: 1.201 Introduction To Transportation SystemsDocument68 pagesTransportation Costs: 1.201 Introduction To Transportation SystemsHAFTU TEKLAYNo ratings yet

- Firm'S Cost of ProductionDocument9 pagesFirm'S Cost of ProductionKhurram ShehzadNo ratings yet

- Capitalisation of Losses PDFDocument10 pagesCapitalisation of Losses PDFimadhuryya5023No ratings yet

- Managerial Economics (M.com IVth Sem.) - M COM IV 26-4Document9 pagesManagerial Economics (M.com IVth Sem.) - M COM IV 26-4za714521No ratings yet

- Kelompok 4Document13 pagesKelompok 4KomanghNo ratings yet

- Chapter 5 Exercises LCV - LatestDocument8 pagesChapter 5 Exercises LCV - LatestFarina NajwaNo ratings yet

- Chapter 7-Dynamic OptimizationDocument43 pagesChapter 7-Dynamic OptimizationLou MohamedNo ratings yet

- Accepted Manuscript: 10.1016/j.omega.2017.08.003Document38 pagesAccepted Manuscript: 10.1016/j.omega.2017.08.003ezffsdgNo ratings yet

- Introduction to Economics: Short and Long Run Costs (Econ. 101Document31 pagesIntroduction to Economics: Short and Long Run Costs (Econ. 101Nahom MasreshaNo ratings yet

- Short run costs theory explainedDocument32 pagesShort run costs theory explainedSakshi MatlaniNo ratings yet

- Assessment of Maintenance Effectiveness For Repairable Systems PM and CM Case StudiesDocument5 pagesAssessment of Maintenance Effectiveness For Repairable Systems PM and CM Case StudiesGopi SubramaniamNo ratings yet

- Theory of Costs in Economic AnalysisDocument35 pagesTheory of Costs in Economic Analysisarsalan khanNo ratings yet

- Corrosion EconomicsDocument9 pagesCorrosion EconomicsEmmanuel EkongNo ratings yet

- Lecture 3Document22 pagesLecture 3Arfan Babar ButtNo ratings yet

- Simplified Life Cycle Cost ComputationDocument4 pagesSimplified Life Cycle Cost ComputationWade Coleman100% (2)

- Gess PaperDocument26 pagesGess Paperluupdate digitalNo ratings yet

- Cost Estimation and Analysis1Document49 pagesCost Estimation and Analysis19819143966No ratings yet

- Applying Learning Curve Theory in Construction Cost EstimatingDocument5 pagesApplying Learning Curve Theory in Construction Cost EstimatingayaznptiNo ratings yet

- Managing Business Process Flows 3rd Edition Anupindi Solutions ManualDocument10 pagesManaging Business Process Flows 3rd Edition Anupindi Solutions Manualoutscoutumbellar.2e8na100% (21)

- ECON 3 General Economics Chapter 7 Cost AnalysisDocument5 pagesECON 3 General Economics Chapter 7 Cost AnalysisCarl Jefferson LumabanNo ratings yet

- Revision Sem 1 2017-18Document55 pagesRevision Sem 1 2017-18Farhan Amira100% (2)

- Power System Economics - Unilag Lecture NotesDocument43 pagesPower System Economics - Unilag Lecture Noteseresuyi100% (3)

- Sa Aug12 F2fma ReapportionmentDocument6 pagesSa Aug12 F2fma ReapportionmentWasim.haiderNo ratings yet

- Availability and Operational ReadinessDocument4 pagesAvailability and Operational ReadinessgatoluisNo ratings yet

- Life Cycle Cost Procurement of x2000Document9 pagesLife Cycle Cost Procurement of x2000Qiang LiuNo ratings yet

- Cost Curves and Revenue ConceptsDocument9 pagesCost Curves and Revenue ConceptsPriya NandhakumarNo ratings yet

- Power Transformer Efficiency - Survey Results and Assessment of Efficiency ImplementationDocument7 pagesPower Transformer Efficiency - Survey Results and Assessment of Efficiency ImplementationsergeykrustevNo ratings yet

- Presented By-Trilok, Jaswant, Girish, Lalit, MohitDocument36 pagesPresented By-Trilok, Jaswant, Girish, Lalit, MohitŤŕiļöķ BákøļįâNo ratings yet

- Assessing The Cost Effectiveness of NDE Methods in Civil StructuresDocument10 pagesAssessing The Cost Effectiveness of NDE Methods in Civil StructuresmyronhechtNo ratings yet

- Applications of Cost TheoryDocument25 pagesApplications of Cost Theorytanvir09No ratings yet

- Maintenance CostingDocument9 pagesMaintenance CostingAdJi Abdillah Kharisma100% (4)

- Chandigarh University: Bachelor of Business AdministrationDocument26 pagesChandigarh University: Bachelor of Business AdministrationAmanNo ratings yet

- Cap Riot TiDocument5 pagesCap Riot Tiadamquestion5941No ratings yet

- 394 Tutorial 3Document27 pages394 Tutorial 3You And usNo ratings yet

- Mettu University MSc CUSUM Chart Monitoring Process MeanDocument30 pagesMettu University MSc CUSUM Chart Monitoring Process MeanDame TolossaNo ratings yet

- Part 3.2 Cost EstimationDocument24 pagesPart 3.2 Cost EstimationOmer AbdiroNo ratings yet

- Optimal Replacement DecisionsDocument11 pagesOptimal Replacement DecisionsCalvinhoNo ratings yet

- P Eval04 l3 CostDocument28 pagesP Eval04 l3 CostSjamsuddin PontohNo ratings yet

- Reliability & Maintainability Exam Solutions 2011 v4Document12 pagesReliability & Maintainability Exam Solutions 2011 v4luchogilmourNo ratings yet

- 481-Article Text-831-1-10-20140306Document7 pages481-Article Text-831-1-10-20140306Lubię Używać Twarz PolkNo ratings yet

- Paper by MF Manganye, PM Tlabela and DR DV NicolaeDocument12 pagesPaper by MF Manganye, PM Tlabela and DR DV NicolaekotiniNo ratings yet

- GB MockexamDocument24 pagesGB MockexamAnonymous 7K9pzvziNo ratings yet

- A Concise Capital Investment Cost Model for Gas Turbine Systems Useful in Energy Systems Education (2)Document7 pagesA Concise Capital Investment Cost Model for Gas Turbine Systems Useful in Energy Systems Education (2)Mohamed MohamedNo ratings yet

- Updated Cost Structure PPTDocument35 pagesUpdated Cost Structure PPTtanishasheth26No ratings yet

- 2.4.theory of CostDocument28 pages2.4.theory of CostMotuma AdugnaNo ratings yet

- Case Studies in Engineering Economics For Electrical Engineering StudentsDocument6 pagesCase Studies in Engineering Economics For Electrical Engineering Studentsryan macutoNo ratings yet

- 1.011 Ppt02 CostTerminologyDocument5 pages1.011 Ppt02 CostTerminologyAbdu MohammedNo ratings yet

- Life Cycle Cost Analysis (LCCA)Document9 pagesLife Cycle Cost Analysis (LCCA)Anonymous oTiqzpuNo ratings yet

- Paper 210 Corrected 2Document11 pagesPaper 210 Corrected 2haroldNo ratings yet

- Case Study Rail Road 2Document6 pagesCase Study Rail Road 2Ravi RanasingheNo ratings yet

- Capacity Planning For Products and ServicesDocument25 pagesCapacity Planning For Products and Servicesuma1998No ratings yet

- 22 Cost Estimating For TurnaroundsDocument8 pages22 Cost Estimating For Turnaroundsnilanga123No ratings yet

- Total Solution Services For Advanced Maintenance of Thermal Power-Generation PlantsDocument6 pagesTotal Solution Services For Advanced Maintenance of Thermal Power-Generation PlantsRam MohanNo ratings yet

- Breakeven AnalysisDocument30 pagesBreakeven Analysistadesse geteNo ratings yet

- Module-6 Cost and Revenue AnalysisDocument46 pagesModule-6 Cost and Revenue Analysiskarthik21488No ratings yet

- Cost EstimatingDocument27 pagesCost EstimatingArief Budiman Hermani100% (1)

- 2016 11 Determination of Optimal Calibration Intervals A Risk Based Approach Pashnina EmersonDocument20 pages2016 11 Determination of Optimal Calibration Intervals A Risk Based Approach Pashnina EmersonAnonymous y3tPCbVrNo ratings yet

- BackgroundRevisionDNV RP C2032005Document11 pagesBackgroundRevisionDNV RP C2032005Lucas Arantes MartinsNo ratings yet

- Analysis and Design Methodology For An FRP Cable-Stayed Pedestrian BridgeDocument11 pagesAnalysis and Design Methodology For An FRP Cable-Stayed Pedestrian BridgeDavid IzquierdoNo ratings yet

- Calibration of Load Factor For LRFR Load EvaluationDocument63 pagesCalibration of Load Factor For LRFR Load EvaluationViet Duc Dang100% (1)

- Urban Bridges-Latest Experiences in Andalusia: Alejandro CASTILLO Manuel Escamilla Gonzalo OSBORNEDocument7 pagesUrban Bridges-Latest Experiences in Andalusia: Alejandro CASTILLO Manuel Escamilla Gonzalo OSBORNEDavid IzquierdoNo ratings yet

- LFRD Calibracion PDFDocument94 pagesLFRD Calibracion PDFDavid IzquierdoNo ratings yet

- Bridge Example 1Document38 pagesBridge Example 1Jan Booysen100% (1)

- Design of Adjacent Precast Box Girder Bridges According To Aashto Specifications (12 Pag)Document12 pagesDesign of Adjacent Precast Box Girder Bridges According To Aashto Specifications (12 Pag)mohamedmararNo ratings yet

- Evaluation of The 1993 AASHTO Flexible PavemenDocument116 pagesEvaluation of The 1993 AASHTO Flexible PavemenVajindra WijewickramaNo ratings yet

- Nhi 15047Document1,694 pagesNhi 15047Edilberto Tibacan Villamil100% (1)

- Aashto T 85Document2 pagesAashto T 85coolkaisyNo ratings yet

- Life Cycle Cost Analysis Applied to Reinforcement Corrosion RepairDocument7 pagesLife Cycle Cost Analysis Applied to Reinforcement Corrosion RepairDavid IzquierdoNo ratings yet

- AASHTO Design MethodDocument50 pagesAASHTO Design Methodzavlei100% (1)

- Reliability Analysis of Corrosion in Postensional Tendons: Case StudyDocument6 pagesReliability Analysis of Corrosion in Postensional Tendons: Case StudyDavid IzquierdoNo ratings yet

- Paper Ref - 364 PROBABILISTIC TREATMENT OF REBAR DEPASSIVATION-0Document6 pagesPaper Ref - 364 PROBABILISTIC TREATMENT OF REBAR DEPASSIVATION-0David IzquierdoNo ratings yet

- Demonstration of Lateral-TorsionalDocument28 pagesDemonstration of Lateral-TorsionalTharach JanesuapasaereeNo ratings yet

- Design of Structures and Foundations For Vibrating Machines. Pincus GDocument210 pagesDesign of Structures and Foundations For Vibrating Machines. Pincus GDavid IzquierdoNo ratings yet

- New York Stock Exchange: Price List 2021Document44 pagesNew York Stock Exchange: Price List 2021Venu MadhavNo ratings yet

- Anti-Dumping Duties Explained: Calculation Methods and RequirementsDocument13 pagesAnti-Dumping Duties Explained: Calculation Methods and Requirementsamour860No ratings yet

- YSEALI Seeds Budget TemplateDocument1 pageYSEALI Seeds Budget TemplaterengginatNo ratings yet

- Aqa 71321 QP Jun17Document24 pagesAqa 71321 QP Jun17Linda AgomuoNo ratings yet

- Mixed Economy The Three Economic QuestionsDocument4 pagesMixed Economy The Three Economic QuestionsBasco Martin JrNo ratings yet

- Generic Strategy - CriticismDocument15 pagesGeneric Strategy - Criticismpratyush parmar0% (1)

- OMSS (D) 2021-22 PolicyDocument4 pagesOMSS (D) 2021-22 PolicyPriti PawarNo ratings yet

- Chap2. Public Goods and Private GoodsDocument18 pagesChap2. Public Goods and Private GoodsCitio LogosNo ratings yet

- Standard Costing Ex QuestionsDocument20 pagesStandard Costing Ex QuestionsKaruna ChakinalaNo ratings yet

- Investment AppraisalDocument46 pagesInvestment AppraisalUrmilaAnantNo ratings yet

- Ezra Holdings (EZRA SP) : OW (V) : Shifting Gears - NDR TakeawaysDocument13 pagesEzra Holdings (EZRA SP) : OW (V) : Shifting Gears - NDR TakeawaysTheng RogerNo ratings yet

- ME Final Assignment 1Document21 pagesME Final Assignment 1shaikh shahrukh100% (1)

- Starbucks Coffee Segmentation and Target Market Essay: Don't Use Plagiarized Sources. Get Your Custom Essay OnDocument10 pagesStarbucks Coffee Segmentation and Target Market Essay: Don't Use Plagiarized Sources. Get Your Custom Essay OnNga NguyễnNo ratings yet

- HP-Compaq Merger: Integration Challenges and Failure to Create ValueDocument3 pagesHP-Compaq Merger: Integration Challenges and Failure to Create ValueDurgesh Agnihotri100% (1)

- Fernbank Letter To EU (OPAP) (05.18.11)Document5 pagesFernbank Letter To EU (OPAP) (05.18.11)mattpauls100% (1)

- Case2 MarriottDocument10 pagesCase2 Marriott石曉儒No ratings yet

- A Study of Manufacturing Industry: 3industrial Exposure ProjectDocument70 pagesA Study of Manufacturing Industry: 3industrial Exposure ProjectShubham Khurana100% (1)

- Concept of Value ExplainedDocument20 pagesConcept of Value ExplainedSagar GajjarNo ratings yet

- Marketing Mix & New Product DevelopmentDocument6 pagesMarketing Mix & New Product Developmentsuperd786No ratings yet

- IPODocument4 pagesIPORameezNo ratings yet

- Oligopoly Market Structure ExplainedDocument14 pagesOligopoly Market Structure Explaineduday99says50% (2)

- Exercise 1Document24 pagesExercise 1yu yuNo ratings yet

- SFAC 1 Objective of Financial ReportingDocument18 pagesSFAC 1 Objective of Financial Reportingrhima_No ratings yet

- A Quick Reference Guide For InvestorsDocument8 pagesA Quick Reference Guide For Investorskarunasavi100% (1)

- Solution Manual For Multinational Financial Management 10th Edition Shapiro 1118572386 9781118572382Document36 pagesSolution Manual For Multinational Financial Management 10th Edition Shapiro 1118572386 9781118572382christianjenkinsgzwkqyeafc100% (24)

- Accounts Receivable q3Document3 pagesAccounts Receivable q3Omnia HassanNo ratings yet

- Art of Making 10% PMDocument27 pagesArt of Making 10% PMDavid AngNo ratings yet

- Case Study - Somerset Furniture CompanyDocument8 pagesCase Study - Somerset Furniture CompanyGINANo ratings yet

- Lesson 3 DepreciationDocument8 pagesLesson 3 DepreciationJAN ERWIN LACUESTANo ratings yet

- Lva1 App6891Document28 pagesLva1 App6891Kleant ZhubiNo ratings yet