Professional Documents

Culture Documents

Geotextile PDF

Uploaded by

efren bathan0 ratings0% found this document useful (0 votes)

43 views1 pageOriginal Title

Geotextile.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

43 views1 pageGeotextile PDF

Uploaded by

efren bathanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

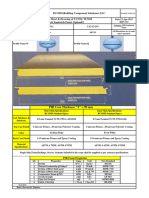

Jumeirah Al Sahel Resort & Spa Specification Package

Kingdom of Bahrain IFC 20th December 2018

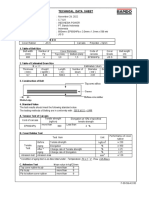

polypropylene / polyester mix. The geotextile shall be ultra violet light stabilised using

an approved method such as incorporation of 1% by mass of carbon black.

The Geotextile being proposed shall have the following properties:

i. Permeability of Geotextile > 10x permeability of underlying subsoil.

ii. Pore size, O90 of Geotextile < D50 of subsoil

iii. Weight >1,000g/m2

iv. Thickness > 5.0mm

v. Tensile Strength > 30kN/m longitudinal, > 60kN/m transverse

vi. CBR puncture resistance > 5.0kN

vii. Permeability l/m2/s under 50mm head < 30

viii. Mean minimum tensile extension > 70%

ix. Mean maximum Cone Drop perforation hole diameter < 1mm

x. Mean minimum CBR puncture displacement > 60mm

xi. Maximum thickness reduction under pressure increase from 2kPa to 200kPa <55%

xii. UV degradation <50% at 500 hours

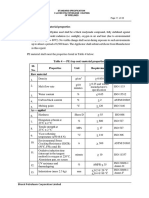

7. Material Data Sheet

The CONTRACTOR shall submit to the ENGINEER for approval a sample of the

proposed geotextile, of minimum size 300mm x 300mm, together with a material

property data sheet. The data sheet shall be substantiated by an index and

performance compliance certificate issued by an accredited geotextile filter fabric

testing organisation e.g. the German Bundesanstalt für Wasserbau (BAW) and shall

contain the properties stated in Clause GTX 1.2.

Test Method Description Test Method Units QA Tolerance

Mean maximum pore size O90 EN ISO 12956 microns +10%

Mean minimum tensile strength EN ISO 10319 kN/m -10%

Mean minimum tensile extension EN ISO 10319 % -10%

Mean maximum Cone Drop perforation hole

BS EN ISO 1343 mm N/A

diameter

Mean minimum CBR puncture BS EN ISO 12236 kN -10%

Mean minimum CBR puncture displacement BS EN ISO 12236 mm -10%

Mean minimum thickness under 2 kPa BS EN ISO 9863-1 mm -10%

Maximum thickness reduction under pressure

BS EN ISO 9864 % +10%

increase from 2 200 kPa

8. Testing

Geotextile Specification - Rev. 00 Page 4 of 8

You might also like

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- Exposure Assessment and Safety Considerations for Working with Engineered NanoparticlesFrom EverandExposure Assessment and Safety Considerations for Working with Engineered NanoparticlesNo ratings yet

- Deckdrain S1200NW8 Data SheetDocument1 pageDeckdrain S1200NW8 Data SheetsdvsdvdsaNo ratings yet

- HDPE-100 Catalogue PDFDocument9 pagesHDPE-100 Catalogue PDFkumar sandeepNo ratings yet

- FIBERTEX 300 Gmp-Fisa Tehnica F-50 (AFER)Document1 pageFIBERTEX 300 Gmp-Fisa Tehnica F-50 (AFER)Relu MateiNo ratings yet

- TDS Filtra 41 15 ST2Document1 pageTDS Filtra 41 15 ST2Bessam AzizNo ratings yet

- Subject: Proposal For Supply and Fixing of Ultralite (Formerly Bayer Material Science) 10mm Multiwall Polycarbonate Sheet Both Sides U.V. ProtectedDocument3 pagesSubject: Proposal For Supply and Fixing of Ultralite (Formerly Bayer Material Science) 10mm Multiwall Polycarbonate Sheet Both Sides U.V. ProtectedRaghvendra AgarwalNo ratings yet

- Fibre-Reinforced Geosynthetic Clay Liner (GBR-C) Bentofix® NSP 4000Document1 pageFibre-Reinforced Geosynthetic Clay Liner (GBR-C) Bentofix® NSP 4000Luis Alberto GutiérrezNo ratings yet

- Hdpe Bl3-MarunDocument1 pageHdpe Bl3-MarunChetan PandyaNo ratings yet

- PVC SpecDocument2 pagesPVC SpecMuhammad Noor FizuanNo ratings yet

- Bontec Protec X 1000-Tds-EnglishDocument1 pageBontec Protec X 1000-Tds-EnglishAli AhmadiNo ratings yet

- Waterproofing Membrane, CharacteristicsDocument4 pagesWaterproofing Membrane, CharacteristicsyamegNo ratings yet

- Ds - TECHDRAIN GTG 720 - enDocument1 pageDs - TECHDRAIN GTG 720 - enThameem SharaafNo ratings yet

- Benfelt 48 140820182 Extended Version 09 2022Document2 pagesBenfelt 48 140820182 Extended Version 09 2022MarijaRRRRNo ratings yet

- Duralay Heatflow Carpet: Technical SpecificationDocument2 pagesDuralay Heatflow Carpet: Technical SpecificationsebkahnNo ratings yet

- Quality Product Certification ReinforcementDocument3 pagesQuality Product Certification ReinforcementsamiNo ratings yet

- SRI-TL-EPC Upgrading Jetty Tuban and Its Ancillary Production and Transportaion Facilities-SBI - MFN22144R0Document8 pagesSRI-TL-EPC Upgrading Jetty Tuban and Its Ancillary Production and Transportaion Facilities-SBI - MFN22144R0Dito NarendraNo ratings yet

- SpecsDocument3 pagesSpecsAladinNo ratings yet

- Instalay 30 Technical SpecificationDocument2 pagesInstalay 30 Technical SpecificationshanNo ratings yet

- 06 HPS6 DatasheetDocument2 pages06 HPS6 Datasheet张浩No ratings yet

- A301 - EN MethodDocument1 pageA301 - EN MethodAhmad ElghazolyNo ratings yet

- Microdyn Bio Cel L 2Document2 pagesMicrodyn Bio Cel L 2antegeia2222No ratings yet

- "Weatherproof" For Outdoor Installation KF 0404 BDocument3 pages"Weatherproof" For Outdoor Installation KF 0404 BRavi KrishnanNo ratings yet

- PDS HEX4460p PE80 1Document3 pagesPDS HEX4460p PE80 1art72 talNo ratings yet

- 3000m3 Double Membranes Biogas Holder Quotation Mingshuo 2020.10.13Document4 pages3000m3 Double Membranes Biogas Holder Quotation Mingshuo 2020.10.13Jesciel Generalao NugasNo ratings yet

- Technical Data Sheet Eurobent Nt-35 (Zakładka)Document1 pageTechnical Data Sheet Eurobent Nt-35 (Zakładka)Dannyamil AriasNo ratings yet

- 2) Data Sheet VDek-703 Standard 2021 FTDocument1 page2) Data Sheet VDek-703 Standard 2021 FTJean CausilNo ratings yet

- CA3-23-219 (TDS TAWQ 90 MM) Option-2 (REV 01)Document1 pageCA3-23-219 (TDS TAWQ 90 MM) Option-2 (REV 01)ahmed ahmadNo ratings yet

- Rilsan Fine Powders Physical PropertiesDocument2 pagesRilsan Fine Powders Physical Propertiesธนาชัย เต็งจิรธนาภาNo ratings yet

- Nylacast Moly Cast Nylon 6, MoS2 FilledDocument3 pagesNylacast Moly Cast Nylon 6, MoS2 Filledprasad.jppmNo ratings yet

- Floline (3-W) Triple Wall Profiled Hdpe Culvert: Physical Properties Test Method Unit ValueDocument3 pagesFloline (3-W) Triple Wall Profiled Hdpe Culvert: Physical Properties Test Method Unit Valuejerryruki71No ratings yet

- L01 - TDS - ID - Matren Plus ZN+Polymer - Rev02 - 2021Document2 pagesL01 - TDS - ID - Matren Plus ZN+Polymer - Rev02 - 2021Wika SentiongNo ratings yet

- Fisa Tehnica PVC Krystal Nou1Document3 pagesFisa Tehnica PVC Krystal Nou1Ioan CovaliovNo ratings yet

- 3Lpe/3Lpp Coating Guide: Activity Standard Acceptance CriteriaDocument1 page3Lpe/3Lpp Coating Guide: Activity Standard Acceptance CriteriaSandeep PrNo ratings yet

- TI 610 43 PE 100 RC HDPE Pressure Pipe Material DataDocument1 pageTI 610 43 PE 100 RC HDPE Pressure Pipe Material DataPablo Santa Cruz RoldánNo ratings yet

- Qdrain ZW8 100 10F Eng Rev0 20Document1 pageQdrain ZW8 100 10F Eng Rev0 20Thameem SharaafNo ratings yet

- 3layer Coating - 03Document5 pages3layer Coating - 03Christian EzeaguNo ratings yet

- 200/200kN/m PP Woven Monofilament Geotextile For Harbor ProtectionDocument3 pages200/200kN/m PP Woven Monofilament Geotextile For Harbor ProtectionSambelteri SelorejoNo ratings yet

- Sikaproof 808Document4 pagesSikaproof 808happyNo ratings yet

- Tabel Test Lengkap Stay Cable + Standard Test PDFDocument1 pageTabel Test Lengkap Stay Cable + Standard Test PDFa_sandroNo ratings yet

- Mac DrainDocument24 pagesMac Drainsundra0No ratings yet

- HD Smooth Geomembrane MetricDocument1 pageHD Smooth Geomembrane MetricAndreas Erdian WijayaNo ratings yet

- Tensile Test CertificateDocument1 pageTensile Test CertificateinfoNo ratings yet

- Bituseal 1000-1200 (SKS)Document2 pagesBituseal 1000-1200 (SKS)khiem44No ratings yet

- Alfdrain S10-225Document1 pageAlfdrain S10-225Aladin AbrashNo ratings yet

- 1.A-DQ BN SR 2Y 1.200N CT-General-2021.04.07-03Document7 pages1.A-DQ BN SR 2Y 1.200N CT-General-2021.04.07-03Emre YıldırımNo ratings yet

- M.S Wet AreaDocument16 pagesM.S Wet Areaahmed samirNo ratings yet

- NSP 4000Document1 pageNSP 4000Naufal IhsanNo ratings yet

- Hensel Junction BoxDocument4 pagesHensel Junction Boxabdulrahman elmograbiNo ratings yet

- TDS EGGER Comfort Flooring en PDFDocument2 pagesTDS EGGER Comfort Flooring en PDFAndrej SetkaNo ratings yet

- Pa66 GF30 NatureDocument1 pagePa66 GF30 NatureGeovane LinoNo ratings yet

- Tds Wikon Ip. C 7&8Document1 pageTds Wikon Ip. C 7&8deni prastikoNo ratings yet

- Siare Technologies - Test ReportDocument1 pageSiare Technologies - Test ReportnikhilbhorNo ratings yet

- The Geotextile Protection Layer For The Geomembrane Shall Be Made by A Needle Punching Process Using Staple Fibres and Should Have The Following Physical PropertiesDocument3 pagesThe Geotextile Protection Layer For The Geomembrane Shall Be Made by A Needle Punching Process Using Staple Fibres and Should Have The Following Physical PropertiesIr Ahmad AfiqNo ratings yet

- Profile 45 250 Sandwich Panel Techincal DatasheetDocument2 pagesProfile 45 250 Sandwich Panel Techincal DatasheetEle SultanaNo ratings yet

- Tech. Specification HDPE DUCT 50-43mmDocument2 pagesTech. Specification HDPE DUCT 50-43mmZaman MuhammadNo ratings yet

- 1tech Data - MF HPa Subgrade Stabilization Geotextiles (200 613-Td-0515)Document1 page1tech Data - MF HPa Subgrade Stabilization Geotextiles (200 613-Td-0515)Khengsoon ChinNo ratings yet

- Spec Geocell PDFDocument9 pagesSpec Geocell PDFsankhaginNo ratings yet

- Product Data Sheet EP CC 301Document1 pageProduct Data Sheet EP CC 301David Arturo Ramos GajardoNo ratings yet

- PlayStation MagazineDocument116 pagesPlayStation MagazineFrank Costello67% (3)

- Kyt KtiDocument13 pagesKyt KtiIbunnaya100% (1)

- Tea Board of India PDFDocument18 pagesTea Board of India PDFDebasish RazNo ratings yet

- MaekawaDocument2 pagesMaekawabhaskar_chintakindiNo ratings yet

- Assignment 1 To 7Document23 pagesAssignment 1 To 7KashishNo ratings yet

- Physics 715 HW 1Document13 pagesPhysics 715 HW 1Antonildo PereiraNo ratings yet

- The DAMA Guide To The Data Management Body of Knowledge - First EditionDocument430 pagesThe DAMA Guide To The Data Management Body of Knowledge - First Editionkakarotodesu100% (10)

- Tikkun Kisay HaShemDocument47 pagesTikkun Kisay HaShemYochananMauritzHummasti100% (1)

- BBC Learning English - 6 Minute English - Bitcoin - Digital Crypto-CurrencyDocument38 pagesBBC Learning English - 6 Minute English - Bitcoin - Digital Crypto-CurrencyMohamad GhafooryNo ratings yet

- Mat210 LectureNotes 1Document7 pagesMat210 LectureNotes 1Franch Maverick Arellano LorillaNo ratings yet

- Pengaruh PH Ekstraksi Terhadap Rendemen, Sifat Fisiko-Kimia Dan Fungsional Konsentrat Protein KACANG GUDE (Cajanus Cajan (L.) Millsp.)Document11 pagesPengaruh PH Ekstraksi Terhadap Rendemen, Sifat Fisiko-Kimia Dan Fungsional Konsentrat Protein KACANG GUDE (Cajanus Cajan (L.) Millsp.)Rezaa RezNo ratings yet

- Securing Your Organization From Modern Ransomware: Ransomware Attacks Are Now A Team EffortDocument11 pagesSecuring Your Organization From Modern Ransomware: Ransomware Attacks Are Now A Team EfforttiagouebemoraisNo ratings yet

- 02 Geotechnical Investigation (General)Document35 pages02 Geotechnical Investigation (General)Miftahul JannaNo ratings yet

- Retail ImageDocument76 pagesRetail ImageayushiNo ratings yet

- Proposal For Research Work at Iit Indore: ProjectsDocument2 pagesProposal For Research Work at Iit Indore: ProjectsAman GargNo ratings yet

- National Institute of Industrial Engineering: Part - B (10 Marks) : Answer All The QuestionsDocument4 pagesNational Institute of Industrial Engineering: Part - B (10 Marks) : Answer All The QuestionsTulasi PatleNo ratings yet

- Vastra Grah .Pvt. LTD: In-House Manufacturing FacaltyDocument2 pagesVastra Grah .Pvt. LTD: In-House Manufacturing FacaltySaurabh JainNo ratings yet

- Orifice Plate Calculator Pressure Drop CalculationsDocument4 pagesOrifice Plate Calculator Pressure Drop CalculationsAnderson Pioner100% (1)

- 18TE72 - Wireless Communication Experiential Learning ReportDocument10 pages18TE72 - Wireless Communication Experiential Learning ReportRitika BakshiNo ratings yet

- Water Cement RatioDocument5 pagesWater Cement RatioCastro FarfansNo ratings yet

- AQA Power and Conflict GCSE Revision Guide LADocument49 pagesAQA Power and Conflict GCSE Revision Guide LAderaw11557No ratings yet

- I J E E: Nternational Ournal of Nergy and NvironmentDocument8 pagesI J E E: Nternational Ournal of Nergy and NvironmentsheilamegumiNo ratings yet

- Sharp MX M283 363 453 503 PDFDocument404 pagesSharp MX M283 363 453 503 PDFAlejandro Barraza100% (2)

- With Pneumatic and Electric Actuators: Datasheet 448001 EnglishDocument7 pagesWith Pneumatic and Electric Actuators: Datasheet 448001 EnglishPinak ProjectsNo ratings yet

- MikroC PRO For DsPIC30Document9 pagesMikroC PRO For DsPIC30ivcal20No ratings yet

- But Flee Youthful Lusts - pdf2Document2 pagesBut Flee Youthful Lusts - pdf2emmaboakye2fNo ratings yet

- ParaklesisDocument23 pagesParaklesisDiana ObeidNo ratings yet

- Roy B. Kantuna, MPRM, CESE: (For Midterm) (Instructor)Document8 pagesRoy B. Kantuna, MPRM, CESE: (For Midterm) (Instructor)Athena Mae DitchonNo ratings yet

- Pricelist LV Siemens 2019 PDFDocument96 pagesPricelist LV Siemens 2019 PDFBerlianiNo ratings yet

- Tutorial 2 EtherchannelDocument3 pagesTutorial 2 EtherchannelOng CHNo ratings yet