Professional Documents

Culture Documents

Timber Engineering PDF

Uploaded by

Kesavan DhuraiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Timber Engineering PDF

Uploaded by

Kesavan DhuraiCopyright:

Available Formats

Lintels and Beams: Engineering Basis

The calculator is intended for the design of lintels and beams in timber-‐framed buildings generally within

the scope of NZS 3604. However, the range of applications, loads and spans is beyond what is in

NZS 3604.

For

each

beam

design,

a

range

of

options

is

presented

so

the

user

can

select

the

most

suitable

beam

to

fit

within

the

overall

design

and

details

for

the

building.

The

options

include:

MSG/VSG8 sawn timber 45 mm thick

70 mm thick

2/45 mm, laminated as per NZS 3604

90 mm thick

Laminated veneer lumber (LVL) 45 mm thick

63 mm thick

90 mm thick

Glulam 65 mm thick

90 mm thick

Hot rolled steel sections Universal beams

Parallel flanged channels

Flitch beams The Gang-‐nail range

The Pryda range

Applications

The

following

applications

are

available

for

the

user

to

select:

Application Picture reference

Lintel supporting a roof only 1

Lintel supporting roof and wall 2

Lintel supporting roof, wall and floor 3

Veranda beam 4

Floor beam 5

Deck support beam 6

Roof beam (ridge or intermediate) 7

Garage door lintel 8

Cantilever lintels 9

Loaded

dimension

Loaded

dimension

has

the

same

meaning

as

defined

in

NZS

3604.

It

is

a

measure

of

the

weight

of

construction

supported

by

the

beam

or

lintel,

or

the

area

exposed

to

wind

or

snow

loading.

For

this

tool,

BRANZ Lintels and Beams: Engineering Basis Page 1 of 8

loaded dimension is based on plan dimensions. This is considered more appropriate for use by building

designers, who will generally be working off plans.

Loads

Loads

are

calculated

in

accordance

with

the

AS/NZS

1170

suite,

but

limited

(where

appropriate)

to

the

scope

and

parameters

of

NZS

3604:2011.

They

are

applied

as

a

uniformly

distributed

load

along

the

length

of

the

lintel

or

beam.

Concentrated

loads

are

specified

by

manually

inputting

location

and

magnitude.

Gravity loads – G:

Light roof 0.4 kPa

(0.2 kPa in combination with wind uplift)

(0.1 kPa for veranda roof in combination with wind uplift)

Heavy roof 0.85 kPa

(0.4 kPa in combination with wind uplift)

Floor 0.4 kPa

Deck 0.4 kPa

Light wall 0.2 kPa

(0.1 kPa in combination with wind uplift)

Medium wall 0.8 kPa

(0.2 kPa in combination with wind uplift)

The roof loads allow for the total mass of the roof cladding, the roof and ceiling framing, and the ceiling

lining. Roof loads are converted to equivalent plan area at the roof slope selected by the user.

For downwards acting load cases, light roof cladding is taken as 20 kg/m2 of roof area. This is based on

lightweight roof cladding, as defined in NZS 3604. For upwards load cases (wind uplift) steel sheeting is

allowed for to give a worst case situation. For veranda upwards loading no ceiling lining is assumed.

Similarly, heavy roof cladding weights are 60 kg/m2 for downwards loading, and 20 kg/m2 for upwards

loads.

There

is

no

allowance

for

the

weight

of

internal

walls

on

the

floor.

This

is

the

same

approach

as

followed

in

NZS

3604.

External

wall

loads

are

included

when

selected

by

the

user.

The

weight

of

a

light

wall

allows

for

an

external

cladding

weight

of

30

kg/m2

for

downwards

load

cases

(as

defined

in

NZS

3604),

and

10

kg/m2

for

upwards

load

cases.

Similarly,

medium

wall

cladding

weights

are

70

kg/m2

for

downwards

loading,

and

20

kg/m2

for

upwards

loads.

Live loads – Q:

Roofs (construction and 0.25 kPa (* see below)

maintenance load only)

Floors 1.5, 2.0 or 3.0 kPa

Decks 2.0 kPa

*

The

area-‐dependent

roof

live

load

of

AS/NZS

1170.1

has

been

removed,

in

accordance

with

the

NZBC

Compliance

Document

B1,

which

became

effective

in

December

2008.

BRANZ Lintels and Beams: Engineering Basis Page 2 of 8

The basic floor live loads correspond to those provided for in NZS 3604. Basic loads are reduced by the

area reduction factor, ψa, prescribed by AS/NZS 1170.1,

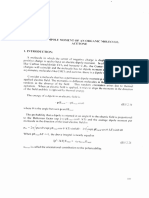

where:

3

!! = 0.3 +

√!

Snow loads – S:

Ground snow load, sg, is calculated from the site elevation and snow region selected by the user. The

snow regions are defined in both AS/NZS 1170.3 and NZS 3604. Equations used for ground snow load are

as set out in clause 5.4.3 of AS/NZS 1170.3, with kp taken as 1.25 for the ultimate limit state, and 0.85 for

the serviceability limit state.

The slope factor, µ1 for balanced load is given by:

µ1 = 0.7(60-‐α)/50 within the range 0.7≥ µ1 ≤ 0.

where α = roof slope (the lower value of the range selected)

The exposure factor, Ce, is conservatively taken as 1.0.

Snow loading is applied to the plan area of the roof supported by the lintel or roof beam.

Wind loads – W:

Wind loads are calculated in accordance with AS/NZS 1170.2, based on the site wind speeds for the wind

zone selected by the user. The five NZS 3604:2011 wind zones are included, along with extras to cater for

the increasing numbers of buildings being constructed on more exposed site.

Wind zone/speed Basic design pressure (kPa)

Low 0.61

Medium 0.82

High 1.16

Very high 1.50

Extra high 1.82

60 m/sec 2.16

65 m/sec 2.54

70 m/sec 2.94

The combined pressure coefficients (Cpi and Cpe) are given in the following table:

Situation External roofs Roofs

over enclosed

(eave overhangs and spaces

verandas)

Wind upwards 1.6 0.96

Wind downwards 0.2 0.5

BRANZ Lintels and Beams: Engineering Basis Page 3 of 8

The area reduction factor, Ka, combination factor, Kc, local pressure factor, kl, and porous cladding factor,

Kp, are all taken as 1.0.

In

calculating

the

reaction

on

the

lintel,

account

is

taken

of

the

“leverage”

effect

of

the

load

applied

to

the

projecting

portion

of

the

eave

(up

or

down),

which

can

be

significant

for

short

loaded

dimensions

and

large

overhangs.

Allowance

was

also

made

for

the

“leverage”

associated

with

the

horizontal

component

of

the

wind

load

on

steep

pitched

roofs.

Load

combinations

The

following

load

combinations

are

considered:

Case

Loads

1

G

+

Ql

2

G

+

Qs

Vibration

(for

floor

3

beams

only)

4

G+S

5

1.35G

6

1.2G

+

1.5Q

7

1.2G

+

ψcQ

+

Wu

8

.9G-‐Wu

9

1.2G

+

ψcQ

+

S

Load

duration

factors

used

are

0.7

for

short

term

loads,

ψs,

0.0

for

long

term

roof

loads,

and

0.4

for

long

term

floor

loads,

ψl.

The factor, ψc, for roof live loads in combination with wind or snow is 0.0.

Material

properties

Sawn

timber

The

tool

may

be

used

with

Radiata

Pine

or

Douglas

Fir

timber

in

grades

VSG8

and

MSG8

(SG8).

Sizes

quoted

are

the

maximum

dry

finished

sizes,

after

machining.

Larger

sizes

may

be

substituted.

Design

is

in

accordance

with

NZS

3603,

including

amendment

4.

“Dry”

timber

properties

as

defined

by

NZS

3603

are

used

for

all

applications

except

decks,

where

“green”

properties

are

used.

The

characteristic

stresses

for

timber

members,

as

given

in

NZS

3603,

are:

Property All applications Decks

except decks

Bending stress fb (MPa) 14.0 11.7

Bearing stress perpendicular to grain fp(MPa) 8.9 5.3

Bearing

stress

parallel

to

grain

fc(MPa)

(used

to

18.0

12.0

calculate

supporting

timber

members)

Modulus of elasticity E (GPa) (lower bound) 5.40 4.40

BRANZ Lintels and Beams: Engineering Basis Page 4 of 8

The strength duration factors are 0.6 for dead loads, 0.8 for live and snow loads, and 1.0 for wind loads.

The duration factor for deflection under long term loads, k2, is 2.0.

The

parallel

support

factor,

k4,

for

doubled

members

(eg

2/90x45)

is

1.14.

The

stability

factor,

k8,

under

uplift

loading

was

calculated

using

a

slenderness

factor

assuming

full

lateral

restraint

of

the

tension

edge

(clause

3.2.5.3

of

NZS

3603).

A strength reduction factor, φ, of 0.8 is used for timber member design.

Laminated veneer lumber (LVL)

Design is in accordance with NZS 3603, using the lower bound of the values of engineering properties of

the products offered by the New Zealand LVL manufacturers.

The relevant characteristic stresses for LVL members used in the tool are:

Property Stress

Bending

stress

fb

(MPa)

38.0

for

45

mm

and

63

mm

thick

beams

34.0

for

90

mm

thick

beams

Bearing stress perpendicular to 12.0

grain fp(MPa)

Modulus

of

elasticity

E

(GPa)

11.0

for

45

mm

and

63

mm

thick

beams

(lower

bound)

9.5

for

90

mm

thick

beams

The

duration

factor

for

deflection

under

long

term

loads,

k2,

is

1.5.

Other

modification

factors

are

the

same

as

sawn

timber.

The

size

factor,

k24,

as

advised

by

the

manufacturers

has

been

applied

to

the

section

properties.

A strength reduction factor, φ, of 0.9 is used for LVL member design.

Glue-‐laminated timber (Glulam)

Design is in accordance with NZS 3603 and AS/NZS 1328, using grade GL8.

The relevant characteristic stresses for glulam members used in the tool are:

Property Stress

Bending stress fb (MPa) 19.0

Bearing stress perpendicular to 8.9

grain fp(MPa)

Modulus of elasticity E (GPa) 8.0

(lower bound)

BRANZ Lintels and Beams: Engineering Basis Page 5 of 8

The duration factor for deflection under long term loads, k2, is 1.5. The parallel support factor, k6, and size

factor, k24, are both calculated in accordance with section 8.7 of NZS 3603. Other modification factors

are the same as sawn timber.

A strength reduction factor, φ, of 0.8 is used for glulam member design.

Hot rolled steel

Design is in accordance with NZS 3404.

The yield stress used for steel sections to AS 3679 Grade 300, is 320 MPa for flanges less than 11 mm

thick, and 300MPa for thicker flanges within the range of sections covered.

All steel members except for lintels are considered fully laterally restrained by the adjacent framing at a

maximum of 1.2 m spacing. Lintels are considered partially restrained at the ends, and unrestrained

between. Member moment capacities, φMbx, are calculated for upwards and downwards loading at the

span selected by the user, using the provisions of clause 5.6 of NZS 3404.

A strength reduction factor, φ, of 0.9 is used for steel member design.

Flitch

beams

The

beams

available

include

the

“GANG-‐NAIL”

range

offered

by

MiTek

NZ,

and

the

“Pryda

Flitch

beam”

range

offered

by

Pryda

NZ.

Both

are

available

from

approved

suppliers

and

fabricators

respectively.

Both

ranges

must

be

installed

dry

and

only

used

in

dry

applications

(lintels

and

floor

beams).

Timber

properties

are

based

on

the

stresses

given

in

NZS

3603

(including

amendment

4)

for

MSG6

and

No1

framing

timber

in

the

“dry”

condition.

Thus

applications

are

limited

by

the

calculator

to

lintels

and

floor

beams

only.

Modification

factors

for

the

timber

components

are

the

same

as

those

for

solid

timber

beams,

as

described

above.

All fabrication details are as per the manufacturer’s standard specifications.

A

strength

reduction

factor,

φ,

of

0.9

is

used

for

the

steel

components,

and

0.8

for

the

timber

components,

depending

on

which

one

governs

the

capacity

of

the

beam

in

each

case.

Deflection

criteria

1. For

lintels

under

short

and

long

term

loading,

and

snow

loading,

deflection

is

limited

to

span/300,

with

a

maximum

of

12

mm.

2. For

veranda

beams

floor

beams,

roof

and

deck

beams,

deflection

under

short

and

long

term

loading

and

snow

loading,

is

limited

to

span/300,

with

no

upper

limit.

3. Floor

beams

have

their

deflection

under

a

1

kN

concentrated

load

limited

to

1

mm,

for

vibration

control.

4. Garage

door

lintels

have

deflection

limited

to

span/300.

There

are

no

deflection

criteria

under

wind

loading

for

any

applications.

End

supports

Supports

to

the

beam

ends

are

checked

against

several

criteria.

For

timber

beams,

the

required

bearing

area

perpendicular

to

the

grain

is

calculated,

and

a

support

appropriate

to

the

application

giving

a

greater

contact

bearing

area

is

given.

BRANZ Lintels and Beams: Engineering Basis Page 6 of 8

The capacity of a range of support options appropriate to the application is matched against the

calculated end reaction from the lintel or beam. Support capacities under axial loads are calculated in

accordance with NZS 3603, based on a 2.7m wall height and in-‐plane bracing by wall lining.

A check is made that the width of the selected lintel will fit into a 90 mm wall frame. Widths of selected

floor and roof beams are matched against number of wall studs required.

Hold

downs

The

calculated

wind

uplift

reactions

are

matched

against

the

capacities

of

a

number

of

hold

down

details,

as

appropriate

for

the

application.

The

capacities

are

calculated

in

accordance

with

the

relevant

material

standard

and

are

tabulated

below.

Picture

Capacity

Fixing

reference

(kN)

4/100x4

end

nails

to

trimmer

stud

1

2.10

25x0.9 mm nail strap with 6/30x3.15 nails (see Figure 8.12 NZS 3604) 2 6.16

2/25x0.9 mm nail straps with 12/30x3.15 nails 3 9.96

Welded cleat with 2/M12 coach screws into trimmer stud 4 13.65

6/100x4 nails to post 5 4.75

1/M12 bolt to post (similar to Figure 9.3 (c) of NZS 3604) 6 4.87

2/M12 bolts to post (see Figure 9.3 (c) of NZS 3604) 7 9.76

Steel bracket each side of beam with 2/M12 bolts to beam and post 8 19.5

Welded cleat with 2/M12 coach screws into post 9 13.65

2/100x4 nails (or 4/90x3.15) 10 1.58

4/100x4 nails (or 6/90x3.15) 11 3.17

6/100x4 nails (or 10/90x3.15) 12 4.75

1/M12

bolt

to

built-‐up

studs

13

9.76

2/M16

bolts

to

built-‐up

studs

14

26.0

Welded

cleat

with

2/M12

coach

screws

into

studs

15

13.65

Base

fixings

The

calculated

wind

uplift

reactions

are

matched

against

the

capacities

of

a

number

of

fixing

details

to

the

selected

foundation,

as

appropriate

for

the

application.

The

capacities

are

calculated

in

accordance

with

the

relevant

material

standard

and

are

tabulated

below.

BRANZ Lintels and Beams: Engineering Basis Page 7 of 8

Picture Capacity

Fixing

reference

(kN)

No specific fixing required. 1

2.5

25x0.9 mm nail strap folded under wall plate, attached to stud with 6/30x3.15

2

3.8

nails

2/25x0.9 mm nail straps 3 7.6

3/25x0.9 mm nail straps 4 11.4

No specific fixing required. (NZS 3604 standard details with normal lining

5

2.5

fixings) Directly support studs by dwang between floor joists

25x0.9 mm nail strap each side of stud attached to 90x90 jackstud 6 7.6

2/25x0.9 mm nail straps each side of stud attached to 90x90 jackstud 7 15.2

3/25x0.9 mm nail straps each side of stud attached to 2/140x45 jackstud 8 18.6

HDG bracket cast into foundation, with M12 bolt to post (Figure 9.2 NZS

9

12.8

3604)

HDG bracket cast into foundation, with 2/M12 bolts to post (Figure 9.2 NZS

10

25.5

3604)

No specific fixing required. (NZS 3604 standard details with normal lining

11

2.5

fixings)

25x0.9 mm nail strap folded under plate, with 6/30x3.15 nails each side of

12

7.6

stud (see Figure 8.12 NZS 3604)

2/25x0.9 mm nail straps folded under plate, with 6/30x3.15 nails each side of

13

15.2

stud (similar Figure 8.12 NZS 3604)

3/25x0.9 mm nail straps folded under plate, with 6/30x3.15 nails each side of

14

22.8

stud (similar Figure 8.12 NZS 3604)

Durability

Timber

treatments

are

in

accordance

with

NZS

3602

for

50-‐year

durability

as

clarified

and

simplified

by

amendment

7

to

NZBC

Clause

B2

Durability,

based

on

the

exposure

conditions

of

NZS

3604.

BRANZ Lintels and Beams: Engineering Basis Page 8 of 8

You might also like

- Lysaght Panelrib 18 Sept 2008Document4 pagesLysaght Panelrib 18 Sept 2008Daniel McCallumNo ratings yet

- Klip Lok 406 Feb 08Document8 pagesKlip Lok 406 Feb 08Faisal AldyNo ratings yet

- Lysaght FLATDEK September 2015Document6 pagesLysaght FLATDEK September 2015Adam NewellNo ratings yet

- Kingspan KS2000 RW PDFDocument4 pagesKingspan KS2000 RW PDFSalvis BralitisNo ratings yet

- SpeedBrace RoofingDocument8 pagesSpeedBrace RoofingArdenNo ratings yet

- EXECUTION AND COMPLETION OF ROOF WORKSDocument70 pagesEXECUTION AND COMPLETION OF ROOF WORKSTOM YEENo ratings yet

- Nordfab In-Line Spark Trap-3Document1 pageNordfab In-Line Spark Trap-3jrouetteNo ratings yet

- DuraGal DCM Lintels Sep01Document30 pagesDuraGal DCM Lintels Sep01Denise2512No ratings yet

- NS Beam-Brochure ENDocument19 pagesNS Beam-Brochure ENMartinNo ratings yet

- 4000 MT WAGON SILO DESIGN BASIS REPORTDocument5 pages4000 MT WAGON SILO DESIGN BASIS REPORTdhan singhNo ratings yet

- Maximum Span Tables: For Joists and RaftersDocument12 pagesMaximum Span Tables: For Joists and RaftersAntonio TorresNo ratings yet

- Lysaght Trimdek: Subtle Square Fluted Steel CladdingDocument6 pagesLysaght Trimdek: Subtle Square Fluted Steel Claddingfahim007No ratings yet

- Guidelines For Bearing Design Using Nylon MaterialDocument3 pagesGuidelines For Bearing Design Using Nylon MaterialDiego ReggianiniNo ratings yet

- Chapter 9Document10 pagesChapter 9Haftom Gebreegziabiher100% (1)

- Chapter 9 Steel TrussesDocument10 pagesChapter 9 Steel TrussesHaftom GebreegziabiherNo ratings yet

- Book 1 - Section C - Steel Framed Wall SystemsDocument57 pagesBook 1 - Section C - Steel Framed Wall SystemsManasi SatbhaiNo ratings yet

- Residential and Low-Rise Steel Framing NZ-Public CommentDocument59 pagesResidential and Low-Rise Steel Framing NZ-Public CommentpengenbangetNo ratings yet

- Kingspan Kooltherm k107 Brochure en GB IeDocument22 pagesKingspan Kooltherm k107 Brochure en GB IeTayeb KazemiNo ratings yet

- SoilDocument26 pagesSoilOsama EL HakimNo ratings yet

- ShaftWall 0Document30 pagesShaftWall 0VictorNo ratings yet

- Lysaght Klip Lok 406 2011Document12 pagesLysaght Klip Lok 406 2011Zuhal ZaeemNo ratings yet

- Design Proceduresfor Wooden TransmissionDocument11 pagesDesign Proceduresfor Wooden TransmissionCharizamaneNo ratings yet

- AGGA Technical Fact Sheet - Glass in Balustrades INDUSTRY - 151216Document5 pagesAGGA Technical Fact Sheet - Glass in Balustrades INDUSTRY - 151216Ashik AliNo ratings yet

- 180827TGN0201 Shelter Assessment Guidance NoteDocument23 pages180827TGN0201 Shelter Assessment Guidance NoteAleksandar SpasojevicNo ratings yet

- Module 4Document15 pagesModule 4Azeezan AlessaNo ratings yet

- Timber Framing Using As 1684.2 Span TablesDocument80 pagesTimber Framing Using As 1684.2 Span TablesAmit Lakhani100% (1)

- QRF 1246Document1 pageQRF 1246SuryaSinghNo ratings yet

- Design Calculations For 3WH36 Composit Steel Deck-1 MMDocument5 pagesDesign Calculations For 3WH36 Composit Steel Deck-1 MMmohanNo ratings yet

- Design of Steel - StructuresDocument23 pagesDesign of Steel - StructuresPandiiitmNo ratings yet

- Purlin Load Tables PDFDocument72 pagesPurlin Load Tables PDFMr TezNo ratings yet

- Trimdek: Design and Installation GuideDocument6 pagesTrimdek: Design and Installation GuideHarold SanaresNo ratings yet

- Design Basis Report - PEB For Ramu Project at Bangalore.Document5 pagesDesign Basis Report - PEB For Ramu Project at Bangalore.sNo ratings yet

- Kingspan GreenGuard BasementsDocument10 pagesKingspan GreenGuard BasementsdesignNo ratings yet

- LOT 4 - Technical Specs - 132 KV Transmission Line AccessoriesDocument13 pagesLOT 4 - Technical Specs - 132 KV Transmission Line AccessoriesPeters Clever OkelloNo ratings yet

- Roof Loads Canada Plan ServiceDocument5 pagesRoof Loads Canada Plan ServiceSugarPOP666No ratings yet

- Curtain Wall-Report REv 1-10-21Document11 pagesCurtain Wall-Report REv 1-10-21MuraleedharanNo ratings yet

- EG-154 Conceptual Design Section 4 PDFDocument22 pagesEG-154 Conceptual Design Section 4 PDFkelvinNo ratings yet

- S-20478-1 RevA Design CalculationsDocument15 pagesS-20478-1 RevA Design CalculationsRAMIL100% (2)

- X ENP Data Sheet Technical Information ASSET DOC 2591592Document9 pagesX ENP Data Sheet Technical Information ASSET DOC 2591592Milos VukobratNo ratings yet

- Diaphragms For Timber Framed Buildings Vol 17 No1 2004Document8 pagesDiaphragms For Timber Framed Buildings Vol 17 No1 2004Tiago Lamy SilvaNo ratings yet

- Floor Drains Tech DataDocument3 pagesFloor Drains Tech DataMohammed RishadNo ratings yet

- RoofDek Structural Roof Decking and Trays BrochureDocument24 pagesRoofDek Structural Roof Decking and Trays Brochuresiddharth vekariyaNo ratings yet

- Long Span Beams Span TablesDocument36 pagesLong Span Beams Span Tableszzlesleyzz100% (1)

- AS1684 SPLIT LEVEL C2 House Tie-DownDocument34 pagesAS1684 SPLIT LEVEL C2 House Tie-DownNhư Lê0% (1)

- Concrete LintelsDocument24 pagesConcrete LintelsAmber ChristensenNo ratings yet

- KLIP-LOK 700 SpecsDocument8 pagesKLIP-LOK 700 Specsmontree SupaphobNo ratings yet

- PPPL-21362 (R-0) Techno Commercial OfferDocument8 pagesPPPL-21362 (R-0) Techno Commercial OfferAtul Kumar EngineerNo ratings yet

- Checklist For Wave Trap Structure Design & DrawingDocument4 pagesChecklist For Wave Trap Structure Design & DrawingRupesh KhandekarNo ratings yet

- QSM Five Rib Technical ManualDocument5 pagesQSM Five Rib Technical ManualAnchor YauNo ratings yet

- Checklist For 33kV DP Structure Design & DrawingDocument4 pagesChecklist For 33kV DP Structure Design & DrawingRupesh KhandekarNo ratings yet

- DAR-J-109-PEB Shed-Estimate-R0Document1 pageDAR-J-109-PEB Shed-Estimate-R0Sunil RahangdaleNo ratings yet

- Topdek 700 Concealed Clip RoofingDocument16 pagesTopdek 700 Concealed Clip RoofingctaciutNo ratings yet

- Aliplast TF VG500 ENGDocument2 pagesAliplast TF VG500 ENGjasenkosNo ratings yet

- Membrane Lined Insulated Gutter - BrochureDocument8 pagesMembrane Lined Insulated Gutter - BrochureAThaddeusAntonioNo ratings yet

- Checklist For 33kV HG Fuse Structure Design & DrawingDocument4 pagesChecklist For 33kV HG Fuse Structure Design & DrawingRupesh KhandekarNo ratings yet

- Stud To Top Plate Fixing ScheduleDocument1 pageStud To Top Plate Fixing Scheduleali husnainNo ratings yet

- K107 Pitched Roof Board: InsulationDocument22 pagesK107 Pitched Roof Board: InsulationAlexandru VasileNo ratings yet

- Modelling of Vibrations of Overhead Line Conductors: Assessment of the TechnologyFrom EverandModelling of Vibrations of Overhead Line Conductors: Assessment of the TechnologyGiorgio DianaNo ratings yet

- Rib and Timber Infill LoadsDocument2 pagesRib and Timber Infill LoadsKesavan DhuraiNo ratings yet

- ProppingDocument36 pagesProppingKesavan DhuraiNo ratings yet

- Treehouse, Waiheke Island: Structural Steelwork NotesDocument12 pagesTreehouse, Waiheke Island: Structural Steelwork NotesKesavan DhuraiNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Ramset Specifiers Anchoring Resource Book ANZ - SpaTec Plus Cracked ConcreteDocument8 pagesRamset Specifiers Anchoring Resource Book ANZ - SpaTec Plus Cracked ConcreteKesavan DhuraiNo ratings yet

- Tower Crane Safety DocsDocument43 pagesTower Crane Safety DocsKesavan Dhurai100% (3)

- V3 I 104Document21 pagesV3 I 104chethanNo ratings yet

- Crib 3D3 2015Document15 pagesCrib 3D3 2015Kesavan DhuraiNo ratings yet

- Beam Bending Stress FormulaDocument11 pagesBeam Bending Stress FormulaIvana DincicNo ratings yet

- Hollow Building PDFDocument6 pagesHollow Building PDFKesavan DhuraiNo ratings yet

- Futurebuild® LVL Products: Specified Through Computeit® Software SolutionsDocument4 pagesFuturebuild® LVL Products: Specified Through Computeit® Software SolutionsKesavan DhuraiNo ratings yet

- Alumino Silicate Fibre Mesh Product DataDocument2 pagesAlumino Silicate Fibre Mesh Product DataKesavan DhuraiNo ratings yet

- GFRC: Recent Uses and Developments: Glass Fiber Reinforcement Applications Are IncreasingDocument3 pagesGFRC: Recent Uses and Developments: Glass Fiber Reinforcement Applications Are IncreasingKesavan DhuraiNo ratings yet

- High Strength Lightweight ConcreteDocument12 pagesHigh Strength Lightweight ConcreteKesavan DhuraiNo ratings yet

- Flexible Bendy Plywood SheetsDocument1 pageFlexible Bendy Plywood SheetsKesavan DhuraiNo ratings yet

- Beam Example1Document2 pagesBeam Example1Indu ShresthaNo ratings yet

- Polymer Concrete BrochureDocument12 pagesPolymer Concrete BrochureKesavan DhuraiNo ratings yet

- Cemfil 62 - 3Document2 pagesCemfil 62 - 3Kesavan DhuraiNo ratings yet

- Designing cladding with weatherboards above brick veneerDocument3 pagesDesigning cladding with weatherboards above brick veneerKesavan DhuraiNo ratings yet

- IB 39 - Fibre Reinforced ConcreteDocument18 pagesIB 39 - Fibre Reinforced ConcreteKesavan DhuraiNo ratings yet

- Building Model II Front Elevation Type IDocument3 pagesBuilding Model II Front Elevation Type IKesavan DhuraiNo ratings yet

- General: Portal Frame Design Tips Seminar ProceedingsDocument21 pagesGeneral: Portal Frame Design Tips Seminar ProceedingsKesavan DhuraiNo ratings yet

- BD SolidTimber PDFDocument4 pagesBD SolidTimber PDFKesavan DhuraiNo ratings yet

- Structural Design of Timber Beams With Modification FactorsDocument38 pagesStructural Design of Timber Beams With Modification FactorsKesavan Dhurai100% (1)

- Building Model IIIDocument2 pagesBuilding Model IIIKesavan DhuraiNo ratings yet

- Metric Threaded Inserts: Design GuideDocument26 pagesMetric Threaded Inserts: Design GuideKesavan DhuraiNo ratings yet

- Building Model III Front Elevation Type IDocument2 pagesBuilding Model III Front Elevation Type IKesavan DhuraiNo ratings yet

- Solution of Strength of Materials ProblemsDocument12 pagesSolution of Strength of Materials ProblemsKesavan DhuraiNo ratings yet

- Non-Local Continuum Mechanics and Fractional Calculus: K.A. LazopoulosDocument5 pagesNon-Local Continuum Mechanics and Fractional Calculus: K.A. Lazopoulosrs0004No ratings yet

- RA 9292 exam questionsDocument12 pagesRA 9292 exam questionsJmae BantilingNo ratings yet

- Soil Mechanics: Arnold Verruijt Delft University of Technology, 2001, 2006Document8 pagesSoil Mechanics: Arnold Verruijt Delft University of Technology, 2001, 2006Sharad BhutoriaNo ratings yet

- Hounsfield Tensometer 20%Document4 pagesHounsfield Tensometer 20%Niyusha Toosi100% (1)

- Transport PhenomenaDocument8 pagesTransport PhenomenaShivaniNo ratings yet

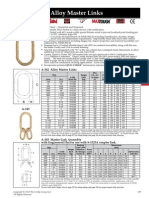

- Master Link CatalogueDocument1 pageMaster Link CatalogueHafizi HZnumismatic50% (2)

- 3 Hardened Properties of Portland Cement Grouts: P.L.J.DomoneDocument36 pages3 Hardened Properties of Portland Cement Grouts: P.L.J.Domoneraahul_nNo ratings yet

- Mohr Circle 2Document6 pagesMohr Circle 2faizan ashiqueNo ratings yet

- 17-4 PH Bar Data SheetDocument2 pages17-4 PH Bar Data SheetBryan KellyNo ratings yet

- Bearing LubricationDocument45 pagesBearing Lubricationjayesh gohilNo ratings yet

- Selection of Flow MeterDocument63 pagesSelection of Flow MeterAnonymous wIPMQ5rh50% (2)

- Assignment QuestionDocument6 pagesAssignment QuestionChin Tiong LeeNo ratings yet

- Dipole Moment AcetoneDocument6 pagesDipole Moment AcetoneP NaveenNo ratings yet

- Homework 3Document8 pagesHomework 3Alferid ShifaNo ratings yet

- HMT Answer 2 & 16 Marks HMTDocument85 pagesHMT Answer 2 & 16 Marks HMTChandra Sekar100% (3)

- Synthesis, Properties and Applications of Cordierite Ceramics, Part 2Document4 pagesSynthesis, Properties and Applications of Cordierite Ceramics, Part 2musonlyNo ratings yet

- 04-Binary Vapour Cycle and Co-GenerationDocument9 pages04-Binary Vapour Cycle and Co-GenerationMohtasin SheikhNo ratings yet

- Chapter 2 P H Diagram Analysis Refrigerant Flow DiagiaramDocument20 pagesChapter 2 P H Diagram Analysis Refrigerant Flow DiagiaramMyo Kyaw KyawNo ratings yet

- The Terrible Beauty of ThermodynamicsDocument9 pagesThe Terrible Beauty of Thermodynamicsels243No ratings yet

- Analysis of Fan BladeDocument80 pagesAnalysis of Fan BladeShripad PachputeNo ratings yet

- A Review: Dissimilar Material Joining of Metal To Polymer Using Friction Stir Welding (FSW)Document5 pagesA Review: Dissimilar Material Joining of Metal To Polymer Using Friction Stir Welding (FSW)IJSTENo ratings yet

- SBBSBDocument130 pagesSBBSBRam KumarNo ratings yet

- Container Yard Geocell Design PDFDocument9 pagesContainer Yard Geocell Design PDFfemiNo ratings yet

- Pcmflash 71Document177 pagesPcmflash 71bb2502No ratings yet

- Heliyon: N.G. Mbewana-Ntshanka, M.J. Moloto, P.K. MubiayiDocument8 pagesHeliyon: N.G. Mbewana-Ntshanka, M.J. Moloto, P.K. MubiayijaiemNo ratings yet

- Distortion Due To Heat Treatment PDFDocument44 pagesDistortion Due To Heat Treatment PDFsmani170No ratings yet

- Laminar Flow Table: Name: Animesh Phatowali Roll No: 17AE30005 Group: 6 Experiment:7Document7 pagesLaminar Flow Table: Name: Animesh Phatowali Roll No: 17AE30005 Group: 6 Experiment:7Animesh PhatowaliNo ratings yet

- Homework No. 1: Department of Strength of Materials and Vibrations Faculty of Mechanical EngineeringDocument2 pagesHomework No. 1: Department of Strength of Materials and Vibrations Faculty of Mechanical EngineeringTolea AdrianNo ratings yet

- CE 51C - Timber Design Problem Set 3 SolutionsDocument3 pagesCE 51C - Timber Design Problem Set 3 SolutionsChrisneil DelosreyesNo ratings yet

- Seismic Performance of X-Braces of Steel Equal-Leg Angle: T. YamashitaDocument10 pagesSeismic Performance of X-Braces of Steel Equal-Leg Angle: T. YamashitaBogdanBNo ratings yet