Professional Documents

Culture Documents

Timber Construction Systems: Materials - Modules

Uploaded by

Stefan Jakovljevic0 ratings0% found this document useful (0 votes)

13 views1 pageTimber construction systems can use either timber frame or timber stud construction. Timber frame construction uses a small module with diagonal braces and loadbearing members united in the wall plane. Timber stud construction, like balloon framing, uses closely spaced standard sized timber sections that extend over multiple stories and are nailed together on site for rapid construction. Both allow for design flexibility but timber stud construction aims to use materials more economically with standardized connections beyond just nailing.

Original Description:

sesnaest

Original Title

016

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTimber construction systems can use either timber frame or timber stud construction. Timber frame construction uses a small module with diagonal braces and loadbearing members united in the wall plane. Timber stud construction, like balloon framing, uses closely spaced standard sized timber sections that extend over multiple stories and are nailed together on site for rapid construction. Both allow for design flexibility but timber stud construction aims to use materials more economically with standardized connections beyond just nailing.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageTimber Construction Systems: Materials - Modules

Uploaded by

Stefan JakovljevicTimber construction systems can use either timber frame or timber stud construction. Timber frame construction uses a small module with diagonal braces and loadbearing members united in the wall plane. Timber stud construction, like balloon framing, uses closely spaced standard sized timber sections that extend over multiple stories and are nailed together on site for rapid construction. Both allow for design flexibility but timber stud construction aims to use materials more economically with standardized connections beyond just nailing.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

MATERIALS – MODULES Timber

Systems

Timber construction systems

Overview

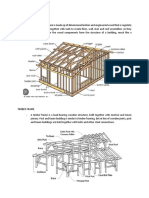

Fig. 39: Timber-frame construction Fig. 40: Balloon frame construction, timber stud construction

Timber frame construction Balloon frame construction,

This traditional method of building with timber, seldom timber stud construction

used today, is based on a relatively small module with The balloon frame system widespread in America con-

diagonal braces in the plane of the walls. We see the first sists of closely spaced squared sections of standard sizes

signs of prefabrication in this form of construction. The based on a “2 x 8 inch” module (roughly 5 x 20 cm).

loadbearing and separating functions are united in the When, as a result of a structural analysis, larger cross-

same plane within the wall. Assembly of the individual sections are called for, these are made by simply nailing

pieces takes place on site storey by storey. The spacing several smaller squared sections together. This timber

between the individual vertical members depends on the stud construction is nailed together on site and usually

loadbearing capacity of the timber sections which, prior extends over two or more storeys. Stability is assured by

to industrialisation, were cut to size with simple means solid timber boarding or wood-based panels attached di-

(saws, axes). The individual connections are not highly agonally.

stressed and can be in the form of true wood joints (e.g. The simplicity of the system, in which additional mem-

tenons, halving joints, oblique dados). Vertical loads are bers are often simply nailed to the main framework as

transferred directly via the contact faces between the vari- required, enables rapid erection with unskilled labour,

ous timber members. despite minimum prefabrication. The system is also char-

As the cross-sections of the members are often not acterised by a great degree of design freedom regarding

derived from a structural analysis, in older timber-frame plan layout, volume and positioning of openings. Indeed,

buildings they tend to be too large and hence uneconomic, openings can even be “cut out” subsequently because the

or are an inevitable consequence of the usually consider- construction is oversized. However, this oversizing is a dis-

able weakening of the cross-section at the joints. Today, advantage compared to newer systems because it leads

mechanical fasteners are therefore preferred in order to to high material consumption.

achieve a more economic sizing of the sections. In Europe timber stud construction is the equivalent

The infill panels of historical timber-frame buildings of the American balloon frame. Timber stud construction

are usually of cob, wattle and daub or clay bricks, with also uses closely spaced squared sections of standard

masonry and render in later buildings. Today, the infilling sizes extending over two or more storeys. However, there

is usually insulating materials with a weatherproof clad- is less standardisation and the connections are not limited

ding. to nailing as in the balloon frame – tenons and halving

joints are also used. Another aim is a more economic use

of material.

96

You might also like

- PostFrameConstructionGuide LowresDocument20 pagesPostFrameConstructionGuide LowresDoug Johns100% (5)

- Sample Minutes of MeetingDocument3 pagesSample Minutes of MeetingMohamad AzmeerNo ratings yet

- The Complete Guide To Installing The 44 Split Defense PDFDocument171 pagesThe Complete Guide To Installing The 44 Split Defense PDFsaid100% (1)

- Engineered WoodDocument24 pagesEngineered WoodColecole Bustamante100% (2)

- Long Span TrussDocument26 pagesLong Span Trussakhtar0% (1)

- Aluminum Cladding Part 03Document7 pagesAluminum Cladding Part 03Anonymous ELujOV3No ratings yet

- Structural Diagrams: Framing: Jeff Graybill & Johanna MikitkaDocument33 pagesStructural Diagrams: Framing: Jeff Graybill & Johanna MikitkaYashika Bhathiya JayasingheNo ratings yet

- Technical Bulletin - Timber Frame StructuresDocument24 pagesTechnical Bulletin - Timber Frame Structuresrexo100% (1)

- Portal Frame Structure: Lect 8Document35 pagesPortal Frame Structure: Lect 8jkaliwonNo ratings yet

- SRT251 Group Project FINALDocument49 pagesSRT251 Group Project FINALPhilip SnowdenNo ratings yet

- When Is Blocking - Bracing Within Wood-Frame Walls Required - WoodWorksDocument3 pagesWhen Is Blocking - Bracing Within Wood-Frame Walls Required - WoodWorksSamia H. BhuiyanNo ratings yet

- AS Film Production Lesson.Document13 pagesAS Film Production Lesson.MsCowanNo ratings yet

- Chemical Recycling of Textile PolymersDocument8 pagesChemical Recycling of Textile PolymersVaishali RaneNo ratings yet

- Framing PDFDocument5 pagesFraming PDFKenneth Ignacio ArcillaNo ratings yet

- Heat TreatmentDocument14 pagesHeat TreatmentAkhilesh KumarNo ratings yet

- CTM - 10TH Sem - SLTDocument27 pagesCTM - 10TH Sem - SLTShashank Dubbalwar90% (10)

- (Basics (Book 82) ) Ludwig Steiger - Basics Timber Construction (2007, Birkhäuser Architecture) - Libgen - LiDocument96 pages(Basics (Book 82) ) Ludwig Steiger - Basics Timber Construction (2007, Birkhäuser Architecture) - Libgen - LiPauloRobertoLiñanFigueiredoNo ratings yet

- Terraform AWSDocument1,531 pagesTerraform AWSTilted Mowa100% (1)

- LIT Era - Module 1Document24 pagesLIT Era - Module 1Kemuel Tabamo100% (1)

- 2019 CLT 2019Document121 pages2019 CLT 2019Sỹ PhạmNo ratings yet

- Safe Use of Power Tools Rev0Document92 pagesSafe Use of Power Tools Rev0mohapatrarajNo ratings yet

- Building: Next One Is Steel Framing, Steel Has Been Used in Construction Since The 19th CenturyDocument4 pagesBuilding: Next One Is Steel Framing, Steel Has Been Used in Construction Since The 19th CenturyGlenn Mendoza100% (1)

- Remoreras - Module 3 ResearchDocument23 pagesRemoreras - Module 3 ResearchChristian RemorerasNo ratings yet

- Prelims Reviewer Biochem LabDocument4 pagesPrelims Reviewer Biochem LabRiah Mae MertoNo ratings yet

- Public Area Attendant ServicingDocument12 pagesPublic Area Attendant ServicingLawrence Cada Nofies100% (2)

- Formwork: Modular Steel Frame Formwork For A FoundationDocument3 pagesFormwork: Modular Steel Frame Formwork For A FoundationKhairul AizatNo ratings yet

- Analysis of Fully Anchored Light-Frame Timber Shear Walls - Plastic ModelDocument12 pagesAnalysis of Fully Anchored Light-Frame Timber Shear Walls - Plastic ModelsirvnNo ratings yet

- As Sing MentDocument5 pagesAs Sing MentTEDNo ratings yet

- Formation of Folded Constructions by Using Contemporary Wooden TrussesDocument8 pagesFormation of Folded Constructions by Using Contemporary Wooden TrussesDesign Cell TODNo ratings yet

- Analysis of Fully Anchored Light-Frame Timber Shear Walls-Elastic ModelDocument12 pagesAnalysis of Fully Anchored Light-Frame Timber Shear Walls-Elastic ModelJoseph BookerNo ratings yet

- Alternative Wood Construction Systems, Pre-Cast & Cast-In-Place ConcreteDocument7 pagesAlternative Wood Construction Systems, Pre-Cast & Cast-In-Place ConcreteRojun AranasNo ratings yet

- Designing Buildings Wiki: Long Span RoofDocument6 pagesDesigning Buildings Wiki: Long Span RoofSonit NemaNo ratings yet

- IndexDocument33 pagesIndexMohammed AmliehNo ratings yet

- Timber Portal Frames Vs TimberDocument8 pagesTimber Portal Frames Vs Timberferlya98angNo ratings yet

- Kallsner (2009) - Analysis of Fully Anchored Light-Frame Timber Shear Walls-Elastic ModelDocument20 pagesKallsner (2009) - Analysis of Fully Anchored Light-Frame Timber Shear Walls-Elastic ModelIonFlorenta100% (1)

- W3 Flooring SystemsDocument21 pagesW3 Flooring SystemsPaul Justine RigorNo ratings yet

- Emag Lounge January 2020Document24 pagesEmag Lounge January 2020Constro FacilitatorNo ratings yet

- Big Box Retail Wood Vs SteelDocument12 pagesBig Box Retail Wood Vs SteelRT1234No ratings yet

- Improvements To Portal Frame Design Using Stressed Skin Action of Sandwich PanelsDocument13 pagesImprovements To Portal Frame Design Using Stressed Skin Action of Sandwich Panelsmehdi_hoseineeNo ratings yet

- Wood ConnectionDocument8 pagesWood ConnectionRyan AbuzoNo ratings yet

- Simplified Modelling of Timber - Framed Walls Under Lateral LoadsDocument10 pagesSimplified Modelling of Timber - Framed Walls Under Lateral LoadsIonFlorentaNo ratings yet

- Framing (Construction)Document9 pagesFraming (Construction)kgato100% (1)

- Economical Reinf Concrete Const - ETN C 1 13Document8 pagesEconomical Reinf Concrete Const - ETN C 1 13MILL3482No ratings yet

- Portal FramesDocument10 pagesPortal FramesManal KhatibNo ratings yet

- The Savill Garden Gridshell Design and ConstructionDocument7 pagesThe Savill Garden Gridshell Design and ConstructionAlex RastyNo ratings yet

- Acadia04 088.contentDocument12 pagesAcadia04 088.contentBleriNo ratings yet

- Topic 8 - Portal Frame Construction - BSR552Document39 pagesTopic 8 - Portal Frame Construction - BSR552NURULFARHANA DAUDNo ratings yet

- General Requirements: Simple Plan Diagram For Single Storey FrameDocument5 pagesGeneral Requirements: Simple Plan Diagram For Single Storey FrameThulasi Raman KowsiganNo ratings yet

- Masonry 9 WEEK 5&6 NewDocument8 pagesMasonry 9 WEEK 5&6 NewMarjohn ElentorioNo ratings yet

- Timber Than Steel Gilham 2009Document4 pagesTimber Than Steel Gilham 2009Oluwaseun AdetayoNo ratings yet

- Tree-Shaped Timber Structural System: An Ecological Way of Designing Spatial StructureDocument7 pagesTree-Shaped Timber Structural System: An Ecological Way of Designing Spatial StructureSaif AshrafNo ratings yet

- Low-Rise Office BuildingDocument108 pagesLow-Rise Office BuildingDenielle Marie PinedaNo ratings yet

- Efficient Nonlinear Modeling of Strong Wood Frame Shear Walls For Mid-Rise BuildingsDocument15 pagesEfficient Nonlinear Modeling of Strong Wood Frame Shear Walls For Mid-Rise BuildingsCristian PNo ratings yet

- 1 Carta VerticalDocument16 pages1 Carta VerticalSebastián BenjamínNo ratings yet

- Timber Folded Plate Structures - Topological and Structural ConsiderationsDocument11 pagesTimber Folded Plate Structures - Topological and Structural ConsiderationsAnonymous IpqcBBNo ratings yet

- Types of Floorings, Walls, Doors, and WindowsDocument20 pagesTypes of Floorings, Walls, Doors, and Windows202340433No ratings yet

- Engineered TimberDocument14 pagesEngineered TimberNaar Muhendislik100% (1)

- MegaStructure - (Fady, Khadiga, Fatma, Farah & Mary)Document88 pagesMegaStructure - (Fady, Khadiga, Fatma, Farah & Mary)marwa1610987No ratings yet

- Elvis and OnitshaDocument21 pagesElvis and OnitshaWilfred NnadiNo ratings yet

- Timber Gridshells - Design Methods and T PDFDocument9 pagesTimber Gridshells - Design Methods and T PDFTani PartnerNo ratings yet

- Design Considerations of Tubular Connections: An Example Through The Singapore Sports Hub National Stadium RoofDocument20 pagesDesign Considerations of Tubular Connections: An Example Through The Singapore Sports Hub National Stadium RoofTed MosbyNo ratings yet

- ConstructionSpecifier Studcast 07Document7 pagesConstructionSpecifier Studcast 07Roberto FernandesNo ratings yet

- Engineer TermsDocument8 pagesEngineer TermsBintang RamadhanNo ratings yet

- Santos-Group8-Written ReportDocument3 pagesSantos-Group8-Written Reportmaddy laneNo ratings yet

- Steelwise Low Floor HeightsDocument2 pagesSteelwise Low Floor Heightsalberto rosadoNo ratings yet

- Sustainable Envelopes With Structural Engineered BambooDocument23 pagesSustainable Envelopes With Structural Engineered BambooJakob UdoNo ratings yet

- Historical Roof Decks - Clay TileDocument7 pagesHistorical Roof Decks - Clay TileMichael SchultzNo ratings yet

- Experimental Study of The Effects of Continuous Rod Hold-Down Anchorages On The Cyclic Response of Wood Frame Shear WallsDocument15 pagesExperimental Study of The Effects of Continuous Rod Hold-Down Anchorages On The Cyclic Response of Wood Frame Shear WallsXavierEstrellaNo ratings yet

- On The Rise: Popularity of Multi-Storey Steel Frame BuildingsDocument2 pagesOn The Rise: Popularity of Multi-Storey Steel Frame BuildingsJaleel Claasen100% (1)

- Facades: 8 8 V V V 2 22 V V V 1 11 V V V 4 44 V V V 3 33Document1 pageFacades: 8 8 V V V 2 22 V V V 1 11 V V V 4 44 V V V 3 33Stefan JakovljevicNo ratings yet

- 1.4 The Social, Cognitive and Experiential: 1.3 The Signi Ficance of Space 11Document1 page1.4 The Social, Cognitive and Experiential: 1.3 The Signi Ficance of Space 11Stefan JakovljevicNo ratings yet

- Chapter ThreeDocument1 pageChapter ThreeStefan JakovljevicNo ratings yet

- Tsukuba, J 1994 Architects: Naito Architects & Ass., Tokyo Hiroshi Naito, Tatsuo Yoshida º Detail 4/1996Document1 pageTsukuba, J 1994 Architects: Naito Architects & Ass., Tokyo Hiroshi Naito, Tatsuo Yoshida º Detail 4/1996Stefan JakovljevicNo ratings yet

- Facades: M Od U L A R Ho Us eDocument1 pageFacades: M Od U L A R Ho Us eStefan JakovljevicNo ratings yet

- Residence and Studio at Gallina Canyon, New Mexico, USA: Built Examples 162Document1 pageResidence and Studio at Gallina Canyon, New Mexico, USA: Built Examples 162Stefan JakovljevicNo ratings yet

- 36.01 Site Plan 1:10000Document1 page36.01 Site Plan 1:10000Stefan JakovljevicNo ratings yet

- Spandrel PanelDocument1 pageSpandrel PanelStefan JakovljevicNo ratings yet

- 34 Becker Architekten Hydroelectric Power Station Kempten, GermanyDocument1 page34 Becker Architekten Hydroelectric Power Station Kempten, GermanyStefan JakovljevicNo ratings yet

- 36 Claus en Kaan Architecten Crematorium Heimolen Sint-Niklaas, BelgiumDocument1 page36 Claus en Kaan Architecten Crematorium Heimolen Sint-Niklaas, BelgiumStefan JakovljevicNo ratings yet

- Designing With Glass - Strength and Loadbearing BehaviourDocument1 pageDesigning With Glass - Strength and Loadbearing BehaviourStefan JakovljevicNo ratings yet

- Shape StackDocument1 pageShape StackStefan JakovljevicNo ratings yet

- 35 Bennetts Associates Mint Hotel Tower of London City of London, UKDocument1 page35 Bennetts Associates Mint Hotel Tower of London City of London, UKStefan JakovljevicNo ratings yet

- Point Fixing Without Penetrating GlassDocument1 pagePoint Fixing Without Penetrating GlassStefan JakovljevicNo ratings yet

- 3.3 Architectural Details Flat Roof JunctionDocument1 page3.3 Architectural Details Flat Roof JunctionStefan JakovljevicNo ratings yet

- Clamping PlateDocument1 pageClamping PlateStefan JakovljevicNo ratings yet

- Profiled GlassDocument1 pageProfiled GlassStefan JakovljevicNo ratings yet

- Clamp FixingDocument1 pageClamp FixingStefan JakovljevicNo ratings yet

- Point Fixing in Drilled HoleDocument1 pagePoint Fixing in Drilled HoleStefan JakovljevicNo ratings yet

- Contact: DurabilityDocument1 pageContact: DurabilityStefan JakovljevicNo ratings yet

- StrengthDocument1 pageStrengthStefan JakovljevicNo ratings yet

- Joint at Unsupported EdgeDocument1 pageJoint at Unsupported EdgeStefan JakovljevicNo ratings yet

- 23Document1 page23Stefan JakovljevicNo ratings yet

- Adhesives For Glass Construction: Eaves Details For Sloping GlazingDocument1 pageAdhesives For Glass Construction: Eaves Details For Sloping GlazingStefan JakovljevicNo ratings yet

- Cleaning and Maintenance Influence On Functional DataDocument1 pageCleaning and Maintenance Influence On Functional DataStefan JakovljevicNo ratings yet

- Setting BlocksDocument1 pageSetting BlocksStefan JakovljevicNo ratings yet

- Panorama Gallery, Mt. Pilatus: Unauthenticated Download Date - 3/25/16 9:34 AMDocument1 pagePanorama Gallery, Mt. Pilatus: Unauthenticated Download Date - 3/25/16 9:34 AMStefan JakovljevicNo ratings yet

- In ContextDocument1 pageIn ContextStefan JakovljevicNo ratings yet

- 3 - 0 - D Copia403mfen 404mfen Smy113840 1Document253 pages3 - 0 - D Copia403mfen 404mfen Smy113840 1Serge MaciaNo ratings yet

- Prishusingh Blogspot Com 2024 03 Digital-Marketing-Course HTMLDocument12 pagesPrishusingh Blogspot Com 2024 03 Digital-Marketing-Course HTMLsudharaj86038No ratings yet

- Triangular Short Crested Weir. Local Geometry ? Discharge CoefficientsDocument7 pagesTriangular Short Crested Weir. Local Geometry ? Discharge CoefficientsTI Journals PublishingNo ratings yet

- Win Darab V7 DatasheetDocument3 pagesWin Darab V7 DatasheetPatrick StivénNo ratings yet

- Prepared by M Suresh Kumar, Chief Manager Faculty, SBILD HYDERABADDocument29 pagesPrepared by M Suresh Kumar, Chief Manager Faculty, SBILD HYDERABADBino JosephNo ratings yet

- Curriculum Vitae: Mobile No: +917019900128 E-MailDocument5 pagesCurriculum Vitae: Mobile No: +917019900128 E-MailJay MNo ratings yet

- 44Document2 pages44menakadevieceNo ratings yet

- Ce-424 PM&CDocument11 pagesCe-424 PM&CAaqib ShoukatNo ratings yet

- AAR Safety Fact SheetDocument2 pagesAAR Safety Fact Sheetrogelio mezaNo ratings yet

- Iraqi Portal of Knowledge and Heritage With Format Edits - 11-21-2023Document6 pagesIraqi Portal of Knowledge and Heritage With Format Edits - 11-21-2023محمد الكربلائيNo ratings yet

- Resume Of: Name: Kingshuk Saha Address: Mobile: E-MailDocument2 pagesResume Of: Name: Kingshuk Saha Address: Mobile: E-MailKingshuk Saha PalasNo ratings yet

- TOS 1st QuarterDocument6 pagesTOS 1st QuarterQuerisa Ingrid MortelNo ratings yet

- UX-driven Heuristics For Every Designer: OutlineDocument7 pagesUX-driven Heuristics For Every Designer: OutlinemuhammadsabirinhadisNo ratings yet

- Data StreamDocument256 pagesData Streamy suresh babuNo ratings yet

- Chapter-Communication & NetworkingDocument70 pagesChapter-Communication & NetworkingAfsar AhmedNo ratings yet

- Tes - 29 October 2021 UserUploadNetDocument120 pagesTes - 29 October 2021 UserUploadNetTran Nhat QuangNo ratings yet

- Fabrication Techniques of A PN Junction DiodeDocument5 pagesFabrication Techniques of A PN Junction DiodeNida Amber100% (3)

- 5EMA BB Dem&Sup VW Bu&Se - 2.35&48&PDDocument13 pages5EMA BB Dem&Sup VW Bu&Se - 2.35&48&PDkashinath09No ratings yet

- Ebook Essentials of Kumar Clarks Clinical Medicine PDF Full Chapter PDFDocument67 pagesEbook Essentials of Kumar Clarks Clinical Medicine PDF Full Chapter PDFjanet.cochran431100% (19)

- Fulltext PDFDocument454 pagesFulltext PDFVirmantas JuoceviciusNo ratings yet