Professional Documents

Culture Documents

Topic 6.0: Quality Cost: Prepared By: Zainal Abidin Bin Ab. Kasim Noor Hapizah Binti Abdullah

Uploaded by

A Lishaaa0 ratings0% found this document useful (0 votes)

5 views12 pagesqcost

Original Title

6

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentqcost

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views12 pagesTopic 6.0: Quality Cost: Prepared By: Zainal Abidin Bin Ab. Kasim Noor Hapizah Binti Abdullah

Uploaded by

A Lishaaaqcost

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

Topic 6.

0 : Quality Cost

Prepared by : Zainal Abidin bin Ab. Kasim

Noor Hapizah binti Abdullah

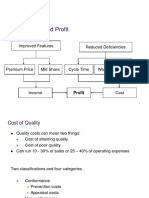

6.1 Quality Cost (general relation)

A product that meets or exceeds its design specifications and

is free of defects that degrade its performance is said to have

high quality of conformance.

Note that if an economy car is free of defects, it can have a

quality of conformance that is just as high as defect-free

luxury car.

The purchasers of economy cars cannot expect their cars to

be as opulently (wealthily) as luxury cars, but they can and

do expect to be free of defects.

6.1 Quality Cost (general reletion)

Quality Cost or Cost of Quality means the costs to

prevent, detect and dealing with defects cause.

Instead the term quality cost refers to all of the costs that are

incurred (earned) to prevent defects or that result from

defects in products.

The use of the term "quality cost" is confusing to some

people. It does not refer to costs such as using a higher grade

leather to make a wallet or using 14K gold instead of gold

plating in jewelry.

6.2 Types of Quality Cost

Quality costs can be broken down into four (4) types.

Two of these groups are known as prevention costs and

appraisal costs.

o These are incurred (acquire) in an effort to keep defective products

from falling into the hands of customers.

The other two groups of costs are known as internal failure

costs and external failure costs.

o Internal and external failure costs are incurred because defects are

produced despite efforts to prevent them therefore these costs are also

known as costs of poor quality.

The quality costs do not just relate to just manufacturing; rather,

they relate to all the activities in a company from initial research

and development (R & D) through customer service

6.2.1 Prevention Costs

Generally the most effective way to manage quality costs is

to avoid having defects in the first place.

It is much less costly to prevent a problem from ever

happening than it is to find and correct the problem after it

has occurred.

Prevention costs support activities whose purpose is to

reduce the number of defects.

Companies employ many techniques to prevent defects for

example statistical process control, quality engineering,

training, and a variety of tools from total quality

management (TQM).

6.2.1 Prevention Costs

Prevention costs include activities relating to quality control circles

and statistical process control.

Quality Control Circles consist of small groups of employees

that meet on a regular basis to discuss ways to improve quality.

Both management and workers are included in these circles.

Statistical process control is a technique that is used to detect

whether a process is in or out of control.

An out of control process results in defective units and may be caused

by a miscalibrated machine or some other factor.

Workers use charts to monitor the quality of units that pass through

their workstations. With these charts, workers can quickly spot

processes that are out of control and that are creating defects.

Problems can be immediately corrected and further defects prevented

rather than waiting for an inspector to catch the defect later.

6.2.2 Appraisal Costs

Sometimes called inspection costs, are incurred to identify

defective products before the products are shipped to

customers.

Any defective parts and products should be caught as early as

possible in the production process.

Unfortunately performing appraisal activates doesn't keep

defects from happening again and most managers realize now

that maintaining an army of inspectors is a costly and

ineffective approach to quality control.

6.2.3 Internal failure Costs

Failure costs are incurred when a product fails to conform to its

design specifications.

Failure costs can be either internal or external. Internal failure

costs result from identification of defects before they are shipped

to customers.

These costs include scrap, rejected products, reworking of

defective units, and downtime caused by quality problem.

The more effective a company's appraisal activities the greater the

chance of catching defects internally and the greater the level of

internal failure costs. This is the price that is paid to avoid

incurring external failure costs, which can be upsetting.

6.2.4 External Failure Costs

When a defective product is delivered to customer, external

failure cost is the result.

External failure costs include warranty, repairs and

replacements, product recalls, liability arising from legal

actions against a company, and lost sales arising from a

reputation for poor quality. Such costs can decimate profits.

In the past, some managers have taken the attitude, "Let's go

ahead and ship everything to customers, and we'll take care

of any problems under the warranty." This attitude generally

results in high external failure costs, customer ill will, and

declining market share and profits.

6.2.4 External Failure Costs

External failure costs usually give rise to another intangible

cost. These intangible costs are hidden costs that involve the

company's image. They can be three or four times greater

than tangible costs. Missing a deadline or other quality

problems can be intangible costs of quality.

Internal failure costs, external failure costs and intangible

costs that make worse the goodwill of the company occur

due to a poor quality so these costs are also known as costs

of poor quality by some persons.

Example of Quality Cost

6.2.1 Prevention Costs 6.2.2 Appraisal Costs

Systems development Test and inspection of incoming

Quality engineering materials

Quality training Test and inspection of in-process

goods

Quality circles

Final product testing and inspection

statistical process control

Supplies used in testing and

Supervision of prevention activities inspection

Quality data gathering, analysis, and Supervision of testing and inspection

reporting activities

Quality improvement projects Depreciation of test equipment

Technical support provided to

Maintenance of test equipment

suppliers

Plant utilities in the inspection area

Audits of the effectiveness of the

quality system Field testing and appraisal at

customer site

Example of Quality Cost

6.2.4 External Failure

6.2.3 Internal failure Costs

Costs

Net cost of scrap Cost of field servicing and handling

Net cost of spoilage complaints

Rework labor and overhead

Re-inspection of reworked products Warranty repairs and replacements

Retesting of reworked products Repairs and replacements beyond

Downtime caused by quality problems the warranty period

Disposal of defective products Product recalls

Analysis of the cause of defects in

production Liability arising from defective

Re-entering data because of keying products

errors Returns and allowances arising

Debugging software errors from quality problems

Lost sales arising from a reputation

for poor quality.

You might also like

- Quality Toolkit For Managers PDFDocument38 pagesQuality Toolkit For Managers PDFMBA EngineerNo ratings yet

- Quality Costing - Cost AccountingDocument20 pagesQuality Costing - Cost AccountingMd. Ruhul- AminNo ratings yet

- Gerson Lehrman GroupDocument1 pageGerson Lehrman GroupEla ElaNo ratings yet

- Enochian Tablets ComparedDocument23 pagesEnochian Tablets ComparedAnonymous FmnWvIDj100% (7)

- Unit I Quality Control and Reliability Engineering IP 33502Document4 pagesUnit I Quality Control and Reliability Engineering IP 33502Nishika chopraNo ratings yet

- Are The Costs of Performing Control ActivitiesDocument2 pagesAre The Costs of Performing Control ActivitiesLee Jeon KimNo ratings yet

- Cause-And-Effect Diagram: Why Implement Cost of Quality (COQ) ?Document3 pagesCause-And-Effect Diagram: Why Implement Cost of Quality (COQ) ?Doren Joy BatucanNo ratings yet

- Quality CostsDocument3 pagesQuality CostsNupur WalawalkarNo ratings yet

- Quality Costing: Priya Tiku Roll-No-25 Mba-Gen-B Sem IDocument23 pagesQuality Costing: Priya Tiku Roll-No-25 Mba-Gen-B Sem IPriya Tiku KoulNo ratings yet

- Quality CostDocument9 pagesQuality CostShanky JainNo ratings yet

- Quality Management - ShahnawazDocument16 pagesQuality Management - ShahnawazShahnawaz ShaikhNo ratings yet

- Cost of Quality FailureDocument5 pagesCost of Quality FailureTheshi VigianNo ratings yet

- Software Quality AssuranceDocument30 pagesSoftware Quality AssuranceSYED SUMAIR AHMED JAFFRINo ratings yet

- Cost of PreventionDocument2 pagesCost of PreventionhariNo ratings yet

- Quality, Time, and TheDocument25 pagesQuality, Time, and Thesoum1111No ratings yet

- Quality Quality Tools - ShowDocument71 pagesQuality Quality Tools - ShowAbhijeet RandhirNo ratings yet

- Quality CostingDocument5 pagesQuality Costingvishi-takhar-281No ratings yet

- Cost of QualityDocument33 pagesCost of QualityImran AnwarNo ratings yet

- Quality Costs PDFDocument9 pagesQuality Costs PDFYvonne Barton100% (1)

- Cost of QDocument6 pagesCost of QManisha Bansal PaulNo ratings yet

- 12 Steps To Implementing A Quality Management SystemDocument18 pages12 Steps To Implementing A Quality Management Systempatricia navasNo ratings yet

- COPQDocument8 pagesCOPQJocelyn Garcia100% (1)

- CsqaDocument79 pagesCsqabipinbadheNo ratings yet

- 05-Target Costing and TQM - 2021Document28 pages05-Target Costing and TQM - 2021MiclczeeNo ratings yet

- Cost of QualityDocument7 pagesCost of QualityLepokkumzuk JamirNo ratings yet

- The Cost of QualityDocument20 pagesThe Cost of QualityMariesz PleytoNo ratings yet

- Cost of Quality - Session3Document27 pagesCost of Quality - Session3Ritu RajNo ratings yet

- Cost of Poor QualityDocument3 pagesCost of Poor QualityrajaNo ratings yet

- Cost of Quality PDFDocument33 pagesCost of Quality PDFAlvin DimasacatNo ratings yet

- Assignment 2-Cost of QualityDocument3 pagesAssignment 2-Cost of QualitySayma LinaNo ratings yet

- t2 Quality Environmental Cost Management Student Sem 2 1718Document12 pagest2 Quality Environmental Cost Management Student Sem 2 1718hunney93No ratings yet

- Managing Quality: Operations Management R. Dan Reid & Nada R. SandersDocument24 pagesManaging Quality: Operations Management R. Dan Reid & Nada R. SandersFaisal KhanNo ratings yet

- Chapter 5 - Quality CostDocument16 pagesChapter 5 - Quality CostDM RodNo ratings yet

- Cost of QualityDocument22 pagesCost of QualityPreetham Vincent Lobo100% (1)

- Cost of QualityDocument20 pagesCost of QualityPankaj JunejaNo ratings yet

- Construction Methods and Managenent: Assignment-IDocument8 pagesConstruction Methods and Managenent: Assignment-INiroj MaharjanNo ratings yet

- Appraisal Costs Are Necessary Costs To The Success of A CompanyDocument9 pagesAppraisal Costs Are Necessary Costs To The Success of A CompanyIffatNo ratings yet

- Cost of QualityDocument33 pagesCost of QualitydrrajputNo ratings yet

- Various Cost of QualityDocument36 pagesVarious Cost of Qualityiqac.ncbNo ratings yet

- Total Quality Management: Goal 2Document34 pagesTotal Quality Management: Goal 2Samuel ReddyNo ratings yet

- Terotechnology SummaryDocument9 pagesTerotechnology SummaryWichard BendixNo ratings yet

- Cost of QualityDocument10 pagesCost of QualityJagadish M Alokh GowdaNo ratings yet

- Quality Control & Quality AssuranceDocument75 pagesQuality Control & Quality Assurancemuhammad omerNo ratings yet

- Cost of QualityDocument1 pageCost of QualityanasNo ratings yet

- CH 2Document18 pagesCH 2suresh84123No ratings yet

- Operation Management: CHAPTER 1: Introduction To Total Quality ManagementDocument24 pagesOperation Management: CHAPTER 1: Introduction To Total Quality ManagementRica CalderonNo ratings yet

- Cost of QualityDocument18 pagesCost of QualityMadhupam BansalNo ratings yet

- Project Management: Tadele MDocument27 pagesProject Management: Tadele MAmanuel GebreNo ratings yet

- Lecture 6 - Project Quality ManagementDocument29 pagesLecture 6 - Project Quality ManagementZain GhummanNo ratings yet

- 5 CopqDocument20 pages5 CopqGULSSHAN NARRANGNo ratings yet

- Total Quality Management and Just-In-Time Production SystemDocument30 pagesTotal Quality Management and Just-In-Time Production SystemJannibee EstreraNo ratings yet

- Cost of QualityDocument43 pagesCost of QualityDhinakaranNo ratings yet

- Productivity - UNIT-3-4 NotesDocument8 pagesProductivity - UNIT-3-4 NotesMelyn Rose CabarlesNo ratings yet

- Cost of Quality: Quality Costs and ProfitDocument5 pagesCost of Quality: Quality Costs and ProfitrahulNo ratings yet

- CH 1-Overview of QualtiyDocument41 pagesCH 1-Overview of Qualtiyadabotor7No ratings yet

- Lesson 2 Total Quality ManagementDocument4 pagesLesson 2 Total Quality Managementsatriajea.faustino.eNo ratings yet

- Unit-Iii: Quality Control and Materials ManagementDocument39 pagesUnit-Iii: Quality Control and Materials ManagementLAKKANABOINA LAKSHMANARAONo ratings yet

- Quality Costs TQM Written ReportDocument19 pagesQuality Costs TQM Written ReportMarie Lyne AlanoNo ratings yet

- Lean Supply Chain Origins 1Document3 pagesLean Supply Chain Origins 1KeviiiNo ratings yet

- 4-Quality ControlDocument75 pages4-Quality ControlVipin K HariNo ratings yet

- Topic 1.0 Statistics QCDocument29 pagesTopic 1.0 Statistics QCA LishaaaNo ratings yet

- 8.0 Iso SeriesDocument8 pages8.0 Iso SeriesA LishaaaNo ratings yet

- 8.0 Iso SeriesDocument8 pages8.0 Iso SeriesA LishaaaNo ratings yet

- Topic 4.0-Control Chart For AttributesDocument22 pagesTopic 4.0-Control Chart For AttributesA LishaaaNo ratings yet

- JF608: Quality Control: Prepared By: Zainal Abidin Bin Ab Kasim Noor Hapizah Binti AbdullahDocument31 pagesJF608: Quality Control: Prepared By: Zainal Abidin Bin Ab Kasim Noor Hapizah Binti AbdullahA LishaaaNo ratings yet

- NAMAAADocument1 pageNAMAAAA LishaaaNo ratings yet

- EZ 220 Songbook Web PDFDocument152 pagesEZ 220 Songbook Web PDFOscar SpiritNo ratings yet

- Truck Driver Contract AgreementDocument17 pagesTruck Driver Contract AgreementMaacahNo ratings yet

- Advanced Stock Trading Course + Strategies Course CatalogDocument5 pagesAdvanced Stock Trading Course + Strategies Course Catalogmytemp_01No ratings yet

- Appointment Letter 17may2022Document6 pagesAppointment Letter 17may2022Gaurav ChoudharyNo ratings yet

- Book History Patton U of U - History - The Murder of General PattonDocument5 pagesBook History Patton U of U - History - The Murder of General PattonKevin CareyNo ratings yet

- Viking Solid Cone Spray NozzleDocument13 pagesViking Solid Cone Spray NozzlebalaNo ratings yet

- Schedules of Shared Day Companies - MITCOEDocument1 pageSchedules of Shared Day Companies - MITCOEKalpak ShahaneNo ratings yet

- Philippine Phoenix Surety vs. WoodworksDocument1 pagePhilippine Phoenix Surety vs. WoodworksSimon James SemillaNo ratings yet

- FINAL-Ordinance B.tech - 1Document12 pagesFINAL-Ordinance B.tech - 1Utkarsh PathakNo ratings yet

- AssignmentDocument25 pagesAssignmentPrashan Shaalin FernandoNo ratings yet

- SOL 051 Requirements For Pilot Transfer Arrangements - Rev.1 PDFDocument23 pagesSOL 051 Requirements For Pilot Transfer Arrangements - Rev.1 PDFVembu RajNo ratings yet

- Nursing Leadership Philosophy PaperDocument6 pagesNursing Leadership Philosophy Paperapi-355764752100% (1)

- Lesson Plan - PovertyDocument4 pagesLesson Plan - Povertyapi-315995277No ratings yet

- CMSPCOR02T Final Question Paper 2022Document2 pagesCMSPCOR02T Final Question Paper 2022DeepNo ratings yet

- My Portfolio: Marie Antonette S. NicdaoDocument10 pagesMy Portfolio: Marie Antonette S. NicdaoLexelyn Pagara RivaNo ratings yet

- Stalin Guided NotesDocument2 pagesStalin Guided Notesapi-536892868No ratings yet

- Adobe Scan 04 Feb 2024Document1 pageAdobe Scan 04 Feb 2024biswajitrout13112003No ratings yet

- BorgWarner v. Pierburg Et. Al.Document9 pagesBorgWarner v. Pierburg Et. Al.PriorSmartNo ratings yet

- Test Bank: Corporate RestructuringDocument3 pagesTest Bank: Corporate RestructuringYoukayzeeNo ratings yet

- Romantic Criticism of Shakespearen DramaDocument202 pagesRomantic Criticism of Shakespearen DramaRafael EscobarNo ratings yet

- Greek Gods & Goddesses (Gods & Goddesses of Mythology) PDFDocument132 pagesGreek Gods & Goddesses (Gods & Goddesses of Mythology) PDFgie cadusaleNo ratings yet

- Personal Data Breach Notifications in The GDPRDocument17 pagesPersonal Data Breach Notifications in The GDPRgschandel3356No ratings yet

- Problem Set 9Document2 pagesProblem Set 9Siham BuuleNo ratings yet

- 2020 HGDG Pimme Checklist 16Document2 pages2020 HGDG Pimme Checklist 16Kate MoncadaNo ratings yet

- Web DesignDocument2 pagesWeb DesignCSETUBENo ratings yet

- Parent Leaflet Child Death Review v2Document24 pagesParent Leaflet Child Death Review v2InJailOutSoonNo ratings yet

- Grand Boulevard Hotel Vs Genuine Labor OrganizationDocument2 pagesGrand Boulevard Hotel Vs Genuine Labor OrganizationCuddlyNo ratings yet

- LAW REFORMS COMMISSION KERALA Final Report Vol IDocument211 pagesLAW REFORMS COMMISSION KERALA Final Report Vol ISampath BulusuNo ratings yet