Professional Documents

Culture Documents

Ideal Pure Shear Strength of Aluminum and Copper: Science October 2002

Uploaded by

Santosa Edy WibowoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ideal Pure Shear Strength of Aluminum and Copper: Science October 2002

Uploaded by

Santosa Edy WibowoCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/11063284

Ideal Pure Shear Strength of Aluminum and Copper

Article in Science · October 2002

DOI: 10.1126/science.1076652 · Source: PubMed

CITATIONS READS

465 1,132

3 authors, including:

Shigenobu Ogata Ju Li

Osaka University Oregon Health and Science University

256 PUBLICATIONS 3,418 CITATIONS 375 PUBLICATIONS 19,554 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Mechanics of energy materials View project

mechanics of nanowires View project

All content following this page was uploaded by Shigenobu Ogata on 03 May 2014.

The user has requested enhancement of the downloaded file.

REPORTS

have a much smaller size than the cooling 5. R. Maezono, S. lshihara, N. Nagaosa, Phys. Rev. B 58, room temperature to TP1, all the images are uniform,

11583 (1998). and from low temperature to TK2 during warming,

images at the same temperatures below TK1.

6. A. Asamitsu, Y. Moritomo, Y. Tomioka, T. Arima, Y. both the size and the contrast of the images are

This difference may be due to the way in Tokura, Nature 373, 407 (1995). nearly unchanged. To maintain the consistency be-

which the sample is cooled. The tip of the 7. C. Martin et al., Eur. Phys. J. B 16, 469 (2000). tween the resistivity hysteresis and the micromag-

MFM vibrates above the sample surface at 8. M. Uehara, S. Mori, C. H. Chen, S. W. Cheong, Nature netic hysteresis, we have simply reproduced the three

399, 560 (1999). highest temperature images in Fig. 1A and the three

the lever’s resonant frequency of 110 KHz, 9. M. B. Salamon, M. Jaime, Rev. Mod. Phys. 73, 583 (2001). lowest temperature images in Fig. 1C.

contacting the sample at the lowest point of 10. N. D. Mathur, P. B. Littlewood, Solid State Commun. 20. P. Levy et al., Phys. Rev. B 65, 140401 (2002).

each oscillation. At this contact point, the 119, 271 (2001). 21. L. Kong, S. Y. Chou, Appl. Phys. Lett. 70, 2043 (1997).

11. C. W. Yuan, E. Batalla, A. de Lozanne, M. Kirk, M. 22. F. Parisi, P. Levy, L. Ghivelder, G. Polla, D. Vega, Phys.

magnetic field applied by the tip is large (102 Tortonese, Appl. Phys. Lett. 65, 1308 (1994). Rev. B 63, 144419 (2001).

to 103 G) (21). Roughly, as the tip is scanned, 12. Q. Lu, C. Chen, A. de Lozanne, Science 276, 2006 23. A. Urushibara et al., Phys. Rev. B 51, 14103 (1995).

a strong periodic magnetic pulse with a fre- (1997). 24. Y.-A. Soh, G. Aeppli, N. D. Mathur, M. G. Blamire,

13. Materials and methods are available as supporting

㛬㛬㛬㛬

quency of 110 KHz is scanned over the sam- Phys. Rev. B 63, 020402 (2000).

material on Science Online. 25. , J. Appl. Phys. 87, 6743 (2000).

ple. We believe that upon cooling, although 14. Park Scientific Instruments (now Veeco Instruments), 26. M. Fäth et al., Science 285, 1540 (1999).

this scanning high-frequency localized mag- Santa Barbara, CA. 27. The work at Austin was supported by NSF grant

netic pulse may not change the relative FM 15. R. Desfeux, S. Bailleul, A. Da Costa, W. Prellier, A. M. DMA-0072834 and The Texas Center for Supercon-

Haghiri-Gosnet, Appl. Phys. Lett. 78, 3681 (2001). ductivity at the University of Houston. The work at

fraction (22), it can partially align the mag- 16. We recorded another set of cooling and warming Maryland was supported in part by NSF grant

netization of the domains and drive the mo- images using a temperature change rate of 0.3 K/min. MRSEC-00-80008. We thank S.-W. Cheong, N. D.

tion of the domain walls, leading to the merg- The temperature-dependent evolution of the FM do- Mathur, A. Guha, Q. Niu, Y. Tsui, and J. Lee for fruitful

mains is qualitatively the same as that of the sets discussions and T. Ruiter (Veeco Metrology Group)

ing and enlargement of the domains. On the shown in the text. We believe that our observation is for providing piezoresistive cantilevers.

other hand, the warming images were ob- largely due to the temperature change and not time

tained after the sample was cooled to the relaxation. Supporting Online Material

17. V. Podzorov, B. G. Kim, V. Kiryukhin, M. E. Gershen- www.sciencemag.org/cgi/content/full/1077346/DC1

lowest temperature in a magnetic field of 25 son, S.-W. Cheong, Phys. Rev. B 64, 140406 (2001). Materials and Methods

G. During this cooling process, the tip is far 18. A. Biswas et al., Phys. Rev. B 61, 9665 (2000). Movies S1 to S4

away from the sample. This cooling field 19. We emphasize that all of our sets of cooling and

warming images obtained on different areas of the 14 August 2002; accepted 9 September 2002

may not be strong enough to move the do- Published online 19 September 2002;

sample with different noncontact piezolevers show

main walls. When scanning during warming, the same temperature-dependent evolution of do- 10.1126/science.1077346

the domain walls are strongly pinned. As a mains. As described in the text, during cooling from Include this information when citing this paper.

result, the shape of the domains is unchanged.

As TP2 is approached, the average magneti-

zation decreases, which results in a rise in the

resistivity (Fig. 1B) (23). Our observations

Ideal Pure Shear Strength of

indicate that during cooling, the percolation

of the FM domains causes the steep resistiv-

Aluminum and Copper

ity drop, whereas during warming, the FM Shigenobu Ogata,1,2,3 Ju Li,1,4 Sidney Yip1*

conductive paths remain until near TP2, but

the decrease in the average magnetization

leads to the jump in resistivity. This also may Although aluminum has a smaller modulus in {111}具112 典 shear than that of

explain why the knee in the resistivity is copper, we find by first-principles calculation that its ideal shear strength is

sharper during cooling than during warming. larger because of a more extended deformation range before softening. This

Below TK1 the enlargement of the domains fundamental behavior, along with an abnormally high intrinsic stacking fault

is mainly due to the merging of the domains, energy and a different orientation dependence on pressure hardening, are

and not to the increase of the FM volume traced to the directional nature of its bonding. By a comparative analysis of ion

fraction. Therefore, the resistivity changes relaxations and valence charge redistributions in aluminum and copper, we

slowly below TK1, as shown in Fig. 1B. arrive at contrasting descriptions of bonding characteristics in these two metals

Even well above TP2, there is still a slight but that can explain their relative strength and deformation behavior.

discernable contrast in some areas, which can be

more clearly seen in the supplemental movies. The minimum shear stress necessary to cause lations therefore would have important impli-

We propose that this is due to the magnetic permanent deformation in a material without cations for the understanding of the behavior

inhomogeneity above TP that is frequently ob- imperfections is fundamental to our concept of solids at the limit of structural stability.

served in similar CMR materials (24–26). of materials strength and its theoretical limits Results on stress-strain behavior of Al and Cu

Owing to the constraining effect of the under large strains (1, 2). With the possible in {111}具112 典 shear, calculated with density

substrate, some effects observed in bulk sam- exception of recent nanoindentation measure- functional theory (DFT) and accounting for

ples may be suppressed or different for these ments (3), it has not been feasible to directly full atomic relaxation, have been reported

thin films (17). This might account for the measure the ideal shear strength of crystals. (4), where Cu was found to have a higher

sharper transitions in the thin films and the The demonstration that this property can be ideal shear strength than that of Al. Using

narrower hysteresis regions. This implies that reliably determined by first-principles calcu- various DFT methods and systematically

the temperature-dependent magnetic micro- cross-checking the results, we further inves-

structure in thin films may be modified due to 1

Department of Nuclear Engineering, Massachusetts tigated the shear strength and deformation of

the effect of the substrate. Institute of Technology, Cambridge, MA 02139, USA. Al and Cu and found instead that Al has the

2

Department of Mechanical Engineering and Systems, higher strength. Here, we report and substan-

3

Handai Frontier Research Center, Osaka University,

References and Notes Osaka 565– 0871, Japan. 4Department of Materials

tiate our findings by detailing the energetics

1. R. von Helmot, J. Wecker, B. Hopzapfel, L. Schulz, K. Science and Engineering, Ohio State University, Co- of shear deformation, the pressure-hardening

Samwer, Phys. Rev. Lett. 71, 2331 (1993). lumbus, OH 43210, USA. behavior, and valence charge redistribution

2. S. Jin et al., Science 264, 413 (1994).

3. C. Zener, Phys. Rev. 82, 403 (1951). *To whom correspondence should be addressed. E- during deformation. These considerations

4. A. J. Millis, Nature 392, 147 (1998). mail: syip@mit.edu show that the ideal shear strength and related

www.sciencemag.org SCIENCE VOL 298 25 OCTOBER 2002 807

REPORTS

properties such as stacking fault energies of constant). The unstable stacking energy ␥us, four other packages, Vienna ab Initio Simu-

Al and Cu can be accurately calculated and an important parameter in determining the lation Package (VASP) (7, 8), Cambridge

that the results can be rationalized by the ductility of the material (6), is ␥1(x0), where Serial Total Energy Package (CASTEP) (9),

underlying electronic structure. We suggest d␥1/dx(x0 ⬍ bp) ⫽ 0. It is instructive to WIEN2k (10), and ABINIT (11), with differ-

that bonding in Al is much more like a compare different ␥n(x) of the same slip sys- ent setups used to cross-check each other.

“hinged rod,” and we emphasize the impor- tem as n varies. The difference should be The results reported here are primarily those

tance of the breaking and reformation of di- relatively small from a local “glue” (shaded obtained from VASP with Perdew-Wang

rectional bonds as compared to the isotropic region in Fig. 1A) viewpoint where we take (PW91) generalized gradient approximation

“sphere-in-glue”–like behavior in Cu. the valence electron cloud to be the glue. We (GGA) exchange-correlation density func-

The intrinsic stacking fault energy, a mea- also have the asymptotic behavior at large n tional (12), ultrasoft (US) pseudopotential

sure of the energy penalty when two adjacent 2␥ twin共 x兲 (8), and Methfessel-Paxton smearing method

atomic planes in a crystal lattice are sheared ␥ n 共 x兲 ⫽ ␥ ⬁ 共 x兲 ⫹ ⫹ 共n⫺ 2 兲 (13) with 0.3-eV smearing width, and the cell

n

relative to each other, is known to play an being oriented as in Fig. 1A. The cutoff

important role in the structure and energetics (2) energies for the plane wave basis set for Al

of dislocations formed by slip processes. Al- where ␥twin(bp) is the unrelaxed twin and Cu are 162 and 292 eV, respectively.

though it is known experimentally that the boundary energy. The rate of convergence Table 1 shows the agreement of our results

intrinsic stacking fault energy is much larger to Eq. 2 reflects the localization range of with experimental and other calculations. To

in Al than in Cu, this finding has not been metallic bonding in a highly deformed bulk compute the equilibrium lattice constant a0,

related to their ideal shear strengths. For this environment. as well as relaxed and unrelaxed {111}具112 典

purpose, we introduce a general function The DFT calculations, following the same shear moduli (Gr⬘ and Gu⬘, respectively) (4),

(Fig. 1A) procedure previously described (4), were per- we use a six-atom supercell of three {111}

E n 共 x兲 formed with our own plane wave code and layers. After relaxation, all stress components

␥ n 共 x兲 § , n ⫽ 1, 2, ... (1)

nS 0

where x is the relative displacement in the Table 1. Benchmark results, comparison of present calculations (Calc), experiments (Expt), and previous

slip direction between two adjacent atomic calculations (Oth calc). Dashes indicate that results are not available.

planes (we focus on {111}具112 典 slip here),

Al Cu

En(x) is the increase in total energy relative to

Variable

its value at x ⫽ 0, with n ⫹ 1 being the Calc* Expt Oth calc Calc* Expt Oth calc

number of planes involved in the shearing

and S0 being the cross-sectional area at x ⫽ 0. a0 (Å) 4.04 4.03† 4.04‡ 3.64 3.62† 3.64§

The series of functions ␥1(x), ␥2(x), . . ., Gr⬘ (GPa) 25.4 27.4㛳 19 –25¶ 31.0 33.3㛳 26 –34¶

␥⬁(x) may be called the multiplane general- Gu⬘ (GPa) 25.4 27.6㛳 24 –30¶ 40.9 44.4㛳 36 – 44¶

␥sf (mJ/m2 ) 158 166# 143**, 39 45# (49)‡‡

ized stacking fault energy, with ␥1(x) being 164††

the conventional generalized stacking fault ␥us (mJ/m2 ) 175 — 183**, 158 — (210)‡‡

energy (GSF) (5) and ␥⬁(x) being the affine 224††

strain energy. The intrinsic stacking fault en-

*VASP, US-GGA, 18 ⫻ 25 ⫻ 11 Monkhorst-Pack kជ points. †(25) Al at temperature T ⫽ 0 K, Cu at T ⫽ 298 K.

ergy ␥sf is ␥1(bp), where bជ p ⫽ [112 ]a0/6 is the ‡(26) GGA. §(27) Full-potential linearized augmented plane wave method ( WIEN97 program), GGA. 㛳(28) calculat-

partial Burgers vector (a0, equilibrium lattice ed from elastic constants at T ⫽ 0 K. ¶(4) LDA. #(29). **(30) LDA. ††(31) LDA. ‡‡(5) LDA, unrelaxed.

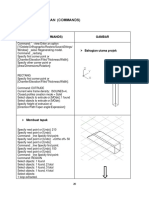

Fig. 1. (A) Multiplane

generalized stacking

fault energy: n ⫽ 1, 2,

. . . , ⬁. (B) Pure shear

stress–displacement re-

sponses of Al (solid

squares) and Cu (open

squares) and (C) ion re-

laxation patterns in Al

and Cu. (D) Simple

shear stress–displace-

ment curves d␥⬁(x)/dx

(squares) compared to

d␥1(x)/dx (circles) in Al

(solid symbols) and Cu

(open symbols).

808 25 OCTOBER 2002 VOL 298 SCIENCE www.sciencemag.org

REPORTS

other than 13 (⫽31) are reduced to ⬍0.1 the scalar-relativistic approximation, respec- pand and contract in the y and x directions,

GPa. For the intrinsic and unstable stacking tively (10). Furthermore, the full-potential respectively.

energies ␥sf and ␥us, respectively, we use a projector augmented-wave (PAW) method The difference in relaxation patterns has

24-atom supercell of 12 layers for Al (10 (16) and the local density approximation important implications for the shear strength–

layers for Cu) with layers 1 and 12 facing (LDA) options of VASP also have been in- hardening behavior (Table 3), which also has

vacuum and shearing between layers 6 and 7. cluded in the cross-check. The difference be- been noted and discussed in terms of third-order

Relaxation of all layers along the ⬍111⬎ tween US and PAW is ⬍5% in the maximum elastic constant (18). When pressurized in the

direction is terminated when the force on stress values, and LDA consistently gives a 具110典 direction, Cu hardens, whereas Al softens

each atom is ⬍0.01 eV/Å. Al has a much stress that is 10 to 20% higher than that of substantially; however, if pressurized in the

larger ␥sf value than that of Cu, yet their ␥us GGA. With all methods used, Al is found to 具111典 direction, Al hardens substantially,

values are quite close. have ideal simple shear and pure shear whereas Cu softens slightly. These results show

For affine deformation calculations, we strengths that are higher than those of Cu that the pressure-hardening effect is highly de-

consider pure shear (ij ⫽ 0, except 13) and (Table 2) (17). pendent on orientation. A rough estimate of the

simple shear (x ⫽ 0 with no relaxations). The At equilibrium, Cu is considerably stiffer stress state at the displacement burst observed

corresponding stress-displacement curves are than Al; its bulk, simple, and pure shear in nanoindentation experiments (3) shows that

shown in Fig. 1, B and D, respectively. The (along {111}具112 典) moduli are greater than the pressure components are at the level indi-

stress values are obtained from analytical ex- those of Al by 80, 65, and 25%, respectively. cated in Table 3. Thus, a large effect on the

pressions; they have been checked against However, Al has an ideal pure shear strength shear strength is to be expected. However, be-

numerical energy derivatives at several val- that is 32% larger than that of Cu because it cause the actual stress state is a complicated

ues of strain. After analyzing the effects of has a longer range of elastic strain before triaxial condition and given that the pressure-

smearing width, energy cutoff, and Brillouin softening (Fig. 1B): xmax/bp ⫽ 0.28 or hardening behavior is very anisotropic, one

zone integration kជ-point convergence, we es- ␥max ⫽ 0.20 in Al, which are the displace- cannot ascertain its real effect without an accu-

timate that the maximum stress values in ment and the engineering shear strain at the rate stress analysis. For this purpose, we apply

Table 2 have an uncertainty of ⬍0.1 GPa maximum shear stress, respectively, versus a method combining atomistic and finite-ele-

within each method used. ABINIT uses the xmax/bp ⫽ 0.19 or ␥max ⫽ 0.13 in Cu. The ion ment calculations (19).

Perdew-Burke-Ernzerhof GGA functional relaxations in these two metals are different Because Al has no core d states, its par-

(14) and norm-conserving Troullier-Martins (Fig. 1C). In Al, when the top atom slides tially occupied valence d bands are abnormal-

(TM) pseudopotential (15); CASTEP uses over the bottom atoms, the top atom hops in ly low in energy, which gives rise to direc-

PW91-GGA/US; our own plane wave code the z direction, and the bottom atoms contract tional bonding. At the six-atom interstice in

uses PW91-GGA/TM; and WIEN2k is a full- in the y direction (relaxation in x is almost Al, the pocket of charge density has cubic

potential augmented plane wave plus local zero). In Cu, there is almost no relaxation in symmetry and is very angular in shape, with

orbitals method, where the core and valence the z direction; the top atom translates essen- a volume comparable to the pocket centered

states are treated by the Dirac equation and tially horizontally, and the bottom atoms ex- on every ion (Fig. 2A). In Cu, there is no such

Fig. 2. Charge-density isosurface in (A) Al and (B) Cu and ⌬[(r, x)Vcell(x)]

(compared to a perfect crystal) along path a-b-c (, normalized path length

variable) during pure shear in (C) Al and (D) Cu. The figure shows

box-shaped extra charges in interstice volumes and their active evolutions

in Al, but not in Cu. The r max arrows point to positions of maximum

(r)Vcell along a-b-c at x ⫽ 0, indicating the size of the “atomic spheres”

centered at a, b, and c.

www.sciencemag.org SCIENCE VOL 298 25 OCTOBER 2002 809

REPORTS

Table 2. Ideal simple shear and pure shear strengths ( and , respectively).

u r

Table 3. Maximum shear stress under external

loading. P, hydrostatic pressure; yy and zz, nor-

Al Cu mal stress in the y and z directions, respectively.

Code

(number of kជ points)

u (GPa) r (GPa) u (GPa) r (GPa) External stress Al (GPa) Cu (GPa)

VASP (12 ⫻ 17 ⫻ 7) 3.67* 2.76* 3.42 2.16 P ⫽ 0 (GPa) 2.84 2.16

VASP (18 ⫻ 25 ⫻ 11) 3.73 2.84 3.44† 2.15† P ⫽ 10 (GPa) 4.49 2.46

VASP (21 ⫻ 28 ⫻ 12) — — 3.45† 2.15† P ⫽ 20 (GPa) 5.90 2.84

VASP (27 ⫻ 38 ⫻ 16) 3.71* 2.84* — — yy ⫽ ⫺10 (GPa) 1.78 3.12

CASTEP (13 ⫻ 22 ⫻ 9) — — 3.22† 2.10† yy ⫽ ⫺20 (GPa) 1.41 3.54

CASTEP (17 ⫻ 29 ⫻ 12) 3.73* 2.84* — — zz ⫽ ⫺3 (GPa) 3.64 2.03

WIEN2k (38 ⫻ 33 ⫻ 38)‡ 3.83* 2.98* 3.61† 2.23† zz ⫽ yy ⫽ ⫺10 (GPa) 3.98 4.38

ABINIT (12 ⫻ 17 ⫻ 7) 3.68* 2.84§ — — zz ⫽ yy ⫽ ⫺20 (GPa) 5.26 6.52

ABINIT (18 ⫻ 25 ⫻ 11) 3.71* 2.90* — —

Own code (12 ⫻ 17 ⫻ 7) 3.73* 2.89* 3.48† 2.18†

*Cell dimension from VASP (18 ⫻ 25 ⫻ 11) calculations. †Cell dimension from VASP (12 ⫻ 17 ⫻ 7) calcula- the electrons can redistribute well, and the

tions. ‡ One-atom cell (atomic sphere radius Rmt ⫽ 2.2 bohr; plane wave cutoff KmaxRmt ⫽ 10; charge density system does not incur a large energy penalty.

Fourier expansion cutoff Gmax ⫽ 20 ryderg ).

1/2 §Cell volume was relaxed by using ABINIT. In this work, we exploit the connection

between the generalized stacking fault energy

interstice pocket, and the charge density is and less accommodating, as manifested in a and the stress-strain response to show that the

nearly spherical about each ion (Fig. 2B). larger intrinsic stacking fault energy, for abnormally high ideal shear strength and in-

Thus, Al has an inhomogeneous charge dis- example. trinsic stacking fault energy of Al have the

tribution in the interstitial region because of To quantify our interpretation, we return same electronic-structure origin (namely, di-

bond covalency (20) and directional bonding to the behavior of the multiplane generalized rectional bonding). On one hand, directional

(21), whereas Cu has relatively homogeneous stacking fault energies in the form of stress- bonds give rise to a relatively longer shear

distribution and little bond directionality. To displacement functions d␥1(x)/dx and d␥⬁(x)/ deformation range, which accounts for the

probe these bonding characteristics further, dx (Fig. 1D). First, we note that for Cu, larger ideal shear strength of Al in relation to

we look at how the valence charge density d␥1(x)/dx and d␥⬁(x)/dx are not very different that of Cu; on the other hand, once the exist-

(r, x)Vcell(x) varies along a path in cell, across the entire range of shear, so the local ing bonds are broken and new bonds are

a-b-c, during pure shear, as atom b moves glue picture is appropriate. The fact that the formed with unfavorable bond angles, the

away from its initial nearest neighbor atom a sliding of a layer is effectively decoupled electrons cannot readjust easily, resulting in

(at x ⫽ x1) and takes on a new nearest from that of adjacent layers indicates that an anomalous intrinsic stacking fault energy

neighbor atom c (at x ⫽ x2 ). The ⌬[(r, bonding in Cu has nearly no bond-angle de- for Al. Our findings are supported by the

x)Vcell(x)] patterns, with Vcell being the cell pendence. On the other hand, the same func- detailed behavior of the valence charge den-

volume, for Al and Cu again show substantial tions behave much more differently in Al, sity obtained from first-principles calcula-

contrast. In Al (Fig. 2C), the maximum especially when x ⬎ xmax, at which the gra- tions that have been systematically cross-

change occurs halfway between the two near- dient reaches a maximum. Even in the range checked. We studied the pressure dependence

est ions, which indicates that when atoms of x ⬍ xmax, the relative magnitudes of of the shear strength and have shown its very

change neighbors, the breaking and reforma- d␥1(x)/dx and d␥⬁(x)/dx are opposite in order anisotropic character. These results suggest

tion of directional bonding is an important in Al as compared to those in Cu, suggesting that conventional crystal plasticity notions

activity. There is little such activity in Cu a possibly different nature of bonding. Sec- such as a scalar or pressure-independent yield

(Fig. 2D). ⌬[(r, x)Vcell(x)] mainly reflects an ond, the value of xmax is almost identical criterion based on critical resolved shear

accommodation process, like soft spheres between d␥1(x)/dx and d␥⬁(x)/dx in both Al stress, although successful for macroscopic

squeezing past each other by distorting their and Cu, with Al having the larger xmax value, face-centered cubic metals, should be viewed

own shape. A similar attempt to connect implying that the longer range directional cautiously when interpreting nanoindentation

stacking fault energy with redistribution and bonding in Al could be a more general feature experiments (3). Contemporary empirical po-

topological properties of charge density was than being specific to the affine strain energy tentials (24) may be useful for providing a

made recently (22). ␥⬁(x). Third, we see that when x ⬎⬎ xmax and qualitative description of the nonlinear,

The charge-density behavior just discussed, the directional bonds in Al are broken (con- anisotropic stress distribution under the

along with the relaxation patterns seen in Fig. firmed by a depleted charge at the interstice nanoindenter and for ascertaining the likely

1C, suggest a hinged-rod model to describe the in Fig. 2C), d␥1(x)/dx in Al stays positive for site and character of the instability; the quan-

shear strength for Al, in contrast to the conven- an extended range, whereas d␥1(x)/dx in Cu titative importance of these results remains to

tional “muffin-tin” or sphere-in-glue model for becomes negative quickly. Thus, although Al be scrutinized by more accurate ab initio

Cu. It is reasonable to think that when the and Cu have approximately the same unstable calculations.

bonding is directional (rodlike), a longer range stacking energy (Table 1), we see that when

of deformation can be sustained before break- the displacement x reaches bp and the config- References and Notes

ing than when the bonding is spherically sym- uration becomes an intrinsic stacking fault, 1. J. Wang, J. Li, S. Yip, S. Phillpot, D. Wolf, Phys. Rev. B

52, 12627 (1995).

metric, because of different geometrical factors Cu has recovered most of its losses in the 2. J. W. Morris Jr., C. R. Krenn, Philos. Mag. A 80, 2827

of charge-density decay with bond length. In sense of a low value of ␥sf , whereas Al has (2000).

covalent systems like Si (23) and SiC, we ver- recovered very little as its ␥sf value remains 3. A. Gouldstone, H. J. Koh, K. Y. Zeng, A. E. Giannako-

close to the ␥us value. The implication is that poulos, S. Suresh, Acta Mater. 48, 2277 (2000).

ified that during shear, the bonds generally do 4. D. Roundy, C. R. Krenn, M. L. Cohen, J. W. Morris,

not break until the engineering shear strain when a directional bond is broken, it is more Phys. Rev. Lett. 82, 2713 (1999).

reaches 25 to 35%, which is substantially larger difficult for the electrons to readapt. In con- 5. J. A. Zimmerman, H. Gao, F. F. Abraham, Model.

than those of metallic systems. Conversely, trast, for sphere-in-glue–type systems, even if Simul. Mater. Sci. Eng. 8, 103 (2000).

6. J. R. Rice, G. E. Beltz, J. Mech. Phys. Solids 42, 333

when the bonds do break, a directionally bond- the bond angles are wrong, as long as the (1994).

ed system can be expected to be more frustrated volumes fit as in the intrinsic stacking fault, 7. G. Kresse, J. Hafner, Phys. Rev. B 47, RC558 (1993).

810 25 OCTOBER 2002 VOL 298 SCIENCE www.sciencemag.org

REPORTS

8. G. Kresse, J. Furthmüller, Phys. Rev. B 54, 11169 are maintained at a publicly accessible Web site 27. F. Jona, P. M. Marcus, Phys. Rev. B 63, 094113 (2001).

(1996). (available at http://asm.mit.edu/sogata/AlCu/). 28. Landolt-Börnstein III/29a, Low Frequency Properties

9. V. Milman et al., Int. J. Quantum Chem. 77, 895 18. C. R. Krenn, D. Roundy, J. W. Morris Jr., M. L. Cohen, of Dielectric Crystals Second and Higher Order Elastic

(2000). Mater. Sci. Eng. A 317, 44 (2001). Constants, D. F. Nelson, Ed. (Springer-Verlag, New

10. P. Blaha, K. Schwarz, G. Madsen, D. Kvasnicka, J. Luitz, 19. J. Li, K. J. Van Vliet, T. Zhu, S. Yip, S. Suresh, Nature York, 1992).

WIEN2k, An Augmented Plane Wave ⫹ Local Orbitals 418, 307 (2002). 29. J. P. Hirth, J. Lothe, Theory of Dislocations ( Wiley,

Program for Calculating Crystal Properties ( Tech- 20. P. J. Feibelman, Phys. Rev. Lett. 65, 729 (1990). New York, ed. 2, 1982).

nische Universität Wien, Vienna, 2001). 21. J. C. Grossman, A. Mizel, M. Côté, M. L. Cohen, S. G. 30. J. Hartford, B. von Sydow, G. Wahnström, B. I. Lund-

11. The ABINIT code is a common project of the Univer- Louie, Phys. Rev. B 60, 6343 (1999). qvist, Phys. Rev. B 58, 2487 (1998).

sité Catholique de Louvain (Louvain-la-Neuve, Bel- 22. N. Kioussis, M. Herbranson, E. Collins, M. E. Eberhart, 31. G. Lu, N. Kioussis, V. V. Bulatov, E. Kaxiras, Phys. Rev.

gium), Corning Incorporated (Corning, NY ), and oth- Phys. Rev. Lett. 88, 125501 (2002). B 62, 3099 (2000).

er contributors (available at www.abinit.org). 23. Y. Umeno, T. Kitamura, Mater. Sci. Eng. B 88, 79 32. We thank J. W. Morris Jr. for comments on the

12. J. P. Perdew et al., Phys. Rev. B 46, 6671 (1992). (2002). manuscript. S.O. thanks Y. Shibutani and H. Kitagawa

13. M. Methfessel, A. T. Paxton, Phys. Rev. B 40, 3616 24. Y. Mishin, M. J. Mehl, D. A. Papaconstantopoulos, A. F. for discussions and acknowledges support by a Mu-

(1989). Voter, J. D. Kress, Phys. Rev. B 63, 224106 (2001). rata-Kaigai-Ryugaku-Syogakukai fellowship. J.L. and

14. J. P. Perdew, K. Burke, M. Ernzerhof, Phys. Rev. Lett. 25. Landolt-Börnstein III/14a, Structure Data of Elements S.Y. acknowledge support by Honda R&D; the Air

77, 3865 (1996). and Intermetallic Phases. Elements, Borides, Carbides, Force Office of Scientific Research; NSFKDI and

15. N. Troullier, J. L. Martins, Phys. Rev. B 43, 1993 Hybrides, K.-H. Hellwege, A. M. Hellwege, Eds. ITR initiatives; and Lawrence Livermore National

(1991). (Springer-Verlag, New York, 1988). Laboratory.

16. G. Kresse, D. Joubert, Phys. Rev. B 59, 1758 (1999). 26. C. Stampfl, C. G. Van de Walle, Phys. Rev. B 59, 5521

17. For verification, the input files for the different codes (1999). 26 July 2002; accepted 11 September 2002

The Effect of Size-Dependent gaseous Pb and a Pb atom in a nanoparticle as

a detailed function of particle size (Fig. 1).

Nanoparticle Energetics on We then develop a model for predicting par-

ticle size evolution based on modified bond

additivity that better approximates the calori-

Catalyst Sintering metric data. Kinetic models of sintering rates

based on our modified bond-additivity esti-

Charles T. Campbell, Stephen C. Parker, David E. Starr mate are compared to the W-J model, as well

as to heuristic models that have been devel-

Calorimetric measurements of metal adsorption energies directly provide the oped because of the inaccuracies of the W-J

energies of metal atoms in supported metal nanoparticles. As the metal cov- model. We use our modified bond-additivity

erage increases, the particles grow, revealing the dependence of this energy on model to predict the sintering of gold parti-

particle size, which is found to be much stronger than predicted with the usual cles on TiO2 and compare these model results

Gibbs-Thompson relation. It is shown that this knowledge is crucial to accu- to experimental data we obtained via temper-

rately model long-term sintering rates of metal nanoparticles in catalysts. ature-programmed low-energy ion scattering

(TP-LEIS).

Metal nanoclusters, dispersed across the sur- catalyst supports can make it difficult to de- We can convert our calorimetric data for

face of an oxide or other support, can be termine particle sizes via microscopic meth- Pb on MgO(100) (16) to energy versus par-

much more active and selective as catalysts ods as a function of temperature. In the ab- ticle size, because there is good evidence that

than can larger metal particles (1, 2). How- sence of direct measurements, a commonly Pb grows on this surface as nearly hemispher-

ever, metal nanoclusters invariably sinter used approach for estimating the dependence ical particles with roughly constant number

(form larger clusters) under reaction condi- of particle energy on size has been to use the density of ⬃8.1 ⫻ 1011 islands/cm2, after the

tions, especially in some very important tech- Gibbs-Thompson relation, which states that first few percent of a monolayer. Using this

nical catalysts (2–8). The development of the chemical potential ( partial molar free en- particle density, the measured Pb surface

supported metal nanoclusters that resist long- ergy) of a metal atom in a particle of radius R, concentration can be converted directly into

term sintering has been hampered by the lack (R), differs from that in the bulk [(⬁)] by the average number of atoms per particle, and

of a kinetic model that accurately predicts then into the average hemispherical particle

long-term sintering based on short-term mea- 共R) – (⬁) ⫽ 2␥⍀/R (1) radius (Fig. 1). As can be seen, the stability of

surements. Without such a model, every where ␥ is the surface free energy of the the metal atoms in a Pb particle (that is, their

promising new catalyst must be tested for the metal and ⍀ is the bulk metals volume per heat of adsorption, relative to gaseous Pb)

actual length of time it must resist sintering in atom (4, 12). The use of this relation is decreases dramatically as the radius decreas-

application (⬃1 year). implicit in all current atomistic models of es below a few nanometers (17). For com-

We show here that the inclusion of accu- sintering (13–15), starting with the pioneer- parison to these direct measurements of the

rate size dependence of particle energies in ing models of Wynblatt and Gjostein (W-J) effect of the metal particle size on the metal

kinetic models is crucial in this respect. Little (3, 4). atom’s energy, the predictions of the Gibbs-

is currently known experimentally about the In this report, we use our recent micro- Thompson relation [Eq. 1, taking ␥ ⫽ 58.6

energetics of atoms within metal nanopar- calorimetric measurements of the heat of ad- J/cm2 for Pb (18)] are also plotted in Fig. 1

ticles, although the energy of gaseous Sn sorption (qad) of Pb onto MgO(100) (16) to as “constant ␥ model”. Here, we neglect en-

clusters as a function of size was measured show that the energy of a metal atom in a tropy differences (12), so that qad(R) –

recently (9), and theoretical calculations con- nanoparticle increases much more dramati- qad(⬁) ⫽ –[(R) – (⬁)] ⫽ –2␥⍀/R, where

tinue to address this important issue (10, 11). cally with decreasing size than predicted by qad(R) is the differential molar heat of adsorp-

The direct determination of particle energies the Gibbs-Thompson relation. Because the tion of Pb at fixed radius R. As is seen, Eq. 1

via calorimetry has been developed relatively Pb immediately forms Pb nanoparticles upon severely overpredicts the stability of Pb in

recently. In addition, the roughness of real adsorption, and these grow in radius smooth- small Pb particles, by ⬃60 kJ/mol at 1 nm

ly with increasing coverage, this measured radius (19). This shows that the surface en-

Department of Chemistry, Box 351700, University of adsorption energy versus coverage directly ergy increases substantially as the radius de-

Washington, Seattle, WA 98195–1700, USA. provides the difference in energy between creases below ⬃3 nm, which could be ex-

www.sciencemag.org SCIENCE VOL 298 25 OCTOBER 2002 811

View publication stats

You might also like

- Regtronic Eh EngDocument44 pagesRegtronic Eh Enggogame2014100% (1)

- Daifloil Daifloil Grease: Product InformationDocument2 pagesDaifloil Daifloil Grease: Product InformationIsmail Ahmad100% (1)

- Calculate The Relieving Temperature & Latent Heat of Vaporization For Fire Case PSV Sizing by Shell DEP MethodDocument3 pagesCalculate The Relieving Temperature & Latent Heat of Vaporization For Fire Case PSV Sizing by Shell DEP Methodrohitkush80% (5)

- High-Accuracy Ab Initio Rotation-Vibration Transitions For WaterDocument4 pagesHigh-Accuracy Ab Initio Rotation-Vibration Transitions For WaternchpascualNo ratings yet

- Cultural ViolenceDocument6 pagesCultural ViolencesdurkinNo ratings yet

- Chalfie 1994Document4 pagesChalfie 1994Basab BijayeeNo ratings yet

- Spinal Cord Stimulation Restores Locomotion in Animal Models of Parkinson S DiseaseDocument6 pagesSpinal Cord Stimulation Restores Locomotion in Animal Models of Parkinson S DiseaseDiego Eduardo HurtadoNo ratings yet

- Biocatalytic Asymmetric Synthesis of Chiral Amines From Ketones Applied To Sitagliptin ManufactureDocument6 pagesBiocatalytic Asymmetric Synthesis of Chiral Amines From Ketones Applied To Sitagliptin ManufacturemnjagaNo ratings yet

- Photonic Band Gap Guidance in Optical Fibers: J. C. Knight, J. Broeng, T. A. Birks, P. St. J. RussellDocument3 pagesPhotonic Band Gap Guidance in Optical Fibers: J. C. Knight, J. Broeng, T. A. Birks, P. St. J. RussellArnab BhowmikNo ratings yet

- 2005 TrexDocument6 pages2005 TrexD HMNo ratings yet

- Fotosintesis en IR - Clorofila FDocument3 pagesFotosintesis en IR - Clorofila FAruaco AruacoNo ratings yet

- Visualizing Individual Nitrogen Dopants in Monolayer GrapheneDocument6 pagesVisualizing Individual Nitrogen Dopants in Monolayer Graphene김영찬No ratings yet

- EoS Transactions - 2011 - Doran - Examining The Scientific Consensus On Climate ChangeDocument3 pagesEoS Transactions - 2011 - Doran - Examining The Scientific Consensus On Climate Changewenhao.yuNo ratings yet

- Calor Especifico - SerpentineDocument5 pagesCalor Especifico - SerpentineAna Flávia CamposNo ratings yet

- Nanoscale Tunable Reduction of Graphene Oxide For Graphene ElectronicsDocument6 pagesNanoscale Tunable Reduction of Graphene Oxide For Graphene Electronicsadrianoreis1No ratings yet

- Science 2005 Nguyen 844 7Document5 pagesScience 2005 Nguyen 844 7Florin AndreiNo ratings yet

- Phenology Under Global Warming: Plant ScienceDocument3 pagesPhenology Under Global Warming: Plant ScienceAriadne Cristina De AntonioNo ratings yet

- High-Throughput Synthesis of Zeolitic Imidazolate Frameworks and Application To CO2 Capture (DRX)Document6 pagesHigh-Throughput Synthesis of Zeolitic Imidazolate Frameworks and Application To CO2 Capture (DRX)Annaíres AlmeidaNo ratings yet

- Buckler2009 PDFDocument6 pagesBuckler2009 PDFCarlitos MaldonadoNo ratings yet

- Thermal Dissociation Kinetics of SolventsDocument7 pagesThermal Dissociation Kinetics of SolventsaccofaceNo ratings yet

- Superluminal and Slow Light Propagation in A Room-Temperature Solid - Science, 2003-200-2, BigelowDocument4 pagesSuperluminal and Slow Light Propagation in A Room-Temperature Solid - Science, 2003-200-2, BigelowRado JaNo ratings yet

- 382 FullDocument5 pages382 Fullchalmers6400No ratings yet

- Art 258Document4 pagesArt 258Javi VRNo ratings yet

- 2005 NatureDocument5 pages2005 NaturecrackintheshatNo ratings yet

- Ultrahigh Porosity in Metal-Organic Frameworks: 'KeeffeDocument6 pagesUltrahigh Porosity in Metal-Organic Frameworks: 'Keeffeクマール ヴァンツNo ratings yet

- 4D Electron Tomography ScienceDocument6 pages4D Electron Tomography Sciencehappynewyear11No ratings yet

- A Porous Silicon-Based Optical Interferometric BiosensorDocument5 pagesA Porous Silicon-Based Optical Interferometric BiosensorTahmid Hassan TalukdarNo ratings yet

- Porous Silicon BiosensorDocument5 pagesPorous Silicon BiosensorTahmid Hassan TalukdarNo ratings yet

- Crowder 1969Document4 pagesCrowder 1969rexNo ratings yet

- Sarmiento 2004Document5 pagesSarmiento 2004PabloNo ratings yet

- Takats Science04Document4 pagesTakats Science04Abinasha PattanayakNo ratings yet

- Excellent Wave Absorption by Zr-Based BMG Composites Containing CNTDocument6 pagesExcellent Wave Absorption by Zr-Based BMG Composites Containing CNTcat nightNo ratings yet

- Science 282 5386 98Document3 pagesScience 282 5386 98scribduserme123No ratings yet

- Jobaria PDFDocument7 pagesJobaria PDFkallenhard1No ratings yet

- Banerjee 2008Document6 pagesBanerjee 2008paulaNo ratings yet

- Base-Pair Stacking in Oriented Films of DNA Surfactant ComplexDocument4 pagesBase-Pair Stacking in Oriented Films of DNA Surfactant ComplexferNo ratings yet

- S. K. Solanki W. Livingston T. Ayres: Science, New Series, Vol. 263, No. 5143. (Jan. 7, 1994), Pp. 64-66Document4 pagesS. K. Solanki W. Livingston T. Ayres: Science, New Series, Vol. 263, No. 5143. (Jan. 7, 1994), Pp. 64-66lila moradoNo ratings yet

- Reactome ArrayDocument7 pagesReactome ArraySigfredo B. MataNo ratings yet

- Fluides Non Newtoniens1Document4 pagesFluides Non Newtoniens1Shanez IdirNo ratings yet

- Thermodynamics With Internal State Variables - Coleman - Gurtin - 1967Document18 pagesThermodynamics With Internal State Variables - Coleman - Gurtin - 1967Nidhal JridiNo ratings yet

- Reducing The Dimensionality of Data With Neural Networks: ReportsDocument4 pagesReducing The Dimensionality of Data With Neural Networks: Reportsapi-25914596No ratings yet

- Walteretal 2000 NatureDocument6 pagesWalteretal 2000 NatureAtef AlshehriNo ratings yet

- The Following Resources Related To This Article Are Available Online atDocument5 pagesThe Following Resources Related To This Article Are Available Online atKoussa Monchi DalmarNo ratings yet

- E.Behnke Et Al., Science, 319, (2008) - Spin Dependent WIMP Limits From A Bubble ChamberDocument4 pagesE.Behnke Et Al., Science, 319, (2008) - Spin Dependent WIMP Limits From A Bubble ChamberIvan FelisNo ratings yet

- Superconductivity at 39 K in Magnesium Diboride: AcknowledgementsDocument2 pagesSuperconductivity at 39 K in Magnesium Diboride: AcknowledgementssenaNo ratings yet

- Monodisperse Double EmulsionsDocument5 pagesMonodisperse Double EmulsionsmiliamcarterNo ratings yet

- Relaxor Behaviour in The System (1-X) Ba1-Xbi2X/3Tio3 + X Ba1-Y Y2Y/3Tio3 Proper Ferroelectric Transition in The Multiferroic YmnoDocument1 pageRelaxor Behaviour in The System (1-X) Ba1-Xbi2X/3Tio3 + X Ba1-Y Y2Y/3Tio3 Proper Ferroelectric Transition in The Multiferroic Ymnorajadasari5682No ratings yet

- Causal Protein-Signaling Networks Derived From Multiparameter Single-Cell DataDocument8 pagesCausal Protein-Signaling Networks Derived From Multiparameter Single-Cell DataarchsarkNo ratings yet

- Science 1202393Document8 pagesScience 1202393CARLOS FRANCISCO MANTILLA MONTALVONo ratings yet

- The Following Resources Related To This Article Are Available Online atDocument5 pagesThe Following Resources Related To This Article Are Available Online atihzaoloanNo ratings yet

- 1962 Smith Bi2Te3-Sb2Te3 PDFDocument6 pages1962 Smith Bi2Te3-Sb2Te3 PDFМакс ИванцовNo ratings yet

- SAW-1-Anal ChemDocument7 pagesSAW-1-Anal ChemsaineelimaNo ratings yet

- Mears Science 2005Document17 pagesMears Science 2005Dom DeSiciliaNo ratings yet

- Yeager 1980 J. Electrochem. Soc. 127 303Document6 pagesYeager 1980 J. Electrochem. Soc. 127 303pinitNo ratings yet

- Behavior of Fluidized Beds of Small Particles at Elevated TemperaturesDocument6 pagesBehavior of Fluidized Beds of Small Particles at Elevated Temperaturespapapa14No ratings yet

- An Experimental Study On The Effect of Various StaDocument8 pagesAn Experimental Study On The Effect of Various StaakilanrameshNo ratings yet

- Reducing The Dimensionality of Data With Neural Networks: ReportsDocument5 pagesReducing The Dimensionality of Data With Neural Networks: ReportsBruno Fabio Bedón VásquezNo ratings yet

- Atomicmagnetometer-Kominis Et Al. - A Subfemtotesla Multichannel Atomic MagnetometerDocument4 pagesAtomicmagnetometer-Kominis Et Al. - A Subfemtotesla Multichannel Atomic MagnetometerSumitNo ratings yet

- Approaching Nanoxerography: The Use of Electrostatic Forces To Position Nanoparticles With 100 NM Scale ResolutionDocument5 pagesApproaching Nanoxerography: The Use of Electrostatic Forces To Position Nanoparticles With 100 NM Scale Resolutiong zero100% (2)

- Barriopedro 11Document6 pagesBarriopedro 11JxPNo ratings yet

- PhDThesisH Bartolf-DefenseNov2009Document24 pagesPhDThesisH Bartolf-DefenseNov2009Michelle CedNo ratings yet

- Strouhal NumberDocument3 pagesStrouhal NumbergastonNo ratings yet

- Theory and Fundamental Research in Heat Transfer: Proceedings of the Annual Meeting of the American Society of Mechanical Engineers New York, November 1960From EverandTheory and Fundamental Research in Heat Transfer: Proceedings of the Annual Meeting of the American Society of Mechanical Engineers New York, November 1960Rating: 3 out of 5 stars3/5 (1)

- Variability in Ballistic Impact Performance Due To Projectile Physical Properties and DimensionsDocument9 pagesVariability in Ballistic Impact Performance Due To Projectile Physical Properties and DimensionsSantosa Edy WibowoNo ratings yet

- 20mm PGU 28 A B F 16Document1 page20mm PGU 28 A B F 16Santosa Edy WibowoNo ratings yet

- 20mm X 102 PGU USAFDocument2 pages20mm X 102 PGU USAFSantosa Edy WibowoNo ratings yet

- 2 and 2 U RDR Ry XV U M M 2 P RDR: 2 R y y y X y Ry R RyDocument1 page2 and 2 U RDR Ry XV U M M 2 P RDR: 2 R y y y X y Ry R RySantosa Edy WibowoNo ratings yet

- Investigation of Turbine Flammability Within Aircraft Fuel Tank 669001 PDFDocument92 pagesInvestigation of Turbine Flammability Within Aircraft Fuel Tank 669001 PDFSantosa Edy WibowoNo ratings yet

- Ballistic Impact On Composites: January 2007Document11 pagesBallistic Impact On Composites: January 2007Santosa Edy WibowoNo ratings yet

- Evaporation: - Slides Prepared by Daene C. Mckinney - Reading: Applied Hydrology Sections 4.1 and 4.2Document29 pagesEvaporation: - Slides Prepared by Daene C. Mckinney - Reading: Applied Hydrology Sections 4.1 and 4.2Santosa Edy WibowoNo ratings yet

- Ijems 20 (2) 125-131Document7 pagesIjems 20 (2) 125-131Santosa Edy WibowoNo ratings yet

- A Thermal Theory For Estimating The Flam PDFDocument10 pagesA Thermal Theory For Estimating The Flam PDFSantosa Edy WibowoNo ratings yet

- Energies 11 01677 PDFDocument17 pagesEnergies 11 01677 PDFSantosa Edy WibowoNo ratings yet

- The Standard AtmosphereDocument1 pageThe Standard AtmosphereSantosa Edy WibowoNo ratings yet

- M88 2 - Ang 2Document2 pagesM88 2 - Ang 2Santosa Edy WibowoNo ratings yet

- Numerical and Experimental Investigations On Subsonic Air Intakes With Serpentine Ducts For UAV ConfigurationsDocument22 pagesNumerical and Experimental Investigations On Subsonic Air Intakes With Serpentine Ducts For UAV ConfigurationsSantosa Edy WibowoNo ratings yet

- Ijfmr30 2003Document18 pagesIjfmr30 2003Santosa Edy WibowoNo ratings yet

- Pompa Hydraulic CT - 195715 PDFDocument8 pagesPompa Hydraulic CT - 195715 PDFSantosa Edy WibowoNo ratings yet

- T-X Program R44856Document35 pagesT-X Program R44856Santosa Edy WibowoNo ratings yet

- Me412-Heat Transfer: Week 1-2:introduction & Fundamental ConceptsDocument34 pagesMe412-Heat Transfer: Week 1-2:introduction & Fundamental ConceptsKyroNo ratings yet

- SPM Chemistry Revision Module On The BasicsDocument64 pagesSPM Chemistry Revision Module On The Basicssuritanu96No ratings yet

- Plate Buckling NotesDocument0 pagesPlate Buckling NotesSharyn PolleyNo ratings yet

- ChemistoryDocument8 pagesChemistorySparkles PinkyNo ratings yet

- Designing Compact Gussets With The Uniform Force MethodDocument8 pagesDesigning Compact Gussets With The Uniform Force MethodJonathan Schauder100% (1)

- Epa-1664 (Oil and Grease)Document28 pagesEpa-1664 (Oil and Grease)iqciro0% (1)

- Introduction To WaveletDocument26 pagesIntroduction To WaveletSridhar Koneru VenkkatNo ratings yet

- Waterfront Seismic Survey ReportDocument39 pagesWaterfront Seismic Survey ReportVis CharoonvisNo ratings yet

- Lib-Planets-Overview-2000001741-Article Quiz and AnswersDocument4 pagesLib-Planets-Overview-2000001741-Article Quiz and Answersapi-302899266No ratings yet

- ARAHANDocument9 pagesARAHANSanjana AnjaNo ratings yet

- Oral Program FinalDocument7 pagesOral Program FinalCostas AggelidisNo ratings yet

- New Geometric-Arithmetic Indices: Piotr WilczekDocument50 pagesNew Geometric-Arithmetic Indices: Piotr WilczekTache Alexandru-PetreNo ratings yet

- HM Abaqus 2of2Document30 pagesHM Abaqus 2of2zhiqianxuNo ratings yet

- Humidity Conversion: Barometric PressureDocument7 pagesHumidity Conversion: Barometric PressureJose David IriarteNo ratings yet

- Experiments in General Chemistry: Additional Pre-Lab ComponentsDocument10 pagesExperiments in General Chemistry: Additional Pre-Lab ComponentsPrince WoodNo ratings yet

- Vojt Ech Pleskot: Doctoral ThesisDocument116 pagesVojt Ech Pleskot: Doctoral ThesisMarina RotaruNo ratings yet

- Add Maths ProjectDocument35 pagesAdd Maths ProjectPrasanth Munusamy0% (1)

- Civil-Iii-Surveying-I 10CV34 - Notes PDFDocument105 pagesCivil-Iii-Surveying-I 10CV34 - Notes PDFAS Animesh Sinha84% (25)

- Photoshopstar Com 2Document21 pagesPhotoshopstar Com 2Abriel HaqqaniNo ratings yet

- Common Engineering Unit ConversionsDocument3 pagesCommon Engineering Unit Conversionsravandkumar100% (1)

- Water 11 00773 PDFDocument17 pagesWater 11 00773 PDFSaga MursalNo ratings yet

- Math Solution IITKDocument9 pagesMath Solution IITKcombatps1No ratings yet

- 9817 - Manual On Wind Shear 2005Document213 pages9817 - Manual On Wind Shear 2005Huy Thanh NguyenNo ratings yet

- What Is The Relation Between Gauge Pressure Absolute Pressure Atmospheric Pressure and Vacuum Pressure - QuoraDocument3 pagesWhat Is The Relation Between Gauge Pressure Absolute Pressure Atmospheric Pressure and Vacuum Pressure - QuoraMauliNo ratings yet

- Div II AssDocument5 pagesDiv II AssKimberly ⎝⏠⏝⏠⎠ YambaoNo ratings yet

- Simple Linear RegressionDocument24 pagesSimple Linear RegressionBie JhingcHayNo ratings yet